Achieving Sustainable Paint Operations with Electric Pumps

Responding to the rise in energy costs and environmental concerns, U.S. manufacturers are being prompted to look at alternate technologies and processes to achieve sustainable finishing operations. This has particularly been true on the paint line. Since the dawn of centralized mix rooms, new strategies have been developed to improve efficiency, reduce operating costs and minimize environmental impact – all while delivering a world-class paint finish.

These changes include advances in mix room equipment, especially pumps. Although pumps have been a staple in mix rooms for decades, the technology has changed considerably. Up until the late 1960s, most automotive manufacturers were using 2-ball pneumatic pumps until paint plants became standardized and they started using centrifugal pumps.

Over the next 10-20 years pump technology continued to evolve, and many operations shifted to pneumatic 4-ball pumps because they reduce degradation and extend the paint life. This made them a great replacement for centrifugal pumps and ideal for industrial applications. For more than 30 years, pneumatic systems have been the accepted choice of most mix rooms because they are intrinsically safe, easy to operate, less expensive to purchase and use an existing power source in the plant.

Another option that never gained much traction in the United States is hydraulic pumps. Although they are more cost efficient than pneumatic systems (approximately 25%), they have a reputation for being messy. Hydraulic pumps are generally expensive to retrofit into existing operations, but can be a good option if installing into a completely new paint line.

Perhaps the most important emerging technology to reduce long-term energy consumption, especially in large plants building new mix rooms, has been the use of electric pumps.

With typically a higher up-front capital expense, electric 4-ball pumps often provide the largest energy savings in a typical finishing operation. Most notably, they offer direct conversion of electrical energy to mechanical pumping. This not only uses less energy, but it also eliminates the inefficiency of compressed air systems.

Air compressors have ongoing liabilities including leaks, maintenance and equipment downtime that can lead to further inefficiencies. In fact, the majority of air compressor costs are not from the initial capital investment, but rather from energy usage in its 10-year lifespan.

Another benefit of electrical pumping is the improved control and automation potential. Pumps often run during off shifts or non-peak operating modes. By automating the pump using off-production settings, the system can be set to operate only when absolutely needed – greatly reducing or eliminating energy consumption (Table 1).

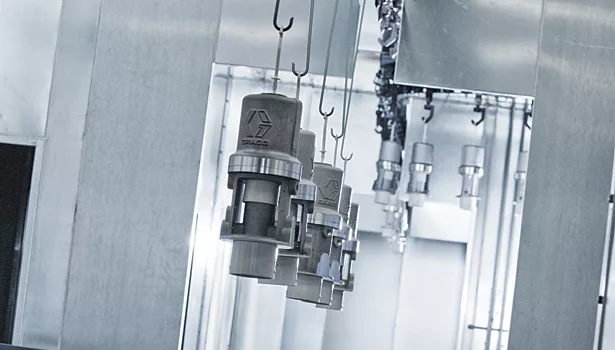

One particular electric circulating pump, manufactured by Graco, demonstrates these benefits. The E-Flo DC has the ability to maintain constant fluid pressure like a pneumatic pump while delivering cost savings through the use of a highly efficient electric motor. This unique technology not only provides less pulsation at changeover for consistent finishes, it uses less energy – making it up to five times more efficient than similar-sized pneumatic pumps. It is also rated for use in hazardous locations.

One large North American manufacturer of heavy equipment quickly recognized the benefits of electrical pumping after making the switch. When a pneumatic pump needed replacing on their paint line, they decided to try something more efficient. After selecting and installing a Graco E-Flo DC electric pump because of its advanced control and networking features, painters could immediately tell that something was different about how the paint was being delivered to the gun. The rapid changeover of the pump led to less pulsation, delivering a smoother finish and ultimately making it easier to paint.

Another car manufacturer based in Europe was also looking for a more efficient pump. The small footprint of the E-Flo DC made replacing the existing pump pretty simple, and they were also impressed by how easy the system was to install. Because there was good surge performance on changeover, they noticed better, more consistent finishes. The simple controls also made it easier to train mix room employees.

To protect the pumps from premature wear, the E-Flo DC was also developed with an integrated runaway protection system that is standard on all models. If the pump exceeds a certain flow rate, it automatically shuts off. This safety mechanism not only prevents costly material loss, but also reduces maintenance and increases longevity of the product.

A leading truck manufacturer in North America saved a great deal of money and material because of this feature. When a long circulation line was damaged, the E-Flo DC went to work. Rather than pumping hundreds of gallons of paint out of the damaged circulation line, it was estimated that only five more gallons of paint pumped through the line before the integrated runaway protection stopped the pump. Because this line was connected to an E-Flo DC, this manufacturer saved thousands of dollars on material and cleanup costs, and could easily justify purchasing additional E-Flo DC pumps as a result of these savings.

Table 1 illustrates how switching from pneumatic to electrical pumps can yield thousands of dollars in savings for finishing operations.

Conclusion

While it may be a challenge, achieving sustainable paint operations is possible. To be successful, remember that one size does not fit all. Do your homework. Evaluate current trends. And understand the unique requirements of your application. One thing is for sure, pump technology is continuing to evolve and electric pumps are really showing promise as an energy- and money-saving technology. They offer many great advantages that are prompting manufacturers to make the switch to electric.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!