Lindsey’s Volatile Recommendation

“The Director would like to see you before your first appointment,” the young lady said as she hurried into the lobby. Lindsey Doyle sat up straight in her chair, surprised to see the Director’s administrative assistant, and even more surprised that the Director wanted to see her. Lindsey had been waiting only a couple of minutes for her first appointment with one of the Director’s chemists, and now rose quickly from her chair and followed the young lady through the door. Lindsey had been trying for several months to arrange a meeting with the Director of the research group of one of Big Time Paint’s largest customers. The Director had not returned her call. Now she was about to meet him in person.

Even though the assistant’s voice sounded a little strained and impersonal, Lindsey was excited about the opportunity to meet Dr. E. Coates. She was sure that he was going to thank her for meeting with his chemists and helping them with their formulation problems. The last time she visited, she had met with several of the researchers about a problem they were having with an electrocoat primer application.

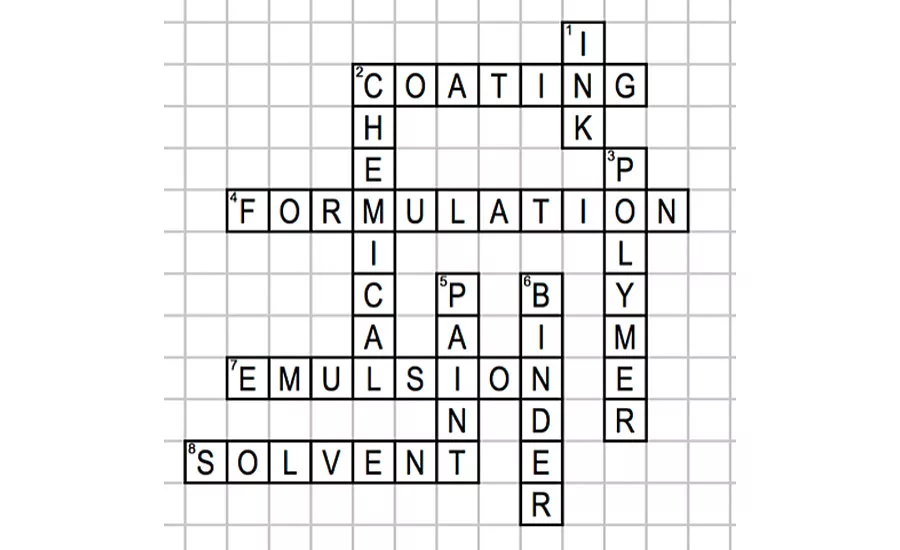

One of Dr. Coates’ senior scientists had asked Lindsey to recommend a different organic solvent for their e-coat formulation. Even though e-coat formulations are primarily waterborne systems, they can contain up to 5% by weight of solvents. The solvents assist in film formation and can have a big effect on the coating appearance and properties. The senior scientist had been using a high molecular weight ester alcohol in their formulation, but needed a recommendation for another very similar solvent that was a “little less volatile”. The scientist had added that she needed to “reduce the VOC of my e-coat”.

Lindsey knew that when customers talked about solvent volatility they were referring to the relative evaporation rate (RER) of the solvent. The relative evaporation rates are important properties for all solvents and are measured in a special chamber under very controlled environmental conditions (temperature of 25 °C, air flow at 21 L/min, and 0 % relative humidity). The time, in seconds, is measured for 90% of a known volume of the pure solvent to evaporate. In the U.S., the rates are all compared to the time for butyl acetate evaporation of 468 seconds. The ratio of the times is normalized to 1.0 by dividing the time for butyl acetate with the time for the other solvents. If the time in seconds for a solvent to evaporate is less than 468 seconds, the relative evaporation rate will be greater than 1, and this solvent will be “more volatile, or faster” than butyl acetate. If the time for a solvent to evaporate is greater than 468 seconds for butyl acetate, the relative evaporation rate will be less than 1, and this solvent will be “less volatile or slower” than butyl acetate.

Lindsey had immediately opened her solvent chart and looked at the large assortment of solvents all arranged from “very volatile or very fast” with RER greater than 1, to “low volatility or very slow” with RER much less than 1. She found the solvent that the scientist had been using close to the bottom of the list among the very slow and low volatility solvents. Lindsey then looked below it on the list to the even “slower” solvents. To her surprise, she found the “diester” version of the same solvent the scientist had been using. The diester version had a lower relative evaporation rate than the original ester alcohol solvent.

One of the ways that solvent manufacturers had of making new and different solvents was to take their line of alcohols and react them with small chain acids to generate the new ester solvent. Acetic acid reacts with the alcohol on glycol ether solvents to make the acetate ester of many glycol ether solvents. For example, taking ethylene glycol butyl ether (EB solvent) and reacting it with acetic acid produces the new solvent, ethylene glycol butyl ether acetate (EB acetate). Lindsey also knew that since the new molecule has a higher molecular weight, the glycol ether acetate always has a slower evaporation rate than the glycol ether. EB acetate is less volatile than EB solvent, propylene glycol methyl ether acetate (PM acetate) is slower than PM solvent, and diethylene glycol butyl ether acetate (DB acetate) is less volatile than DB solvent.

Lindsey Doyle showed the scientist the relative evaporation rate of the diester solvent and explained that since the diester had a similar structure to the ester alcohol, it should have very similar properties in the e-coat compared to the ester alcohol solvent that they had been using. The senior scientist seemed overjoyed that there was a less volatile, yet similar, solvent with a lower relative evaporation rate than the original solvent. The scientist requested a sample of the diester, and Lindsey had overnighted the sample to the customer. Less than a week later, the scientist had called Lindsey to let her know that they were switching to the new solvent. And now, Lindsey was sure the Director wanted to thank her in person for the valuable help she had provided in their e-coat formulation.

When Lindsey entered the Director’s spacious office, he glared at her over the top of his glasses, as if she had done something wrong. After she greeted him with a friendly smile, he asked her if she had recommended a new solvent to his senior researcher. She smiled again and quickly said, “Why yes. She had asked if I knew of a less volatile solvent like the one she had been using and I recommended one with a lower relative evaporation rate.” As he walked from behind his desk, he said to her, “Come over to the window and tell me what you see in the parking lot below?” As she walked to the window, she could see a shiny tank wagon with the company’s name on the side. Dr. Coates asked, “Do you see anything unusual about that truck?” She thought it a little unusual that there appeared to be six quality control chemists, all with white coats and all taking samples from the tank wagon. Before she could answer, Dr. Coates said “Because of your disastrous recommendation, our largest customer returned that truck of electrocoat. It was out of specification for weight percent nonvolatiles.” He continued in an even louder voice, “Because of your solvent recommendation, the formulation we sent, when added to their e-coat tank, caused the whole electrocoat tank, all 5,000 gallons, to be out of specification for weight percent solids!”

Why did replacing the ester alcohol with a less volatile ester solvent cause the e-coat tank to now be out of specification? What had been wrong with Lindsey’s recommendation? Send your answers to Keith Moody at keithmmoody@aol.com. And be sure to look for the answer in our July issue!

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!