New X-Ray Diffraction Technology to Study Thin Polycrystalline Coatings

Thin films as polycrystalline coatings are used in many different application areas ranging from biomedical coatings on medical implants to spray-coated paints on automotive steels, deposited films on electrodes in batteries or metallic contacts in semiconductors, and optical coatings on displays, to name a few.

As new applications for thin films emerge and existing applications become mainstream, the technology of deposition is always advancing, and the materials deposited are always being improved.

The crystalline phases deposited and the residual stresses in deposited films are key parameters for assessing the efficacy of a deposition method or a processing step. Monitoring the integrity of a film during the use is also vital to ensuring the long-term success of a product. With grazing incidence X-ray diffraction (GIXRD) you can target your configuration to maximize the signal from your coating. This gives you the best possible data from which to obtain the results you need, whether you need detailed studies of crystalline phases or rapid high-throughput quality control.

This article provides some example data and analysis showing the performance of Aeris for studying polycrystalline coatings.

Aeris Configured for Grazing Incidence X-Ray Diffraction

With grazing incidence X-ray diffraction, you achieve a much-improved peak signal from thin films, where regular symmetric (Bragg-Brentano) powder scans may not yield sufficient peak intensity or give too much interference from the substrate.

Aeris can be a dedicated thin film diffractometer for routine measurements or alternatively a versatile powder diffractometer enabling occasional thin film measurements. The high-performance de-coupled goniometer scanning technology provides highly reproducible 2θ scans at a range of precise incident beam (ω) angles suitable for GIXRD and residual stress measurements. The parallel plate collimator on the diffracted beam side converts Aeris into the parallel beam measurement mode, providing accurate peak positions and resolving defocusing effects, to bring you high-quality data. A range of robust sample holders provides a variety of sample mounting options to suit your requirements (Figure 1).

50-nm Thin Film of Polycrystalline Iridium on Silicon Substrate

The refractory metal iridium has many applications in high-performance optical devices due to its high reflectivity of X-rays, low-oxidation rate, and high melting point. For example, iridium is researched as an alternative to gold and silver as an optical coating in high-performance telescopes.

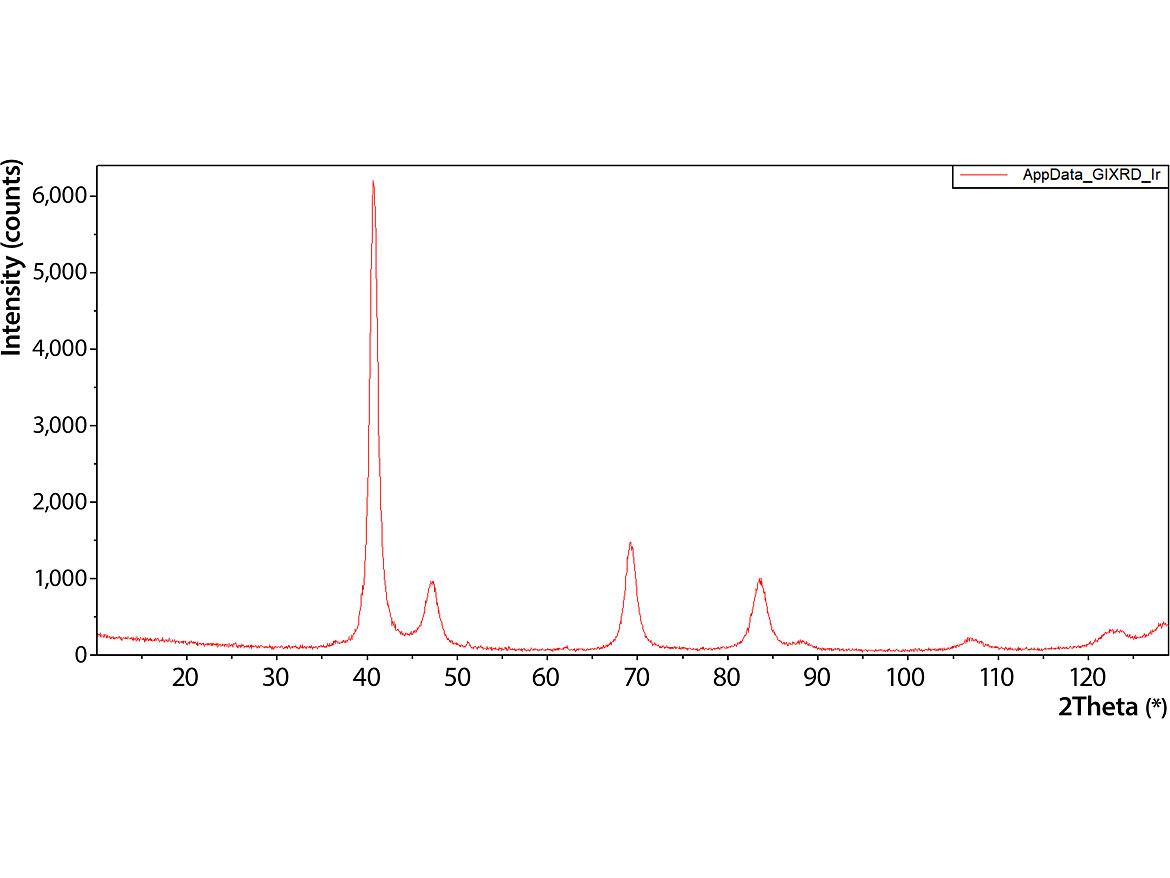

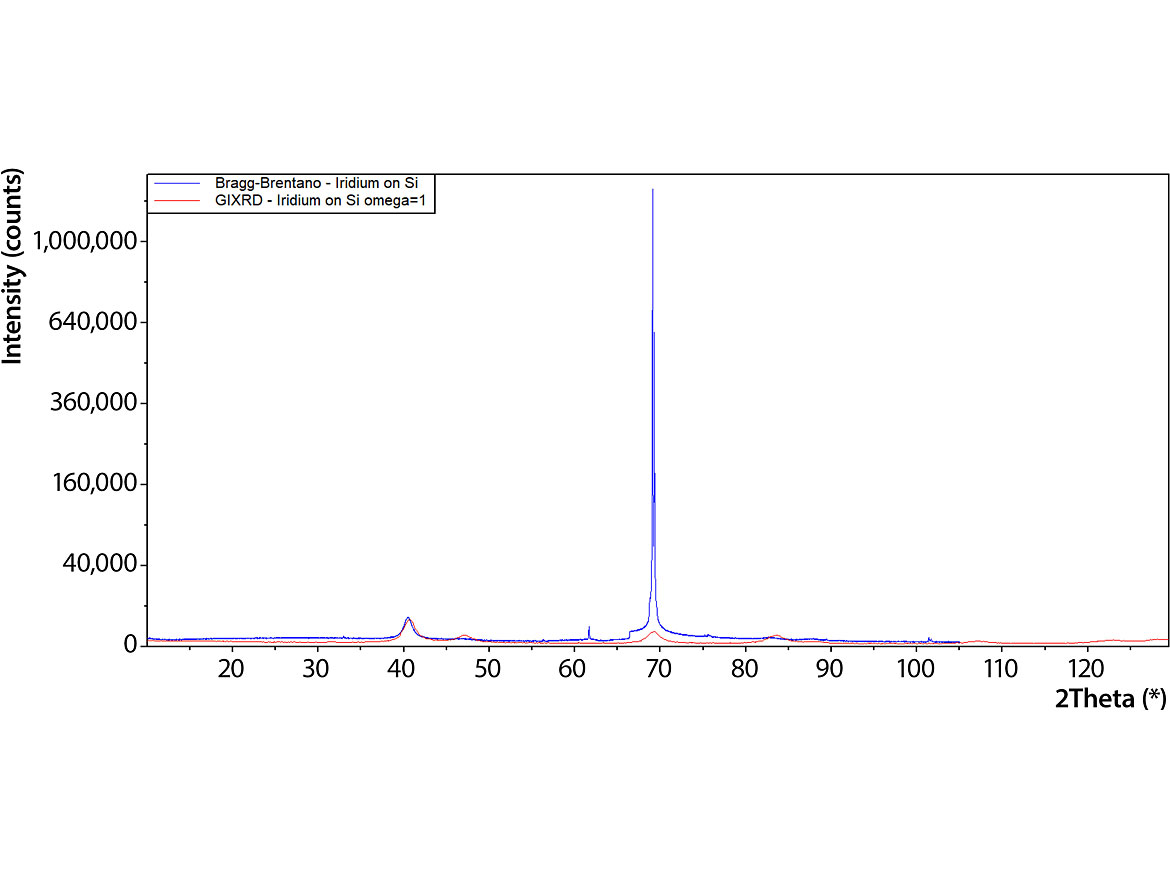

The crystallite size and micro-strain are good indicators of the film microstructure and overall quality of the film and can be quickly and non-destructively monitored by looking for changes in the diffraction peaks. For such a thin film, the iridium diffraction peaks could easily be lost in the signal from the substrate peak. By using the grazing incidence diffraction geometry, it is possible to get clear and useful data quickly (Figure 2.1). The high-angle peaks from the layer, such as the 85° peak, are only visible in the GIXRD scans as they are too weak to be seen in the reflection configuration.

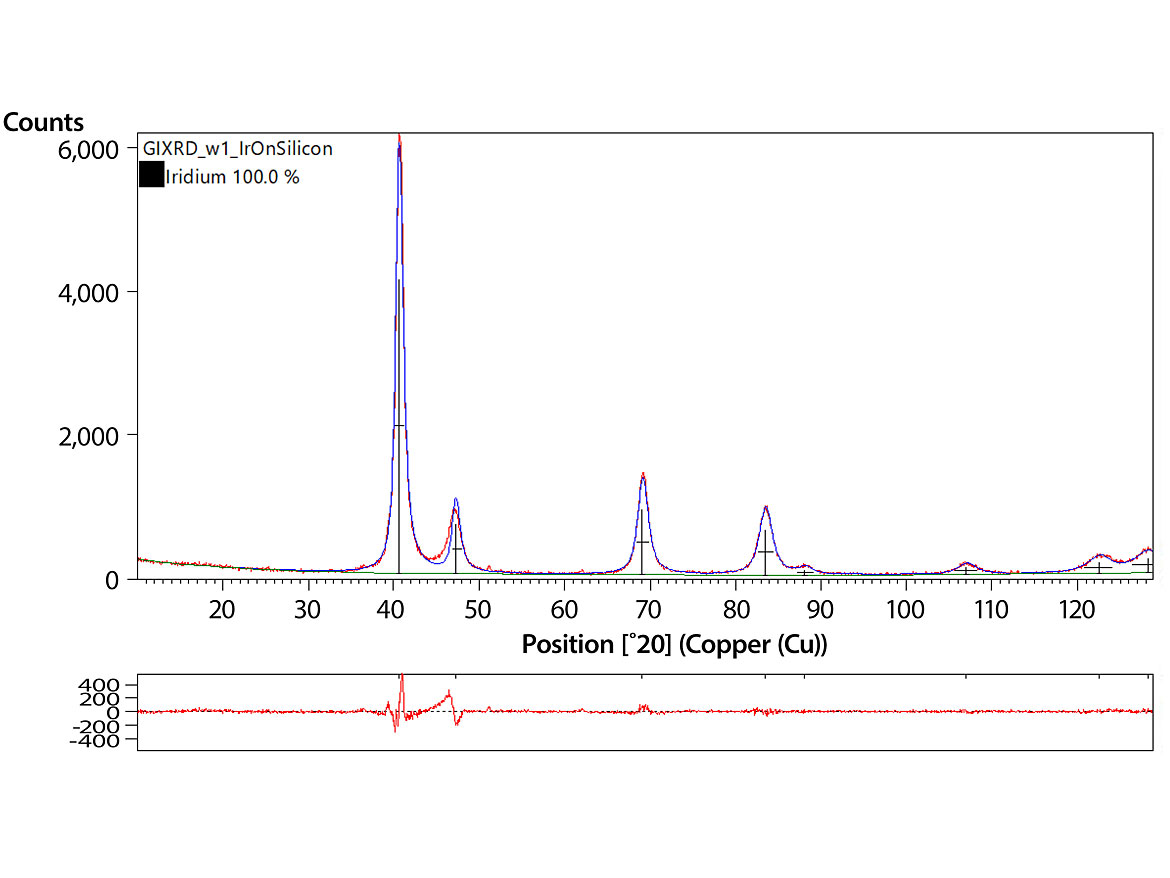

Using HighScore analysis software,1 results for average crystallite size (11.1 nm), and micro-strain (0.585%) are quickly obtained (Figure 2.2). These are structural parameters that help you to monitor and optimize your fabrication processes to obtain the required layer performance and product quality control.

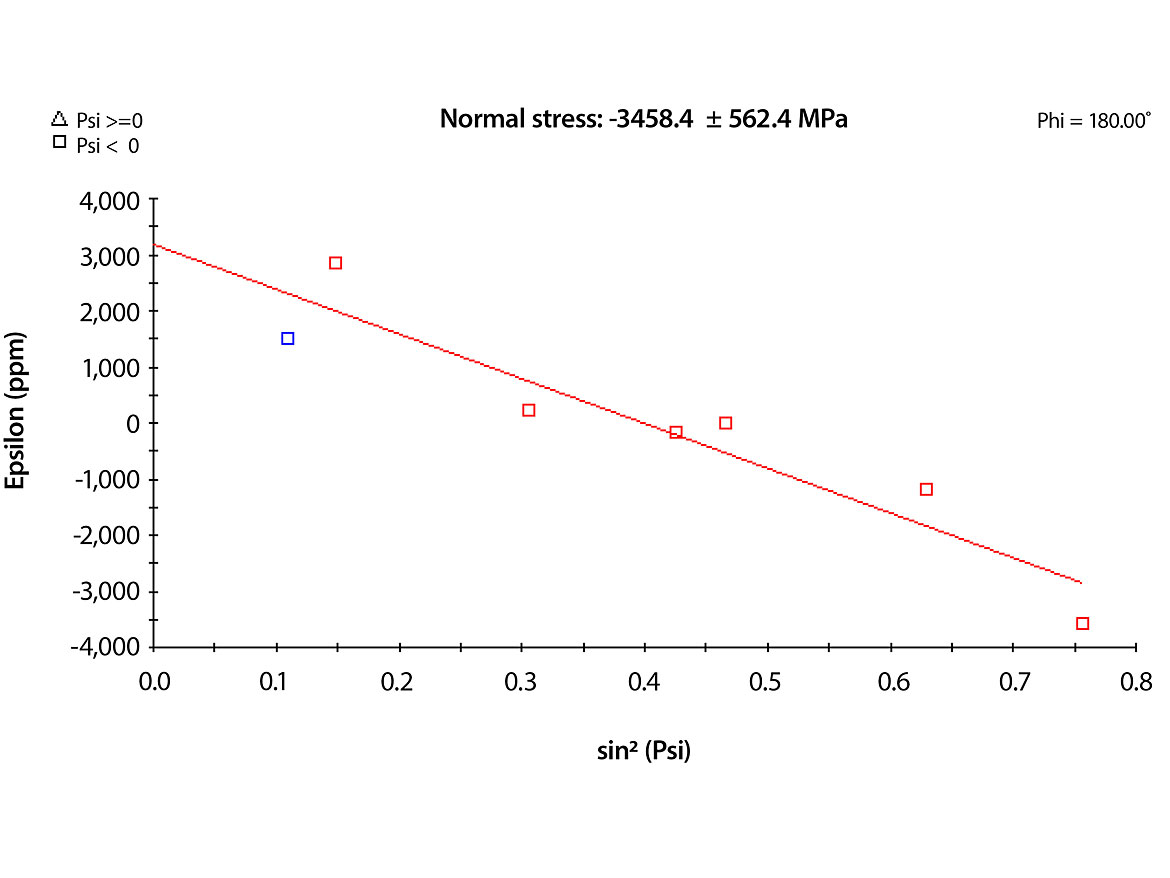

For thin films and coatings, it is important to measure residual stress in the film both to understand how the residual stress forms in the layer during deposition and to understand the final quality of the film. Thin films can support high stresses and, in addition to offering chemical protection to a component, coatings can provide additional strength to a component or conversely weaken the whole component. Alternatively, a thin film that is overstressed can crack easily or become detached from the substrate. Crystallographic residual stress is a major quality control parameter in thin film processing. The residual stress within the layer can be determined using multiple-{hkl} residual stress analysis in Stress Plus2 software (Figure 2.3).

Comparison of the GIXRD data with conventional Bragg-Brentano data in Figure 2.4 shows that both iridium and silicon have strong diffraction peaks close to 69°2θ. With a GIXRD scan, the smaller iridium peak is now clearly visible and not hidden by the silicon substrate peak, and the higher angle peaks such as at 85° and 107° are more easily seen.

Pb-Br-Perovskite on Glass Substrate

The processing methods and properties of PbBr3NCH5 perovskite thin films are being researched, as promising candidates for solar cells and detectors. They can be produced by a variety of deposition methods including cost-effective liquid coating. It is always important to maintain control of the structure throughout any processing steps. The crystal structure, crystallite size and residual stress are all important parameters in determining both the optoelectronic efficiency and structural robustness of the material during use.

These layers are designed for optimum absorption of solar energy wavelengths, and this means that they are quite transparent to X-rays. The grazing incidence configuration therefore maximizes the signal that can be obtained from the layers and so is the preferred geometry for the most efficient data collection.

Here we show examples of high-quality GIXRD data and analysis. The parallel beam optics with grazing incidence reduces beam broadening and hence leads to more accurate determination of crystallite size, strain, and residual stress. Grazing incidence geometry improves intensity from thinner films, where regular powder scans may not yield sufficient intensity for analysis.

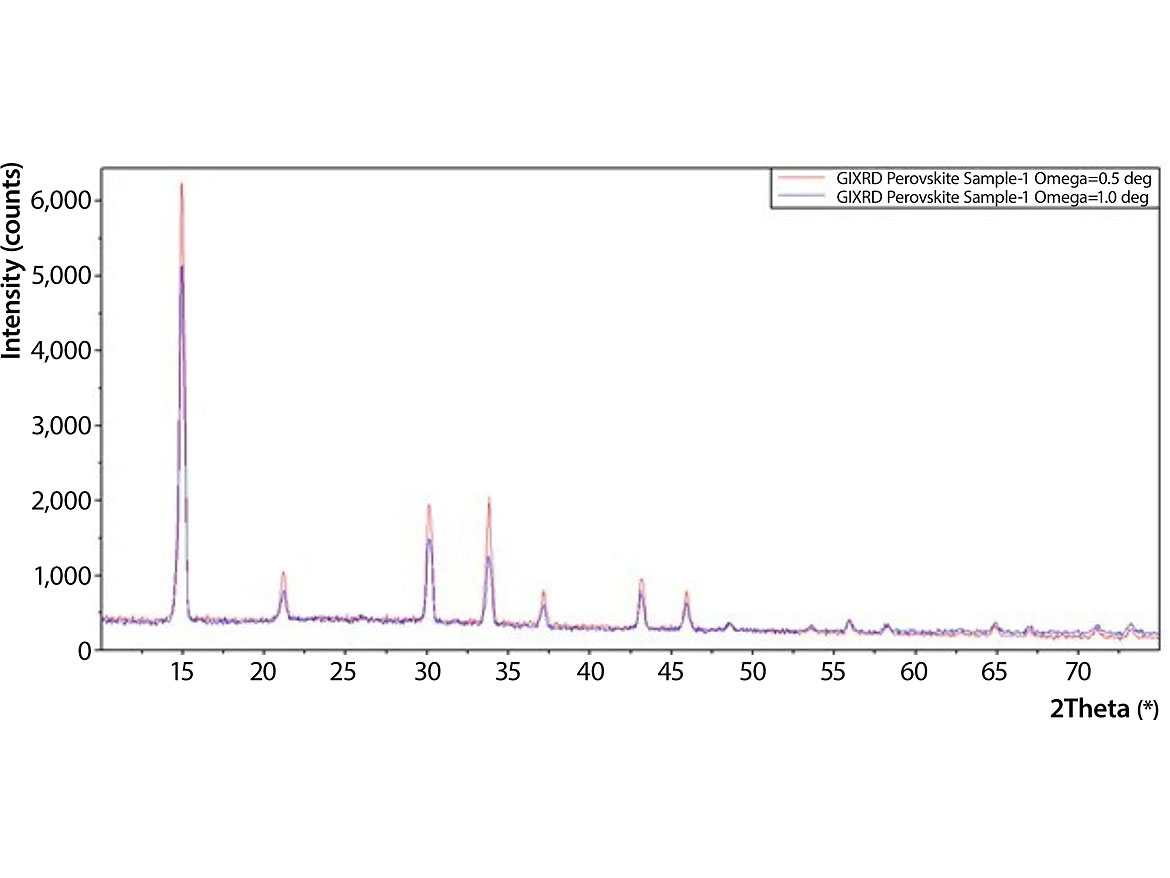

Figure 3.1 shows data collected at different angles of incidence (omega). At omega 0.5° (red scan) the signal to background of the layer peaks are better than with omega 1° (blue scan). Unlike the example in section 3, the substrate is glass, which, being amorphous, provides a high background intensity. Being able to optimize the scan and reach low incident angles such as 0.5° is a great benefit for this kind of sample.

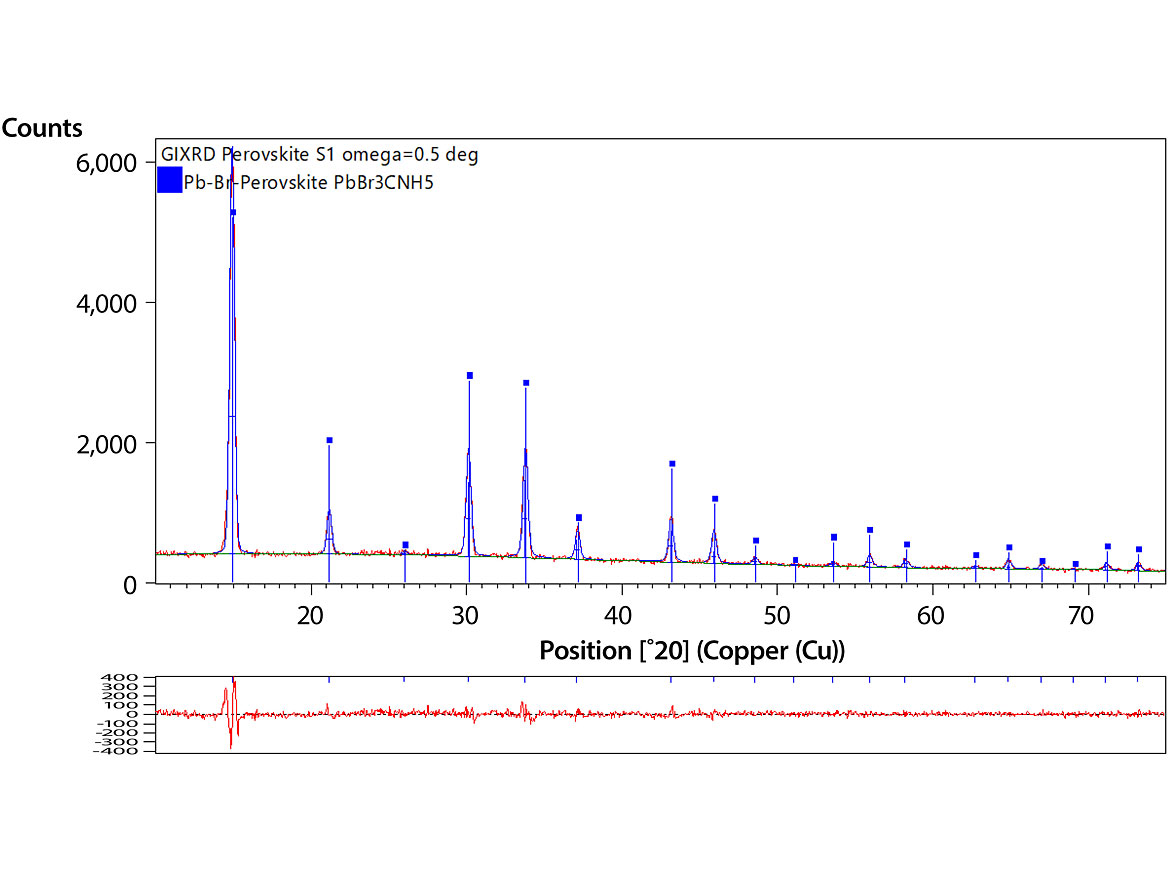

Crystal structure refinement is an important measurement for perovskites, even small changes in the crystal structure can have a large effect on the optical properties of this material. Figure 3.2 shows a best fit for refinement of the Perovskite structure using HighScore Plus analysis suite. In this way, the crystal structure can be continuously understood, and the optical properties controlled.

Summary

With Aeris, you have all the capability of powder diffraction in one compact instrument. Here we have shown two examples of GIXRD that demonstrate the versatility of Aeris and the quality of data. With the patented and unique PreFIX optical mounting system, Aeris is easily reconfigured for quick comparison of data from Bragg Brentano, transmission, and GIXRD methods. GIXRD scans can be obtained within minutes, and data at different angles of incidence can be compared to optimize the data collection settings. Together with the analysis software HighScore Plus and Stress Plus, high-quality data show the phase purity, crystallinity, crystallite size, micro-strain, and residual stress for a complete view of your polycrystalline thin-film sample.

References

1 Degen, T.; Sadki, M.; Bron, E.; König, U.; Nénert, G. Powder Diffr. The HighScore Suite, Vol. 29, No. S2; 2014.

2 Welzel, U.; Ligot, J.; Lamparter, P.; Vermeulen, A.C.; Mittemeijer, E.J. Stress Analysis of Polycrystalline Thin Films and Surface regions by X-ray Diffraction, J.Appl.Cryst., 38; 2005; 1–29.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!