A New Approach To Using Self-Healing Coatings

A traditional protective coating system on a metal substrate generally consists of a pretreatment, primer and a topcoat. The base metal is pretreated and primed for enhanced adhesion and corrosion resistance. A topcoat is then applied on the primer. Many of the coatings in use today to inhibit corrosion are “passive” in nature, in that they provide only barrier protection and/or promote adhesion between the metal and overlaying paint. While these are important attributes, passive solutions do not offer the same level of protection as coatings that provide “active” corrosion protection. To date, coatings that repair themselves when damaged are limited to either unconventional chemistries or uncommonly used polymers, which require forming a complex molecular network and are too soft to satisfy the mechanical robustness required in a protective topcoat.

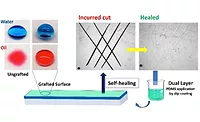

An “active” corrosion protection coating, or self-healing coating, can be categorized into two classes according to their self-healing mechanisms: chemical or physical. The traditional chromate-based corrosion protection coating uses hexavalent chromium either in the pretreatment or the primer, or both, to achieve chemical self-healing. In contrast, NEI Corp.’s self-healing coating involves physical gap closing and crack sealing, which has the potential to impart performance that matches that of a chromate-based system. Figure 1 illustrates the coating architecture containing NANOMYTE® MEND-RT, a self-healing intermediate layer between the topcoat and the primer. When the coating is physically damaged, the self-healing intermediate layer physically repairs the damage autonomously, closing and sealing the gap and providing an active physical barrier.

An obvious advantage with the use of a self-healing intermediate layer as shown in Figure 1 is that the topcoat is a standard topcoat, which satisfies all industrial standards. The main function of NANOMYTE MEND-RT, the intermediate self-healing layer, is to self-repair damages. By separating the topcoat functions and the self-healing function into two distinct layers, a self-healing capability is added to the conventional coating system. The composition of MEND-RT is such that the adhesion between the primer and the topcoat is preserved. The MEND-RT layer can be introduced in any coating system, without deteriorating the original properties of the coating stack. MEND-RT can be used with any coating system applied on ferrous or non-ferrous metals, such as magnesium, aluminum, copper, zinc and alloys thereof, and steel.

The efficacy of the self-healing intermediate layer, MEND-RT, was verified using the standard accelerated test method. A chromate-free, self-healing coating system was applied on aluminum 2024 and 7075 alloys. Aluminum was selected for this evaluation, as it is extensively used with chromate coatings in the aerospace and aircraft industry due to its high strength and light weight. Two sets of coating systems were applied and compared for corrosion resistance. The first coating stack consisted of a chromate-free corrosion-resistant pretreatment, a chromate-free epoxy primer and a standard polyurethane topcoat. The second stack was identical to the first one, but had MEND-RT inserted between the primer and topcoat. Corrosion resistance was evaluated using the Salt Spray Test (SST) ASTM B-117 method. Artificial defects (“X” shaped scribes) were made on the coated panels before exposing them to salt spray. The photographs in Figure 2 show the progression of corrosion on Al 2024 and 7075 coupons after 1,250 hours of SST.

The first set of panels, i.e. without the self-healing interlayer, exhibited early signs of corrosion with white corrosion buildup in the scribed region. The samples with MEND-RT showed enhanced protection with no signs of corrosion. Examination under the microscope revealed that the defects in the coating were physically sealed by the MEND-RT coating. In addition, the gap closing occurred at near ambient temperature, without any external heat or other stimuli. This is direct evidence that the introduction of MEND-RT enhances the corrosion resistance of a coating system, leading to a longer lifetime of the coating.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!