The Road to Permanently Hygienic Wooden Surfaces

Eleven months down the road, the new coronavirus (COVID-19) pandemic already sickened more than 80 million people, and it is not going away anytime soon. It is more than a health crisis - it had destructive consequences such as cultural, social, economic and political effects. The pandemic has changed how we clean and disinfect offices, schools, hospitals while returning to a new normal.

The virus is transmitted after infected people sneeze, cough on or touch surfaces, such as tables, doorknobs and handrails. Other people may become infected by touching these contaminated surfaces, then touching their eyes, nose or mouth without having cleaned their hands first.(1)

High-Touch Wooden Surfaces

Wood stands out as a natural, sustainable and renewable architectural material. Manufacturing wood products requires considerably less carbon than alternatives such as plastics and metals. In addition to sustainability of wood, its strength, flexibility, electrical and heat resistance makes it an ideal candidate for both interior and exterior design.

Many high-touch surfaces such as doors, tables, furniture or benches are made of wood or its derivatives. Therefore, it is essential to keep the surfaces clean in order to eliminate the risk of surface contamination. One of the options to prevent transmission through touch is to frequently disinfect the communal areas. However, the disinfection process only provides short-term protection and needs to be repeated regularly at certain intervals. Considering the effects of harmful chemicals in disinfectants on human health and the environment, it is predicted that frequent disinfection will cause more harm in the long term.

The Role of Hard Surfaces on Transmission of Pathogens

Pathogens can live on hard surfaces for days, weeks and months, posing an ongoing risk for transmission and acquisition. Contaminated surfaces are an important route not only for transmission of viruses but also for bacteria and fungi. High-touch surfaces can harbor harmful microorganisms including drug-resistant organisms, cold and flu viruses and coronaviruses.

According to Kampf (2) and his colleagues, most gram-positive bacteria, such as Enterococcus spp., Staphylococcus aureus (including MRSA) or Streptococcus pyogenes, survive for months on dry surfaces. Many gram-negative species, such as Acinetobacter spp., Escherichia coli, Klebsiella spp., Pseudomonas aeruginosa, Serratia marcescens, or Shigella spp., can also survive for months. Mycobacteria, including Mycobacterium tuberculosis, and spore-forming bacteria, including Clostridium difficile, can also survive for months on surfaces. Candida albicans, as the most important nosocomial fungal pathogen, can survive up to four months on surfaces.

Early studies suggested SARS-CoV-2 can remain on different surfaces from hours to days. It lived on plastic for three to seven days, on paper for four days, on copper for four hours and on wood for two days.(3) However, in October 2020, researchers at Australia's national science agency, the Commonwealth Scientific and Industrial Research Organization, revealed the new coronavirus remains infectious on non-porous surfaces such as glass, steel and plastics at least 28 days at 20 °C.(4)

How Can the Coatings Industry Contribute to the Fight Against COVID-19 Pandemic?

Paint and coatings manufacturers can join the collaborative effort to battle the pandemic by incorporating antiviral and antibacterial coatings in their product range. Antiviral/antibacterial coatings prevent transmission of harmful microorganisms by touch via creating an invisible barrier on high-touch surfaces. This barrier lasts as long as the coating film is unharmed. Permanently hygienic surfaces reduce the cleaning costs, maintenance costs and increase the lifespan of the coating.

Antiviral, Antibacterial and Antifungal Wood Coatings

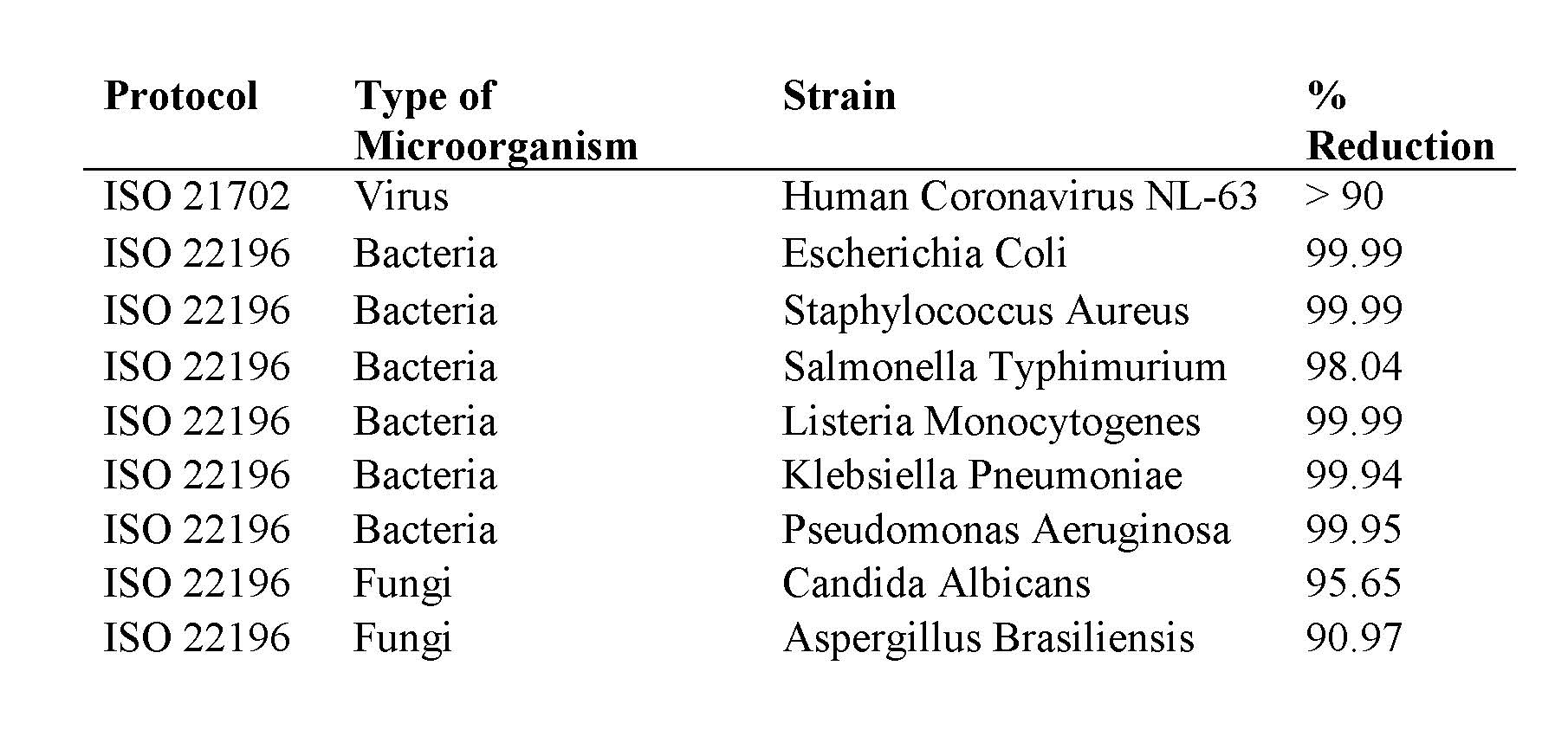

Turkish wood coatings manufacturer Kubilay Boya has successfully developed an antiviral, antibacterial and antifungal wood coating system. This new coating system showed efficacy against human coronavirus NL-63 – an enveloped, single stranded RNA virus used as laboratory model to SARS-CoV-2 – as well as bacteria including Escherichia coli and Staphylococcus aureus, Salmonella typhimurium, Listeria monocytogenes, Klebsiella pneumoniae and Pseudomonas aeruginosa, and fungi such as Candida albicans and Aspergillus brasiliensis. Table 1 summarizes antimicrobial activity of the system.

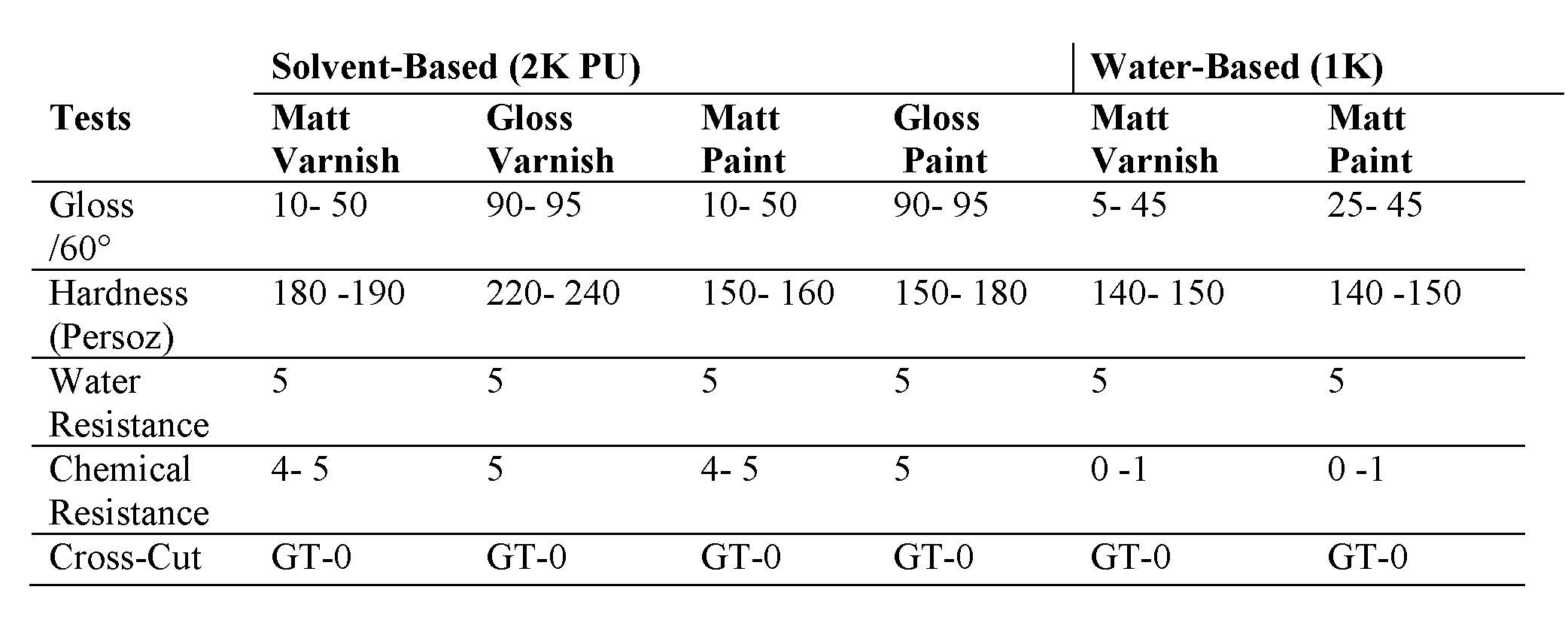

This novel antiviral wood coating system is available in both water-based and solvent-based coatings. In addition to its antimicrobial activity, the system is no different than conventional wood coatings in terms of gloss, hardness, adhesion, chemical resistance and curing time. Table 2 represents test results of antimicrobial coatings. Water and chemical resistance are evaluated between 0-5, where 0 is very bad and 5 is excellent. Adhesion is measured according to ISO 2409 cross-cut test standard, and hardness is measured via pendulum hardness tester.

In many antimicrobial coatings in the market today, antimicrobial activity is acquired by addition of an active ingredient. However, there is no antimicrobial agent that has efficacy against the entire spectrum of microorganisms. Kubilay Boya has carefully designed its new product to have antimicrobial activity especially against enveloped viruses such as coronavirus and bacteria causing hospital-acquired infection including K. Pneumoniae, P. Aeruginosa, E. Coli, S. Aureus and other harmful bacteria causing typhoid fever, S. Typhimurium.

Testing Process

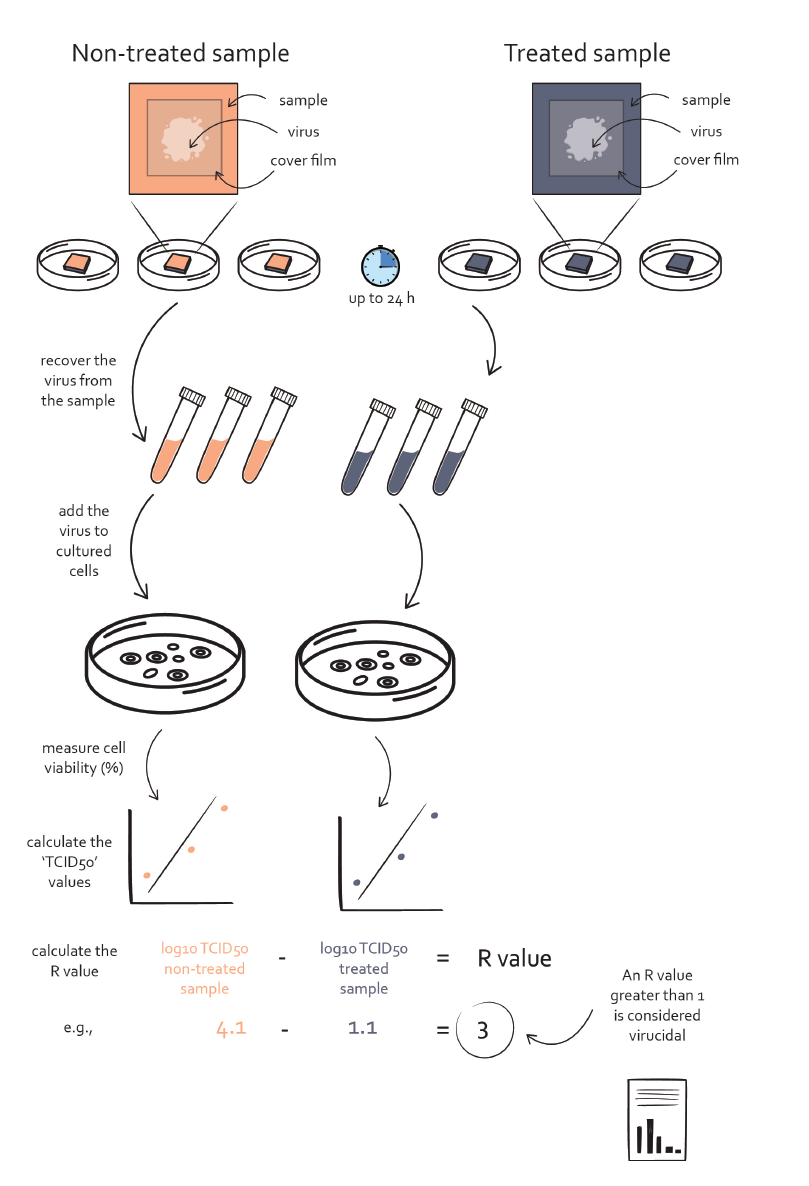

ISO 21702: Measurement of Antiviral Activity on Plastics and other Non-Porous Surfaces

ISO 21702 is a standard protocol to quantify the antiviral properties of non-porous surfaces. In this protocol, a pre-determined concentration of virus is dispensed onto test and reference surfaces and incubated at room temperature in a humidified chamber. Next, the samples are recovered by neutralizer, and the amount of infectious virus in each suspension is quantified using a TCID50 assay (Figure 1). For the assay to be valid, the material tested must have no cytotoxic activity on the cells used to quantify the virus, nor interfere with cell sensitivity to infection.(5)

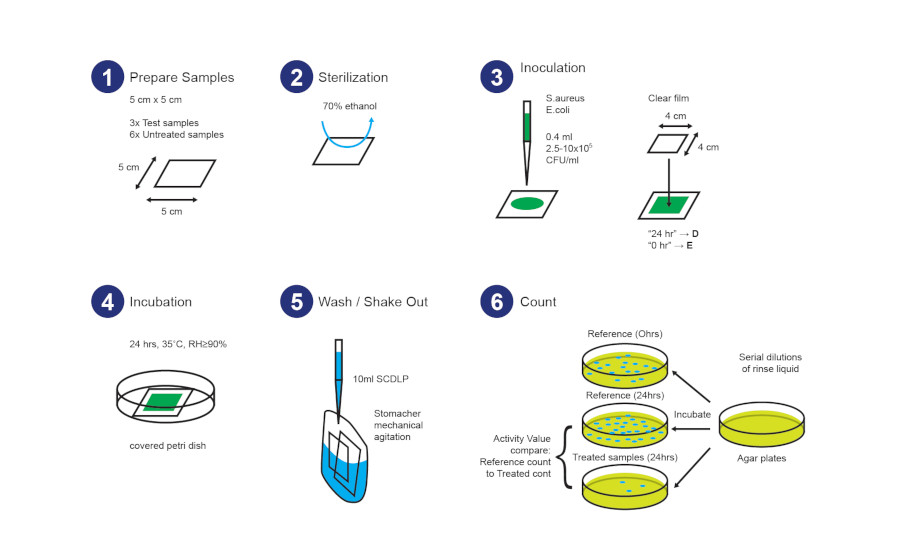

ISO 22196: Measurement of Antibacterial Activity on Plastics and other Non-Porous Surfaces

ISO 22196 is a standard protocol to quantify the antibacterial properties of non-porous surfaces. In this protocol, a quantified bacterial suspension is introduced to treated and untreated samples. Following a period of incubation at 35 °C and relative humidity of more than 90%, colony-forming units (cfu) are counted in an agar. The antibacterial activity is then quantified according to calculations for satisfaction criteria of a valid test, which is outlined in the standard (Figure 2). The standard uses Escherichia coli and Staphylococcus aureus although adaption to other bacteria or fungi is possible.(6)

Conclusions

The COVID-19 pandemic is not the first pandemic in human history, nor is it the last. The pandemic taught us fundamental lessons, one of which is the importance of hygiene. This, of course, includes surface hygiene as well. Wooden surfaces are everywhere, especially in high-touch surfaces such as office furniture, dining tables, doors, bathroom furniture and school desks, which pose a potential risk for transmission of pathogens by touch.

Nitrocellulose wood coatings are still dominant in developing countries. However, their chemical resistance is poor, therefore frequent disinfection damages the film on wooden surfaces. Employment of antiviral wood coatings will lead to less disinfectant usage, reducing the environmental impact of harsh chemicals present in disinfectants.

Antiviral wood coatings are promising candidates to keep wooden surfaces hygienic continuously. Furthermore, growing concern regarding surface hygiene will lead to a higher demand for antimicrobial wood coatings in the near future.

References

1 Coronavirus disease (COVID-19): How is it transmitted? (n.d.). Retrieved November 1, 2020, from https://www.who.int/news-room/q-a-detail/coronavirus-disease-covid-19-how-is-it-transmitted.

2 Kramer, A.; Schwebke, I.; Kampf, G. How Long Do Nosocomial Pathogens Persist on Inanimate Surfaces? A Systematic Review. BMC infectious diseases, (2006), 6(1), 130.

3 Study Suggests New Coronavirus May Remain on Surfaces for Days. (2020, March 31). Retrieved November 11, 2020, from https://www.nih.gov/news-events/nih-research-matters/study-suggests-new-coronavirus-may-remain-surfaces-days.

4 CSIRO Scientists Publish New Research on SARS-COV-2 Virus 'Survivability'. (2020, October 12). Retrieved November 12, 2020, from https://www.csiro.au/en/News/News-releases/2020/CSIRO-scientists-publish-new-research-on-SARS-COV-2-virus-survivability.

5 Virology Research Services Ltd.

6 ISO 22196 Test for Antimicrobial Activity of Plastics. (n.d.). Retrieved November 19, 2020, from https://microchemlab.com/test/iso-22196-test-antimicrobial-activity-plastics.

7 JIS Z 2801/ISO 22196. (n.d.). Retrieved November 19, 2020, from https://www.microbe-investigations.com/testing-methods/jis-z-2801-iso-22196/.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!