Using Spectros for Print, Packaging and Manufacturing

A company’s brand is its image, and accurately reproducing each color is crucial to brand integrity. But as color moves through the supply chain, among machines, printers and sites, a color can quickly shift away from its original intent.

Spectrophotometers allow brand owners to measure and specify color using a universal language — spectral values — and to share that information with their suppliers. Suppliers use spectrophotometers to monitor color accuracy during manufacturing to ensure that it remains exact.

This article will look at how spectrophotometers help provide peace of mind when reproducing critical brand colors.

What is a Spectrophotometer?

To see color, you need three things: light, an object and an observer. If a human eye is the observer, color judgment alone can’t be trusted. Refer to X-Rite’s post on color vision to learn about the many ways our eyes can be fooled.

A spectrophotometer, on the other hand, can simulate the way humans see color without the confusion of color vision anomalies. They don’t have bad days. They don’t get tired. Background colors don’t influence their perception. As long as it’s properly maintained and used correctly, a spectro will give accurate color data, time after time.

The math behind how it works is complicated, but the end result makes it easy to judge, compare and control color. Here’s how it works, in a nutshell.

- Place the spectro on the sample and click the button to measure.

- The spectro projects a light onto the sample’s surface.

- The sample absorbs some of the light and reflects the rest into a set of filters.

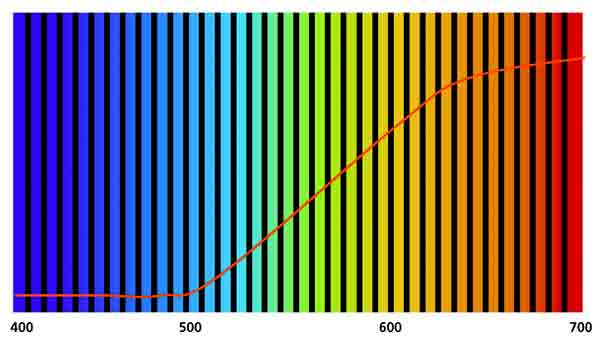

The spectrophotometer measures that reflected light at many different points to capture the fingerprint, or signature, of the sample and presents it as a reflectance curve.

|

| From violets through blues and greens, to yellows, oranges and reds, varying the wavelength from 400 to 700 nanometers changes the color of light. This illustration shows a reddish-orange reflectance curve. The sample absorbed almost all of the violets, purples, and blues, then progressively reflected more and more energy while moving from greens into yellows, oranges and reds. |

The reflectance curves of samples can be compared to the reflectance curves of standards to determine even the most minute color differences. This is how manufacturers determine whether the color they’re producing is on target. If the numbers are close, you’ve got yourself a winner. If not, you know you need to try again. Measuring throughout a production run helps catch color errors early so that changes can be made before time and materials are wasted.

Whether you’re measuring fabric swatches, paint, plastic pellets or cardboard packaging, spectral measurements can ensure that color is consistent across different materials and production processes.

Choosing a Spectrophotometer

When choosing a spectrophotometer, one of the most important factors to consider is the type of surface you’ll be measuring. There are three primary types of spectrophotometers: 0º/45º, spherical, and multi-angle. The name describes the way each device measures color.

Flat surfaces

Most spectrophotometers measure light reflected at a fixed angle to the sample, usually 45?, which works great for smooth or matte surfaces.

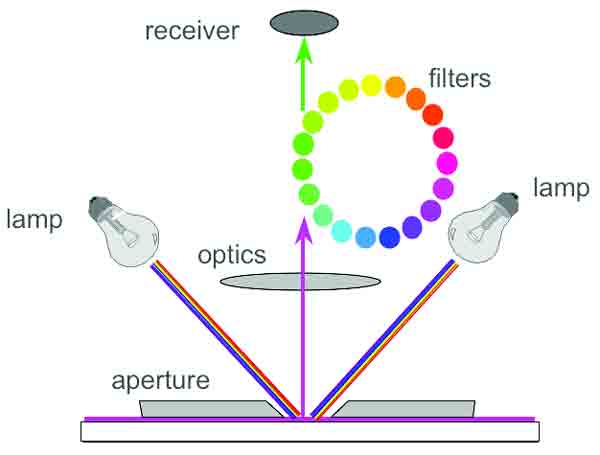

|

| In a 0º/45º spectrophotometer, a ring of filters each sense the reflection from a different portion of the visible spectrum. Today’s instruments usually have 16 or 32 data points, but expensive scanning units can scan wavelength-by-wavelength, yielding hundreds of pieces of reflectance data. |

An added benefit of 0º/45º is that it can exclude gloss from the measurement. This is called “specular excluded.” Why would you need this? Think about reading a glossy magazine. You tilt it so the glare doesn’t reflect into your eye. The 0º/45º does exactly that, allowing it to perceive color the same way we do.

The 0º/45º instruments, such as X-Rite eXact, perform well with most flat surfaces, dyes, pigments and gloss levels, especially paper and packaging materials.

Textured surfaces

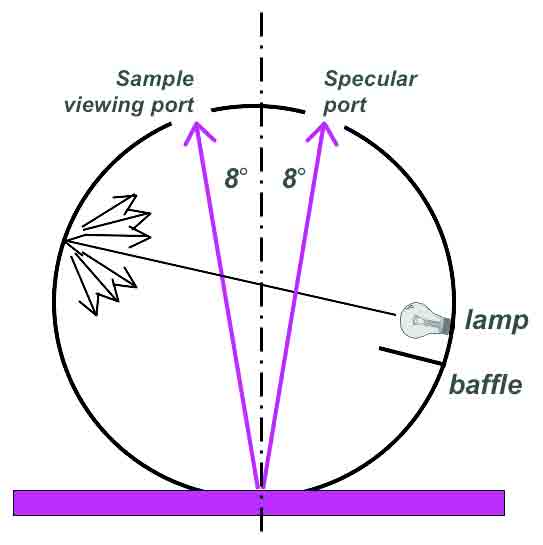

As you can imagine, textured surfaces are difficult to measure because the color changes depending on the angle. Spherical spectrophotometers can measure light reflected at all angles and calculate a color measurements that closely matches what a human eye would see.

|

|

A strong beam of light is flashed into the sphere, which is a near-perfect, white reflector with a low gloss, matte surface. More than 99% of that light is reflected and scattered randomly in all directions, making the sphere a light source that can illuminate the sample from all possible directions. |

Spheres are a good choice for textiles, carpets, wood, plastics, roofing and ceiling materials, and some reflective and metallic surfaces. X-Rite just released a powerful, cost-effective benchtop spectrophotometer — the Ci7800 — for use in labs and for manufacturing and quality assurance.

Metallic surfaces

Auto manufacturers have perfected coatings with special effects that create a whole new experience for car buyers, and nail polish has become more of an art form than a beauty accessory. Special additives such as mica, pearlescent materials — even ground-up seashells — produce a surface that shifts in color when viewed from different angles.

Of course, measuring these colors is a challenge. A multi-angle instrument views the color of the sample as if it is being moved back and forth, just as you would twist a sample to see the color at various angles. Today’s multi-angle instruments measure at five distinct angles relative to the specular or gloss angle.

|

|

Metallic paint has two reflective elements that interact with the white light from a light source. As in normal paint, there is a colored pigment that absorbs light colors, and the remaining light is scattered back out of the paint layer. For example, a blue pigment absorbs red and green light, and the remaining blue light reflects back and can be seen from any angle. |

Large, expensive goniometers used to be the only option for measuring metallics, until X-Rite introduced the first compact multi-angle devices. These portable, battery operated spectrophotometers, such as X-Rite’s MA98, are used by most automakers and their colorant supply chains around the globe.

Spectrophotometers come in many shapes and sizes, from the portable i1Pro 2 that can be carried around the lab for spot measurements, to the robust VeriColor in-line system that measures color as it moves down the supply chain.

No matter the size or measurement process, the purpose remains the same: Spectrophotometers ensure that your color stays true from start to finish.

Learn More

If you’re in the market, refer to X-Rite’s whitepaper for more information about how to choose the best spectrophotometer for your needs.

To learn more about how spectrophotometers fit in a color-managed workflow, or to see the many software solutions to help you get the most out of your spectro, check out X-Rite’s industry-specific online training courses.

Source: X-Rite

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!