Stabilizer Solutions: Methods to Improve Resistance of BPA/BPF-Based Epoxy Resins to Light and Heat Damage

costasss, iStock / Getty Images Plus, via Getty Images

Coatings can be applied to various materials to give unprecedented functions or to prevent damage to the underlying surface caused by external factors. They can also enhance the value of objects through a variety of color and gloss characteristics. Appropriate resin selection is essential to meet specific application requirements. Epoxy resins, the main subject of this article, are widely used in coatings thanks to their excellent adhesion to materials and their durability. Bisphenol A- and bisphenol F-based epoxy resins and amine hardeners are common components of epoxy coatings. However, epoxy resins typically contain aromatic groups with strong absorption in the UV range. This makes epoxy structures vulnerable to UV degradation. Their poor UV light resistance limits their suitability for exterior applications. Light stabilizers retard the effects of UV degradation such as yellowing by screening UV light and by slowing down the rate of radical degradation reactions. Antioxidants further reduce the yellowing caused by heat. The performance of SONGWON stabilizers in a typical commercial epoxy resin with hardeners was tested and reviewed below.

Experiment

Materials and Preparation

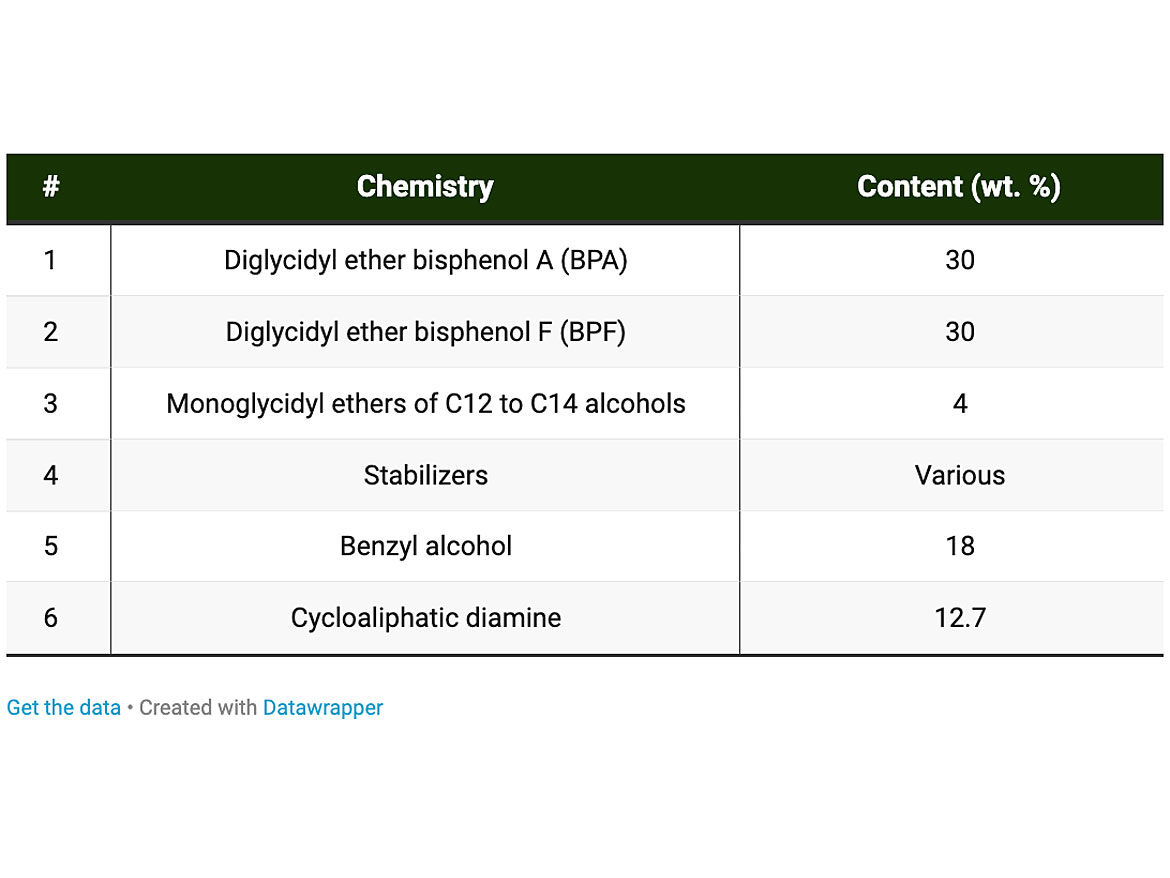

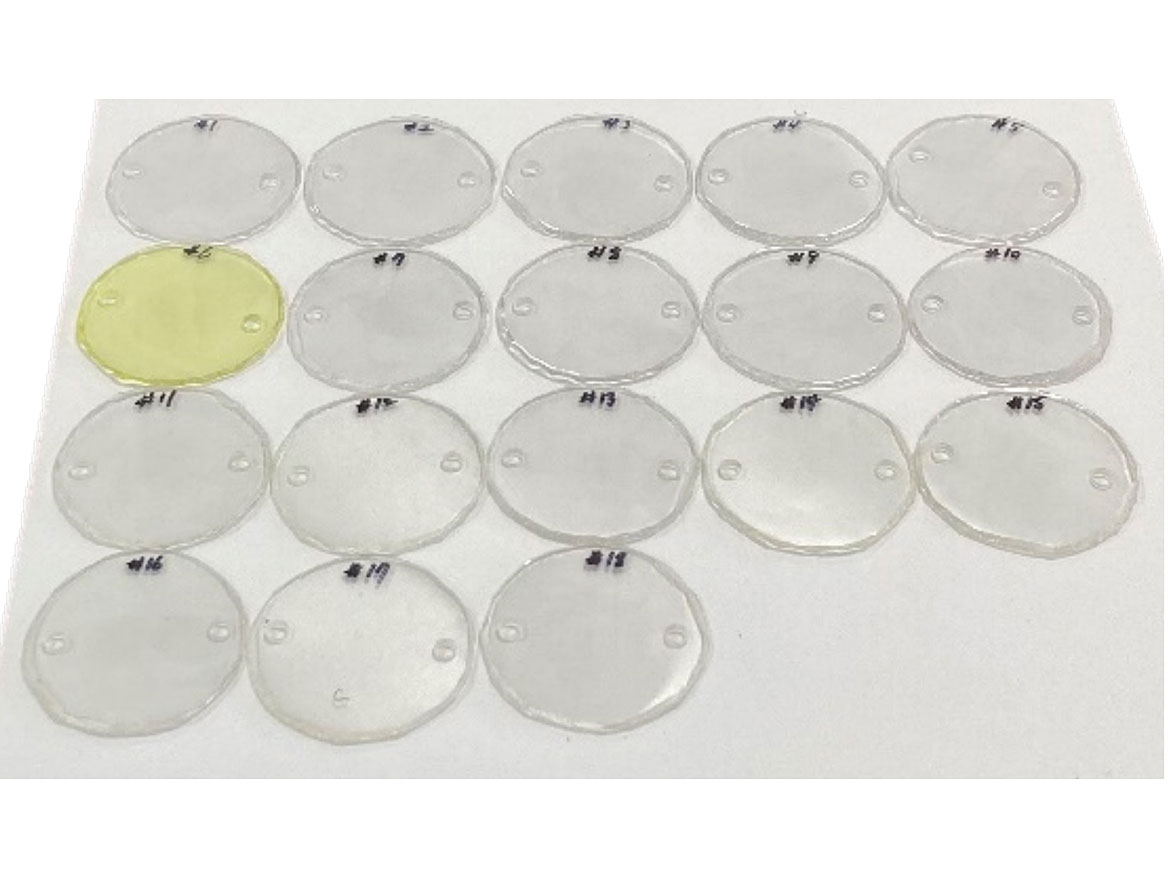

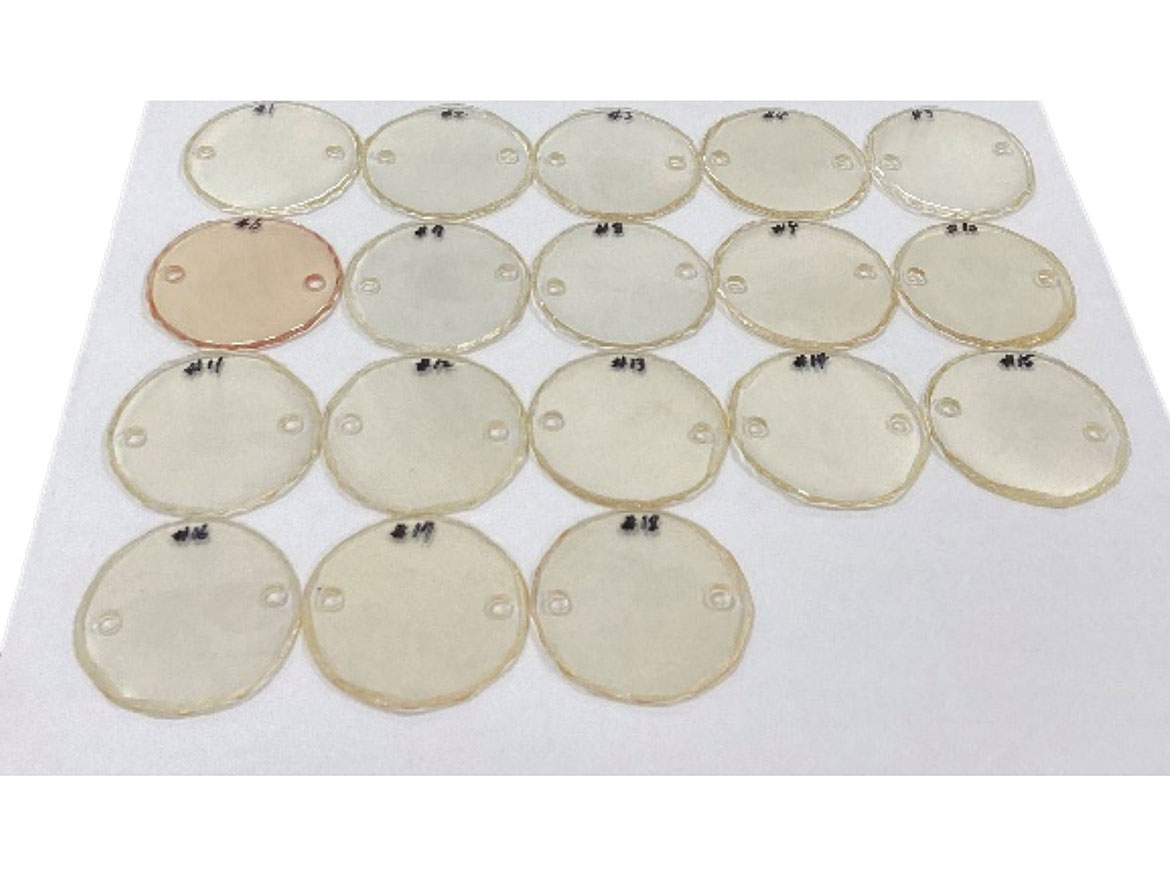

The formulation incorporating a 50:50 resin mixture of BPA/BPF (Table 1) was designed to evaluate the performance of stabilizers. Cycloaliphatic diamine was reacted with the resin to initiate curing. The amounts of resin and hardener were calculated according to the stoichiometric ratio. Diluents and solvents were added to control viscosity and improve workability. Stabilizers were classified as UV absorber, HALS, and antioxidant to test their performance. The film thickness was adjusted to 2 mm through weighing and actual measurement in an aluminum dish used as a molder. The prepared specimens were placed in an air circulation oven (Memmerts UF110) set at 30% fan speed, 100% ventilation, and 40 °C, and cured for 12 hours. After conditioning for 7 days at 23 °C and 50% relative humidity, the specimens were exposed to weathering as described below.

Artificial Weathering

The specimens were exposed to photo-aging in a Bandol Wheel® H400 developed by SEVAR/SEVN Bandol. The specimens were mounted on a circular rack around the horizontal axis. The rack rotates around a medium-pressure UV mercury lamp whose bulb is enclosed in a borosilicate envelope. The lamp provides an irradiance of 95 W/m2 at wavelengths between 300 and 400 nm. The Bandol Wheel reproduces the main natural phenomena responsible for chemical alterations on polymer matrices and additives. It considerably accelerates the kinetics of alteration that would occur naturally. The samples were exposed to a nominal UV radiation level corresponding to about “2 suns”. Degradation effects become visible after shorter periods than with other methods.

The programmed protocol was set to a black panel temperature of 60 ℃. The rack speed of six rounds per day ensured that the specimens were immersed in water for 17% of the time. The Bandol Wheel meets the requirements specified by the EN 16472 standard. Exposed specimens were withdrawn every 20 hours for color data measurement by spectrophotometer.

Color Measurement

Color development on the exposed specimens was determined using a HunterLab MiniScan EZ spectrophotometer (geometry; diffuse/8°) with a 2.5 cm diameter aperture (illuminant 65, and 10° standard observer). The color was measured on a standard white tile (Hunterlab, 11-0108-50), taking into account the transparency of the specimens.

To express the discoloration ΔE (color difference), the Euclidean distance between two coordinates profiled as L*, a*, and b*, and ΔYI (Yellowness Index) were adopted according to:

∆E*ab = [(∆L2) + (∆a2) + (∆b2)]1/2.

Yellowness Index was expressed as the number calculated from spectrophotometric data in accordance with ASTM E313:

YI = 100(CXX-CZZ)/Y

CX,CZ: coefficients of the equations for Yellowness Index.

X, Y, and Z: CIE tristimulus values.

The higher the color difference values (ΔE, ΔYI), the stronger the color change. Three measurements were taken for each specimen and the average was calculated in each case.

Light and Heat Stabilizers

SONGWON develops and manufactures both light and heat stabilizers. SONGSORB® CS light stabilizers retard the damaging effects caused by UV light. UV absorbers (UVAs) absorb ultraviolet energy and convert it into harmless heat. Hindered amine light stabilizers (HALS) trap the radicals that form and deactivate them. SONGNOX® CS heat stabilizers or antioxidants interrupt the auto-oxidation process caused by the effects of elevated temperatures.

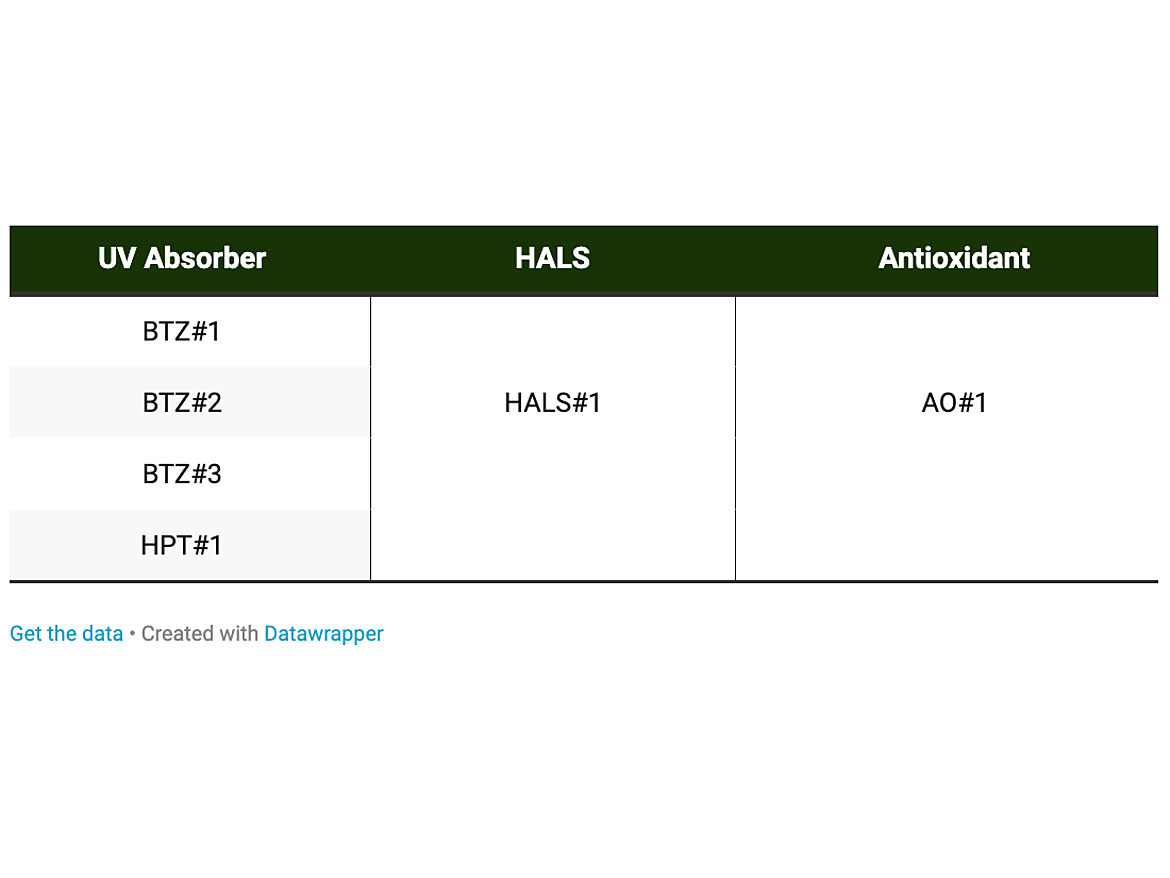

The study includes a performance comparison of three benzotriazole (BTZ) and one hydroxyphenyl triazine (HPT) UV absorber as well as the combined effects at various HALS ratios and with an additional antioxidant. Added stabilizers are listed in Table 2 and their dosage is given in the following figures, expressed as wt. % based on resin.

Results

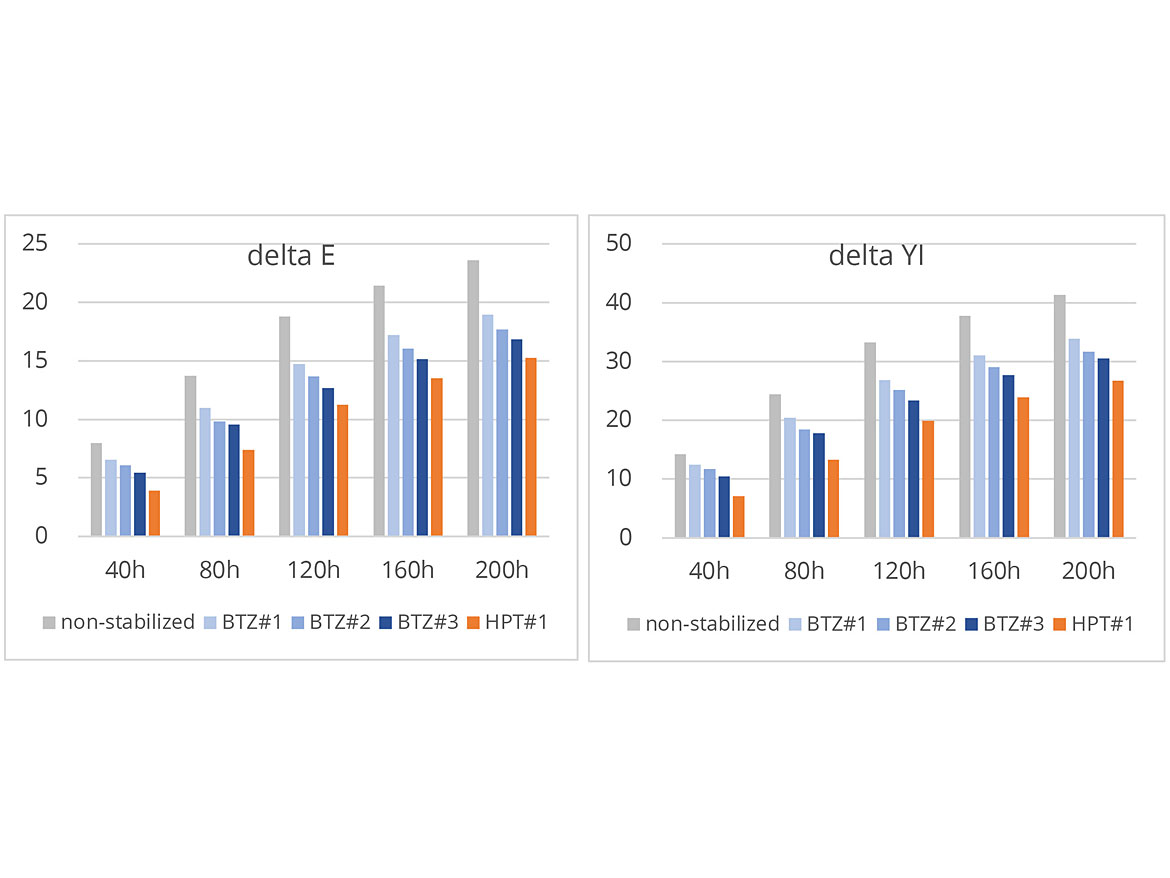

Figure 3 shows ΔE color change and ΔYI results over an aging period of 200 hours. All three benzotriazole UVAs show a positive effect on the light stabilization of the epoxy coating. The hydroxyphenyl triazine UVA outperforms the BTZ materials by at least 4 ΔYI units. HPT#1 shows a lower color difference of 8 ΔE units than the non-stabilized formulation.

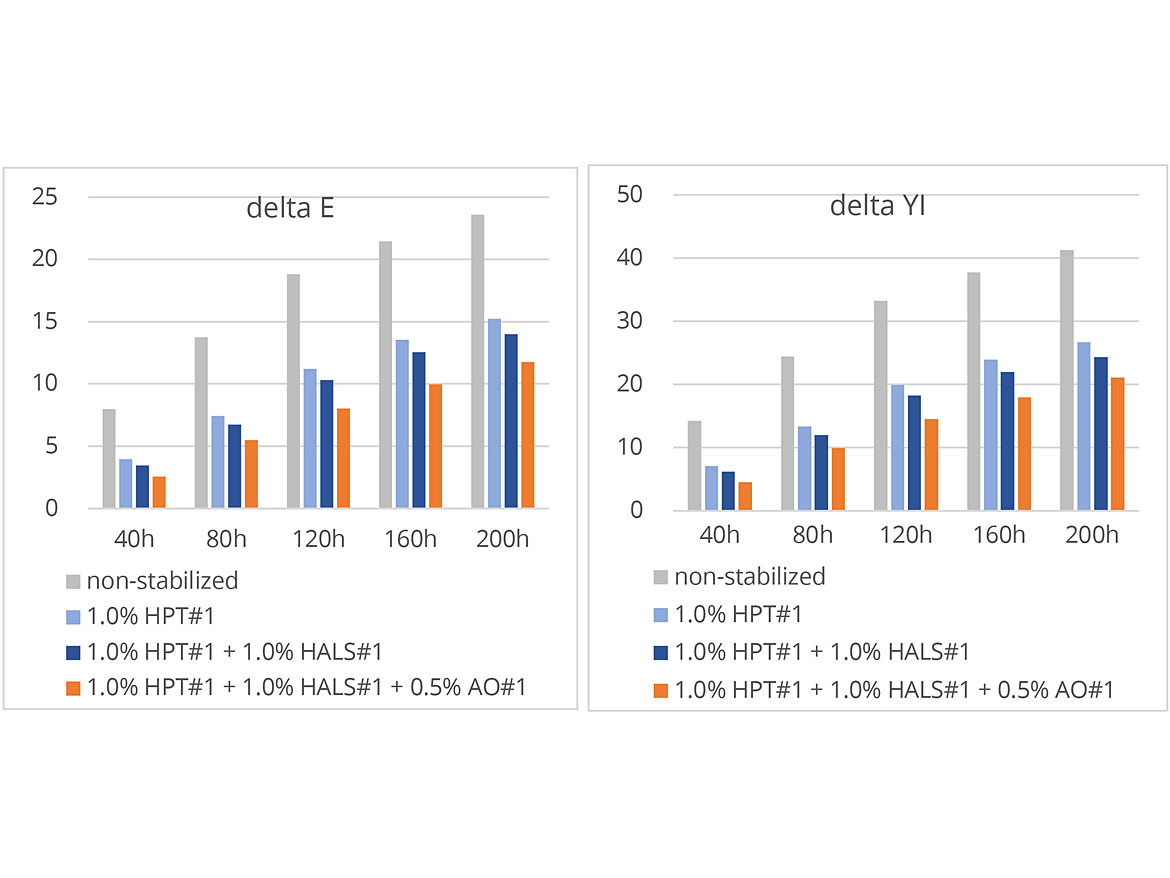

The HPT#1-containing coating was further modified with a HALS and an antioxidant. The aging results are shown in Figure 4. Both additions further improve the light stability of the epoxies. The formulation containing all three stabilizer chemistries results in a further ΔE reduction of 2.5 units. This combination shows ΔYI to be 20 units lower than the non-stabilized formulation.

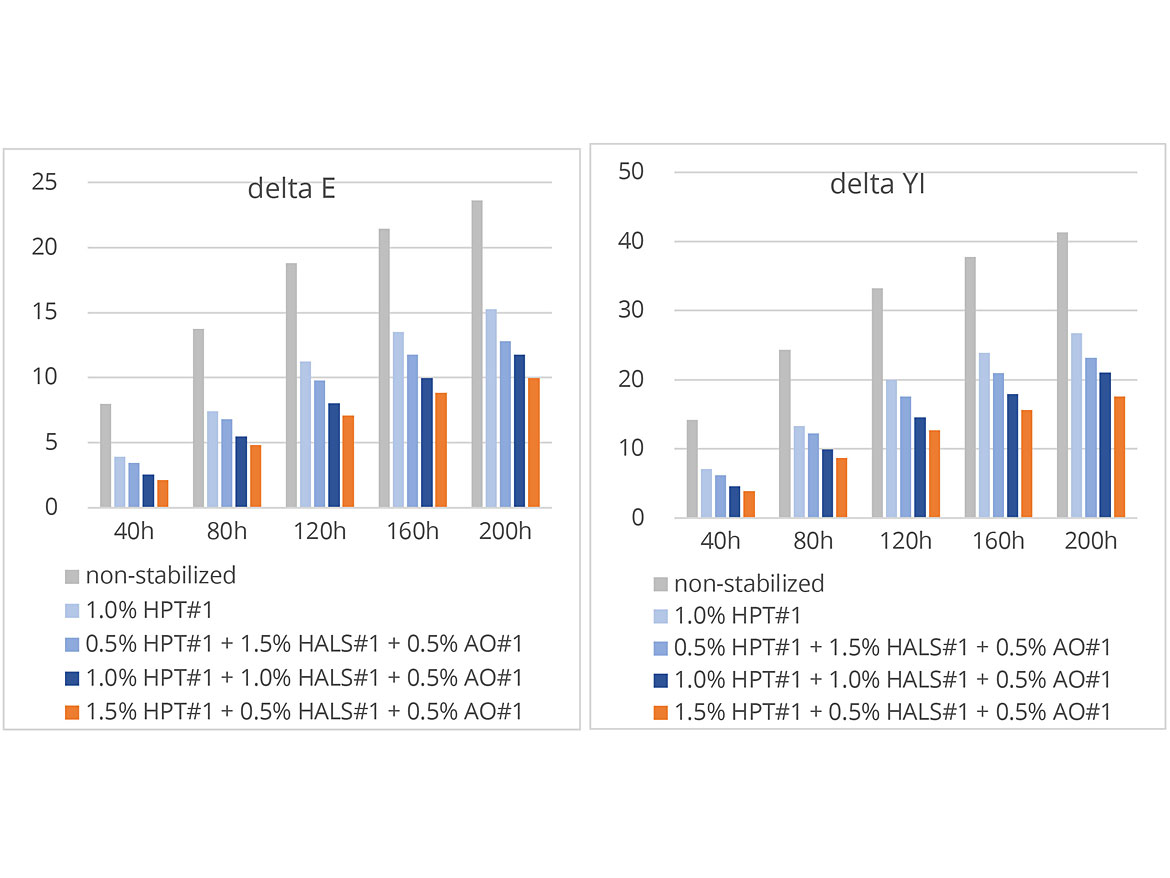

The effects on protection of varying UVA:HALS ratios are shown in Figure 5. Being a non-pigmented model coatings system, the 3:1 ratio of HPT#1 to HALS provides another approximately 2 ΔE-unit improvement, while keeping the overall stabilizer quantity constant.

Conclusion

Yellowing of epoxy coatings is caused by photo- and thermochemical oxidation. These degradation processes can also lead to deterioration of a coating’s physical and mechanical properties. The inherent tendency to discoloration of epoxy coatings can be minimized by suitable selection of preferably aliphatic amines or by initially setting the color of the system to yellowish or dark shades. For this reason, epoxy coatings are frequently top coated with more weather-resistant materials.

To respond more fundamentally, SONGWON’s stabilizers help to retard the degradation of epoxy coatings caused by both oxidation processes. The study shows that the combination of hydroxyphenyl triazine UV absorber, hindered amine light stabilizer (HALS) and phenolic antioxidant provides substantial benefits as regards discoloration. Optimization and adjustment of UVA:HALS ratio can further improve performance, depending on the specific characteristics of the epoxy coating. With light or white pigmented systems in particular, stabilizer combination and add-on quantity needs to be further balanced with a view to initial color.

For further information or technical support, contact coatings@songwon.com or visit www.songwon.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!