A Glimpse into the Manufacturing Process

The process of manufacturing a powder coating is a relatively complex, semi-continuous endeavor that must be carefully controlled to ensure a high-quality final coating

Thousands of people have been applying powder for decades, but how many applicators really understand how powder coatings are manufactured?

Thousands of people have been applying powder for decades, but how many applicators really understand how powder coatings are manufactured?

Making powder coatings is a multi-step process, essentially composed of batching, premixing, extrusion and particle size reduction. It can be described as being semi-continuous because it begins as a batch process (weighing and pre-mixing) but evolves into a continuous process (extrusion and milling).

Basically, a compilation of somewhat dissimilar materials are blended, melted, cooled and then pulverized. Two major types of mixing are accomplished in successful processing. The resins, additives and pigments are distributed among themselves to create a consistent blend. Uniform mixing affords a consistent appearance and performance of the finished coating, while inconsistent mixing results in variable gloss, smoothness and quite possibly poor durability. It is therefore essential to achieve an adequate distribution of the raw materials.

Manufacturing powder coatings also involves dispersing pigments throughout the resin system, which entails the de-agglomeration of the pigment. Most pigments naturally exist as agglomerates. The powder manufacturing process, and more specifically the extrusion process, endeavors to disperse these agglomerates to achieve a more consistent and intense color. Incomplete pigment dispersion results in uncontrolled color consistency. Finally, the particle size of the extrudate must be reduced from flakes to a particle size distribution usable with the customer's application equipment.

All of these steps must be carefully controlled to ensure a high-quality final coating.

Batch size influences yield. Relatively small batches (less than 500 lbs.) generate smaller yields than larger batches. A well run process will operate at an efficiency level between 95 and 99%. The yield of smaller batches typically runs between 90 and 95%. Experience dictates the capability of the process and guides the formulator in determining how much excess raw material to use.

Premixing equipment is designed for an optimal range of vessel filling. Charges that are too small will be poorly mixed because the mixing blades will be incompletely covered. Excessively large charges will be inconsistently mixed due to a lack of free space to agitate the contents of the vessel. Excessively large charges can also tax the drive mechanism of the mixer to the point of tripping circuit breakers and damaging motors and gear drives.

The distribution aspect of the extrusion process entails melting the resinous components and mixing the non-melting constituents throughout the molten mass. This mixture is achieved by introducing the homogenized dry ingredients into an extruder. The goal is to shear the mixture against a hard surface until it melts. Mechanical force is put into the mixture to increase the ambient temperature of the mixture and its surroundings. The increased temperature, combined with the mechanical force or shear, melts the resinous components, distributes the non-melting constituents and de-agglomerates the pigments. This is all accomplished as the material is moving rapidly through the extruder.

The extrusion process basically consists of a feeding mechanism, a compounding section and cooling. The material is fed into a rotating mechanism, which is usually a screw device encased by a barrel. The screw is configured with flights or nodes that exert work on the molten mass as it passes through the extruder.

Extruders can be of a single- or twin-screw design. The single-screw types have flights along the circumference of the screw, which convey the mixture into pins that emanate from the interior of the barrel. This creates shearing of the material that, in turn, melts the mass and affects the distribution and dispersion of the components. The molten mass exits the barrel and is then cooled and broken into flakes.

Twin-screw extruders operate on a similar principle; however, they use the shearing action of two co-rotating screws encased in a smooth barrel. Work is exerted into the mixture by the kneading blocks on the screws. The coordinated rotation of the screws pushes the material from screw to screw as it travels the length of the barrel. The heat generated during this process allows the resinous components to melt, and the shearing action affords the distribution raw materials and dispersion of the pigments.

The cooling process typically involves introducing the moving extrudate into a set of chilled rolls, which then convey a ribbon of material onto another cooling surface, such as a continuous belt or rotating drum. After the extrudate is sufficiently cooled, it is broken into flakes that are suitable for feeding into a pulverizing process.

The temperature of extruders is controlled with either electrical resistance heaters or heater/cooling units that circulate fluid media through cavities in the extruder barrel and screw(s). The medium can be oil or a glycol/water mixture. Resistance heated units are used in conjunction with media circulating chillers. When the extrusion process is initiated, the mixture quickly becomes molten and the work put into it establishes a rather consistent temperature. The role of the heater/cooling device becomes more of a cooling process at this point.

Extruder screw speed can be adjusted. Most powder manufacturers run their extruders at full speed to provide the highest output possible. This makes sense in nearly all cases. For formulas that contain difficult-to-disperse components, such as carbon black pigment, a slower screw speed might be needed to achieve adequate dispersion.

After extrusion, the only way to modify the formula is by re-extruding material with raw components. This process is costly and is avoided whenever possible.

From the grinding chamber, the powder is pulled through a cyclone and drops into a sifting device. The sifting device eliminates only a very small coarse fraction of ground powder. This coarse material can be re-introduced into the grinding process to optimize the yield.

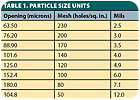

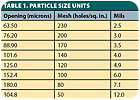

General-purpose powder formulas can be sifted through 80- to 120-mesh screens. Powders requiring a high level of smoothness are typically sifted through a finer mesh screen (e.g. 140 to 200 mesh) (see Table 1).

Powder coatings are typically packaged in boxes or barrels that are lined with a plastic bag. The plastic bag should be at least 3.0 mils (75 microns) thick; however, it is recommended that a 4.0 mil (100 micron) bag be used to ensure integrity and isolation from the environment. The box must possess adequate strength to withstand transportation, storage and handling. A burst strength of 200 lbs/in2 is sufficient.

A closed barrel twin-screw extruder. Photo courtesy of B&P Process Equipment.

A close-up of an extruder barrel liner. Photo courtesy of B&P Process Equipment.

Making powder coatings is a multi-step process, essentially composed of batching, premixing, extrusion and particle size reduction. It can be described as being semi-continuous because it begins as a batch process (weighing and pre-mixing) but evolves into a continuous process (extrusion and milling).

Basically, a compilation of somewhat dissimilar materials are blended, melted, cooled and then pulverized. Two major types of mixing are accomplished in successful processing. The resins, additives and pigments are distributed among themselves to create a consistent blend. Uniform mixing affords a consistent appearance and performance of the finished coating, while inconsistent mixing results in variable gloss, smoothness and quite possibly poor durability. It is therefore essential to achieve an adequate distribution of the raw materials.

Manufacturing powder coatings also involves dispersing pigments throughout the resin system, which entails the de-agglomeration of the pigment. Most pigments naturally exist as agglomerates. The powder manufacturing process, and more specifically the extrusion process, endeavors to disperse these agglomerates to achieve a more consistent and intense color. Incomplete pigment dispersion results in uncontrolled color consistency. Finally, the particle size of the extrudate must be reduced from flakes to a particle size distribution usable with the customer's application equipment.

All of these steps must be carefully controlled to ensure a high-quality final coating.

Batching

The first process involves weighing the raw materials in ratios prescribed in the master formula. The weigh-up coincides with the amount needed by the customer order and also the capacity of the premixing vessel. Typical production batches require a number of premix charges to achieve the targeted quantity. Multiples of weigh-up charges are therefore necessary.Batch size influences yield. Relatively small batches (less than 500 lbs.) generate smaller yields than larger batches. A well run process will operate at an efficiency level between 95 and 99%. The yield of smaller batches typically runs between 90 and 95%. Experience dictates the capability of the process and guides the formulator in determining how much excess raw material to use.

Premixing

The premixing step homogenizes the raw materials mix so that a consistent mixture can be fed into the extruder and comminutes large resin particles so that the mix can be fed more easily. A high-speed impeller can achieve premixing in a relatively short duration (two to five minutes). Adequate blending can also be accomplished with a slower, less intense process. Some mixers use detachable bowls that offer versatility in managing multiple mixes with the same mixing head. This design also allows for ease in cleaning. An impeller design can make a difference in the consistency of the final mixture.Premixing equipment is designed for an optimal range of vessel filling. Charges that are too small will be poorly mixed because the mixing blades will be incompletely covered. Excessively large charges will be inconsistently mixed due to a lack of free space to agitate the contents of the vessel. Excessively large charges can also tax the drive mechanism of the mixer to the point of tripping circuit breakers and damaging motors and gear drives.

Extrusion

After the raw materials have been successfully mixed into a homogeneous dry blend, the extrusion process can begin. The extrusion step can be described as the "paint-making" process and is where the powder coating formula is compounded. At this point, the formula is locked in; very few alterations can be made (with the exception of particle size reduction) after this step.The distribution aspect of the extrusion process entails melting the resinous components and mixing the non-melting constituents throughout the molten mass. This mixture is achieved by introducing the homogenized dry ingredients into an extruder. The goal is to shear the mixture against a hard surface until it melts. Mechanical force is put into the mixture to increase the ambient temperature of the mixture and its surroundings. The increased temperature, combined with the mechanical force or shear, melts the resinous components, distributes the non-melting constituents and de-agglomerates the pigments. This is all accomplished as the material is moving rapidly through the extruder.

The extrusion process basically consists of a feeding mechanism, a compounding section and cooling. The material is fed into a rotating mechanism, which is usually a screw device encased by a barrel. The screw is configured with flights or nodes that exert work on the molten mass as it passes through the extruder.

Extruders can be of a single- or twin-screw design. The single-screw types have flights along the circumference of the screw, which convey the mixture into pins that emanate from the interior of the barrel. This creates shearing of the material that, in turn, melts the mass and affects the distribution and dispersion of the components. The molten mass exits the barrel and is then cooled and broken into flakes.

Twin-screw extruders operate on a similar principle; however, they use the shearing action of two co-rotating screws encased in a smooth barrel. Work is exerted into the mixture by the kneading blocks on the screws. The coordinated rotation of the screws pushes the material from screw to screw as it travels the length of the barrel. The heat generated during this process allows the resinous components to melt, and the shearing action affords the distribution raw materials and dispersion of the pigments.

The cooling process typically involves introducing the moving extrudate into a set of chilled rolls, which then convey a ribbon of material onto another cooling surface, such as a continuous belt or rotating drum. After the extrudate is sufficiently cooled, it is broken into flakes that are suitable for feeding into a pulverizing process.

The temperature of extruders is controlled with either electrical resistance heaters or heater/cooling units that circulate fluid media through cavities in the extruder barrel and screw(s). The medium can be oil or a glycol/water mixture. Resistance heated units are used in conjunction with media circulating chillers. When the extrusion process is initiated, the mixture quickly becomes molten and the work put into it establishes a rather consistent temperature. The role of the heater/cooling device becomes more of a cooling process at this point.

Extruder screw speed can be adjusted. Most powder manufacturers run their extruders at full speed to provide the highest output possible. This makes sense in nearly all cases. For formulas that contain difficult-to-disperse components, such as carbon black pigment, a slower screw speed might be needed to achieve adequate dispersion.

After extrusion, the only way to modify the formula is by re-extruding material with raw components. This process is costly and is avoided whenever possible.

A clamshell barrel twin-screw extruder. Photo courtesy of B&P Process Equipment.

Particle Size Reduction

The next step involves reducing the particle size of the extrudate from flakes to a particle size distribution usable with the customer's application equipment. This reduction is typically accomplished with an air-classified mill, which operates on a system of continuous negative pressure created by a large fan associated with a baghouse. This negative pressure pulls the flakes into a chamber that contains a rapidly rotating plate. This plate has pins or hammers situated on its perimeter, which impact the incoming flakes. In addition to this impaction, the rotation of the plate propels the fractured flake into a corrugated liner that further reduces the particle size. The particles are held in this pulverizing chamber with a classifying wheel. The rotation of this wheel creates a buffer of air, which restricts the exit of powder until it is ground to a certain particle size. The classifier speed will affect the ultimate particle size distribution.From the grinding chamber, the powder is pulled through a cyclone and drops into a sifting device. The sifting device eliminates only a very small coarse fraction of ground powder. This coarse material can be re-introduced into the grinding process to optimize the yield.

General-purpose powder formulas can be sifted through 80- to 120-mesh screens. Powders requiring a high level of smoothness are typically sifted through a finer mesh screen (e.g. 140 to 200 mesh) (see Table 1).

Powder coatings are typically packaged in boxes or barrels that are lined with a plastic bag. The plastic bag should be at least 3.0 mils (75 microns) thick; however, it is recommended that a 4.0 mil (100 micron) bag be used to ensure integrity and isolation from the environment. The box must possess adequate strength to withstand transportation, storage and handling. A burst strength of 200 lbs/in2 is sufficient.

High-Quality Coatings

The process of manufacturing a powder coating is a relatively complex, semi-continuous endeavor. The raw materials are committed early in the process, and the formula cannot be easily changed after extrusion. It is therefore important for manufacturers to control their raw materials and processes. This level of control requires a well-trained production staff, vigilance in adhering to manufacturing procedures and a steadfast respect for process control. Keeping these principles in the forefront allows for the successful manufacture of high-quality powder coatings, time and time again.Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!