Rheology of Coatings

Flow Point Determination

For evaluating the flow behavior of coatings, it is important to find a measurement method that provides a comparison value quickly and accurately. The flow point is a very suitable parameter, which is directly connected to the internal structure of the material. It describes the necessary force that must be expended to make a substance flow. This characteristic value can be determined by using an amplitude sweep in an oscillation measurement. Using the flow point, various samples can be clearly distinguished from each other and evaluated.

This article provides insight into determining the flow point of coatings by using oscillation measurements with the Anton Paar rotational rheometer, MCR 92.

Experimental Setup

Samples

For the measurements, two different commercially available wall colors were used. These were water-based suspensions.

The Instrument

All measurements were carried out by using the MCR 92 rheometer with a cone-plate CP50-1 measuring system (50 mm diameter, 1° cone angle). The temperature of the measuring system was controlled by means of a Peltier plate P-PTD. Both the rheometer and the temperature device can be fully controlled with the RheoCompass™ software from Anton Paar.

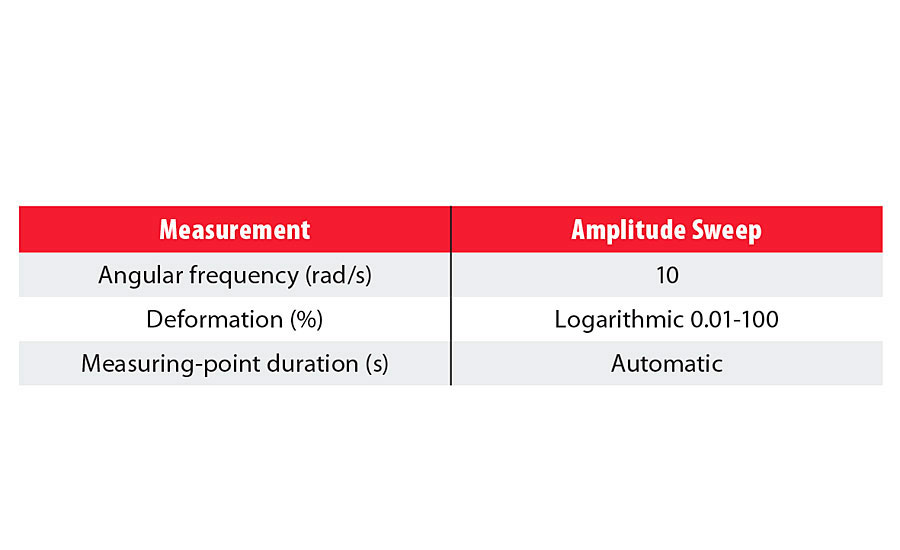

The measurements were carried out at a constant temperature of 25 °C. Amplitude sweeps were carried out with deformation preset according to the experimental instructions in Table 1.

TABLE 1 » Experimental measurement method.

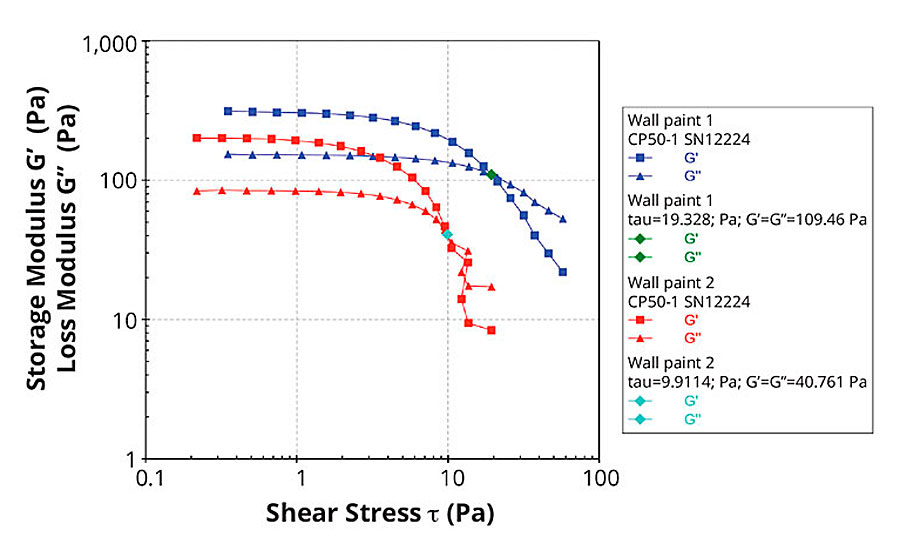

The intersection of G’ and G” was then plotted against the shear stress. The resulting value is the flow point, t0. Although the evaluation refers to the shear stress, a deformation preset in the measurement gives a more defined curve in the area of the intersection.

Results and Discussion

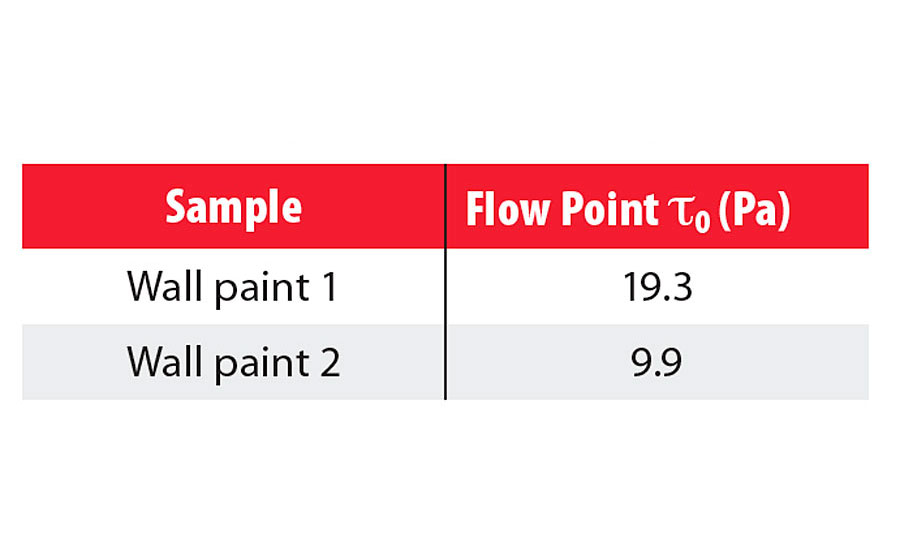

As can be seen in Figure 1, the samples give significantly different measurements. These differences are also reflected in the flow point (Table 2). Wall Paint 1 (blue curve) shows higher values for G’ and G’’ as well as a higher flow point. This means that more force has to be expended to make this sample flow than for Wall Paint 2. In addition, it can be seen that Wall Paint 2 undergoes a much stronger structure collapse than Wall Paint 1, which is reflected in the earlier and steeper change in the slope of G’ and G’’. Because of this rapid structure collapse, the data points measured after the intersection are no longer uniformly distributed.

TABLE 2 » Flow points of the samples determined by amplitude sweep tests

FIGURE 1 » Amplitude sweeps of two different wall paints with subsequent evaluation of the flow point by determining the intersection of G’ (storage modulus) and G’’ (loss modulus).

Summary

The flow point is an important parameter for quality control, as well as for research and development of coatings. One of the most accurate methods for determining this is by using an amplitude sweep in oscillation with a rotational rheometer. It was shown that the MCR 92 is highly suitable for such measurements.

For more information, visit www.anton-paar.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!