Testing High-Performance Coatings

A business unit of Curtiss Wright Surface Technologies, E/M Coating Services (based in Evesham, UK) develops and applies technical surface coatings to components from diverse industrial sectors. Applications range from small pins for seat belts to tonne-scale valve blocks for subsea Christmas trees (oil wells) and fan blades for aero engines. What unites these applications is the need for a surface coating that has a closely specified wear profile, corrosion resistance and/or frictional characteristics.

As part of E/M Coating Services’ (EMCS) strategy of continuous development, the company recently conducted a project to assess certain proprietary coatings for food and pharmaceutical applications. To support this work, testing was carried out in collaboration with Freeman Technology using its FT4 Powder Rheometer®, which enables precise and highly reproducible dynamic, shear and bulk property testing. Determination of the wall friction angles of the coatings, using a range of different powders, allowed an assessment of their effectiveness for improving powder flow performance within a hopper or other piece of processing equipment.

Coating Metals to Improve Performance

Coatings are applied to metal components to fulfil a multitude of requirements. They may, for instance, provide a relatively inexpensive shield between a costly construction material, chosen for its strength, and a corrosive process stream. In an analogous way, coatings may be applied to protect from wear, or more proactively to reduce the friction between interacting components in an assembly. In processing plants, coatings can reduce interactions between material travelling through a vessel, pipe, valve or pump and the confining metal walls. Coating metals to enhance the movement of powders through or across them is a good example of this type of use, and is the focus of this article.

In his pioneering work to establish a design methodology for hoppers, Jenike recognized that the flow of powder through a vessel is governed by interactions between particles in the powder, and between the powder and the container wall.1 As a powder flows, the planes within it shift relative to one another and, at the edges of the powder mass, relative to the inner surfaces of the container. Once the properties of the powder are fixed, the ability to control the interactions between the wall and the powder – wall friction – becomes an important degree of flexibility for designers looking to optimize plant design. Wall friction angles quantify the magnitude of frictional interactions between a material of construction and a powder and are, therefore, helpful in terms of ranking coatings, not just for hopper design, but more broadly for their ability to ease powder flow in a variety of process equipment.

Wall Friction Testing

Figure 1 shows a typical apparatus for wall friction testing. A sample of powder is consolidated in the test vessel at a specified normal stress before measuring the shear stress or force needed to rotate one plane relative to another, shearing the powder against the test disc surface.

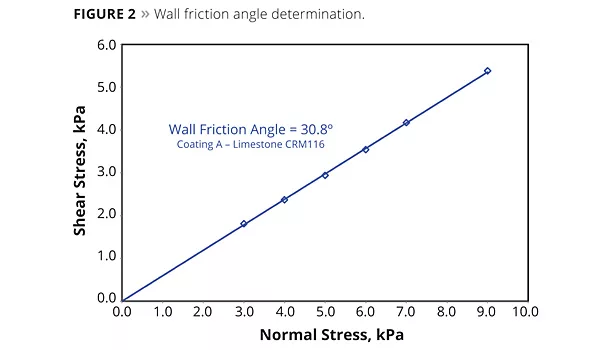

Applying different consolidation stresses generates a series of data points, from which an overall plot is produced to derive wall friction angle (Figure 2). Higher wall friction angles are indicative of greater frictional forces between the metal and powder. Reference 1 provides a more detailed account of the test method used.

One thing worth highlighting about wall friction testing is that the results obtained are a function of the properties of the ‘wall’ and the powder. Different powders vary in their response to different surfaces, making it important to match material of construction and powder in any specific application. Testing with a variety of powders is a useful strategy when looking to generally assess and scope the performance of a new coating.

Case Study: Using Wall Friction Angle to Compare the Performance of a Range of Coatings

EMCS is currently assessing the potential of a number of proprietary coatings for pharmaceutical and food applications. These include: Flurene 611; Flurene 177; Everlube 6102G (referred to as Everlube in the tests); and Parylene (a medical-grade low-friction coating). The first three of these coatings are fluoropolymer-based but differ in terms of their chemical analysis and properties.

Flurene 611 is a resin-reinforced fluoropolymer that offers low friction and good wear resistance. Flurene 177 combines low friction with high chemical and abrasion resistance and can be applied as a self-bonding, non-porous, single-coat film of just 20 to 25 microns. No fusion is required to form a coating. Everlube is a thermally cured, PTFE/MoS2-based solid film lubricant with a high-molecular-weight phenolic binder system that offers good wear, corrosion and chemical resistance and is suitable for medical ISO 10993 bio-compatibility testing. Parylene is an extremely versatile coating that has unique properties of lubricity, bio-compatibility, moisture impermeability and electrical insulation.

Evaluating the performance of these coatings took the form of back-to-back testing with two competitor products already offered for food and pharmaceutical applications: Coating A and Coating B. To provide a further baseline for comparison, tests were also carried out with a standard fine brushed stainless steel (1.2 microns).

Assessing Performance

EMCS provided Freeman Technology with six coated stainless steel wall friction discs, one for each coating including the competitor products. The standard brushed steel disc forms part of the standard Freeman Technology wall friction testing apparatus. All wall friction measurements were made using the FT4 Powder Rheometer.

Each of the discs was tested with a range of powders: Limestone CRM 116 (a standard for shear testing); Respitose and FlowLac 100 (pharmaceutical grades of lactose – a common excipient); skimmed milk powder and cornflour (food ingredients). All tests were carried out with 48 mm accessories using the 50 mm-diameter vessels and repeated twice to assess repeatability.

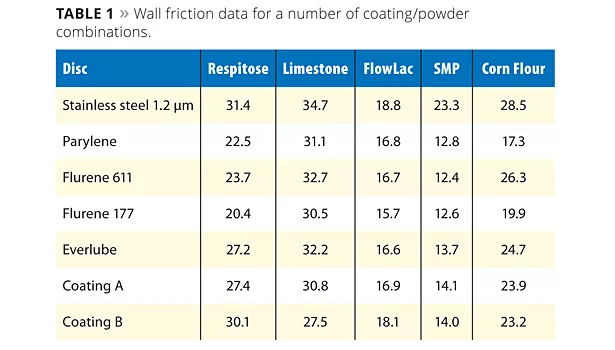

The standard 9 kPa test program was used throughout. This is one of the automated test methodologies available on the instrument and involves sample consolidation at 9 kPa followed by pre-shearing for 60º at a rate of 18º min-1 to ensure precise and repeatable sample preparation ahead of measurement. Subsequent shearing at 9, 7, 6, 5, 4 and 3 kPa generates the wall yield locus from which the wall friction angle (WFA) is derived. Table 1 summarizes all the measurement results.

Limestone exhibits quite limited variability with the different discs, but Coating B clearly yields the lowest WFA. Of the EMCS coatings, Flurene 177 has the lowest WFA, 30.5º, suggesting that it most closely matches the best performing disc, Coating B, in terms of frictional performance. Testing against Respitose produces lower WFAs in all cases, but Flurene 177 clearly has the lowest value of all (20.4º), better than both of the competitor products. Parylene also performs very well. The performance of Everlube closely matches that of Coating A but both are measurably inferior to the best performing disc. All coatings have substantially lower WFAs than those obtained with the brushed stainless steel, a widely used material of construction within the pharmaceutical industry.

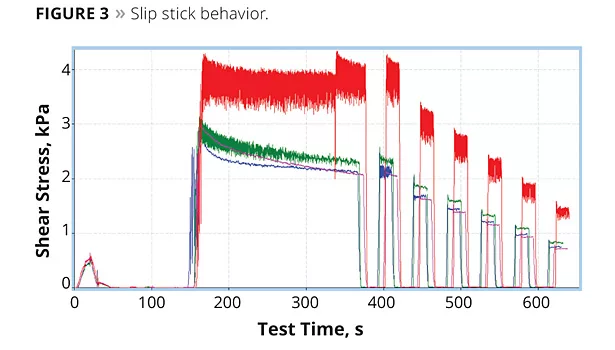

With the skimmed milk powder (SMP) the Parylene and both Flurene discs outperform all the other discs, although with the exception of the brushed steel, results are closely similar. Detailed analysis of the SMP data (Figure 3) reveals more about coating performance and the occurrence of slip-stick behavior with certain discs. This is, as the name suggests, when a powder begins to flow under the applied stress but quickly locks up again, resulting in an oscillatory and unstable state. Such behavior is indicative of an increased likelihood of erratic performance in the processing environment and, therefore, is undesirable.

Slip-stick behavior is evident during the pre-shear process (Figure 3) with the brushed stainless steel disc (red trace) and to a lesser extent with the Everlube disc (green trace). However, Flurene 177 (blue trace) and Coating B (pink trace) both prevent this behavior, suggesting that they might be a more consistently performing choice for handling the powder. To further investigate the slip stick performance of the coatings, tests were duplicated with cornflour, a material known to be problematic in terms of erratic behavior. All the discs exhibited slip-stick behavior with the exception of Coating B, but the problem is appreciably less pronounced with the Parylene and Flurene 177. Figure 4 displays the extent of variability in shear stress recorded during pre-shearing, a direct measure of the extent of slip-stick behavior with any given powder/coating combination.

The calculation of hopper design parameters – half angle and outlet size – sets these results in a specific design context (Figure 5). Hopper half angle defines the gradient of the sloped, lower element of a hopper, relative to the vertical, while outlet size is the dimension of the hole through which the powder exits.

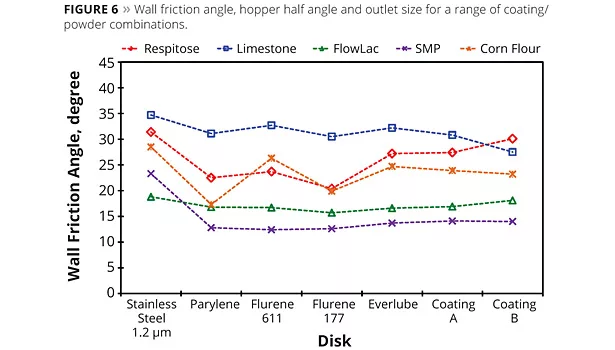

Generally speaking, the higher wall friction angles associated with less free-flowing systems result in steeper hopper half angles and wider outlet sizes. The results for the coatings detailed here are presented in Figure 6 alongside data for a wide range of other coatings from previous studies, all measured using Respitose. This graph confirms that the Flurene products and the Parylene rank very highly in terms of flow properties; Coating A and Everlube are associated with mid-range performance; Coating B is a relatively poor choice when it comes to hopper design.

Conclusion

Wall friction testing is an established method for quantifying the frictional interaction between a powder and a potential material of construction. In this study, extensive testing illustrates how examining wall friction can rank coatings in terms of their ability to ease powder flow, for more efficient hopper design and the specification of other items of equipment. Such testing also highlights the potential for slip stick behavior, which can be associated with erratic performance in the process.

Of the coatings tested here the Flurene products trialed by E/M Coating Services appear to offer good performance characteristics for a number of powders including Respitose, which is widely used in the pharmaceutical industry as an excipient. These coatings compare well with established products for the food and pharmaceutical industry, suggesting that they may have considerable commercial value in this application space.

References

1 Jenike, A.W. Storage and flow of solids, Bulletin 123 of the Utah Engineering Experiment Station, November 1964 (Revised 1980), University of Utah.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!