New Alliance Creates "Metal-over-Plastic" Technology - Posted 10/31/07

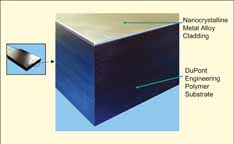

The new technology - MetaFuse™ nanometal/polymer hybrids - uses a proprietary process that precisely applies ultra high-strength nanometal to components made of DuPont engineering polymers. This creates lightweight components in myriad, complex shapes with the stiffness of magnesium or aluminum and higher strength. The patented technology produces metals with grain size 1,000 times smaller than those of conventional metals, according to Gino Palumbo, president and chief technology officer of Integran Technologies Inc. This technology directly creates an integral metal cladding with a nanocrystalline grain structure. Nanoparticles are not created at any stage in the manufacturing process. “Nano-crystalline nickel or nickel-iron are high-performance metals that are two to three times stronger than normal steel and also are significantly harder, with better wear and friction performance,” Palumbo said.

Initial developments will focus on selected applications in the automotive, consumer electronics and sporting goods markets. Under the agreement, DuPont will lead application development to bring this innovative technology to market by using its global development, R&D and customer-support centers.

For more information, visit www2.dupont.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!