Aluminum Concentrates for Low-VOC Metallic Finishes

Figure 1

Table 1

For the past several decades, tightening environmental regulations have been the primary driver for change in the paint industry. China, the world’s largest coatings producer, has struggled with poor air quality in many metropolitan areas. To help reduce air pollution, the government recently enacted a new coatings regulation related to volatile organic compounds (VOCs). This new regulation imposes a tax (4 percent in terms of the invoice price) on coatings manufacturers for any coating whose ready-to-spray VOC level exceeds 420 g/L.

In addition to environmental regulations, product safety is another area driving change. Paint producers, globally and specifically within China, are focused more than ever on developing manufacturing processes and finished goods with the highest level of workplace and transportation safety in mind.

These changes in the marketplace present challenges for producers of metallic finishes based on aluminum pigments. Solvent-based metallic finishes are prevalent in all types of coatings segments including automotive (OEM and refinish), industrial, consumer electronics, can, coil, marine and more. One major challenge is the inherent chemical reaction between aluminum and water, resulting in hydrogen gas evolution. Therefore, successful transition of metallic finishes from solvent to water requires aluminum pigments that are stabilized for aqueous systems.

This article highlights Benda-Lutz® COMPAL WS, a new range of nonhazardous, aluminum pigment concentrates designed specifically for long-term stability in waterborne coatings and inks. These pigments allow for the manufacture of low- to zero-VOC, sustainable coatings. Furthermore, the pigments are delivered in an easily dispersible granular form for safe and easy handling, improved shelf stability and numerous advantages in transport.

The Technology

COMPAL WS is a unique pigment delivery form consisting of aluminum flake incorporated into a water-soluble solid carrier. This nonhazardous, solid pigment concentrate or granule is easily dispersible in a wide range of waterborne coatings, such as water-based acrylics, urethanes, epoxies and more. Once dispersed, the carrier provides long-term stability and gassing resistance without detracting from the optical properties of the base aluminum flake.

Most solvent and waterborne silver coatings produced today are prepared with aluminum pastes. For solvent-based systems, the pigment is most commonly supplied at roughly 60 to 75 percent aluminum in mineral spirits or mineral spirits blended with solvent naphtha.

One immediate advantage of this new pigment is that it contains no solvent. Therefore, restrictions associated with the carrier solvent, which is most often flammable, are removed. Classified as nonhazardous, these pigments present numerous advantages in terms of shipping, storage, handling and dosing.

For most waterborne coatings, the metal paste is generally supplied at 60 to 75 percent passivated aluminum flake dispersed in water or glycols. These pastes allow for reduced VOC coatings but are typically characterized by a short shelf life.

In addition, the passivated aluminum flake is often exposed to water present in the carrier vehicle while in storage. COMPAL WS granules provide longer shelf life and eliminate any potential for gassing while in storage. In fact, the nonhazardous product handling makes these solid granules ideal for point-of-use applications.

Due to the unique product form, incorporation of these metallic pigments is slightly different than working with traditional pastes. For incorporation, it is recommended to briefly soak the granule in roughly an equivalent amount of water. This premix should be blended via low-shear mixing. Once fully dispersed, the premix should then be added to the desired water-based system.

These aluminum pigments have been tested in a wide variety of paint systems and have been found to have outstanding long-term gassing resistance once formulated. It is important to note that paint chemistry can greatly influence water stability. Formulators should avoid extreme pH conditions and resins with very high acid numbers. Therefore, lab trials are highly recommended to verify product performance.

The First Generation

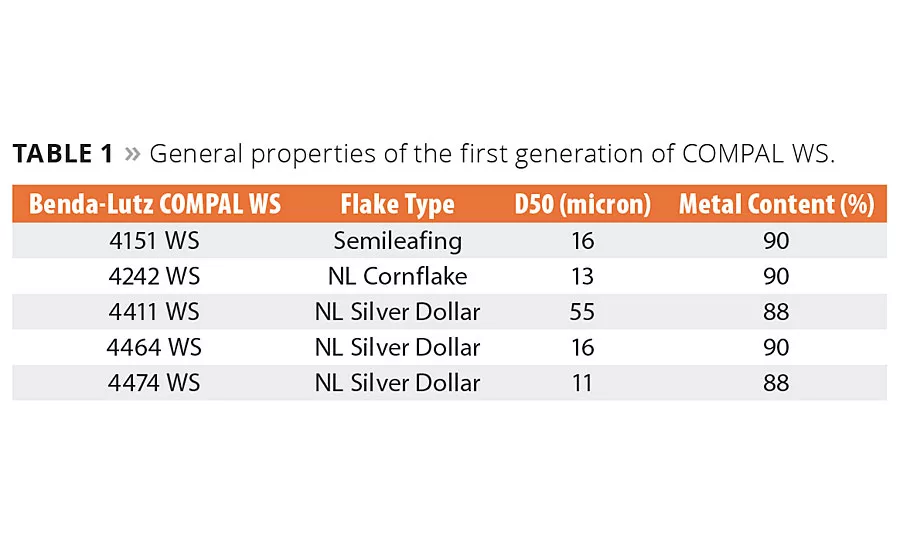

General properties of the first generation of COMPAL WS are shown in Table 1. As shown, this technology can be utilized to deliver highly pigmented aluminum concentrates comprised of a wide range of flake types. All pigments shown in Table 1 are VOC-free. The high pigment content, from 88 to 90 percent metal, allows producers to develop sustainable coatings with optimal formulation flexibility.

Both leafing and nonleafing (NL) pigment intermediates have been developed. For leafing intermediates, the COMPAL WS process slightly reduces the leafing characteristics of the flake. Therefore, grades like COMPAL 4151 WS are classified as semileafing.

This technology can be applied to both cornflake and silver dollar types. The first generation includes a medium-fine (D50 ~ 13 µm) NL cornflake and three NL lenticular grades with a particle size (D50) ranging from 11 to 55 µm.

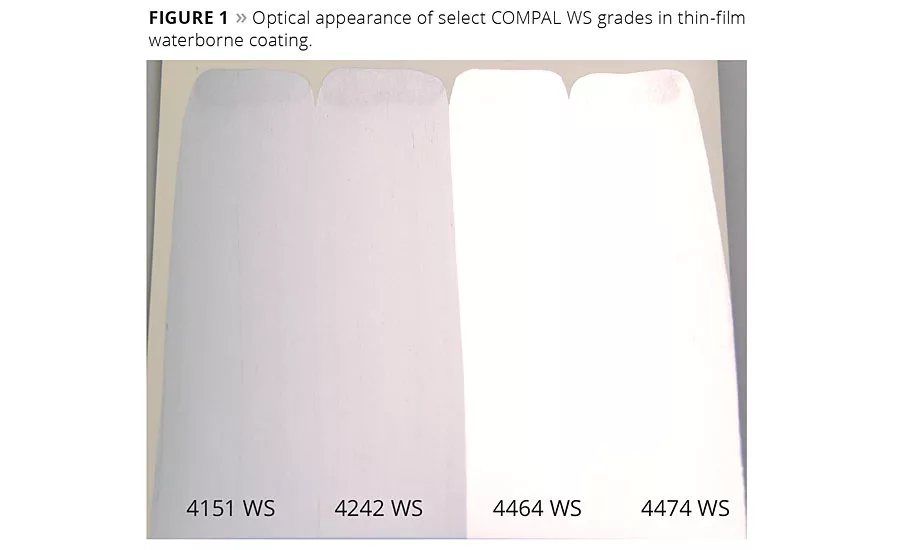

The first generation was selected to cover a wide range of optical effects. COMPAL 4411 WS, the largest particle size in the first generation, is generally used to provide high metallic sparkle for straight silver or tinted industrial coatings. The optical appearance of the fine to medium-fine grades is shown in Figure 1. This side-by-side comparison was prepared using a WB acrylic system containing roughly 19 percent pigment.

As clearly shown in the figure, the silver dollar grades (COMPAL 4464 WS and 4474WS) provide significantly higher metallic brilliance at the face angle. As expected, these lenticular flake geometries also show significantly higher travel or flop.

Comparing the cornflake grades, COMPAL 4151 WS is slightly more brilliant than COMPAL 4242 WS in most waterborne systems. This is due to the slightly larger particle size and semileafing properties of this pigment.

This first generation can be utilized to produce sustainable coatings with premium brilliance and travel (using 4464 WS or 4474 WS), intense metallic sparkling effect (using 4411 WS) or more economical silvers with outstanding hiding powder at low pigment concentration (using 4151 WS or 4242 WS). Due to their ease of handling, the various products can easily be blended to produce a limitless array of metallic effects.

Conclusions

Global regulations controlling emission standards and volatile organic content will continue to tighten. Coatings manufacturers need solutions to produce more sustainable, environmentally friendly products. COMPAL WS is a nonhazardous, easy-dispersing aluminum pigment concentrate that allows formulators to produce VOC-free metallic finishes with long-term stability.

For more information, contact aaron.hollman@sunchemical.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!