Rules of the Road

While society remains years away from fully autonomous or self-driving cars, today’s advanced driver assistance systems (ADAS) in vehicles work to remove human error from driving to create safer roads. But while ADAS systems make driving safer, collisions will continue. So the paint and coatings industry is stepping up to best prepare customers for mobility’s future.

What’s Driving ADAS?

Automakers invest billions in rapidly evolving ADAS technology, with an increasing number of today’s new cars sold installed with the technology. ADAS technology uses sensors and cameras to process the world around the vehicle to provide the driver information or enable necessary action. These features can keep cars at a safe distance from one another, ensure vehicles are centered in their lanes, identify other objects or pedestrians on the road, and bring a car to a complete stop for emergencies. ADAS features include forward collision alerts, automatic emergency braking, lane departure warnings, adaptive cruise control and blind-spot alerts.

These features promise to prevent accidents. The Insurance Institute for Highway Safety estimates that even the ADAS technologies available right now could avoid or lessen the effects of 1.8 million accidents each year and potentially save up to 10,000 lives per year. In addition, research shows that rear-end collision rates were 46 percent lower in cars with forward-collision warnings and automatic emergency braking than those without these systems. Lane departure crashes fell 21 percent for vehicles with lane departure warning and lane-keeping assistance.

The Training and Investment Ahead

Despite a downward trend of auto accidents, collisions will continue. Automakers often install the technology (enabled by cameras and sensors) in easy-to-damage areas of the car.

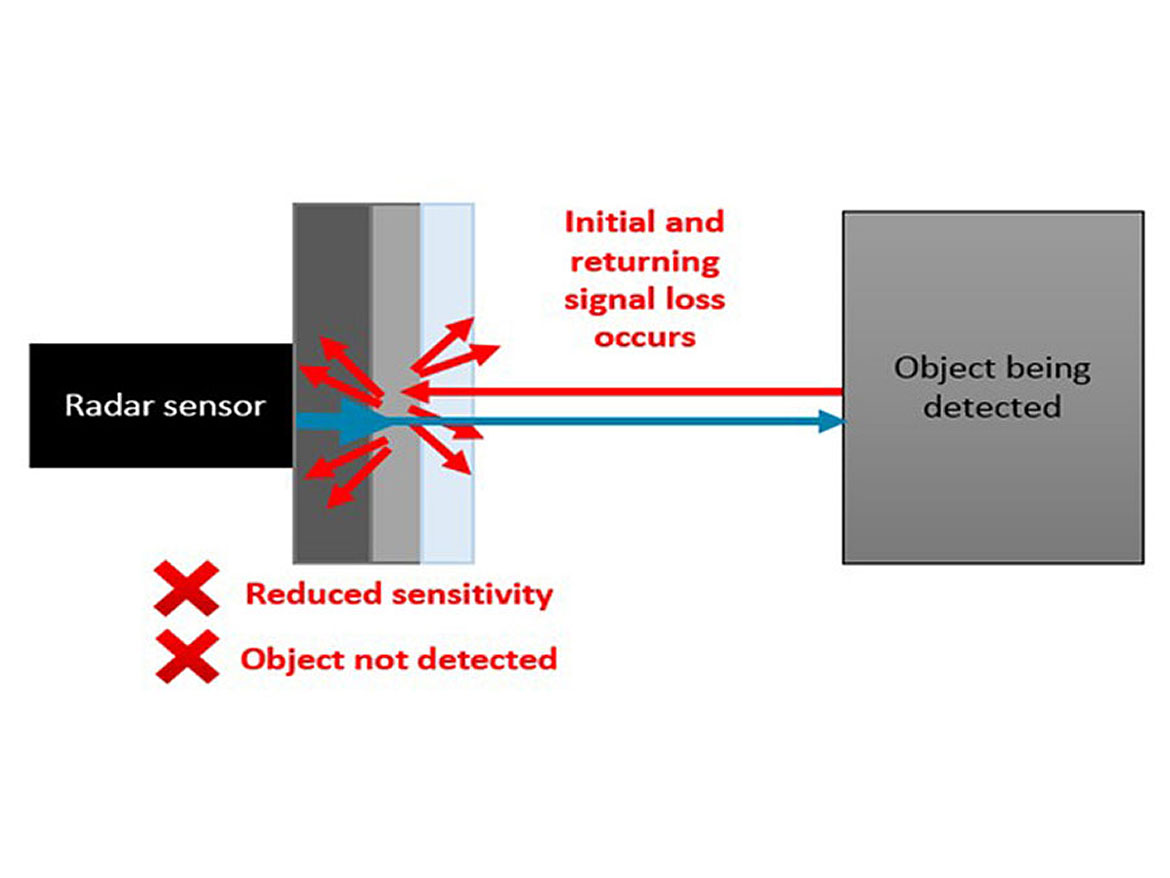

Today’s bumpers can house a host of sensors, including RADAR, a detection system that uses radio waves to determine objects’ distance range, angle or velocity. Body shops have often fixed minor bumper damage by filling scratches and spot-painting. Unfortunately, those body filler compounds coupled with new paint could impact vehicle sensors. As a result, the automotive refinish industry will have to rethink the repair process.

Since these safety systems can be difficult to detect visually, technician training to spot these systems more precisely will be critical. Right now, body shops rely on customer discussions, visual indicators and automaker data to identify ADAS. Technicians will also need the training to recalibrate these sensors to keep drivers safe.

Finally, technicians will also need to know how the paint and coatings industry is working to resolve the impact some colors and finishes can have on these safety sensors.

The Metallic Finishes Solution

Paint and coatings suppliers developed a solution after discovering repainting bumpers with certain colors and finishes may negatively impact these safety sensors. For example, PPG has partnered with automakers to calculate the impact of dozens of colors on repainted bumpers (including metallic finishes) to understand the loss of transmission of RADAR signals. The data showed that while the majority of colors do not impact ADAS functionality, a handful of metallic finishes do pose an issue. At certain concentrations, the aluminum pigments used in metallic paints can reduce the transmission of RADAR signals and may interfere with ADAS operation.

Paint and coatings suppliers, such as PPG, have evaluated swapping the aluminum pigments in the metallic finish to reduce the impact with alternatives to improve RADAR transmission and enhance ADAS (Figure 1). These reformulated colors maintain a good match to the vehicle’s original finish while reducing the RADAR transmission loss so that safety systems can function as they should.

Twenty-five percent of new vehicles sold have metallic finishes. As a result of their popularity, these color choices are not likely to disappear. And since automakers consider RADAR a key sensor in highly automated vehicles (85 percent of new cars are forecasted to have RADAR by 2025), the solution for certain metallic finishes will become increasingly important.

What’s the Road Ahead?

Greater paint and coatings suppliers and automakers must work together to identify the key attributes needed to develop those technologies that retain RADAR capability while still providing accurate color matches.

Today automakers, and paint and coatings suppliers will need to continue to provide best practices for ADAS repairs, with guidelines, technical and service bulletins, training and tutorials to ensure drivers remain safe. In addition, carmakers, trade associations, paint and coatings suppliers, and regulatory bodies will need to work together to create a technical standard to address the acceptable loss of RADAR transmission for worldwide distribution. Research predicts a $19 billion growth of the ADAS market over the coming years, with most new cars and trucks now available with various ADAS features.

Looking further down the road, automakers, and paint and coatings suppliers are currently researching and developing solutions that will improve RADAR and maintain the metallic finishes’ glory. PPG has partnered with vehicle manufacturers on its color choices in the preliminary research stage to determine the impact of its color choices on ADAS functionality. Automakers are even looking five years out when selecting color styles to stay ahead of emerging mobility trends and the increasing production of electric vehicles.

While it may be years before consumers adopt fully autonomous cars, ADAS safety features make driving safer today. Now, paint and coatings suppliers can support collision repair technician training and the development of industry standards to address RADAR loss. The industry can also continue collaborating with automakers to drive the research and development necessary to enhance ADAS and the future of self-driving vehicles.

To learn more, visit www.ppgrefinish.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!