Potential for a New Generation of Solar-Reflective Coatings

New Coating Pigment Gives High Infrared Reflectance

The global trend to reduce energy consumption undoubtedly poses many challenges for industry. How can we adapt our products and services to play a role in reducing energy consumption and associated carbon footprint? How can we use our knowledge and expertise to innovate? In the wake of a far-reaching economic recession, we also have to ask ourselves how we can do these things efficiently and with minimal risk.

These questions are becoming more urgent as legislative and environmental guidelines drive us along the path towards more efficient energy usage. In considering our response, we must also add consumer expectation to the mix. While many consumers are focused on both the cost and environmental benefits of reduced energy consumption, they may be reluctant to accept energy-reducing products that compromise other criteria such as product choice or aesthetics.

In the coatings world, the growing global demand for energy reduction presents opportunities and provides the impetus for innovation. The apparent scope for a new generation of solar-reflective coatings is a prime example. The potential for energy savings enabled by these coatings is increasingly recognized. The scene is set for new formulations that add more value and offer more choice than conventional solar-reflective coatings.

In our view, cool roof technology for buildings is probably the best current illustration of how solar-reflective coatings can play an effective role in combating the rise in energy consumption. Cool roofs can help to prevent the air inside a building heating up to high levels when the sun is most intense. This in turn reduces the demand for power required by air-conditioning systems and potentially, surges in peak electricity demand.

The time is arguably right for exploring other potential applications for these coatings. Marine, automotive and aerospace products are likely candidates to benefit from a new generation of solar-reflective coatings, and who is to say that the list ends there?

Importance of Solar-Reflective Coatings

The sun’s energy, when absorbed by exterior surfaces, can transfer through to the interior of a building, vessel or vehicle, raising the internal temperature. An increase in temperature can make the interior more uncomfortable and place heavy loads on air-conditioning systems. This, in turn, can lead to a rise in associated energy consumption, carbon dioxide and greenhouse gas emissions.

What is the scale of this problem – and how big a role can solar-reflective coatings play in tackling it? According to the International Energy Agency, buildings currently account for as much as 40% of primary energy consumption in most International Energy Agency member countries, and are also a significant source of carbon dioxide emissions.1 The World Business Council for Sustainable Development reports that the carbon footprint of buildings exceeds that of all transportation sectors combined. The Council suggests that energy use in buildings could be cut by up to 60% by 2050.2

The energy consumed by building air-conditioning units can account for more than 20% of total energy consumption in some Western countries. According to Levinson and Akbari, increasing the solar reflectance index of a roof from 0.20 to 0.55 could yield annual cooling energy savings of 5.02 kW/m² across the United States. This could reduce carbon dioxide emissions by 3.02 kg/m².3

Globally, national and local government bodies are paying more attention to the value that can be delivered by cool roof technology. In Australia, the City of Melbourne Council has suggested that the use of cool roofs in its commercial building district could theoretically reduce the city’s energy consumption by 1.25 million kW/hr (4.5 million MJ) per year – equivalent to reducing emissions by 1.5 million kilograms of carbon dioxide.4

In Delhi, the Power Ministry’s Bureau of Energy Efficiency maintains that electricity consumption could be brought down by 25% with the adoption of cool roofs.5

Population rise and the development of urbanization in many parts of the globe also point the way to an increasingly important role for solar-reflective coatings in combating the urban heat island effect. The urban heat island effect can be explained by the dark surfaces of cities absorbing energy from the sun. This heat is then slowly released into the city air, making the built-up region hotter than surrounding rural areas. Urban heat islands can increase the formation of smog, adding to city pollution levels, and solutions to help mitigate urban heat islands effects are welcome.

Emerging Standards for Solar Reflectance

Improved energy efficiency, reduced energy consumption and the promotion of low-carbon developments are important environmental targets for governments and organizations worldwide. Finding energy-efficient, low-carbon ways of keeping surfaces and interior spaces cool will become more important and pressing. This premise is supported by the continuing emergence of national and international standards for solar reflectance.

The United States introduced solar reflective coatings in the 1990s. They were used in cool roofing installations to carry out energy-saving research. This started the ‘Cool Roof Rating Council’ program, which saw the solar reflectance index (SRI) standard set at 25% for high-sloped roofs. Legislators and influencers globally have used this platform to formulate a series of policies, standards and user recommendations:

- In Europe, the European Cool Roof Council (ECRC) has been formed to make an important contribution to mitigating climate change through increasing the energy efficiency of buildings. It is promoting the certification of cool roof products and their use across Europe.

- In France, AFNOR is reviewing its current standard DTU 59.1 to include a solar reflectance value.

- Japan has issued the JIS K 5 675 standards for roof coatings with high solar reflectance.

- In North America, Title 24 standards being introduced in 2014 recommend cool roofs to help building owners to save potentially 30 percent on their energy bills.6

Emerging standards for energy efficiency and, in particular, solar reflectance, are not confined to buildings. In 2011 the International Maritime Organization introduced a new chapter, making the Energy Efficiency Design Index mandatory for new ships. The regulations are non-prescriptive. It means ship designers and builders are free to use the most cost-effective solution(s) for each particular vessel as long as the required energy efficiency level is attained.

Innovative Response to Consumer Demand

In 2007, Huntsman recognized that emerging standards and environmental imperatives could be expected to fuel a growing demand for solar-reflective coatings. The question was, how should Huntsman, as a producer of titanium dioxide pigment, best respond to that demand?

Our scientific team proposed an idea for an innovative pigment with the power to transform solar-reflective coatings. At the time, white or light-colored coatings were traditionally used, along with a limited range of earthy tones to help reflect the sun’s radiation. We all know that white or light-colored objects reflect more solar energy than black or dark-colored objects. But modern-day consumers, along with architects and product designers, have come to expect an increasing choice of products and colors. That suggested the need for a wider color palette of solar-reflective coatings. This supposition was the starting point for a research and development project that has resulted in Huntsman’s novel ALTIRIS® infrared reflecting pigment.

The ALTIRIS pigment has been engineered to reflect infrared radiation from the sun. It can be easily mixed with colored pigment to yield high solar reflectance in an unprecedented range of colors. Huntsman can demonstrate that the pigment can dramatically increase solar reflection in exterior coatings across color space. We have color matched several paints including:

-

Beige (L*66.56, a*4.12, b*17.15)

- Control – 34% solar reflectance

- With ALTIRIS pigment – 54% solar reflectance

-

Violet (close to RAL 4009)

- Control – 27% solar reflectance

- With ALTIRIS pigment – 58% solar reflectance

In proving the novel pigment, the team prepared a variety of colored coatings containing ALTIRIS pigment, testing their solar reflectance against coatings containing standard TIOXIDE® pigments. The results showed that solar reflective coatings formulated with ALTIRIS pigment can increase solar reflectance by more than 100% in some colors. The Huntsman research team prepared coatings containing ALTIRIS pigment and control samples containing TIOXIDE pigment with the same RAL index. The team then compared total solar reflectance using a Cary 5000 spectrophotometer. Even black coatings could reach total solar reflection levels greater than 25% after the addition of ALTIRIS pigment. This is a substantial improvement over conventional black coatings that generally only reflect about 5-8% of the sun’s energy.

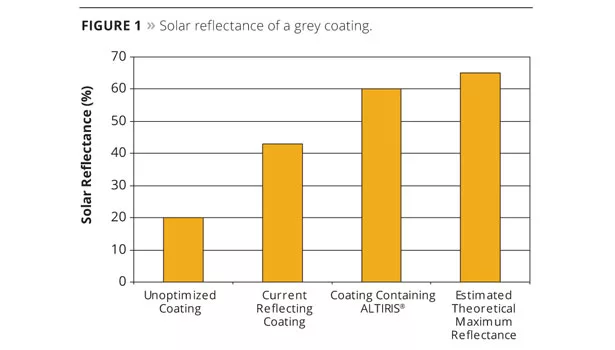

Tests with a grey coating, a popular color for roofs, showed that use of ALTIRIS pigment can increase the total solar reflectance significantly (Huntsman has produced hundreds of starter formulations for a wide range of colored coatings with high solar reflectance.) Figure 1 demonstrates the effectiveness of the ALTIRIS pigment by comparing the total solar reflectance measurements for paints that have been color matched to within Delta E < 2 drawn down over a black substrate at approximately 75 microns film thickness.

Range of Benefits

- An important criterion for the design of ALTIRIS infrared-reflecting pigment was that coating formulators and technicians should be able to use it with ease and without the need for costly, additional or revised process steps.

- ALTIRIS pigment has been designed as a single additive, making it simple to incorporate into coatings and polymer systems.

- The ALTIRIS pigment can help achieve high levels of solar reflectance in a wide range of colored coatings and polymers, helping to provide color flexibility for architects and designers.

- By increasing solar reflectance in exterior coatings, ALTIRIS pigment can help reduce the energy needed to power air-conditioning systems. In turn, this may reduce associated greenhouse gas emissions.

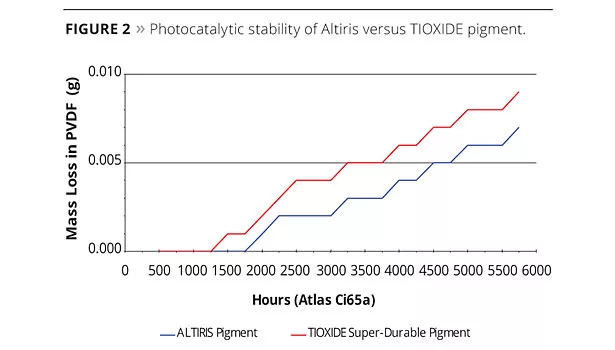

- To enhance the photocatalytic stability of the novel pigment, a dense silica coating has been applied for durability. The coating acts like a protective shell around the pigment particles, helping prevent escape of charged species from the TiO2 and consequent creation of harmful radicals within the resin. The increased photocatalytic stability of the pigment was demonstrated using a durable alkyd melamine formaldehyde paint system, which tests durability with particular emphasis on the photocatalytic aspect of the pigment. These results are shown in Figure 2.

Industry Recognition

Huntsman’s infrared-reflecting technology has been recognized by the coatings industry, winning the Institution of Chemical Engineers (IChemE) award for innovative product of the year in November 2012.

It is immensely satisfying to receive an industry accolade like this. But the most exciting part of the ALTIRIS pigment story is yet to come – as we work with customers to further explore the potential of this pigment.

Could this pigment help to extend a coated product’s lifetime? Increasing the solar reflectance of a structure’s surface may have a positive impact on durability, and reducing thermal cycling stress and coating temperature could lower the probability of delamination or peeling of the surface coating.

ALTIRIS pigment could potentially provide solar reflectance properties to thousands of products worldwide. The benefits could be immeasurable in our growing, energy-conscious world. n

Sidebars:

What is ALTIRIS Pigment? |

|

ALTIRIS pigment has been engineered, by crystal size modification of rutile titanium dioxide, to give high infrared reflectance. The pigment is modified and coated to make it super durable. There are two distinct products. ALTIRIS 800 pigment

ALTIRIS 550 pigment

|

Modeling and Prototype Production |

|

The ALTIRIS pigment project began in 2007. A multi-disciplinary project team was formed to evaluate the market potential and to establish the technical feasibility of the concept. Titanium dioxide pigment is traditionally optimized for reflection in the visible spectrum. To keep colored surfaces cool in the sun, it is critical that they reflect the invisible part of the solar spectrum, the near infrared (IR), as this is what generates the most heat (Sidebar Figure 1). In order to create a solar-reflecting pigment, the Huntsman team had to shift the main reflection band of titanium dioxide into the near-infrared region of the solar spectrum. It was also necessary to diminish the traditional whiteness of the product – enabling customers to develop dark and vibrant solar-reflective colors. Senior research scientists developed light-scattering models to define a titanium dioxide pigment with near-infrared-reflecting properties. |

References

- http://www.iea.org/aboutus/faqs/energyefficiency/.

- World Business Council for Sustainable Development (2009). Transforming the Market: Energy Efficiency in Buildings, target is set against the predicted Business as Usual (BAU) figure for 2050, which is a minimum requirement to generate stabilized CO2 levels as sought by the Intergovernmental Panel on Climate Change (IPCC).

- Potential benefits of cool roofs on commercial buildings: conserving energy, saving money, and reducing emission of greenhouse gases and air pollutants; Ronnen Levinson and Hashem Akbari; 14 March 2009.

- www.melbourne.vic.gov.au/AboutCouncil/MediaReleases/Pages/WhiteroofstomakeforcoolerMelbournebuildings.aspx; 24 January 2012.

- http://www.indianexpress.com/news/-cool-roofs--mandatory-for-all-new-buildings/988898.

- http://www.energy.ca.gov/title24/.

- ALTIRIS® and TIOXIDE® are trademarks of Huntsman Corporation or an affiliate thereof in one or more, but not all countries.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!