Thin-Film Analysis Using UV-Vis Spectrophotometry

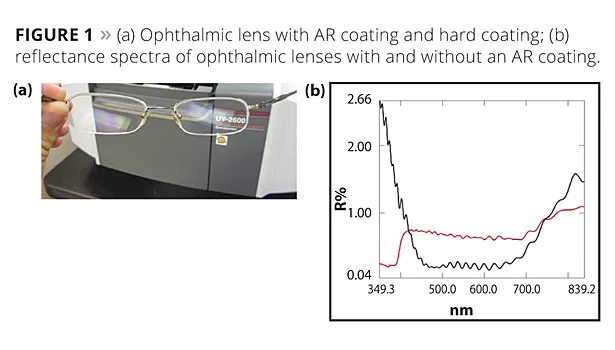

Thin films play a critical role in our lives as they are used, for example, in electronics, solar cells and coatings on eyeglasses in order to reduce glare and increase the amount of transmitted light through the lenses. For example, anti-reflection (AR) coatings are applied to lenses in order to reduce glare that would otherwise be present in uncoated lenses. This has become an attractive feature for many consumers and, therefore, measurement and control of AR coatings has become increasingly important.

Figure 1 shows two reflectance spectra of ophthalmic lenses. The black spectrum is the reflectance spectrum of a lens that contains a hard coating as well as an AR coating, whereas the red spectrum is a lens that only has a hard coating.

Applying coatings as thin films relies heavily on the ability to determine the thickness of the coating for quality control purposes. In ophthalmics, spectral reflectance is used to measure AR as well as hard coating thickness. The ophthalmic industry takes advantage of the capability to add multiple coatings in various combinations in order to provide the best consumer products. Special film thickness software offers the ability to analyze a single film on a lens. In Figure 1, the area of interest for the hard coating is between 500 and 650 nm.

Film thickness, d, is determined from the wavelength between peaks and valleys in interference patterns. It is required that the refractive index of the coating and the incident angle are known prior to calculating film thickness, as given in Equation 1, where n is the refractive index of the film, q is the angle of incidence, λ1 and λ2 are wavelengths of two noticeable peaks (or valleys), and Dm is the number of peaks between λ1 and λ2.1

In ophthalmics, the area of interest lies in the ability to analyze multiple coatings that are comprised of hard coatings and AR coatings. Whether multiple or single coatings are being applied to a substrate, it is critically important that the individual coatings by themselves have been analyzed for film thickness prior to making a finished product.

This article focuses on the ability to measure a single protective coating on an acrylic substrate using a Shimadzu UV-2600 UV-Vis spectrophotometer with 5 degree relative specular reflectance accessory and film thickness software.

Method

Reflectance spectra of an acrylic lens with a single protective coating were acquired on the UV-2600 using the 5 degree relative specular reflectance accessory under the following scan conditions:

- Wavelength range (nm): 350 to 850 nm

- Scan speed: Fast

- Slit width: 5.0

- Sampling interval: 0.5

- Auto sampling interval: Enabled

- Scan mode: Single

A background scan was obtained by mounting the mirror assemblies on the sample and reference stages with the mirrors face down and then acquiring a baseline scan. It should be noted that for measuring lenses and other acrylic materials on the 5 degree relative specular reflectance accessory, the ideal background would be obtained by replacing the sample-side reference mirror with a blank, uncoated lens. However, for the purposes of this study, an aluminum mirror was used as a sample mirror during the baseline scan in order to acquire a baseline scan. The sample mirror was then removed and replaced with the acrylic lens in order to acquire a reflectance spectrum, as shown in Figure 2.

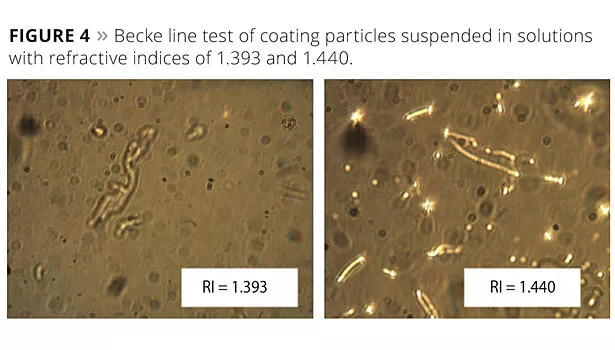

The refractive index of the protective coating on the acrylic lens was estimated by etching away a small layer of the coating and suspending it in solutions of various refractive indices and then using the Becke line test to estimate the refractive index of the coating. In analyzing the coating using the Becke line test, the refractive index was estimated to be between 1.393 and 1.440.

Results and Discussion

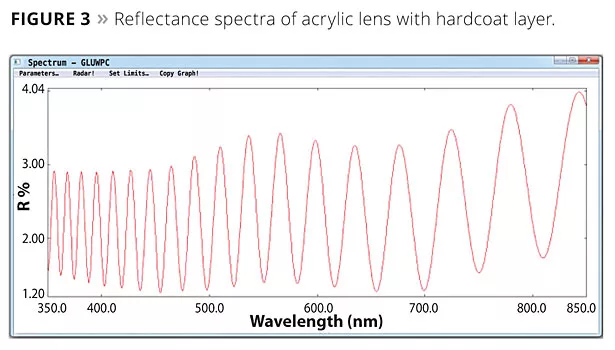

Reflectance spectra of the acrylic lens with protective coating are shown in Figure 3.

The thickness of the protective coating can be determined using the film thickness software. It is required to know the refractive index of the coating as well as the incident angle of light. Figure 4 shows the images acquired of the sample and estimating the refractive index using the Becke line test.

With an incident angle of 5 degrees, the thickness of the coating was calculated to be between 3.638 and 3.761 µm, as summarized in Figure 5.

Conclusion

In conclusion, this article has demonstrated the ability to measure the thickness of a single coating so long as the refractive index and the incident angle of light are known prior to using the film thickness software from Shimadzu. The software allows for a quick and easy way to calculate the film thickness of various coatings.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!