Organic Matting Agent Modifies Aesthetics of Industrial Coatings Made with Aluminum Flake Pigments

Aluminum flake pigments are used to impart a brilliant look to coatings in a wide number of applications. Both the metallic effect itself, as well as the change in appearance from bright to dark as the viewing angle changes, are eye-catching. Formulators have a wide variety of metallic pigments from which to choose to achieve the aesthetics they seek, and this article introduces yet another option for modifying the appearance.

Organic polymethyl urea matting agents are used to lower the gloss of industrial coatings and overprint varnishes on their own or in combination with silica matting agents. They are inert and, compared with other matting agents, impart more abrasion resistance and less thickening in coatings. The use of these same polymethyl urea matting agents impacts the aesthetic appearance of a coating made with a metallic pigment in two ways: it reduces the flop index and increases the “sparkle” effect.

Experiment

A solvent-based coating consisting of a thermosetting acrylic resin and a 20-micron silver dollar aluminum flake pigment from Silberline was used as the control formulation. Formulations containing 5%, 10% and 15% (weight percent of aluminum flake pigment solids) of a polymethyl urea matting agent (Pergopak® M4 organic matting agent from Huber Engineered Materials) with a D50 of 6 microns were also produced. The metallic basecoats were applied using a robotic gun to reduce variability to a film thickness of 0.6-0.8 mils onto metal panels and cured at 250 °F for 25 min. A clear acrylic topcoat with a film thickness of 2 mils was then applied to the basecoat and dried in a 250 °F oven for 30 min.

The L values (brightness readings) from an X-Rite multi-angle spectrophotometer were measured at five different angles (the higher the L value, the brighter/whiter the appearance).

Results

Contrast/Flop Index

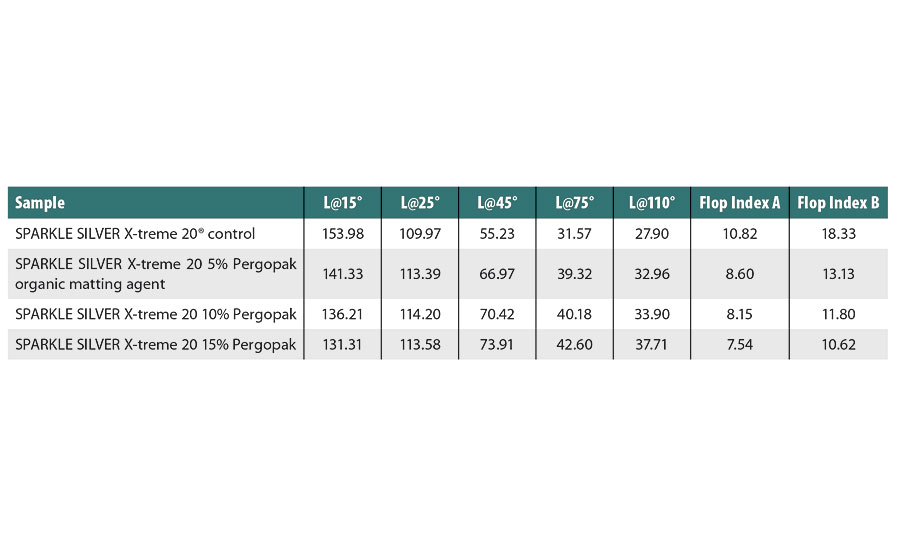

Table 1 shows the L value readings using an X-Rite color instrument at 15°, 25°, 45°, 75° and 110° angles. Aluminum flake pigments show a bright metallic look at one angle and a dark metallic look as you turn the panel. This is known as flop or movement. This is calculated with a “flop index.”

There are two flop index readings in the table:

- Flop index A uses the 25°, 45° and 75° measurements with the formula of flop index = (2.69*((L25-L75)^1.11))/(L45^0.86).

- Flop index B uses the 15°, 45° and 110° measurement angles with the formula of flop index =(2.69*((L15-L110)^1.11))/(L45^0.86).

(^1.11 - indicates raised to the power of 1.11)

If a formulator needs to reduce the contrast (flop index) between the brightest and darkest angles, the addition of a polymethyl urea matting agent was found to reduce the high brightness values and increase the low brightness value.

Sparkle Index

The sparkle index (Si) and sparkle area (Sa) were measured on a BYK MAC unit at 15°, 45° and 75° angles. The grain-iness was also measured on the BYK MAC. Table 2 shows that the addition of Pergopak organic matting agent increases the sparkle index, sparkle area and graininess as compared to the aluminum flake control panel without Pergopak.

Observations

- There seems to be a linear correlation between the addition rate of polymethyl urea matting agent with the reduction in flop index.

- In addition to the reduction in the flop index, the samples containing the polymethyl urea additive appear to have more sparkle or graininess compared to the control.

- The authors believe the graininess increase is further evidence that the polymethyl urea is disrupting the flake orientation, which therefore gives the appearance of a higher sparkle and lower flop index.

Conclusions

The addition of the polymethyl urea additive reduces the flop index. Aluminum flake pigments show a bright metallic look at one angle and a dark metallic look as you turn the panel. If a customer perceives that the contrast (flop index) is too large, they could add a Pergopak organic matting agent to reduce the high brightness value and increase the low brightness value.

The addition of the matting agent also slightly increases the sparkle and graininess appearance.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!