Improving the Wet Track Abrasion of Asphalt Emulsion Sealers

Proper maintenance of asphalt driveways, parking lots and roadways is a critical aspect to providing good performance over an extended period of time. There are many commercially available grades and types of asphalt emulsion-based sealers designed to extend the service life of these surfaces. ADMIXUS® fibrillated HDPE fiber has been shown to significantly improve the properties of these commercially available coatings. Through proper suspension of pigments and fillers, reduced cracking, increased flexibility and reduced shrinkage, overall coating performance can be greatly improved.

The study discussed in this article examined the quality of film formation, tensile properties and wet track abrasion resistance. For this experiment, a commercially available, entry-level asphalt emulsion-based sealer was purchased, and the properties were tested with and without the post addition of various grades of fibrillated HDPE at three different dosage levels.

Review of the Physical Properties of Fibrillated HDPE

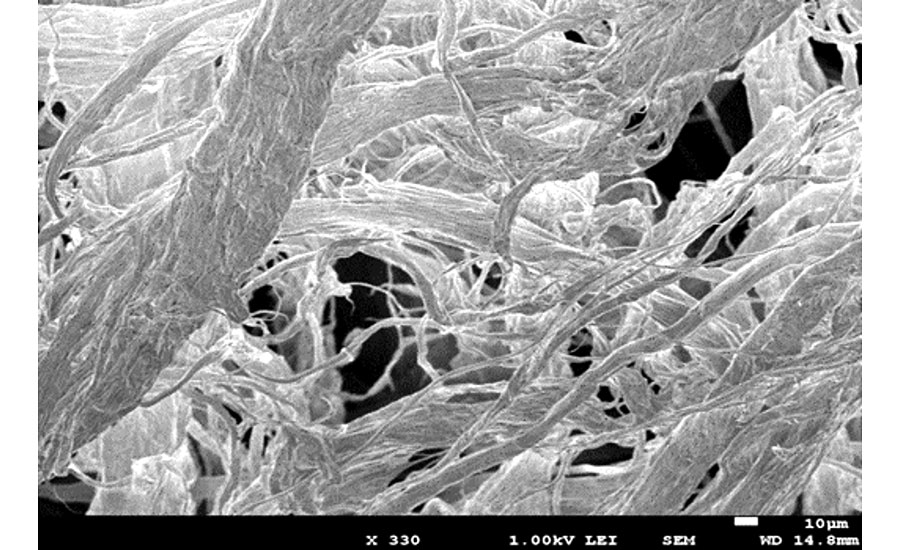

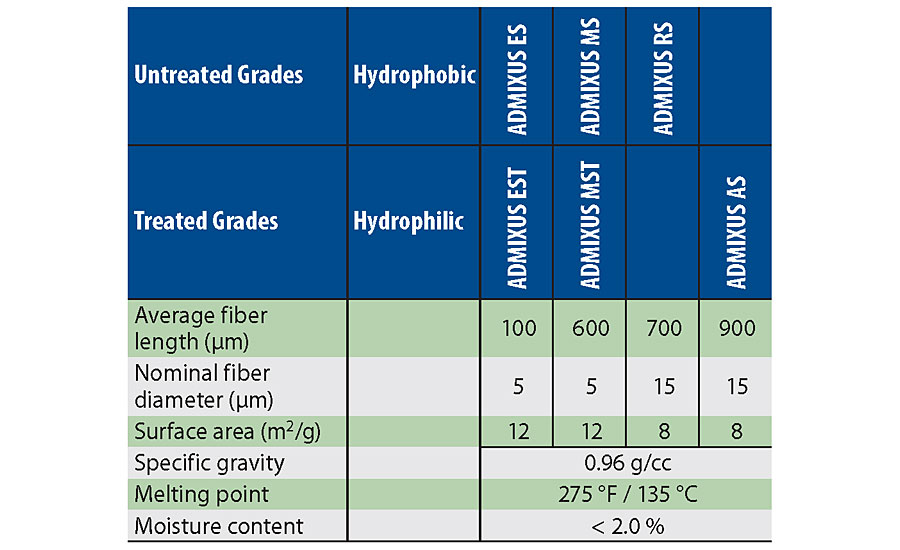

The process for producing a wet lap fibrillated HDPE fiber has been previously described.1 These fibers, produced by Mitsui Chemicals, Inc., are used in a wide variety of applications, including wet laid nonwovens (Figure 1). MiniFIBERS, Inc. believed that a dried product would be useful as an additive in a variety of applications, and so developed a proprietary process that separates the fibers into individual filaments and dries them to a moisture content of less than 2%. The grades of interest for coatings applications have fiber lengths between 100 µm to 900 µm, and fiber diameters between 5 µm and 15 µm. When dried, the wet lap pulp fibers, which are hydrophilic, become hydrophobic. By modifying the process, the hydrophilicity can be maintained, so grades can be produced that are hydrophilic or hydrophobic. The physical properties of commercially available grades of dried fibrillated HDPE fiber are listed in Table 1.

Experimental

Sample Preparation

Samples for testing were prepared by stirring a 5-gallon pail of an asphalt emulsion driveway sealer/coating to a smooth composition. Approximately 700 g of the commercial sealer was transferred to each of 20 tared 1-qt containers. The net weight of sealer in each container was recorded. The mass of fibrillated HDPE fiber needed to achieve the targeted dosage (0.5%, 1.0% or 2.0%) was added and carefully stirred into the commercial sealer. The mixture was then blended using a lab-scale Cowles mixer equipped with a 42-mm sawblade dispersion impeller. Each mixture was blended for 15 min at 1,000 rpm. The resulting mixtures were allowed to equilibrate for a minimum of 24 hrs before casting.

Film Casting

The samples were poured into a 6” x 6” x 0.093”-thick template positioned on top of a 10” x 10” clear glass plate. The samples were drawn down in the template using a sheetrock taping knife.

Asphalt Film Curing and Tensile Test Specimen Preparation

Glass plates containing the sample films were placed in an oven at 45, 55, 65 or 115 ± 3 °F for 1 to 5 days depending on the temperature (more curing time for lower temperature curing). The plates were then cooled and submerged in a water bath for up to 24 hrs to facilitate film delamination from the glass plate. The approximately 1-mm thick films were trimmed and cut into approximately 90-mm x 25-mm strips for tensile testing.

Asphalt Film Tensile Test Method

Tensile testing was performed using an Instron Model 3500 test instrument equipped with an Instron Model 2519-105 force transducer and a pair of Instron 2716-015 wedge grips. The tensile test method involved a pre-test specimen load of 1.00 N at a rate of 1 N/mm, elongation rate of 1.00 mm/min, and end-of-test at an 80% drop in peak force. Average results were calculated and reported from three to five specimens from a single casting.

Film Formation

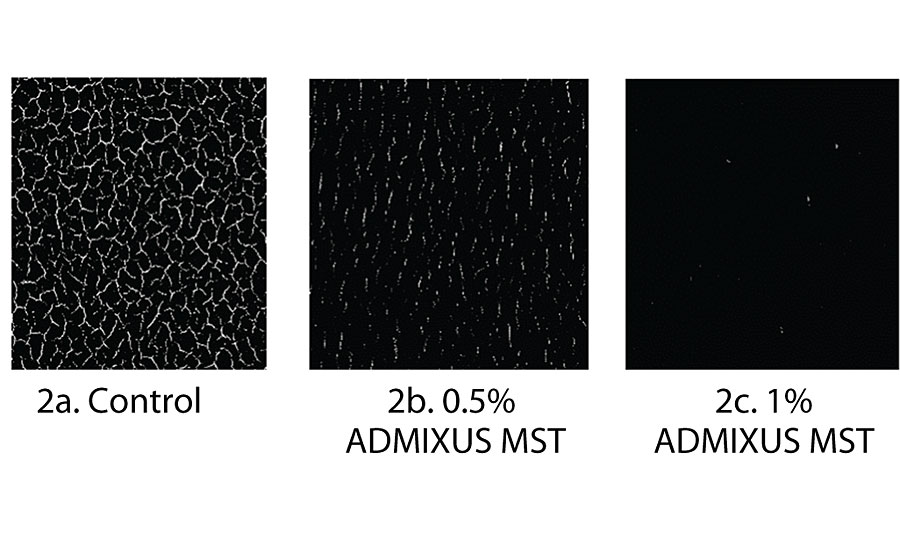

After the films were cast, it was observed that the films at ambient temperature had different amounts of cracking due to poor film formation. We then embarked on a study of the effect of fiber type and addition rate on the degree of cracking observed. Prior to water bath delamination, the cured and cooled films were photographed in the dark on top of a lightbox. Each photo was subjected to image analysis to determine the ratio of the areas of light (crack) and dark (film) parts of the sample.2

As an example, illustrated by the digital photograph in Figure 2, the coating that consistently produced the lowest degree of contiguous film was the control formula containing no fiber at curing temperatures of either 45, 55, or 65 °F.

As shown in Figures 2a, 2b and 2c, the degree of film formation increased progressively with the incorporation of higher load rates by weight.

We then utilized the photographs to calculate the area of each film that is cracked. Film crack areas for the 19 formulations under investigation ranged from zero (unobservable) to approximately 8% of the total area of the film at 45, 55 and 65 °F, which represent 100% to 92% contiguous film formation, respectively.

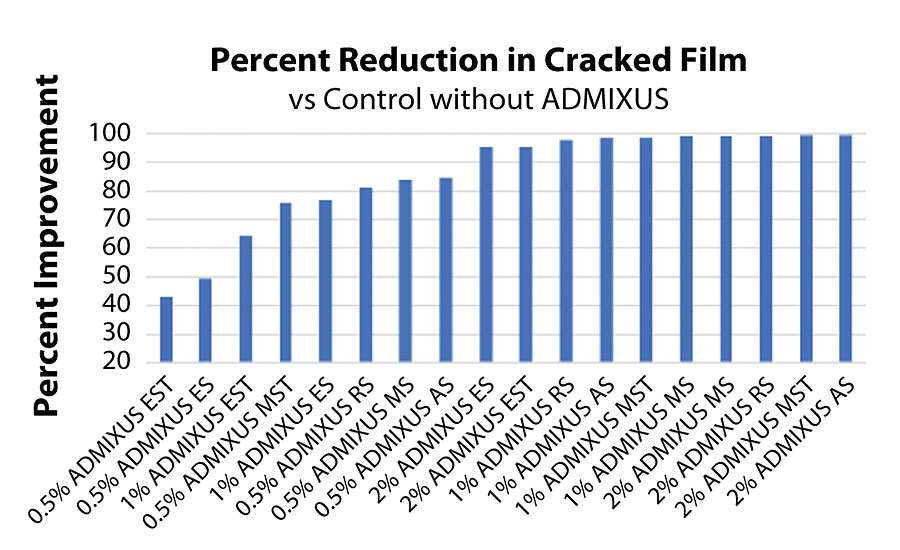

Figure 3 depicts the results. We see that film formation is improved with both larger-size fibers and by increasing the dose of the fiber.

Tensile Stress and Strain Testing

Tensile testing provided stress-to-fracture (ultimate stress) and strain-to-fracture (ultimate strain) and Young’s modulus.

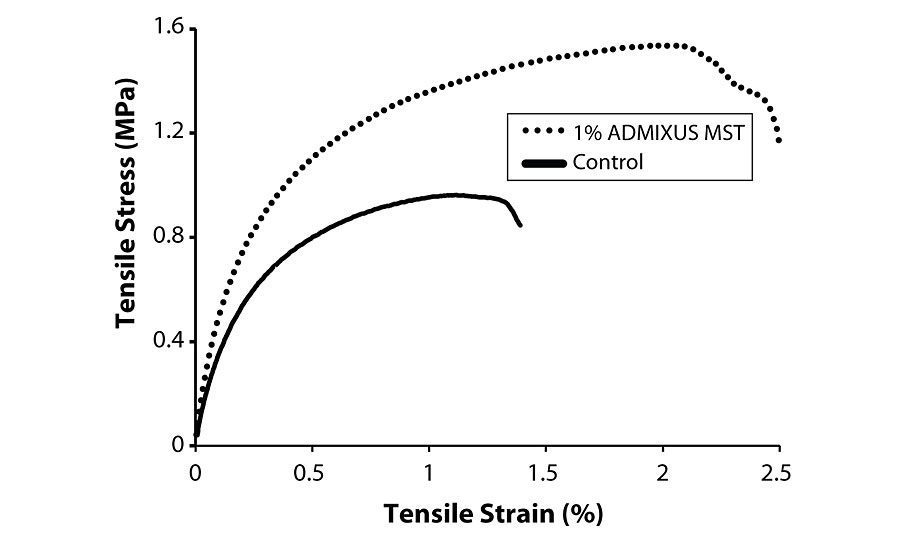

As illustrated in Figure 4, asphalt film specimens exhibited a standard tensile stress-strain relationship with ultimate strain approximately ranging between 1% and 3% of specimen length.

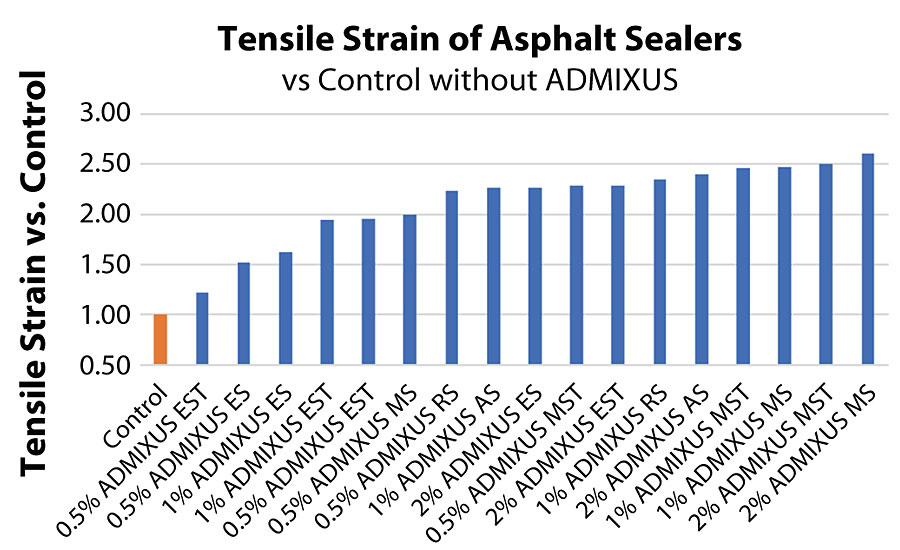

As illustrated in Figure 5, relative to the ultimate tensile strain of the control sample, the ultimate tensile strain of asphalt film increases with the addition of fiber, following trends of fiber size and application rate. In general, we see that smaller fibers give a smaller increase in strain, while larger fibers give a larger increase in strain. Increase in fiber dose also provides increases in the tensile strain observed.

The sample with 0.5% ADMIXUS MST provided the most efficient fiber in promoting tensile elongation. At twice the load rate, 1% ADMIXUS MST produces a supplementary increase in ultimate strain from 2.28 to 2.46 times that of the control.

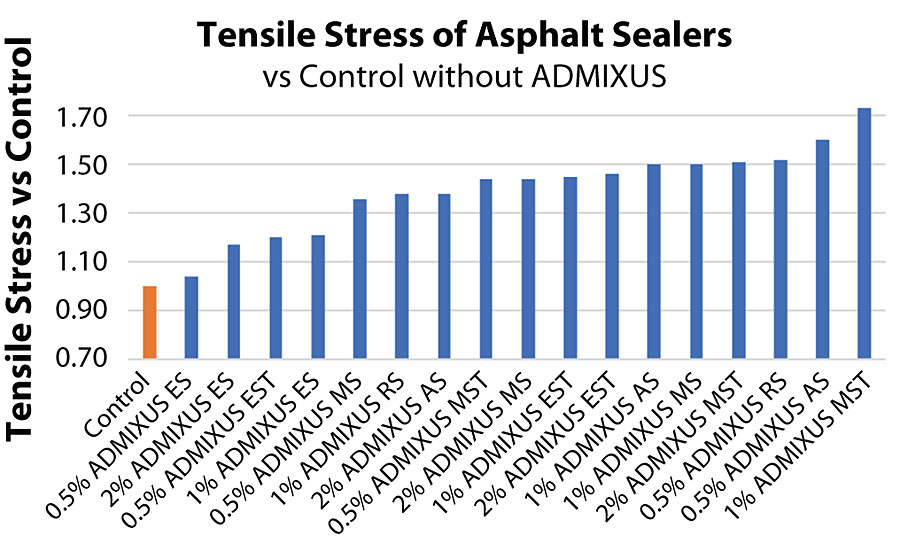

As illustrated in Figure 6, the ultimate tensile stress of asphalt films increased with the addition of fibrillated HDPE fiber also exhibiting higher ultimate stress with medium-length or long fibers than that with short fibers. However, we did not see a direct correlation with application rate.

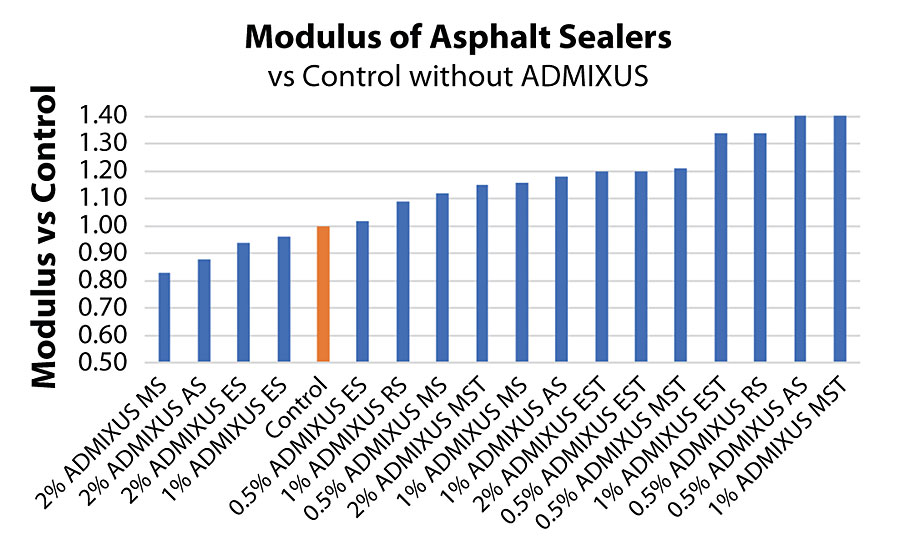

Depicted in Figure 7, the Young’s modulus of asphalt films with fibrillated HDPE fiber varied from 18% lower to 41% higher than that of the control formula with no fiber. The highest loads of fiber (2%) generally produced films with a lower Young’s modulus.

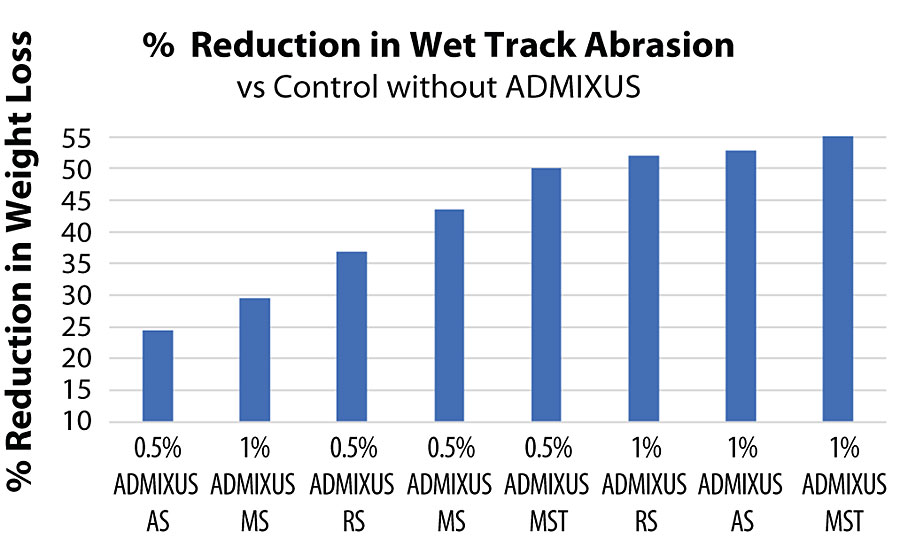

Wet Track Abrasion

Wet track abrasion is a key test method for pavement preservation products. This test is described in standards accepted by the International Slurry Surfacing Association (ISSA). According to the ISSA TB-100 testing protocol, as illustrated in Figure 8, the wet track abrasion resistance of nine selected asphalt emulsion films with and without fibrillated HDPE fiber was compared.5 All of the eight formulations that contained fibrillated HDPE fiber exhibited lower abrasion mass loss and higher abrasion resistance than that of the control formula with no fiber. Four of the formulations with fibrillated HDPE exhibit a mass loss of less than one-half (1/2) that of the control, demonstrating an abrasion resistance of more than twice (2X) that of the control formula.

Chemical Resistance

The chemical resistance of each film was evaluated per acceptable industry standards. The following chemicals are commonly found on driveways, parking lots and roadways - gasoline, motor oil, transmission fluid, brake fluid and power steering fluid - and were included in the study. All samples evaluated in this study performed well, with no softening, blistering, or other visual defects observed.

Conclusions

Overall, the post-addition of six different grades of ADMIXUS fibrillated HDPE fiber has shown to positively affect film formation, tensile properties and wet track abrasion resistance of a commercially available asphalt emulsion driveway sealer/coating.

These results suggest that the incorporation of fibrillated HDPE fiber into asphalt emulsions at levels as low as 0.5% (w/w) of treated or untreated, medium-length fibers, will promote optimum performance, especially at lower application temperatures, which may extend the application season.

References

1 Prezzavento, B.; Hyde, J. Performance Characteristics of Coatings Containing Highly Fibrillated HDPE Fibers, PCI Magazine, June 2016.

2 Relative film crack area was determined by digital image analysis of a center-cropped (1500 x 1500 pixels), negative image area using imageJ software, (https://imagej.nih.gov/).

3 Mitsui Chemicals, Inc., Shiodome City Center, 5-2, Higashi-Shimbashi 1-chome, Minato-ku, Tokyo 05-7117, Japan.

4 MIFI 01-02-01/09, PRI Asphalt Technologies Inc., 6408 Badger Drive, Tampa, FL 33610.

5 MIFI 01-02-01/09, PRI Asphalt Technologies Inc., 6408 Badger Drive, Tampa, FL 33610.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!