Waterborne, Non-Chlorinated, Modified Polyolefin Adhesion Promoters

for Adhering to Low- and High-Surface-Energy Materials

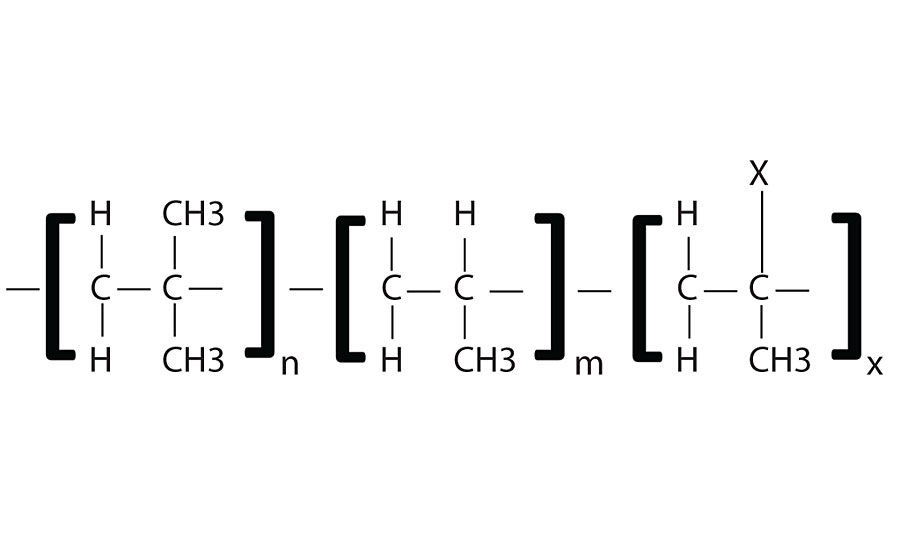

Chlorinated modified polyolefins (CMPOs) are primarily used in solvent-based systems as primers or additives for coatings that need to adhere to low-surface-energy plastic substrates like polypropylene, polyethylene, PET and many others. Non-chlorinated modified polyolefins (NCMPOs) are used for similar applications as the CMPOs, but they have the added benefit of higher chemical and temperature resistance, and they are colorless. NCMPOs are also used in applications where chlorine cannot be tolerated because of potential production of hydrochloric acid when exposure to high temperatures occurs. In Figure 1 the basic structure of an NCMPO is shown. The polyolefin backbone on the polymer allows for better wetting and surface bonding to polyolefin surfaces because of Van der Waals forces. The modification on the polymer allows for potential reactions with reactive groups in resins and for interactions and bonding with inorganic substrates. The structure of the NCMPO allows it to bond to polyolefin and non-polyolefin substrates.

In the last few years there has been a trend in using polyolefin substrates for different applications like roofing and flooring because of raw material costs of using polyolefins versus other plastics. Polyolefins are also being used because of their desirable physical properties and their recyclability potential. There are many applications in which polyolefins could be used, but they are not because there are not practical ways to adhere them to where they need to be placed because of their low surface energy. Polyolefins are often corona or flame treated to increase the surface energy to make them easier to adhere to. Sometimes corona treatment and flame treatment are not enough to make the substrates easier to bond to. So, CMPOs and NCMPOs are used to increase the adhesion to the olefin substrates as adhesion promoters, but they are often used in solvent-based products to achieve the necessary adhesion. There are many applications were solvents cannot be tolerated, and corona and flame treatment are too expensive to do. In this work, we used our waterborne NCMPO emulsions the AdvaBond ® 7400 series adhesion promoters in three different applications to show how they can be used to adhere to polyolefin substrates without the use of harsh solvents and surface modifications, and how they can improve the adhesion to non-polyolefin substrates. The first being a waterborne membrane adhesive, the second a waterborne flooring adhesive, and the last a general caulk/sealant adhesive.

Experimental and Testing

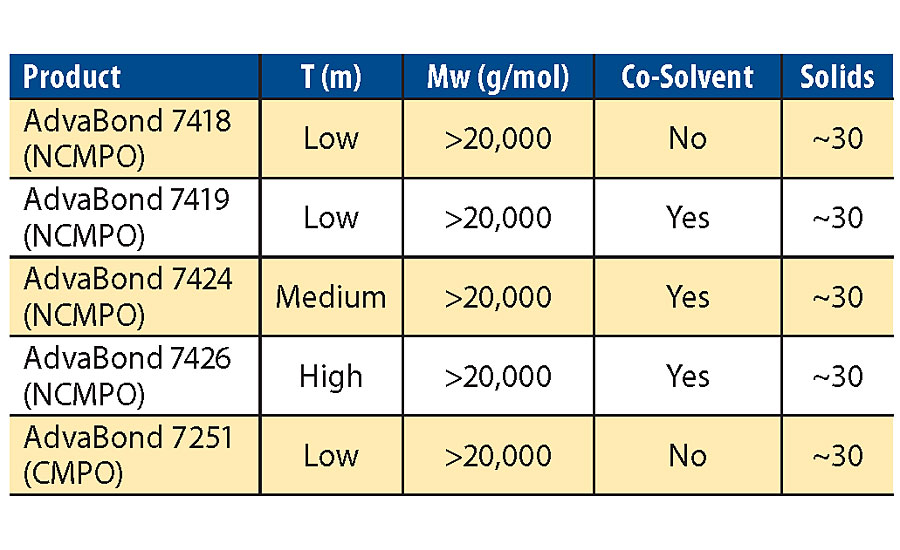

In this study, four different NCMPO emulsions and one CMPO emulsion were evaluated. The physical properties of the emulsions are shown in Table 1. The difference between the different emulsions is the melting point of the base resin, and whether it has a percentage of co-solvent in the emulsion.

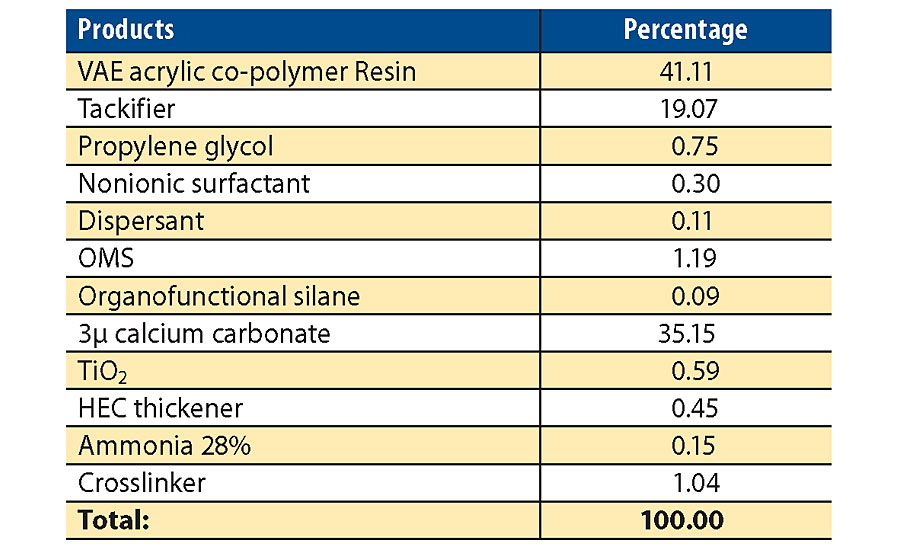

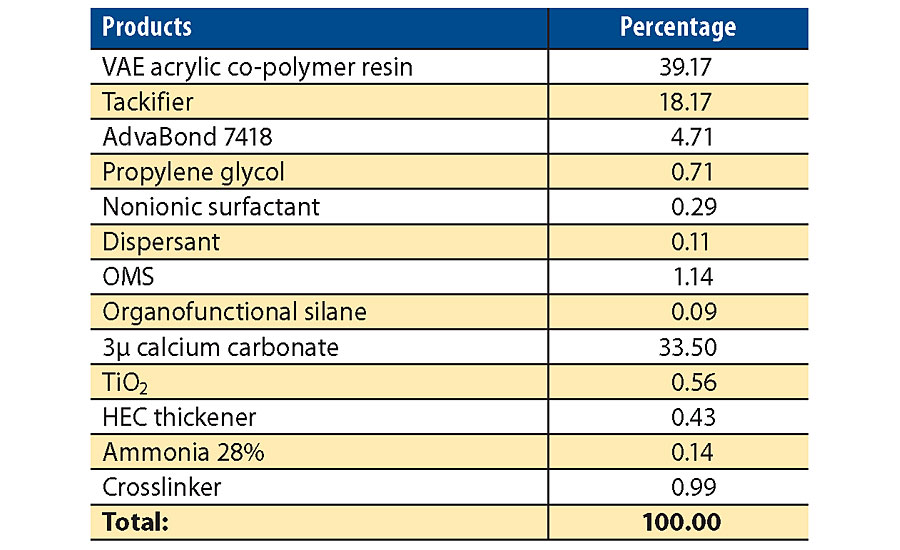

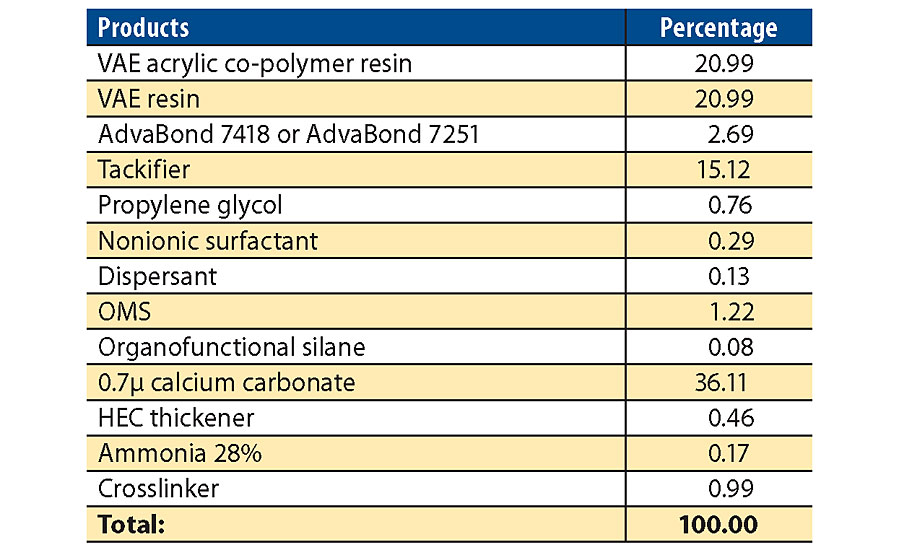

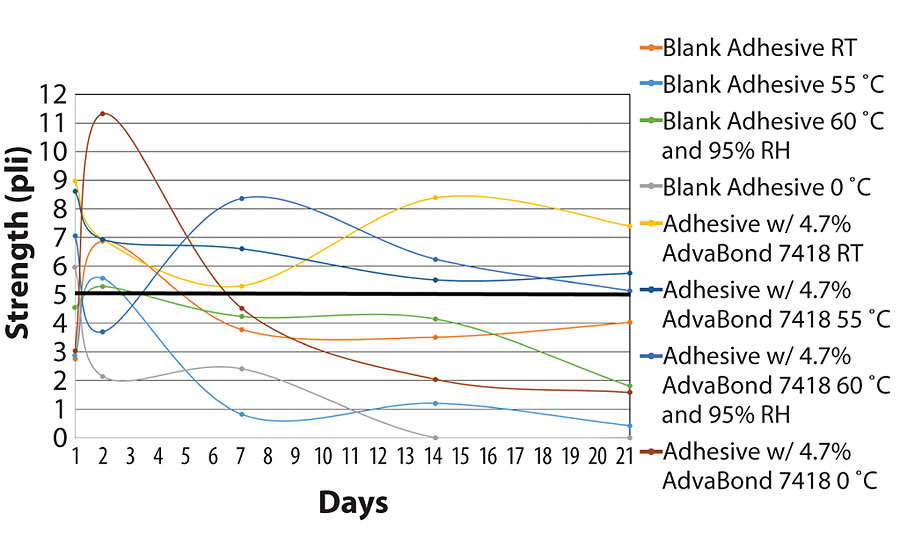

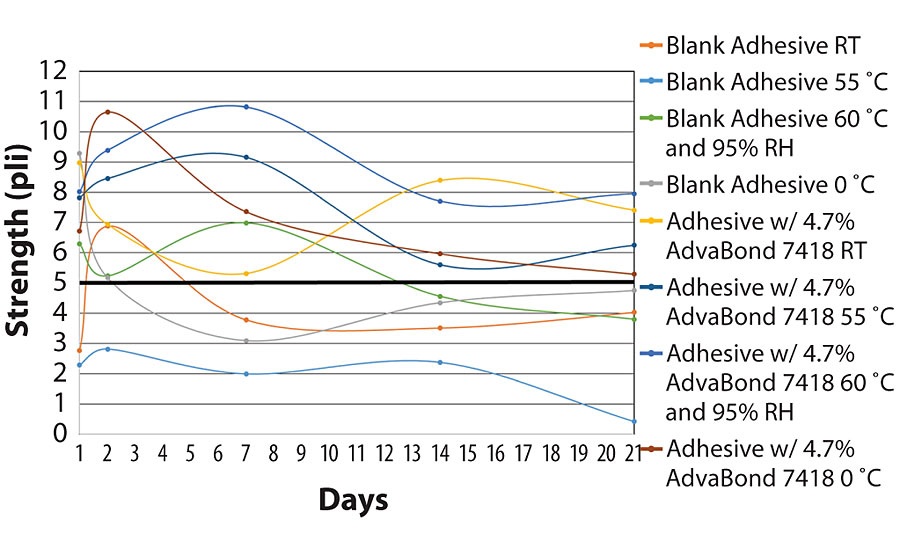

In the first application, which was the waterborne membrane adhesive, the formulations in Table 2 and Table 3 were made by using a dental mixer. The formulations were optimized by evaluating different resins, types of calcium carbonate and NCMPO loading levels. The formulations were applied to plywood at an application rate of 100-150 sq ft/gal. Once the adhesive was applied, a sheet of TPO roofing membrane was applied over the adhesive. The adhesive was allowed to cure for at least 24 hrs before testing, and then it was tested after 24 hrs, 48 hrs, 1 week, 2 weeks and 3 weeks of curing. The adhesive was also cured in four different curing conditions to replicate real-world roof conditions. The first was room temperature conditions, the second was 55 °C, the third was 60 °C and 95% RH, and the fourth was 0° C. The adhesives were tested by performing 180° peels on the TPO substrate bonded to the plywood. The adhesives were also tested while they were still hot/cold and after they came down/up to room temperature.

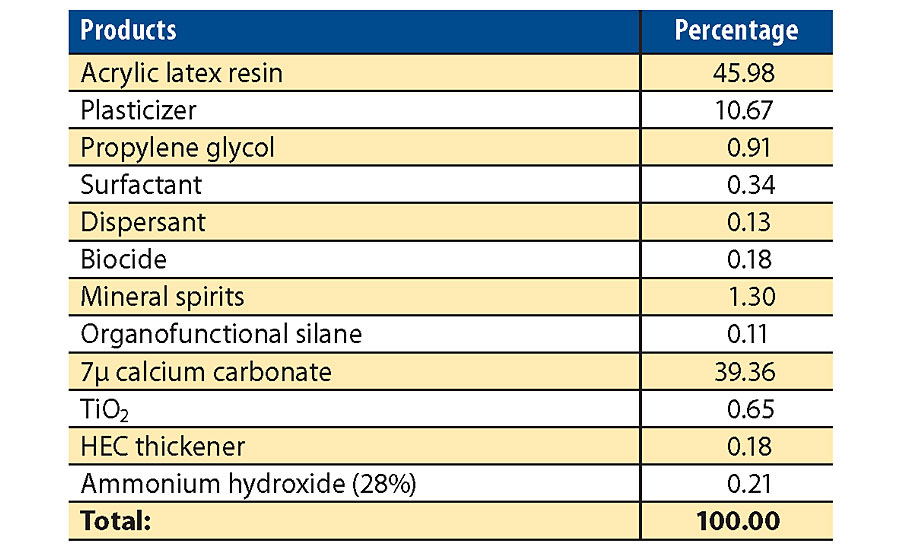

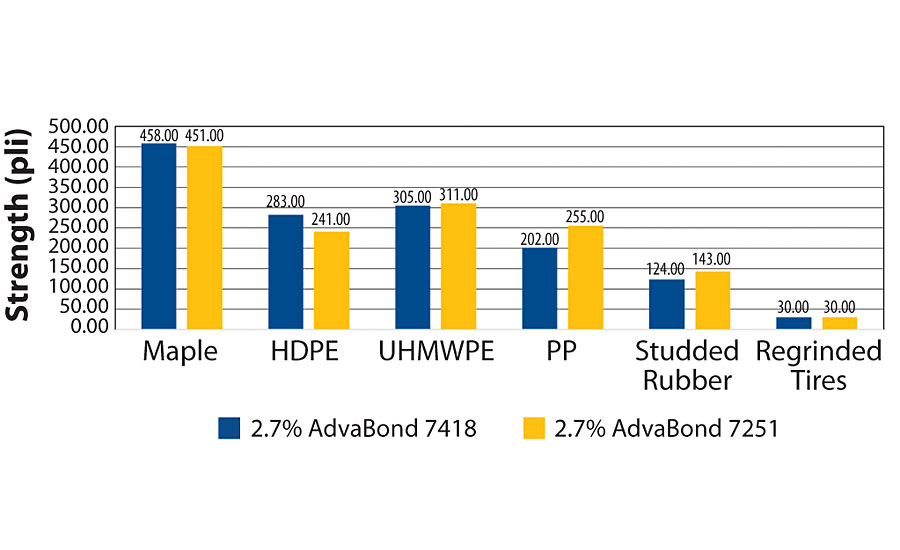

In the second application, the waterborne flooring adhesive shown in the formulation in Table 4 was also made using a dental mixer. The formulations were also optimized by evaluating different resins, types of calcium carbonate, and NCMPO and CMPO loading levels. The formulations were used to make lap shears on maple, polypropylene, low-density polyethylene, ultra-high molecular weight polyethylene, studded rubber and reground tires. Lap shear was tested by following a modified ASTM D3163, where the untreated plastic/rubber substrates were bonded to maple. The lap shears were allowed to cure for 1 week before they were tested.

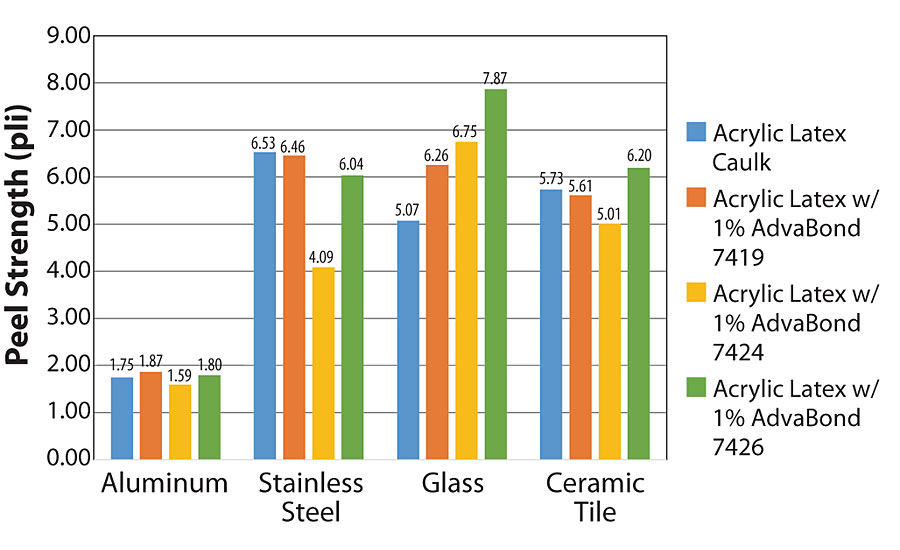

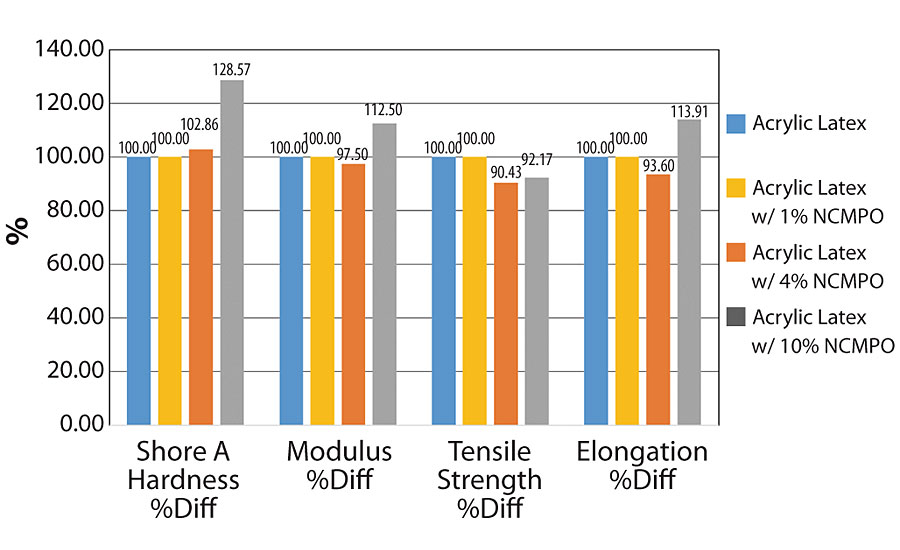

In the third application, the acrylic latex caulk/sealant formulation was made by using a dental mixer. The formulation in Table 5 was modified with the addition of 1wt. % of a NCMPO emulsion as an adhesion promoter. The caulk/sealant’s adhesion was evaluated by performing 180° peels following ASTM C794 on aluminum 6061 T2, 316 stainless steel, glass and glazed ceramic tile. The 180° peels were tested after 14 days of curing. The physical properties of the acrylic latex caulk/sealants were evaluated by Shore A hardness, elastic modulus, % elongation and tensile strength. The elastic modulus % elongation and tensile strength were tested by using a universal tensile tester by following ASTM D412. In the physical property testing, the NCMPO emulsions were used as additives at 1%, 4% and 10% to see the effect that the NCMPO has on the physical properties of the acrylic caulk/sealant formulation.

Results and Discussions

In the membrane adhesive application, it is necessary to have a peel strength greater than or equal to 5 pli (pounds per linear inch). Figure 2 shows how you can achieve the minimum 5 pli with the addition of 4.7% AdvaBond 7418 across the different curing conditions except for the 0 °C condition over the course of 21 days. The performance can be increased at the 0 °C condition by using a different tackifier and resin package. Figure 3 shows the peel strength after the adhesive stabilizes to room temperature. The adhesive with the 4.7% NCMPO adhesive strength stays above 5 pli once the temperature reaches room temperature across the curing conditions over the course of 21 days. The failure of the bonds were mostly cohesive, with some plywood failure if the peel strength was above 5 pli.

In the flooring adhesive application, many polyolefin substrates and rubber substrates were tested to compare a NCMPO emulsion to a CMPO emulsion. A blank adhesive was also tested, but the lap shears failed before they could be tested. Figure 4 shows the lap shear strengths that could be achieved with a NCMPO and CMPO emulsion as an adhesion promoter used at 2.7 wt.%. All of the lap shears excluding the maple, studded rubber and reground tires failed adhesively. The maple lap shears failed cohesively, and the studded rubber and reground tires lap shears failed with substrate failure. The NCMPO and CMPO modification to the adhesives have very similar performance across the multiple substrates.

In the caulk/sealant application, the 180° peel testing is showcased in Figure 5. The adhesion was significantly improved depending on which NCMPO emulsion was used on all the substrates tested, but aluminum. The addition of the NCMPO emulsion did not improve or negatively impact the adhesion to aluminum and stainless steel. There was a significant improvement in glass and glazed ceramic tile adhesion, depending on which NCMPO emulsion was used. In Figure 6, the physical properties are shown as a percentage relative to the acrylic latex caulk/sealant without a NCMPO adhesion promoter. There starts to be a change in physical properties of the caulk/sealant once the NCMPO loading level is 4% and above.

Conclusions

This work demonstrated that using NCMPO emulsions can allow formulators to bond to low-surface-energy substrates and high-surface-energy substrates. In the first application, the membrane adhesive with the NCMPO emulsion was able to pass the minimum peel strength requirements in almost all the different curing conditions. There is still more reformulating to be done to pass the 0 °C curing condition. In the second application, the flooring adhesive can achieve high lap shear strengths by using a NCMPO and CMPO emulsion. Both emulsions perform very similarly, but the NCMPO emulsion has the advantage of being chlorine free. In the last application, the caulk/sealant adhesive, 1% of a NCMPO emulsion can significantly improve the adhesion to glass and ceramic tile without significantly impacting the adhesion to aluminum and stainless steel, depending on which grade of NCMPO is used. The adhesion improvement that is seen at 1% loading of a NCMPO does not impact the physical properties of the caulk/sealant. Based on our results, the use of NCMPO emulsions can improve adhesion in various applications.

For more information, e-mail aandrade@advpolymer.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!