LINE-X Testing Demonstrates the Quality of Its Spray-On Bedliners

HUNTSVILLE, AL – When it comes to chemistry, not all bedliners are the same. Spray-on bedliner producer LINE-X takes testing its product very seriously, educating truck owners how to get the most indestructible protection for their bed.

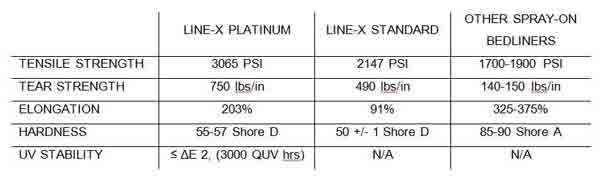

When testing a material for the protection truck owners really need, there are four main tests that can’t be overlooked.

- Tensile strength measures the maximum amount of force a material can withstand before breaking.

- Elongation measures the percentage change in the length of a material before fracturing.

- Hardness describes the resistance of a material to distortion and is measured on an alphabetic scale, type A being softer than type D.

- UV stability tests a material’s resistance to fading or color change under continuous exposure to UV light.

Most spray-on bedliners are made of a polyurea hybrid. They typically have high flex, but score lower in hardness, which eventually affects the ability to withstand abrasion over time. LINE-X offers bedliners made of pure polyurea that combines strength and flexibility to maximize toughness.

With a dedicated full-time research and development team, LINE-X is able to produce a tough, sprayable elastomeric coating for the truck aftermarket. The company has doubled the hardness rating compared to competitors, offering excellent impact resistance and superior tensile strengths (up to 6,600 psi) resulting in outstanding abrasion resistance. Because the material is sprayed, there is a complete seal, making the coating watertight.

The following table illustrates how LINE-X bedliners compare to other similar products.

For more information, visit LINE-X online at www.LINEX.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!