Four Key Components of Robotic Paint Booth Design

The payoffs could be substantial if you’re thinking about designing a robotic paint booth for use in the automotive manufacturing sector. Adding robots into the workflow could lead to greater efficiency, better overall quality, and more. This technology can also increase a facility’s scalability, which is good news if an automaker struggles with frequent demand fluctuations.

However, a poorly thought-out paint booth that uses robotic technology could be worse than getting the job done without robots. Here are some important parts of the paint booth and its functionality to consider.

The Programming

Think of the paint booth’s programming as its backbone. If it’s too complicated for employees to tell the automation cell how to get the right results, it’ll be more challenging to see a return on investment with the technology. Simplicity is a topic that often comes up regarding the programming of automated paint booths used in the automotive sector.

After all, many decision makers at such companies don’t have extensive experience with robots themselves, and they may lack the resources to employ an on-site tech team to troubleshoot programming needs. Additionally, if a company has hundreds or more parts to paint, it’s easy to see how the prospect could soon become too time-consuming.

However, at least one company allows people to program paint or powder robots without offline programming or teaching pendants. Instead, a painter takes the bot through a sequence with all its motors disabled. Pneumatics enable the painting professional to manipulate the machine, showing it the correct movements. The robot’s joints have encoders, so it can record all the respective motions and create the code from them.

This is not the only possibility when it comes to teaching the robotic paint booth to work properly. However, this solution, or one like it, could be instrumental in helping company leaders feel more confident about investing in robots because they know they’re easy to program.

Those diving into the design process should consider the team's current level of design expertise, if any. Additionally, how much time and effort do they want to put into programming the paint booth’s robots, especially if the needs of the automaker change? Answering questions like that will help iron out programming needs.

Coating and Movement Mechanisms

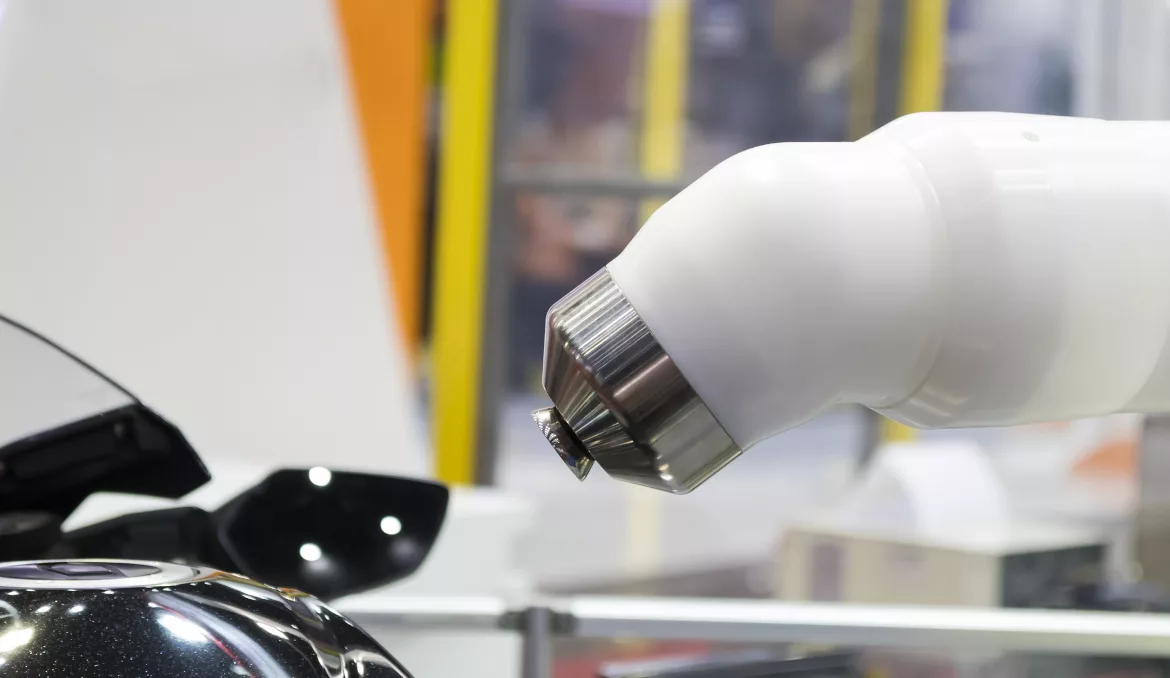

It’s also necessary to consider design-related specifics concerning how paint will be thoroughly applied to components and what you’ll use to keep the production flow happening without interruption. Devoting attention to those aspects will help you design a productive paint booth that fits the automotive company’s needs.

Compressed air is one of the most popular choices to make a robotic paint booth work well. A sprayer and air compressor combination generally results in a smoother finish in less time. However, you’ll get the best results by thinking about relevant details. For example, what air compressor tank size do you need to match the sprayer's capabilities? It’s usually best to select at least a 50-gallon tank to ensure a continuous stream of air.

Figuring out how many nozzles the robotic paint booth needs is essential for high-quality and consistent results. The specifics depend on the booth size, the size of the automotive parts getting painted, and the desired efficiency.

One booth on the market features an impressive 1,000 nozzles in a 100-millimeter space. Together, they can apply more than 1,000 droplets per second, and manufacturers can choose the desired diameter with the dosing control package. Determining the best conveyor system to use is also necessary, especially since so many painted car components are large. Additionally, an efficient conveyor system enhances process flows and helps car companies become more competitive while continuing to meet client needs.

Consider whether the ideal option is to have a floor conveyor or an overhead one. The right selection depends on the size, shape, and weight of what you need to paint. Think about whether a certain type would be more beneficial to employees, too. One Fiat factory uses collaborative robots to help employees apply waterproof liners. That approach provided ergonomic advantages. Even a robotic paint booth won’t entirely replace humans, so keeping workers in mind is always wise.

Data Collection Capabilities

Automotive plants are typically massive operations. That also means they usually provide plenty of opportunities for data gathering. The more decision-makers know about what’s happening inside a robotic paint booth — or anywhere else in the facility — the more often they’ll be able to act confidently and make changes when necessary.

Cloud-based paint-monitoring solutions can capture data for further analysis. Those products give valuable visibility and information at a highly granular level. One product can provide real-time statistics about individual booths or those located in numerous factories.

These products can reveal details such as the total costs to operate a single booth, its total operating hours, or how long it spent in each paint phase. People can also compare multiple booths against each other, including finding out the average job length or the number of items painted in a day.

Artificial Intelligence

Determining how artificial intelligence (AI) will help your robotic paint booth work is a great way to make it future-proof and highly adaptable. One possibility is to utilize AI to make the robot paint cell capable of something solutions on the market don’t currently offer.

Decision makers at BMW saw the value in deploying algorithms that recognize the amount of dust in the paint booth. They connected that information to quality control outcomes. Paint booths usually have highly advanced filtration systems to keep dust out as much as possible. That’s because ambient air pulled into them can get trapped in the wet paint, particularly if the overall dust content in the space exceeds a certain threshold. That issue detracts from the finish quality.

The algorithms used at BMW continually analyze the amount of dust in a booth by comparing what they detect to a database. Company representatives can then use the resulting details to predict the quality level of the paint on each car. Employees can make proactive decisions when the algorithms indicate the overall dust content is too high, such as replacing components of the filtration system sooner than they otherwise would.

The algorithm’s findings could also reveal that people need to tweak it because it’s no longer working as effectively as it should.

Artificial intelligence may not be a component of your paint booth right away, and that’s OK. AI may make the overall setup and programming more complicated, increasing the resources you must use for the project. Moreover, waiting until you use the booth for several months or longer may be more practical before trying to add AI to it. That prolonged usage period will make it easier to determine if AI would offer notable benefits and how you should apply it.

How Will You Benefit From a Robotic Paint Booth?

Deploying a paint booth that works with robotics can help you save time, increase output and maintain high quality levels. These four components are excellent starting points. Considering them during product development will likely bring satisfactory outcomes.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!