Lindsey’s Curdled Dispersion

Lindsey Doyle wasn’t having a good day, and it was just 9 o’clock in the morning. When she got in the lab that morning, she noticed that the material in the glass jar that she had left out overnight had suddenly changed in appearance. Lindsay had pulled the lube emulsion out of a cabinet and placed it on the small oven on her lab bench before she had left for the night. Change in any emulsion formulation is almost always a bad thing. The lube emulsion was a simple formulation that she had thrown together several years earlier, and was her “go to” system for improving the lubricity or slip resistance of the coatings she had developed. The lubricant formulation, which was just water, mineral oil and a short-chain EO surfactant, Tergitol™ 15-S-7, was an opaque white liquid the day before. Now, after sitting overnight, the emulsion had separated into an ugly, water and oil, two-layer heterogeneous system. She had never had a problem with stability of this simple formulation before, but she had usually left her lube emulsion out on the bench top. For some reason her simple formulation had crashed out of solution when left on top of the small oven.

So when she took the call from the very irate customer, she was more distracted and not as helpful as usual. The customer, in a loud, stern tone, with a distinct southern Texas accent, informed her in a not so sweet southern drawl that the 40 drums of aqueous acrylic dispersion that Big Time Paint Co. had shipped only two months before, had a serious problem. The customer had opened up four of the 40 drums, and these drums had changed in appearance and consistency sometime during storage in the South Texas warehouse. The top of the drums were liquid, but when the warehouse foreman had tried to mix the drums using a small bung mixer, the mixer wouldn’t turn. When they opened the top of the drum and poked the liquid with a long wooden boat oar, it appeared that the dispersion had settled in the drum. The customer told Lindsay that they were surprised to discover that all the drums had curdled into white semi-solid that settled in the bottom third of the drum. Lindsay was told that the customer had even tried to pour the four drums into a small tank that allowed for more powerful mixing. The material would not re-disperse. If anything, the mixing with a high-shear agitator only exacerbated the problem, and produced more coagulation and separation of the dispersion components. The customer wanted answers and needed new material, pronto.

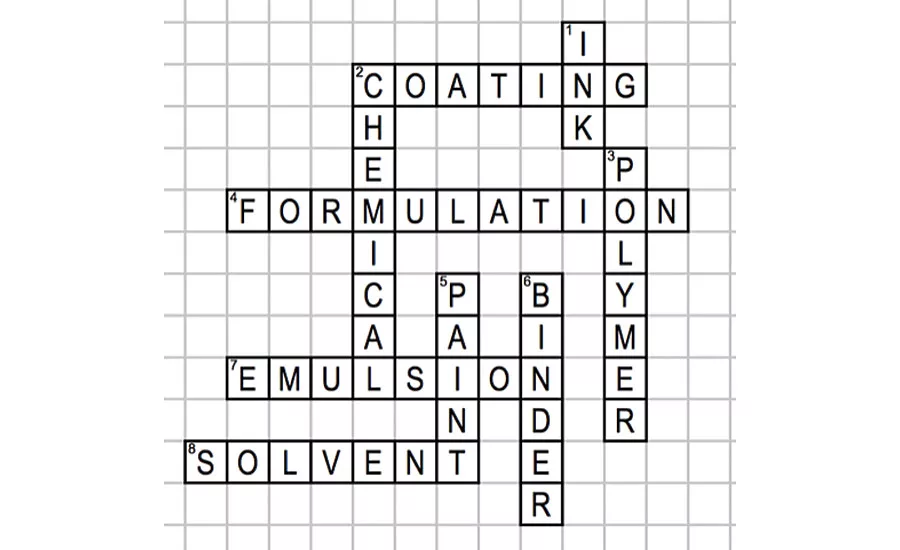

The formulation was made of the following materials:

1. Acrylic acid/butyl acrylate/methyl methacrylate polymer with an acid number of 65;

2. Made by solution polymerization using AIBN catalyst;

3. Then reduced with EB solvent to 78% solids;

4. Cooled to 70 ºC, then dispersed under high shear with water and ammonium hydroxide;

5. The acrylic acid was neutralized to 85% with the base, ammonium hydroxide;

6. Then dispersed under high shear with water to 40% solids;

7. Upon cooling, the dispersion only had a viscosity of 500 centipoise.

Lindsey had shipped this material all over the United States without problem and had never seen this separation problem before. She had checked the material for stability at room temperature for over a year and not seen a problem with stability. However, in the warehouse during the summer, the dispersion had turned to cottage cheese consistency.

Lindsey knew that the material didn’t pass one freeze thaw cycle, but the customer had received the shipment in Texas in early May and had stored it in the warehouse through mid-summer. There was no way the material could have frozen. Likewise, she had asked if any of the drums had been opened before the recent testing, and all had been stored in their original, unopened drums.

Lindsey asked if the customer could ship overnight a sample of both the top and the bottom of one of the drums. She asked Al Kidd to help assess the possible problem. Al had told Lindsay early in her career that the only truly stable emulsion was the one that had settled out. Maybe Al could help her determine why the emulsion had coagulated.

When Al saw the coagulated polymer, he told Lindsey she needed to add some “carb to the cell”. Lindsay didn’t understand what Al meant. Why would adding carbohydrates help? She hadn’t seen any evidence of any cellular material in the dispersion. There was no bacteria or contaminant destabilizing the system. She saw no indication of mold in the dispersion. She didn’t understand how adding carbohydrates or sugars to any cells in the dispersion would help.

When she questioned Al again, he said the problem had nothing to do with contamination but everything to do with temperature. Al Kidd told Lindsay that the problem with the customer dispersion was the same as the problem she saw that morning with her lube emulsion.

What was the problem and how were they related? How did Lindsay solve the problem?

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!