Indirect Food Contact Silica Dispersion Additive for Aqueous Inkjet Pre-Coat on Plastic Substrates

By Tianqi Liu, Patrick Sargent, Zaheed Islam and Koen Burger, Cabot Corporation, Billerica, MA

Inkjet has emerged as one of the most promising printing technologies for commercial, signage and packaging due to its flexibility in variable data processing and customization, high throughput, economical workflow, and cost structures. Packaging demand continues to increase particularly for food packaging, but the industry still faces challenges such as supply chain optimization, waste and cost reduction, flexibility with customization, and EH&S compliance. These challenges result in a highly fragmented market, which plays to the strength of print-on-demand digital inkjet technology.

Aqueous inkjet, among various digital inkjet technologies, stands out for its environmentally friendly features and is often considered the best technology for food packaging. The aqueous inkjet inks are mainly composed of water, humectants, surfactants, colorants (pigments or dyes) and binder resins. They are designed to be safer to handle compared to solvent or UV-based inkjet inks. However, one drawback with aqueous inkjet inks is that the inks are designed for specific print head technology satisfying certain viscosity, surface tension and flow characteristics. They are not tailored to substrates other than traditional office papers or photo quality papers, or end use applications such as food packaging.

Materials used for food packaging encompass a wide spectrum of chemical substances and forms, with the main purpose of food containment, preservation and protection. Plastics are the most common and widely used materials for food packaging. They can be made into packaging by themselves as flexible (foils, wraps, packets, bags and pouches), rigid (bottles, trays and pots) and semi-rigid (caps, boxes and tetra packs) forms, or used as labels or wraps for other food packaging materials such as metals, paper, paperboards and glass. Among plastics, polyethylene terephthalate (PET) and polyolefins (polyethylene or polypropylenes) are the two predominant types of materials used. Due to the low surface energy, hydrophobicity and non-porous nature of these plastics, they are considered incompatible substrates for aqueous inkjet printing. Attempts have been made to use binders in the aqueous inkjet inks to achieve ink adhesion to these plastics after corona treatments; however, ink drying on top of the plastics remains a critical issue for most aqueous printing systems. As described above, aqueous inkjet inks contain water and humectants as the liquid bulk. Humectants are used to achieve a certain viscosity range and protect print heads from drying and nozzle clogging to ensure jetting consistency. Humectants, having high boiling points and low vapor pressure, once jetted onto these non-porous substrates, will require strong drying capacities downstream from printing stations to evaporate. However, drying at higher temperature or for longer times can cause the plastic substrates to undergo undesired warp or deformation.

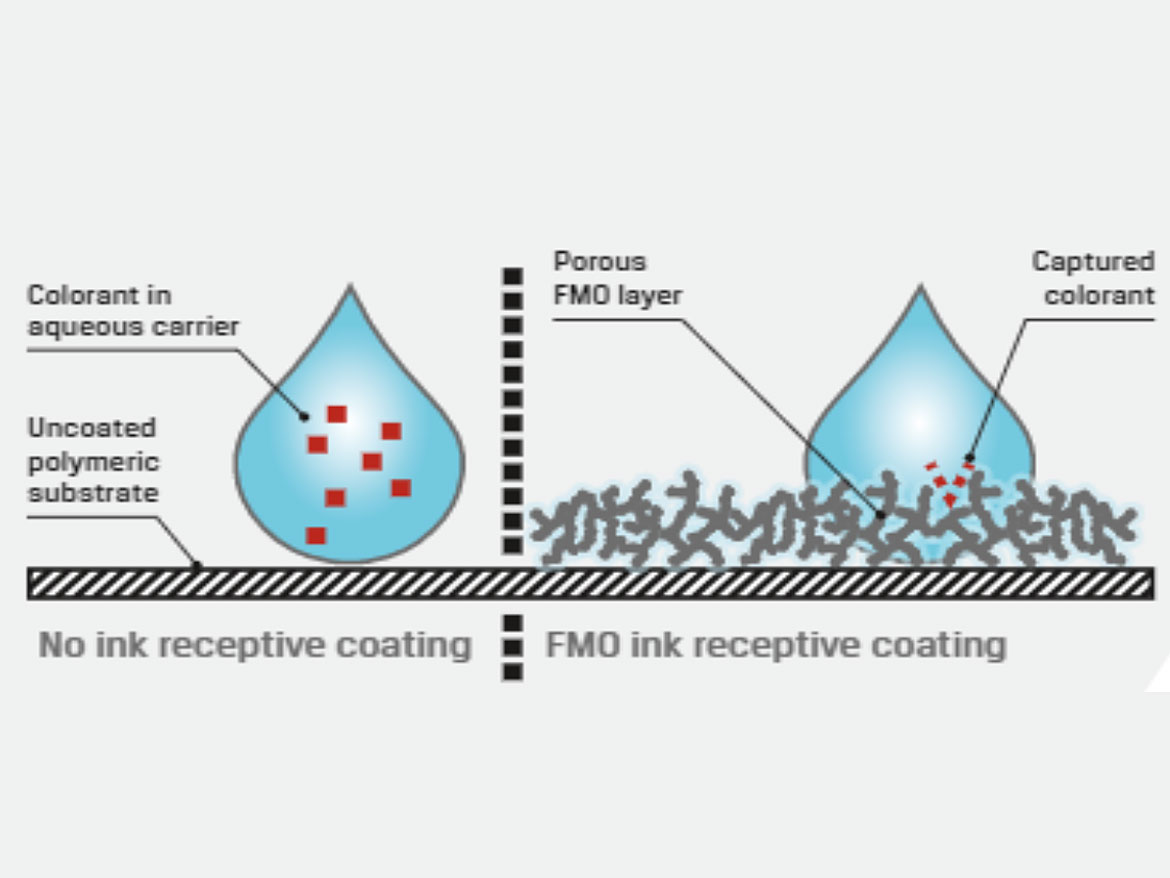

To solve the incompatibility issue between plastic substrates and aqueous inkjet printing techniques, an inkjet receptive coating can be applied onto the plastics to create a microporous layer to accept ink droplets.

As shown in Figure 1, an inkjet receptive coating for plastics is typically composed of fumed metal oxide (FMO) particles, which impart porosity and binders that provide adhesion to the plastic substrates. FMO particles such as synthetic fumed silica and fumed alumina feature fractal structures with primary particles arranged into branched chains. The branched aggregate structures are not easy to pack closely, thereby creating intra- and inter-particle voids and channels. These voids or porosity generated by the fractal particles are very important features that allow for liquid adsorption and fixation of the pigment in an aqueous inkjet receptive coating.

A Key Component in Aqueous Inkjet Receptive Coating Formulations for Food Packaging

The components in an inkjet receptive coating preferably should be authorized or approved in country-specific regulations if the coatings are intended for food indirect contact packaging. In addition, overall and specific migration tests may be required to ensure the permitted limits are not exceeded and to study any potential adverse chemical substance transfer from packaging to food.

For example, in Europe, the components for inkjet receptive coatings for plastics support fall under Food Contact Plastics Regulation EU 10/2011, in the categories of “materials that can be printed or covered by a coating” and “plastic layers in multi-material and multi-layer materials and articles” without prejudice to national provisions applicable to coatings. The components are also subject to the scope of the Swiss Ordinance ON MATERIALS AND ARTICLES IN CONTACT WITH FOOD (SR 817.023.21) Annex 10, under “permitted substances for the production of packaging inks on materials and articles intended to come into contact with food stuffs”.

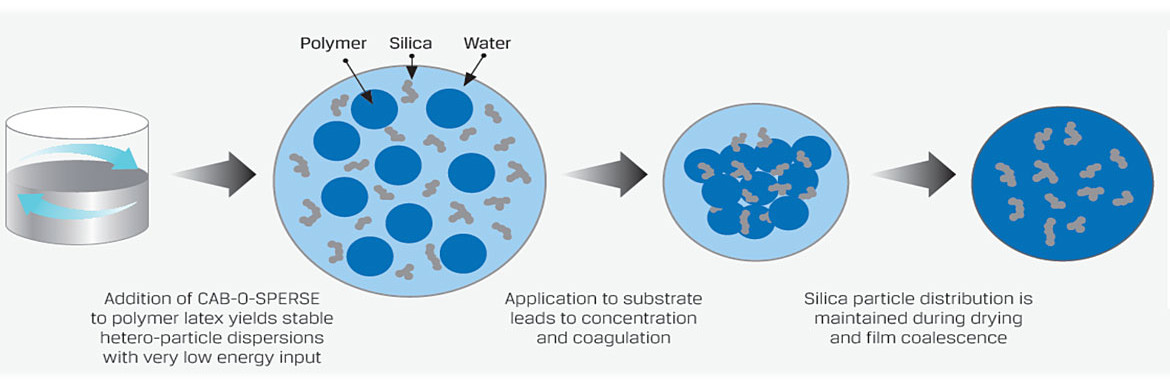

To enable customers to formulate under the indirect food contact regulations, we have developed and commercialized CAB-O-SPERSE® 4012K-F silica dispersion for food packaging applications. The dispersion is colloidally stable, eliminating the need for grinding and dust handling. The silica dispersion is dispersant-free to minimize incompatibility issues in a formulation. The high purity from the silica production and dispersion process offers good chemical and temperature stability without yellowing. Formulators need only low-shear mixing equipment to incorporate the silica dispersion, resin binders, coalescing additives and surfactants, as shown in Figure 2. The base silica used for making CAB-O-SPERSE 4012K-F has high surface area and small aggregate size, and can generate high gloss and translucent coatings compared to fumed silicas with lower surface areas or precipitated silicas with much bigger aggregate sizes.

Porosity, Adhesion and Transparency Performance

Particles such as those in CAB-O-SPERSE 4012K-F silica dispersion are needed to form porous networks in the coating to help absorb liquid from inks. The pores generated in the coatings can range from 10 to 150 nm in size. Dynamic fluid absorption in porous media is driven by the capillary pressure, which is inversely proportional to the pore size. Therefore, these nanometer-size pores should allow for rapid ink liquid absorption. When a resin (in soluble or particulate form) is added to the formulation, it acts as the binder to help the coating adhere to the plastic surface and hold the particles together like a glue to prevent cracking upon drying or mechanical abrasions resulting from roller operations. However, if too much binder is used, it will fill some of the pores generated by the particles, leading to a reduction in total pore volume at a constant coat weight.

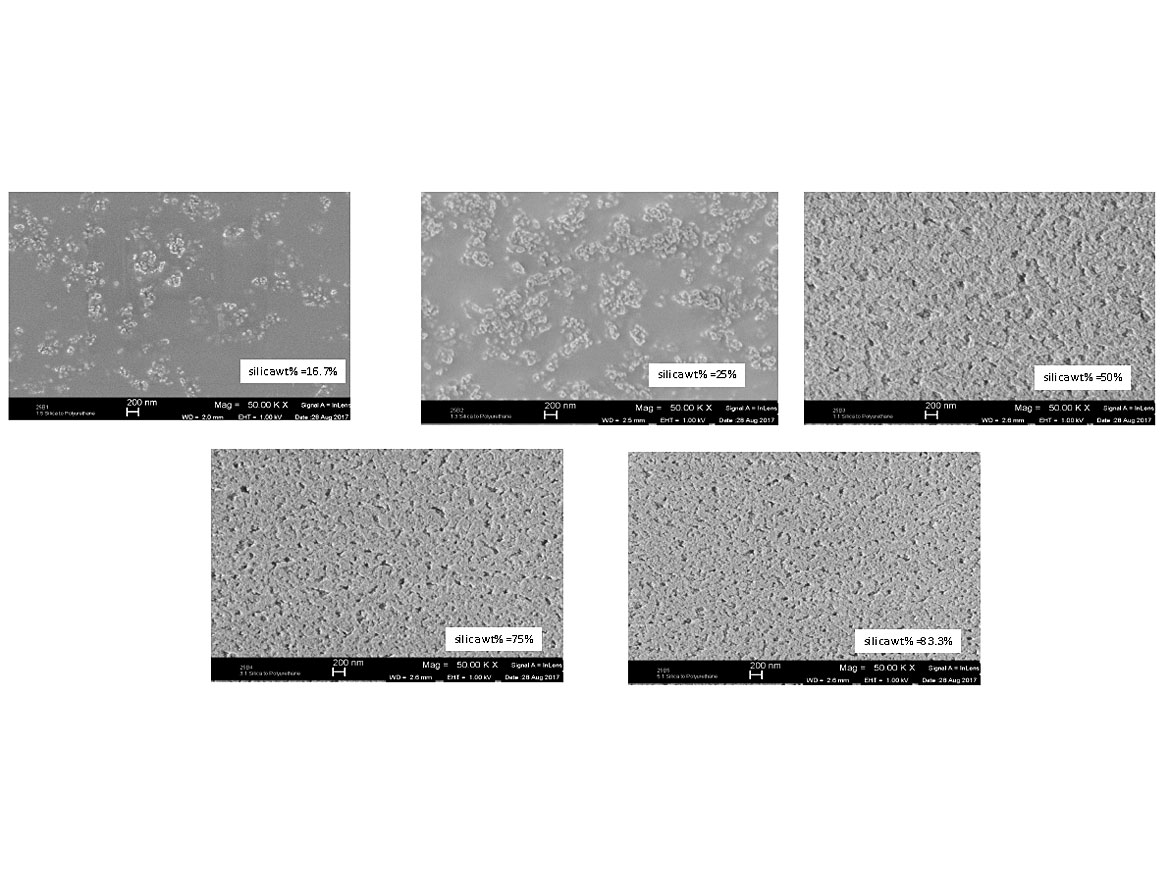

A series of five coatings based on various loadings of a silica dispersion (with a different surface area) and a polyurethane binder were generated to study the morphology of the coatings under Scanning Electron Microscopy (SEM) (Figure 3). When the silica loading is low (e.g., 16.7%), a continuous film is observed. The binder serves to homogenize the surface and cover over the silica particles, filling in voids, nicks and inter-particle contacts. As the silica loading increases, the surface starts to roughen and open up, with pores indicating less binder coverage on the surface.

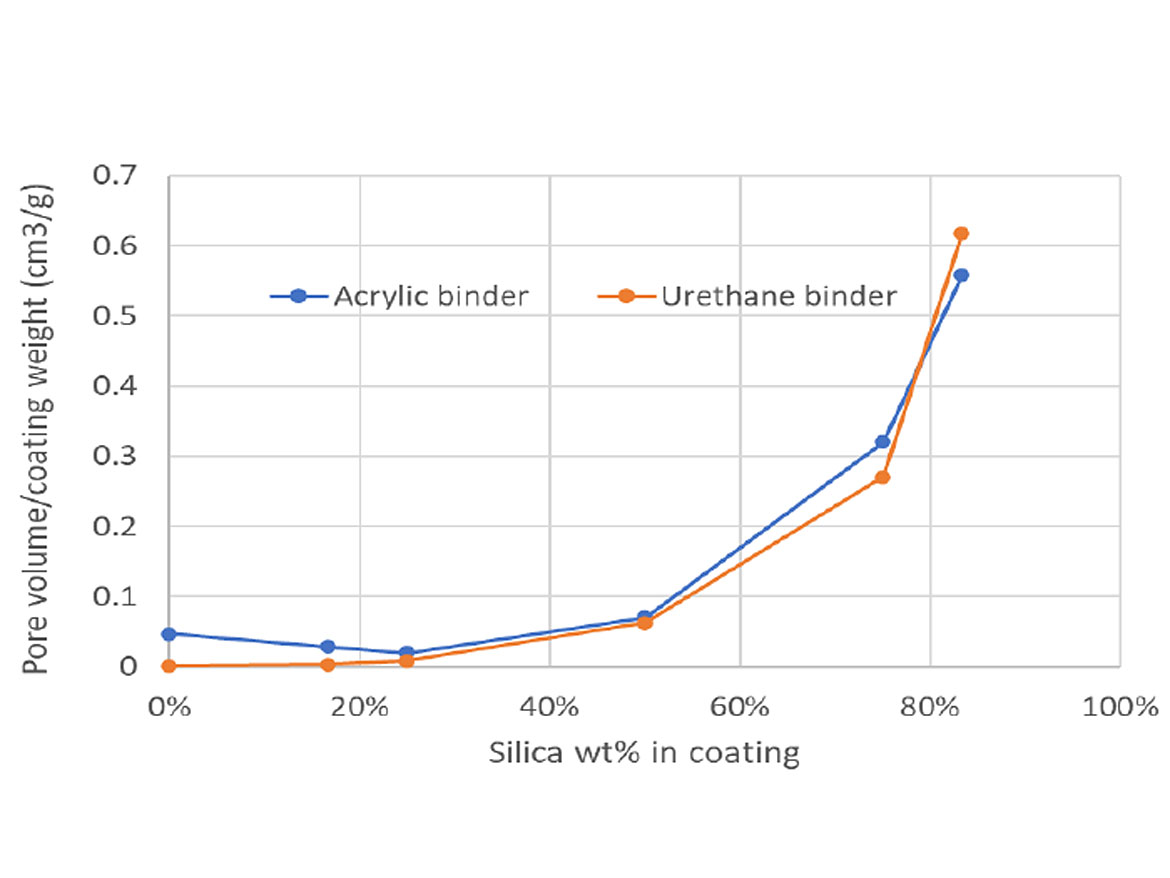

The pore volumes generated by both these coatings and a second series of coatings based on an acrylic binder were measured by nitrogen adsorption and desorption isotherms and calculated using the BJH (Barrett, Joyner and Halenda) model (Figure 4). A sharp transition in the pore volume is observed between 25% and 50% loading of silica regardless of the binder chemistry. It is likely that in this range the amount of binder is exactly enough to fill the voids between the silica particles completely. Below this threshold, the coating could be considered a dispersion of silica particles in a continuous matrix of binder polymer. Above this range, porosity arises as the binder is no longer sufficient to fill the voids between the particles.

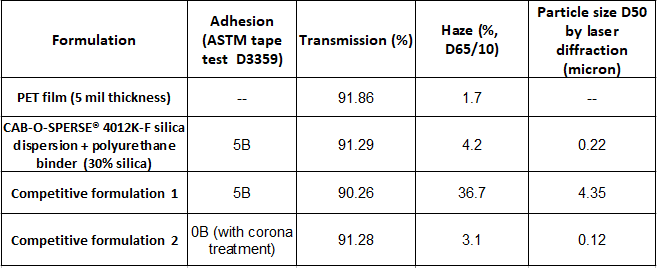

A formulation based on CAB-O-SPERSE 4012K-F silica dispersion and a polyurethane binder, with 30% of silica on a dry basis, was compared with commercially available Competitive Formulations 1 and 2 in terms of adhesion and film appearances on a PET film at 0.5 mil dry film thickness (Table 1). Competitive Formulation 1 has excellent adhesion without corona treatment and good transmission but displays high haze, indicating light scattering by the large particles in the coating. Particle size measurements by laser diffraction confirmed that Competitive Formulation 1 has particles in the 4-5 micron range. Competitive Formulation 2 has poor adhesion even after corona treatment but provides good transparency, which is consistent with the small particle size observed. The formulation based on CAB-O-SPERSE 4012K-F silica dispersion exhibits the best overall performance in adhesion and transparency.

Intercolor Bleed, Ink Drying and Color Performance

As discussed previously, particle loading in a composition affects the porosity of the coating and its ink receptive capabilities such as ink drying and intercolor bleed. The morphology and chemistry of the particles and the coat weight also play important roles.

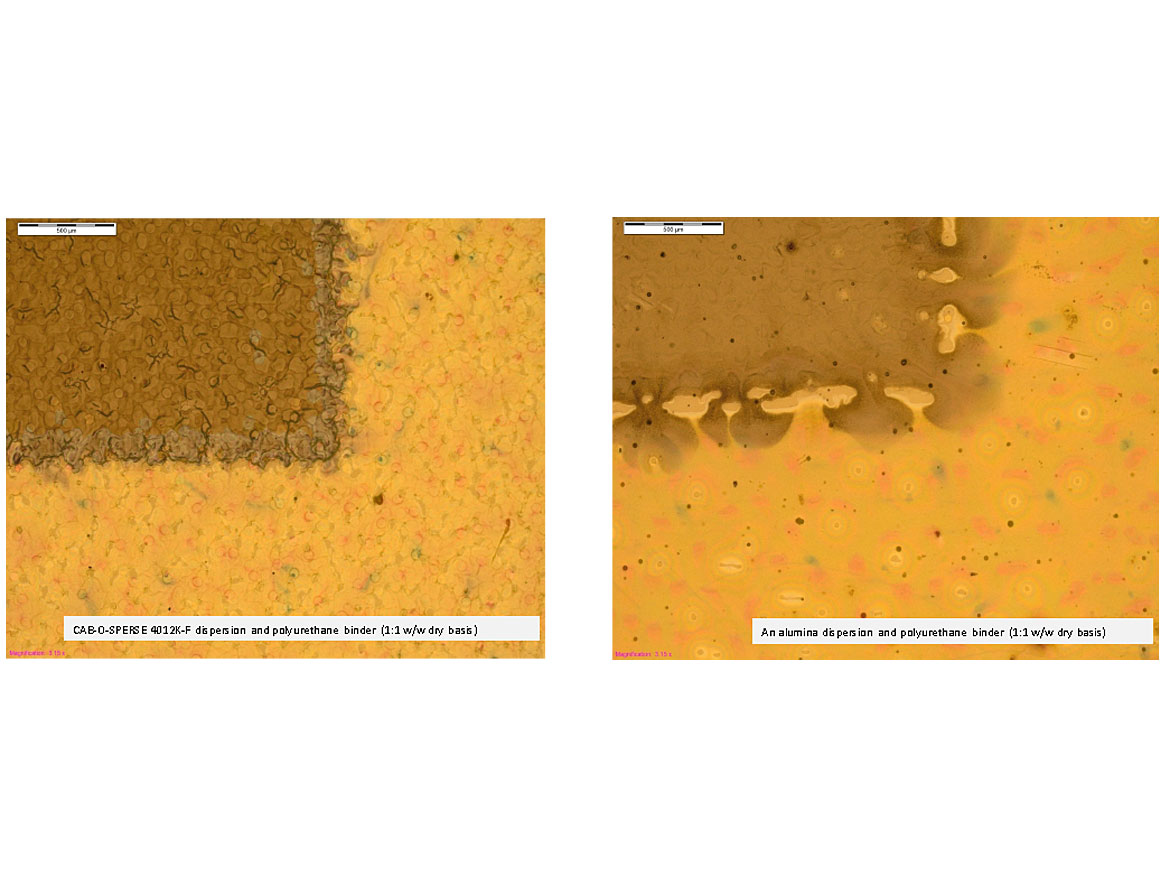

Figure 5 shows microscope images of inks jetted from an Epson Workforce WF-3730 printer on 0.5 mil dry coatings based on the new CAB-O-SPERSE 4012K-F silica dispersion and an alumina-based dispersion respectively. The edge acuity of the black square against the yellow background indicates black to yellow intercolor bleed performance. Both coatings have 50% (w/w) of particles in the composition and the same thickness. It is obvious that the coating based on the new silica dispersion has much better intercolor bleed, as shown by the sharper edges compared to the blooming features observed with the alumina-based coating.

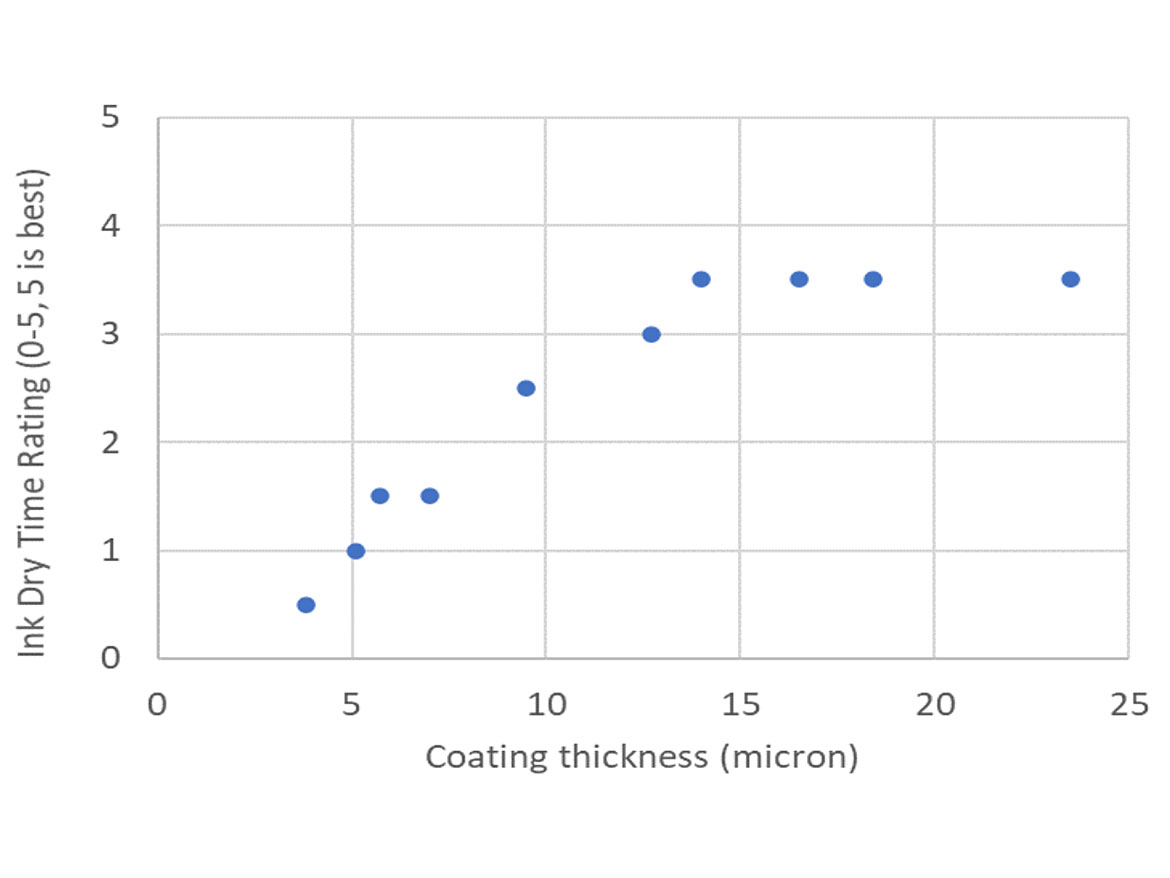

Ink drying was measured according to ASTM 2498 using different coat weights while keeping the silica loading constant (30%). A linear increase in ink drying is observed until a critical thickness of around 14 micron is reached, after which the performance plateaus (Figure 6). The plateau may indicate that the speed of liquid adsorption is limited by the rate of ink diffusion within the porous networks. Although the bulk coating weight still increases, the ink liquid does not necessarily diffuse inward faster. This result emphasizes the importance of keeping open-pore structures at the top surface of the coating and illustrates the benefit of high porosity enabled by higher loadings of silica particles without sacrificing substrate adhesion.

Ink adhesion and color gamut were also evaluated with inks jetted from the Epson Workforce WF-3730 printer. Ink adhesion was measured following ASTM D3359. Seven colors (black, red, green, blue, yellow, magenta and cyan) were printed as columns. Each color received an adhesion rating from 0-5, with an ink adhesion total ranging anywhere from 0 to 35. For color gamut, squares of all seven colors were printed and measured using a Hunter XE lab-scan colorimeter. The total color gamut was determined by adding up the chromaticity for each color; the higher the number, the better color gamut achieved.

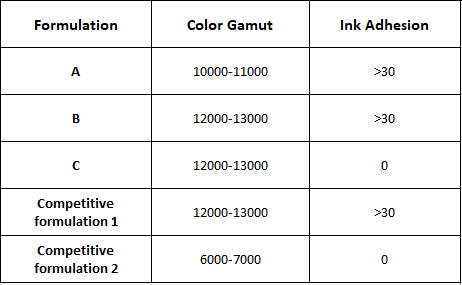

Three different polyurethane dispersions based on different polyols were combined with CAB-O-SPERSE 4012K-F silica dispersion to create Formulations A, B and C in which the silica to binder weight ratio was 3:7. Color gamut and ink adhesion were evaluated for all three formulations and for preformulated Competitive (commercial) Formulations 1 and 2 (Table 2). Although most of the formulations provided good color gamut, only Formulations A and B containing the new silica dispersion showed good ink adhesion, indicating that resin chemistry plays an important role in ink pigment fixation. Competitive Formulation 2 displayed inadequate color gamut and no ink fixation, and is therefore not a good candidate for this application.

New Silica Dispersion Used in Jettable Inkjet Receptive Formulations

Not only can CAB-O-SPERSE 4012K-F silica dispersion be formulated into inkjet receptive coatings targeting analog applications on plastic films, it can also be applied in a digital jettable formulation and used in a primer jetting station as part of the digital printing process.

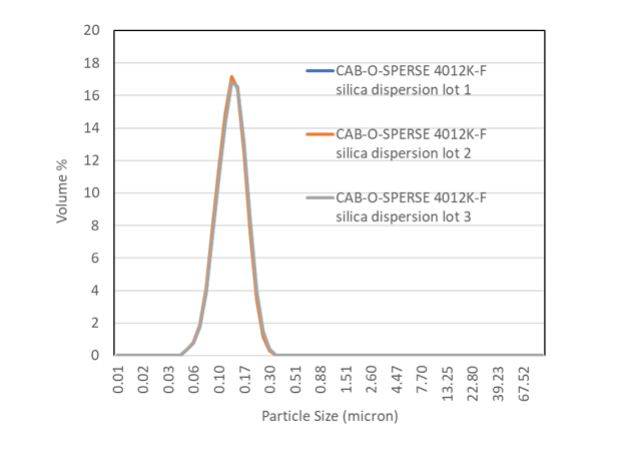

Current inkjet printhead technology has stringent requirements for particles used in the printhead to avoid nozzle drying and clogging issues. For example, the typical size for the particles should be ideally below 0.3 micron with a narrow particle distribution. Figure 7 shows the particle size measurements by laser diffraction of three lots of CAB-O-SPERSE 4012K-F silica dispersions. With D50 around 125 nm and D90 below 200 nm, the consistency in particle size and particle size distribution satisfies the particle size requirements of many inkjet print heads.

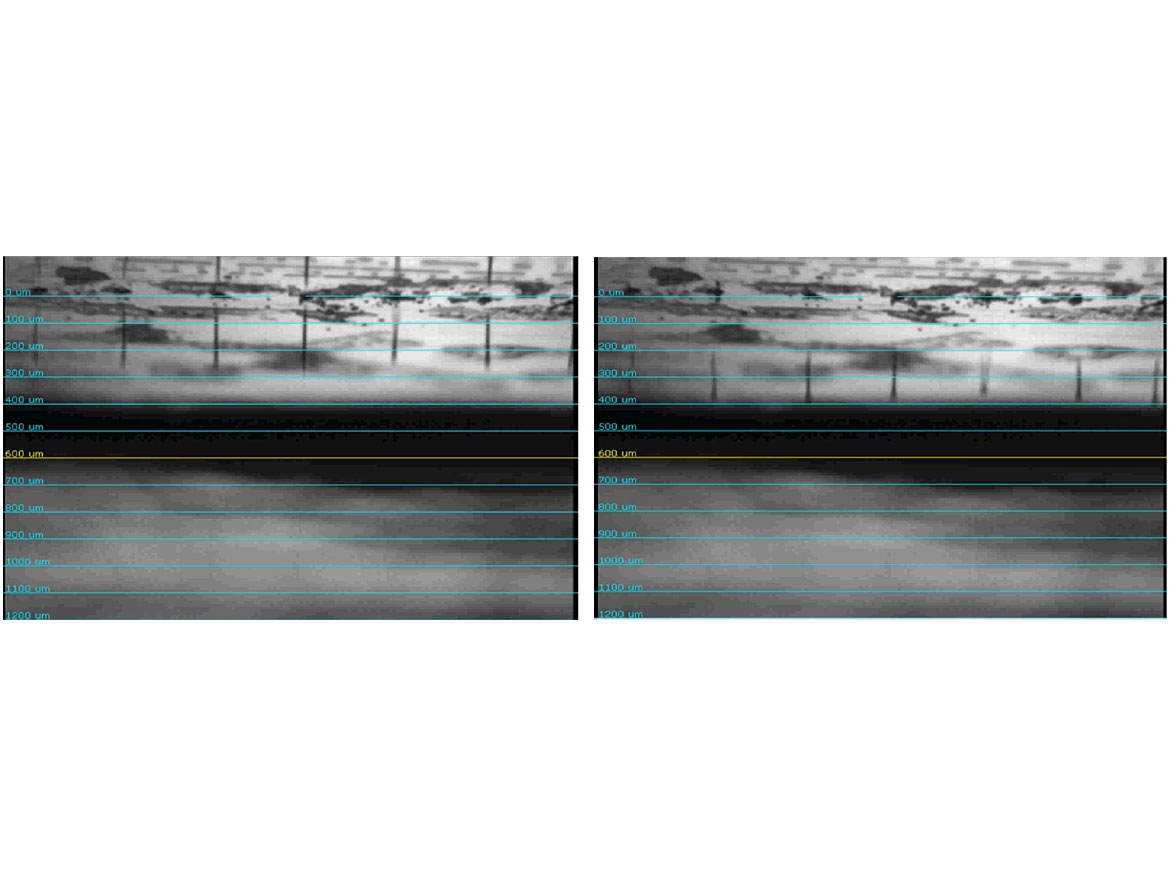

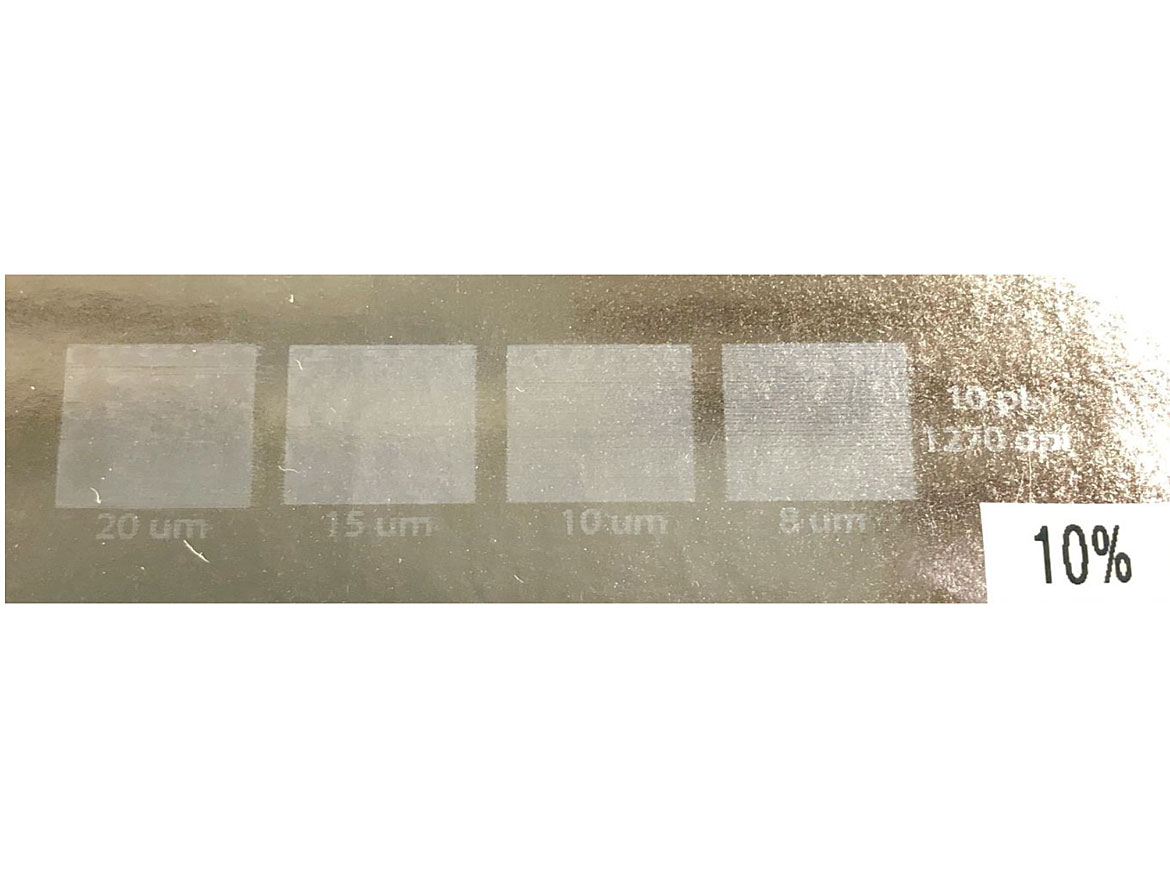

When formulated at a viscosity around 2.85 cp (25 °C) and surface tension of 31.5 dynes/cm, an experimental formulation with a total solids content of 10% can be jetted using a Fujifilm Dimatix MEMS piezo inkjet printer. During drop watching, straight liquid droplets can be seen coming out of the nozzles consistently (Figure 8). The image in Figure 9 was jetted onto a glass slide to observe coverage at varying thicknesses using a 10 pL cartridge at 1220 dpi. A silver coated paper was placed underneath for better visualization. The jetted image shows crisp graphics and solid areas without evidence suggesting drying of the nozzles.

Conclusions

The development and commercialization of CAB-O-SPERSE 4012K-F silica dispersion allows us to supply the fast-growing digital printing segment of packaging and labels with an indirect food contact-compliant product. It has shown to be a beneficial ingredient for developing aqueous inkjet receptive coatings on difficult-to-print plastic substrates. The new silica dispersion enables the formation of porous receptive coatings with good adhesion and transparency, and excellent ink performance (inter-color bleed, adhesion and color gamut) in the presence of an appropriate selection of resin binders. Additionally, preliminary results have shown the silica dispersion may be used in digital jettable primer formulations or digital inks due to its small particle size and narrow particle size distribution.

Acknowledgment

The authors would like to thank a former colleague, Melissa Monello, for her dedicated support in the project and thoughtful contributions to this article.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!