Noncontact, Real-Time Detection and Analysis of Silicone Films on Surfaces

This article focuses on the use of Block Engineering’s LaserScan™ analyzer (Figure 1) as a handheld spectrometer, based on quantum cascade laser (QCL) technology, for detecting and quantifying silicone film thicknesses.

Infrared spectroscopy is a well-established technique for detecting and identifying contaminants on surfaces, in particular metallic surfaces. Detection levels can be as low as fractions of a microgram, depending on factors such as viewing/measurement angles and use of a polarized infrared beam. Detection of silicone films is an important application. For example, silicone release coatings are applied to surfaces to facilitate the manufacture of carbon-fiber/epoxy laminating materials.

The silicone is supposed to remain on the fabricating equipment, but in some cases it will migrate in small quantities to the fabricated material, which becomes problematic. For example, if the fabricated material is subsequently painted or otherwise coated, this silicone residue will result in poor adhesion, affecting the quality, appearance and longevity of the coating. Also the silicon coating on the fabricating equipment must be monitored and maintained for the equipment to perform properly.

The Technology

The LaserScan analyzer is an ideal tool for inspecting surfaces to detect the presence of silicone, validate its removal or chemically analyze the properties of any films on the surface. For example, it can be used by a production engineer to examine metal surfaces and provide rapid feedback for the presence of residual silicone on surfaces that are being prepared for bonding or painting. In another potential application, this instrument can be used in a noncontact fashion to evaluate new silicone materials by analyzing adhesion properties and chemical composition changes during production or application.

The LaserScan analyzer is the result of many years of development and utilizes infrared spectroscopy. FTIR spectrometers have been used for decades in the laboratory to detect silicone, but these instruments use a diffuse infrared source, so for these to work effectively they either have to make contact with the surface (ATR methods) or the measurement head has to get very close (within a centimeter or so) to the surface, which creates a potential for further contamination due to accidental contact. Because the LaserScan QCL technology uses a collimated, but eye-safe laser, it can measure residue on surfaces from distances of six inches to several feet, depending on the application.

The fundamental principle behind this technology is that when infrared light reflects off of a substance, it gets absorbed or reflected at rates that are absolutely unique to, and characteristic of, the substance. Therefore, when the reflected light is collected by the LaserScan’s built-in detectors, a “fingerprint”-like pattern emerges, which contains all the necessary information for detecting or analyzing the substance. Built-in libraries are typically used to pattern and provide real-time detection or analysis. Furthermore, LaserScan is a lightweight, handheld unit that provides readings in seconds.

Experimental Results

Three samples of methyl silicone were dissolved in n-hexane 97%. Sample A was 26 mg/mL; B was 50 mg/mL; C was 70 mg/mL. A micro-syringe was used to apply 0.01 mL of each sample onto a diffused gold substrate. The hexane completely evaporated in 30 min, leaving concentrations of 173 µg/cm2 for sample A; 313 µg/cm2 for sample B; 438 µg/cm2 for sample C. The three samples were then examined with the LaserScan at a standoff distance of 6 inches.

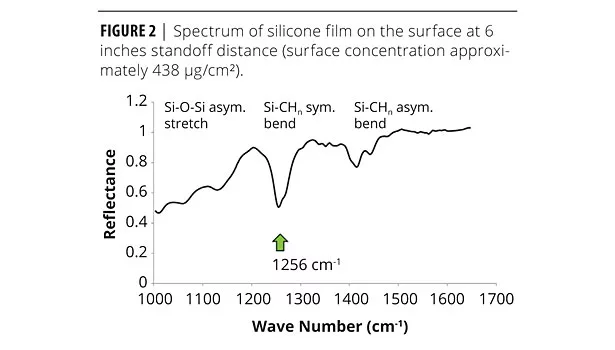

Figure 2 shows the silicone spectrum for Sample C. As can be seen, there are distinctive features, including a strong feature at 1256 cm-1.

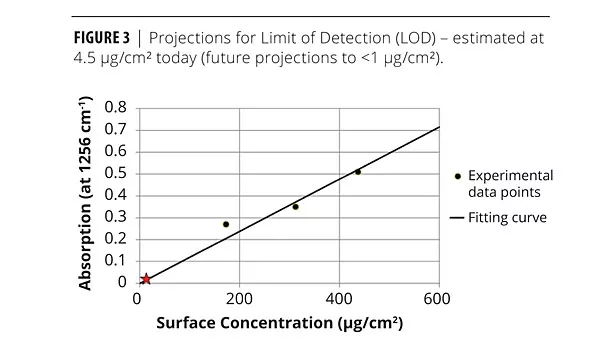

Figure 3 shows a plot of absorption at wavelength 1256 cm-1 for each sample. Extrapolating the data points implies a limit of detection of 4.5 µg/cm2, which is sufficient for most applications. Future versions of LaserScan currently under development should reduce the LOD to <1 µg/cm2, if needed.

Conclusions

The LaserScan is the optimal tool for the standoff measurement of silicone films on surfaces. LOD of 4.5 µg/cm2 on a metal surface has been demonstrated. LaserScan provides a new tool for production engineers and quality control departments tasked with ensuring the proper and effective use of silicone in important industrial applications. Future LaserScan devices will be much lighter (flashlight size) and more sensitive (projected LOD <1 µg/cm²).

For more information, call 508/251.3105, visit www.blockeng.com or e-mail sales@blockeng.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!