Lower Yellowing Epoxy System for Improved Sustainability of Concrete Coatings

via Getty Images.

Traditional Epoxy Floor Coatings

Epoxy floor coatings offer superior protection for concrete and metal substrates. Superior performance properties like high chemical resistance, superior adhesion, and well-balanced mechanical properties make epoxy coatings more sustainable than other binder types like alkyds or polyesters due to their long-term service life.

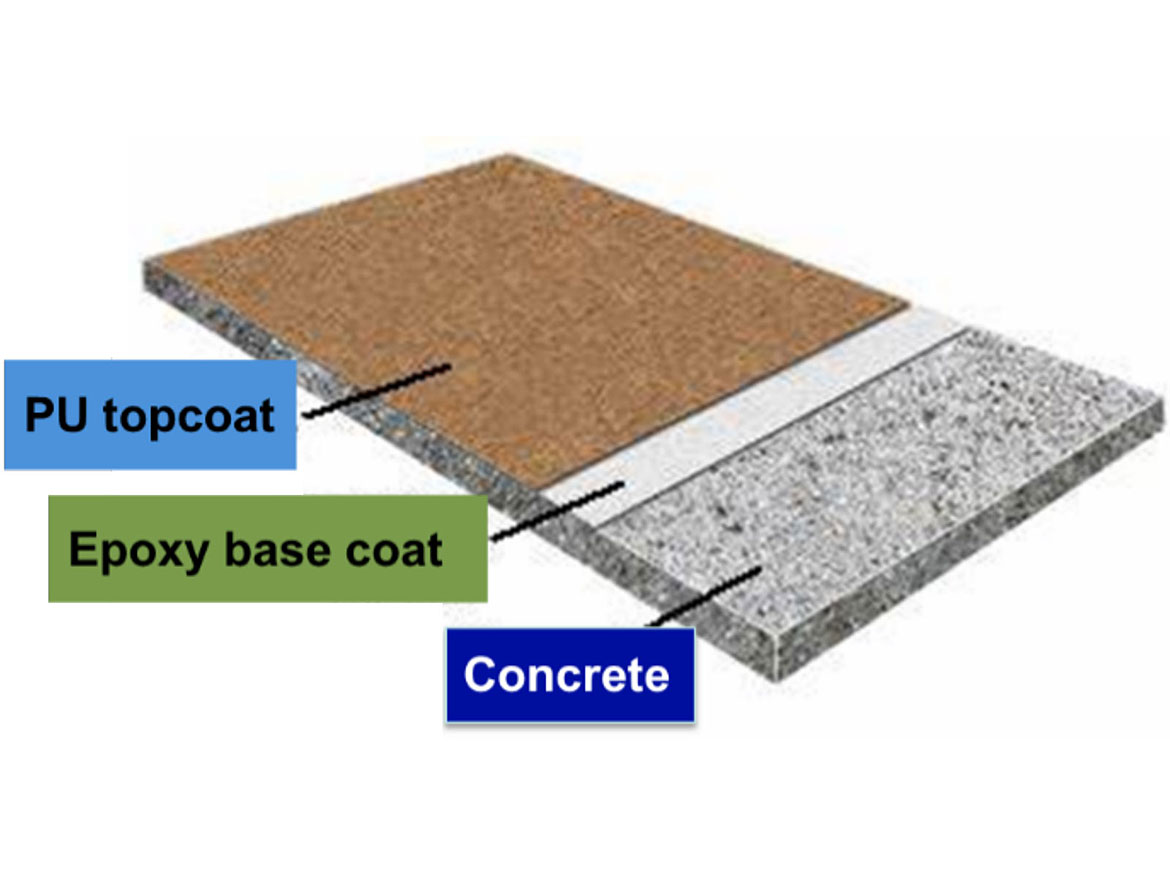

Floor coatings typically combine a liquid epoxy resin with a cycloaliphatic amine curing agent. To protect the epoxy layer, a polyurethane topcoat is added to create a multi-layer coating system.

A well-known limitation of standard epoxy coatings is that they turn yellow and lose their gloss when exposed to sunlight or strong indoor lights. To prevent yellowing, a protective topcoat is applied to create a multi-layer coating system. The downside of using a multi-layer system is that it leads to increased paint use, higher labor costs, and longer down time.

Recognizing this limitation, the Westlake Epoxy experts set out to develop a lower yellowing epoxy system that would be suitable for use as a single-layer coating system, while keeping the same superior performance of a multi-layer system.

Lower Yellowing Epoxy System (LY System)

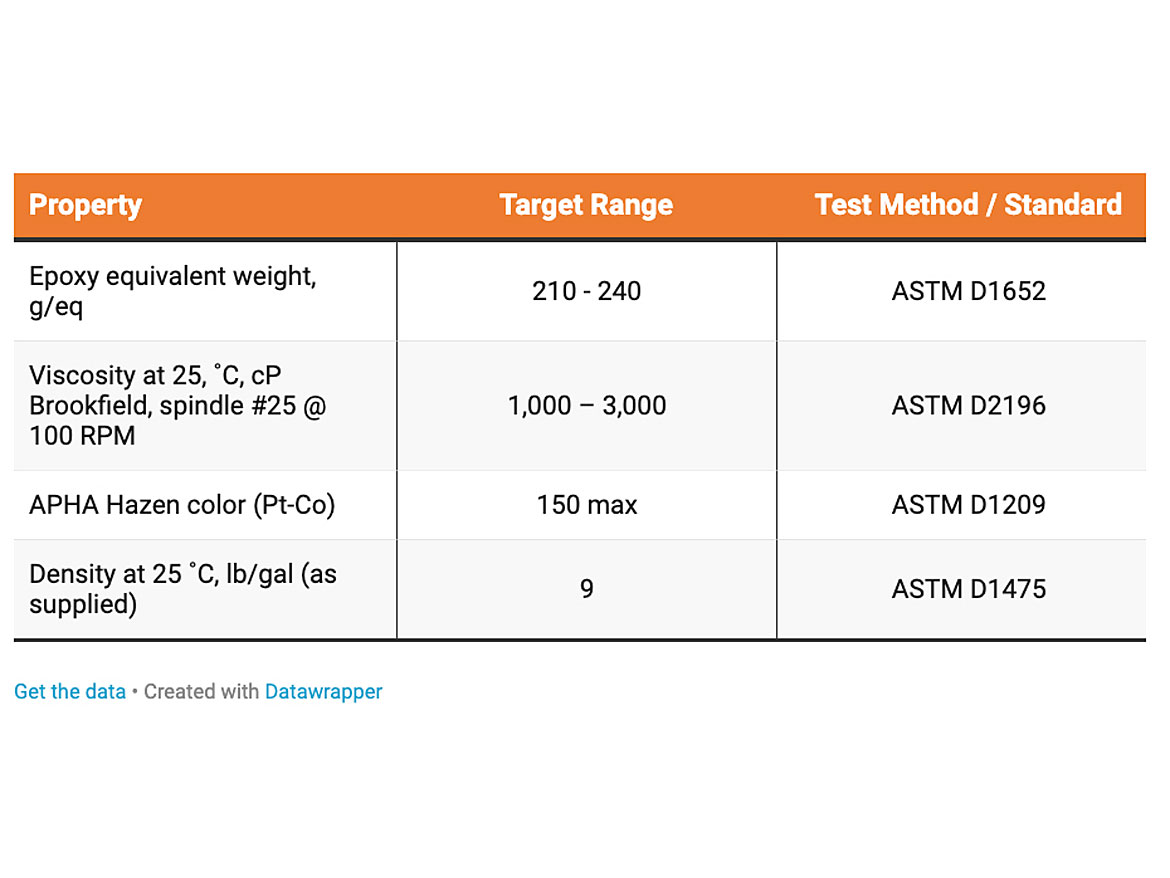

The LY epoxy system uses traditional epoxy / amine chemistry with a solvent-free liquid epoxy resin and a modified cycloaliphatic amine curing agent. The LY epoxy resin is a solvent-free, modified aliphatic epoxy resin that offers lower yellowing and faster cure than alternative aliphatic epoxy resins (e.g., the diglycidyl ether of hydrogenated BPA, aka, EPONEX™ Resin 1510). The properties of this LY epoxy resin are summarized in Table 1.

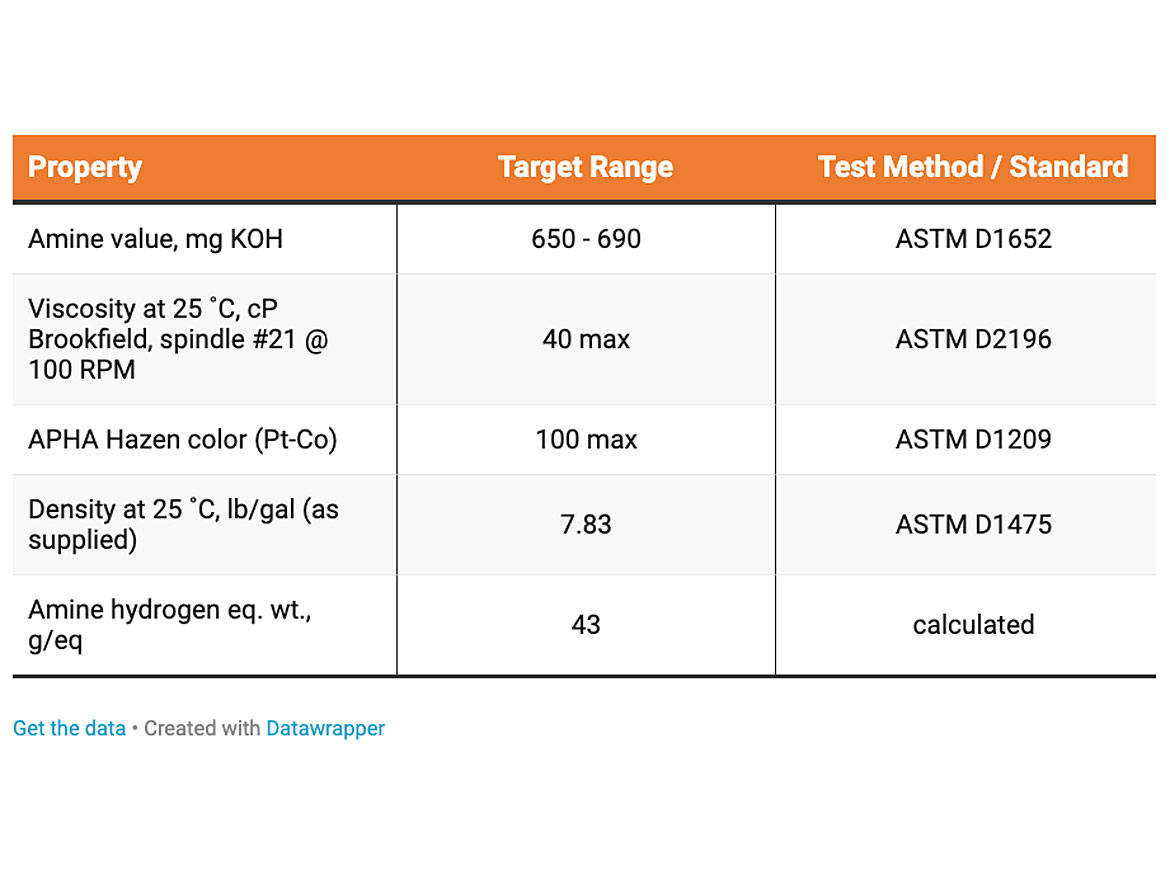

The LY curing agent is a solvent-free, modified cycloaliphatic amine that offers lower yellowing, faster cure, and good surface appearance. The properties of this LY amine curing agent are summarized in Table 2.

For balanced performance and superior compatibility, it is recommended that the LY epoxy resin and LY curing agent should be used together for the formulation of higher performance epoxy concrete coatings. This combination of LY resin and curing agent is known as the INFINIUM™ epoxy system.

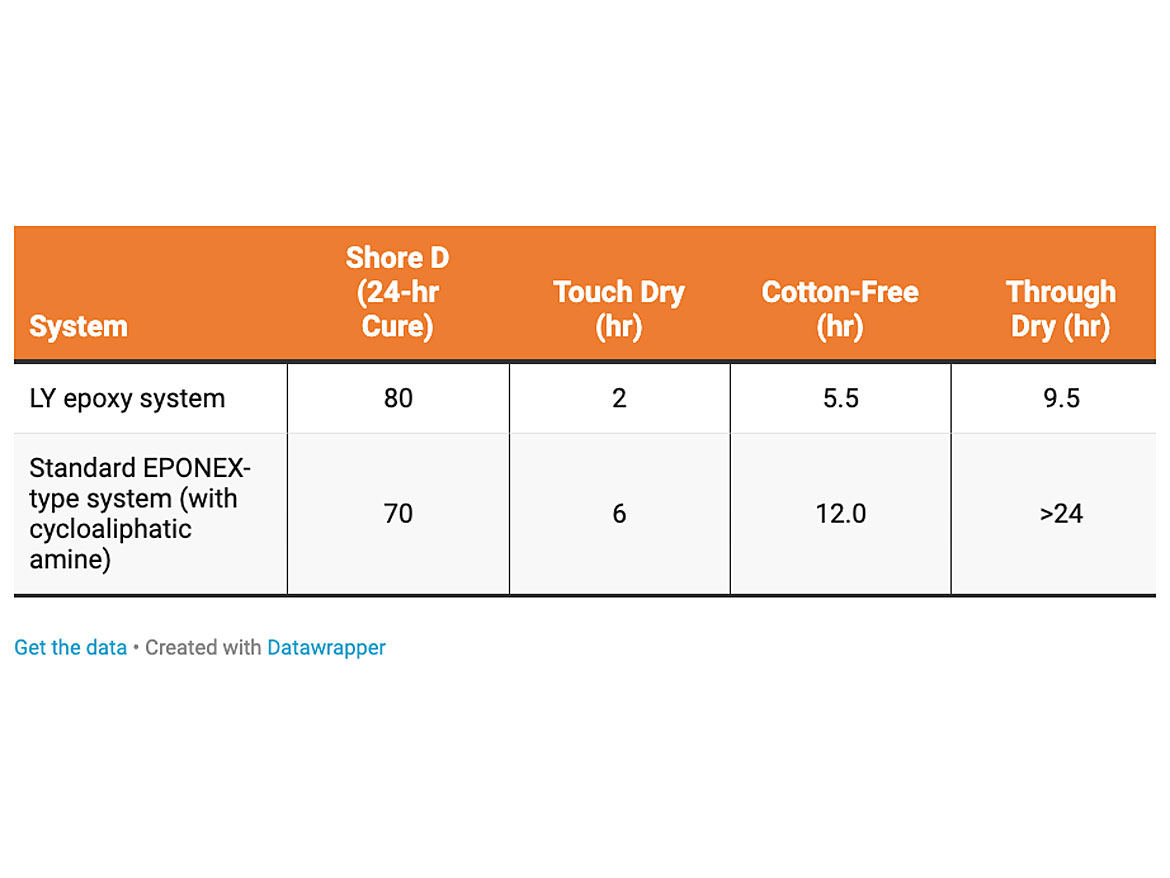

To illustrate the advantages of this LY epoxy system, we compared the performance of a traditional cycloaliphatic epoxy resin (DGE-HBPA) with a standard cycloaliphatic amine curing agent (e.g., EK3378) using a basic clear enamel starting point formulation. The results are summarized in Table 3. The LY epoxy system has improved 24-hour shore D hardness and significantly faster dry times.

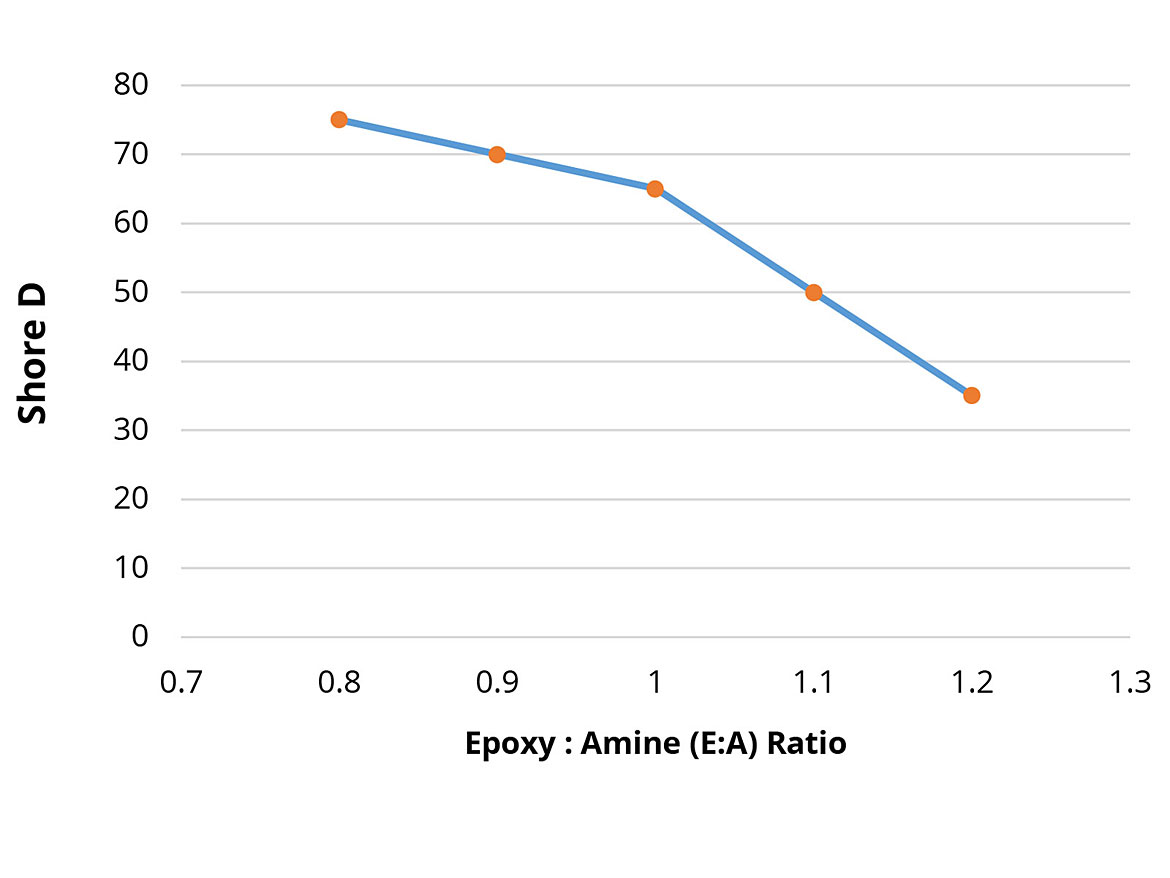

We investigated the effect of epoxy to amine equivalent ratio (stoichiometry) on the overnight (16-hr) shore D hardness. The results are shown in Figure 2, and based on these results, the recommendation is to use an E/A ratio of 0.9:1 or 1:1 ratio.

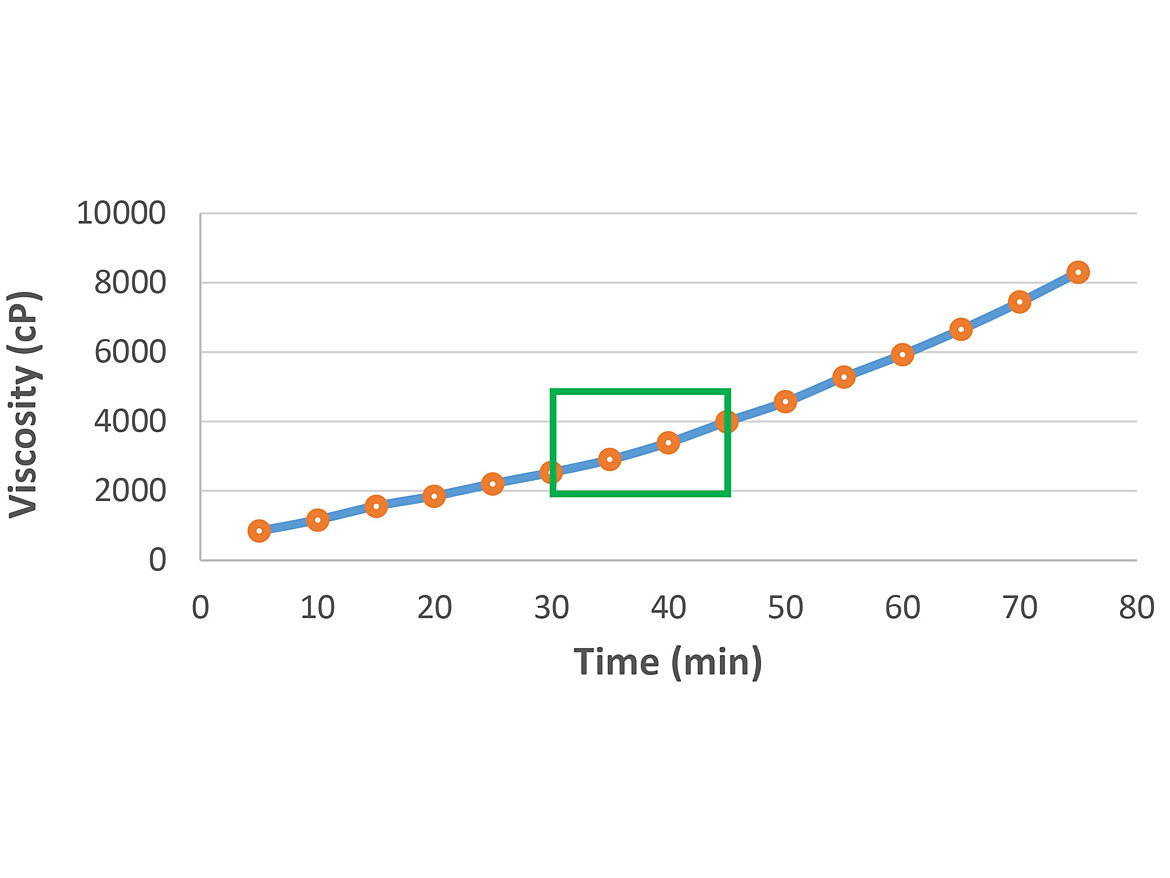

Using a stoichiometric ratio of 0.9 to 1 E:A ratio, the pot life of this clear enamel was determined to be 30 to 45 minutes for ease of application. The recommendation is to mix small quantities of Components A (epoxy side) and B (curing agent side) for 5 minutes, and then dump out on the floor. Spread evenly with stipple roller or squeegee. The mix viscosity of the clear enamel versus time is shown in Figure 3.

The next step was to compare the performance of the LY epoxy system in a simplified white enamel to a standard epoxy system that is used for floor coatings. The standard epoxy was an EEW 190 resin (DGE of BPA) that is modified with a mono-functional reactive diluent. This standard epoxy resin was mixed with a formulated cycloaliphatic amine hardener. The specific materials used were EPON 8132 with EPIKURE 3388. The white enamel is shown in Table 4.

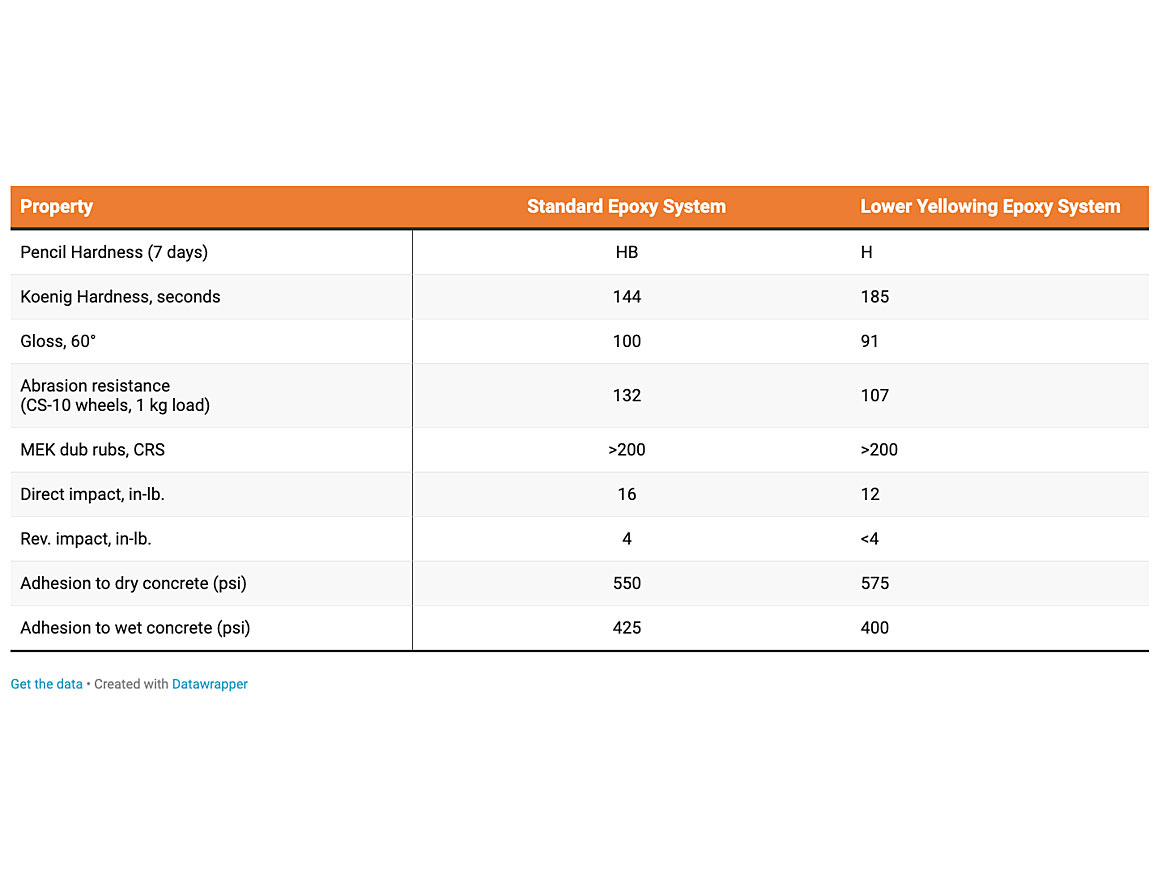

The comparison of performance results is summarized in Table 5. For this side-by-side testing, the clear films were applied to 3-4 mils DFT on smooth cold rolled steel (CRS – Q-panels). After application by drawdown bar, the coatings were cured for 7 days at a constant temperature, constant humidity lab (25 °C, 50% R.H.). The key advantages of the LY epoxy system are improved hardness (pencil and Koenig) and better abrasion resistance. Impact resistance and adhesion to wet and dry concrete are equivalent between the two systems evaluated in this study.

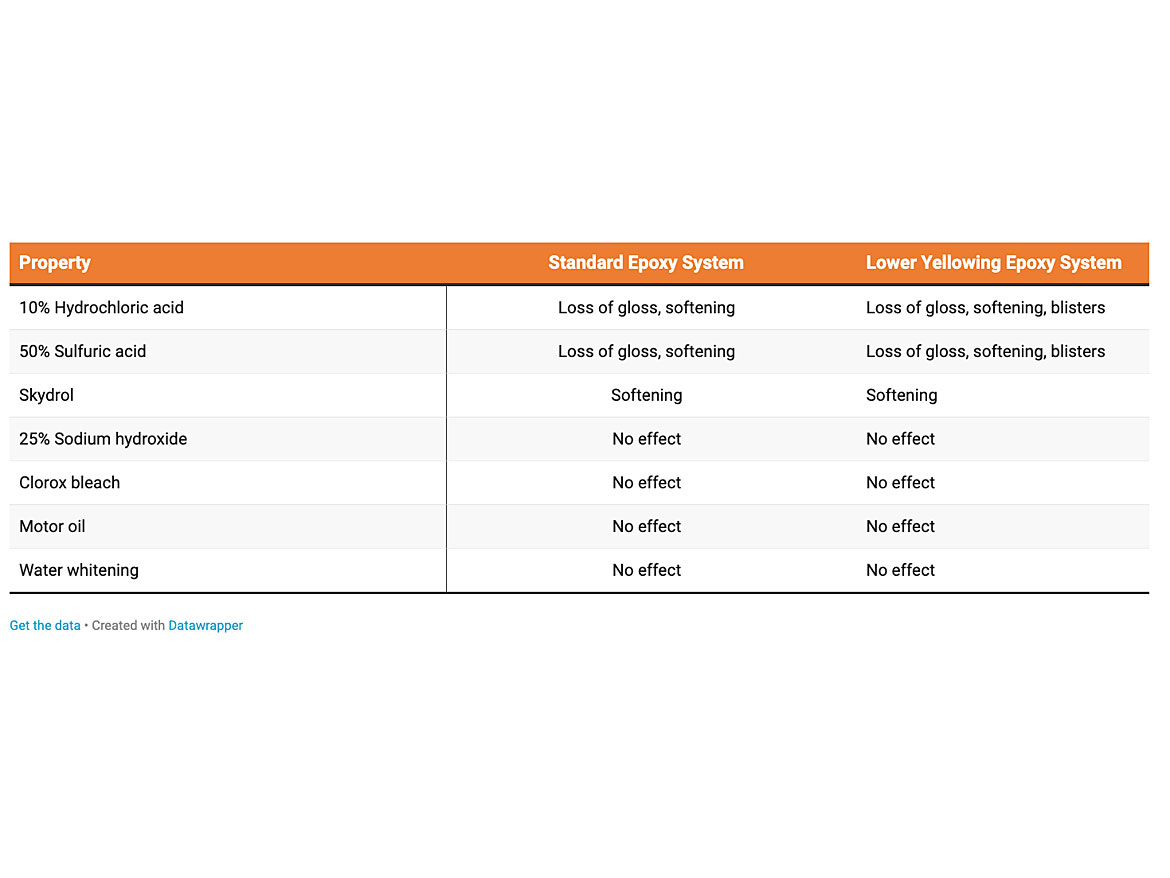

In flooring applications, epoxy systems are valued for their high chemical resistance. A comparison of the resistance to a variety of chemicals is summarized in Table 6. These tests were conducted after 7 days cure using ASTD D1308. This chemical resistance test method is conducted by soaking pieces of felt in each individual chemical, and then placing the saturated felt onto the coating surface. A watch glass is then used to cover the felt and it is sealed with paraffin wax along the edges to prevent the chemicals from evaporating during the testing exposure of 24 hours.

The results show that the LY epoxy system offers nearly equivalent chemical resistance to a standard epoxy system for flooring applications, however, there is somewhat reduced acid resistance.

When this lower yellowing epoxy system (LY epoxy) is formulated into a solvent-free coating, then a coatings applicator saves time, reduces material waste, and saves money. These benefits are the reason that a single-layer coating system is more sustainable than a multi-layer system.

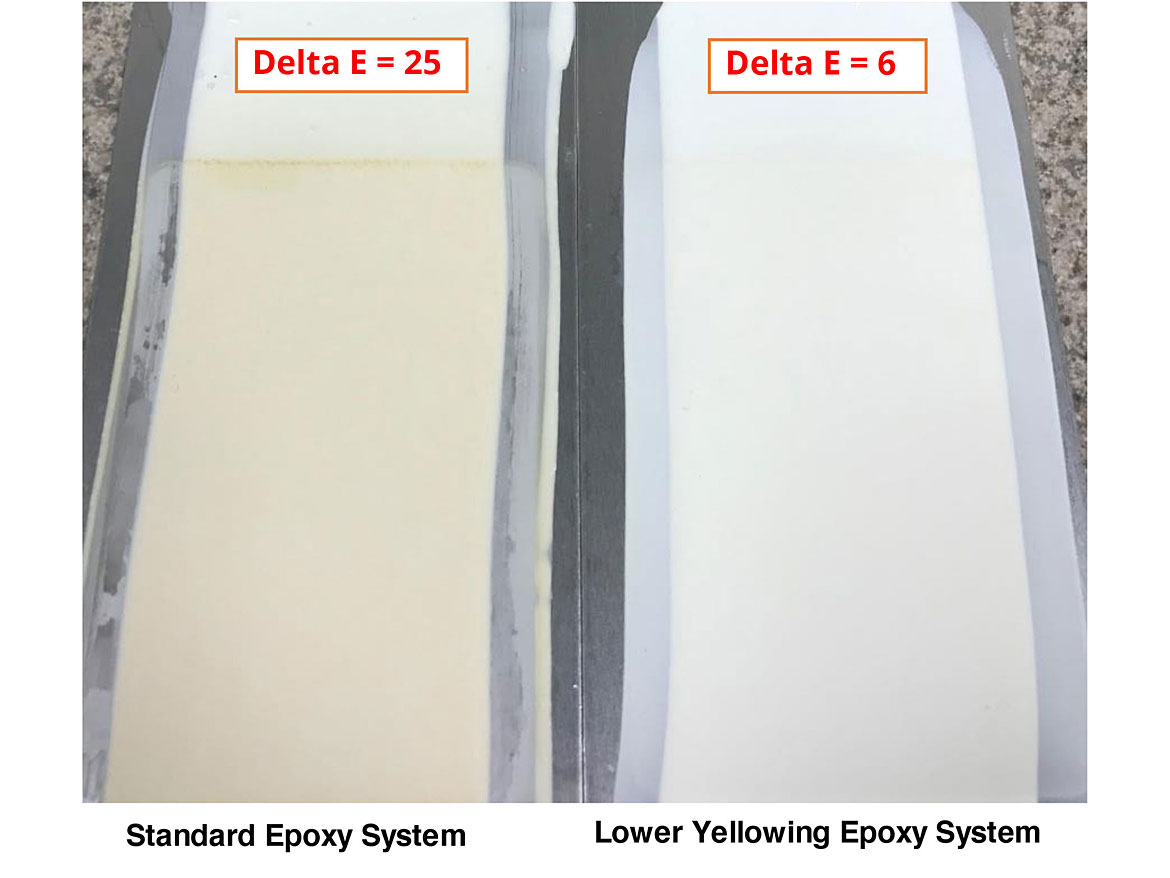

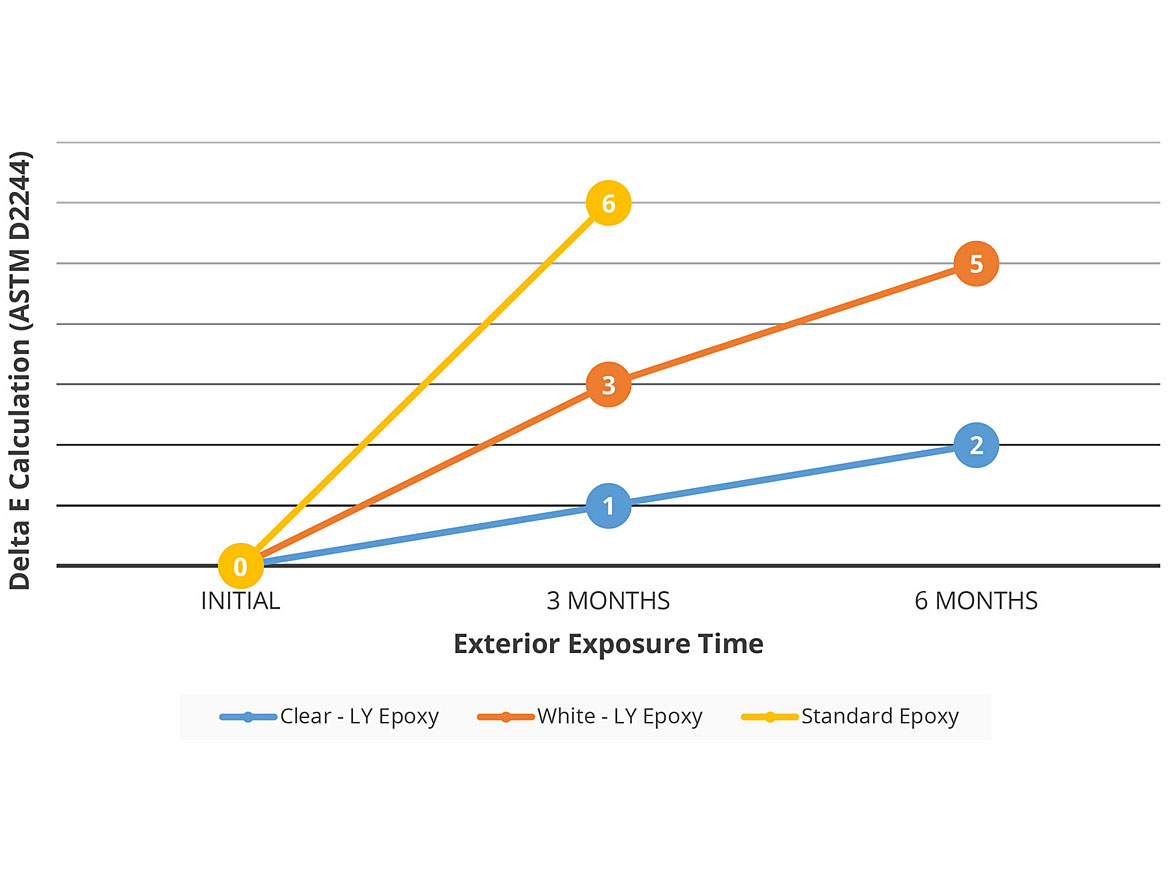

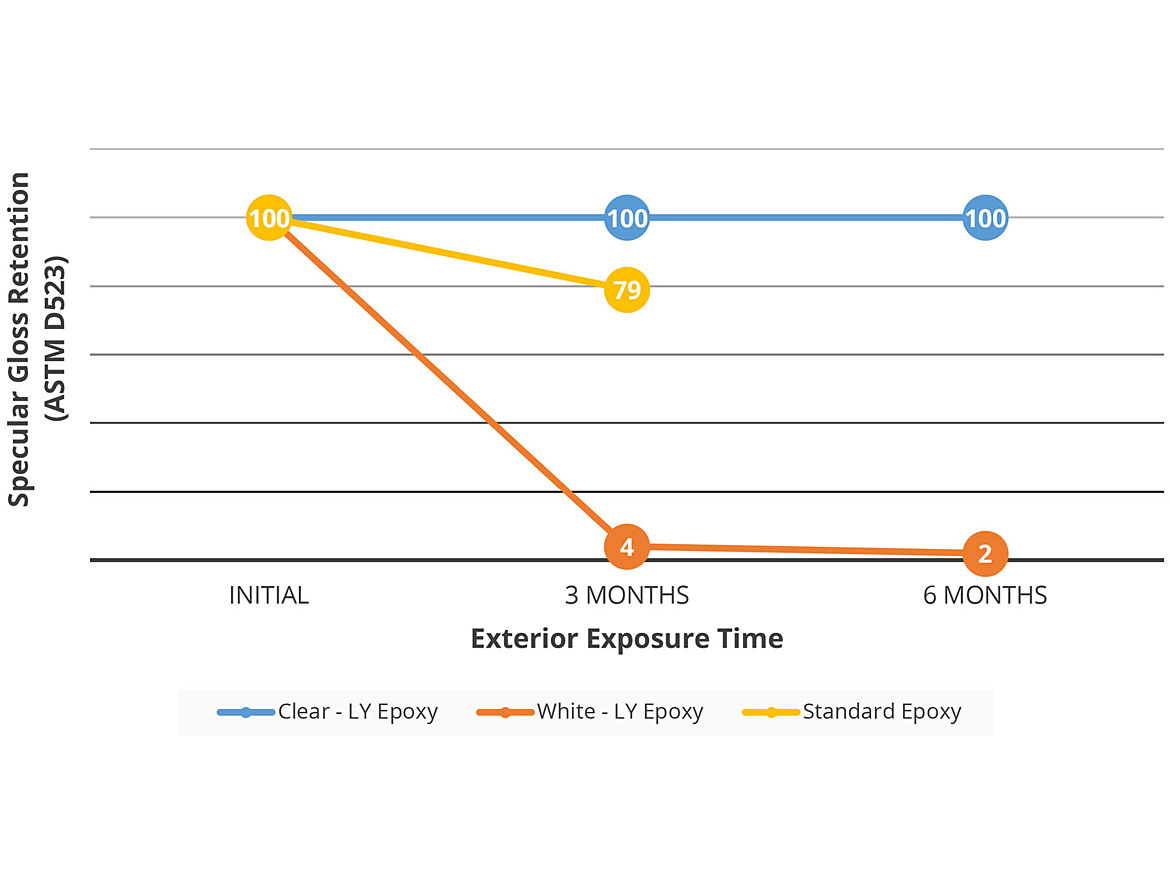

After demonstrating that the new LY epoxy system offers epoxy performance that is suitable for epoxy floor coatings, the next key performance evaluation was to determine the yellowing resistance of the various systems. The two epoxy systems were evaluated in accelerated QUV-A (ASTM G154, Cycle 1). The results are shown in Figures 4 and 5.

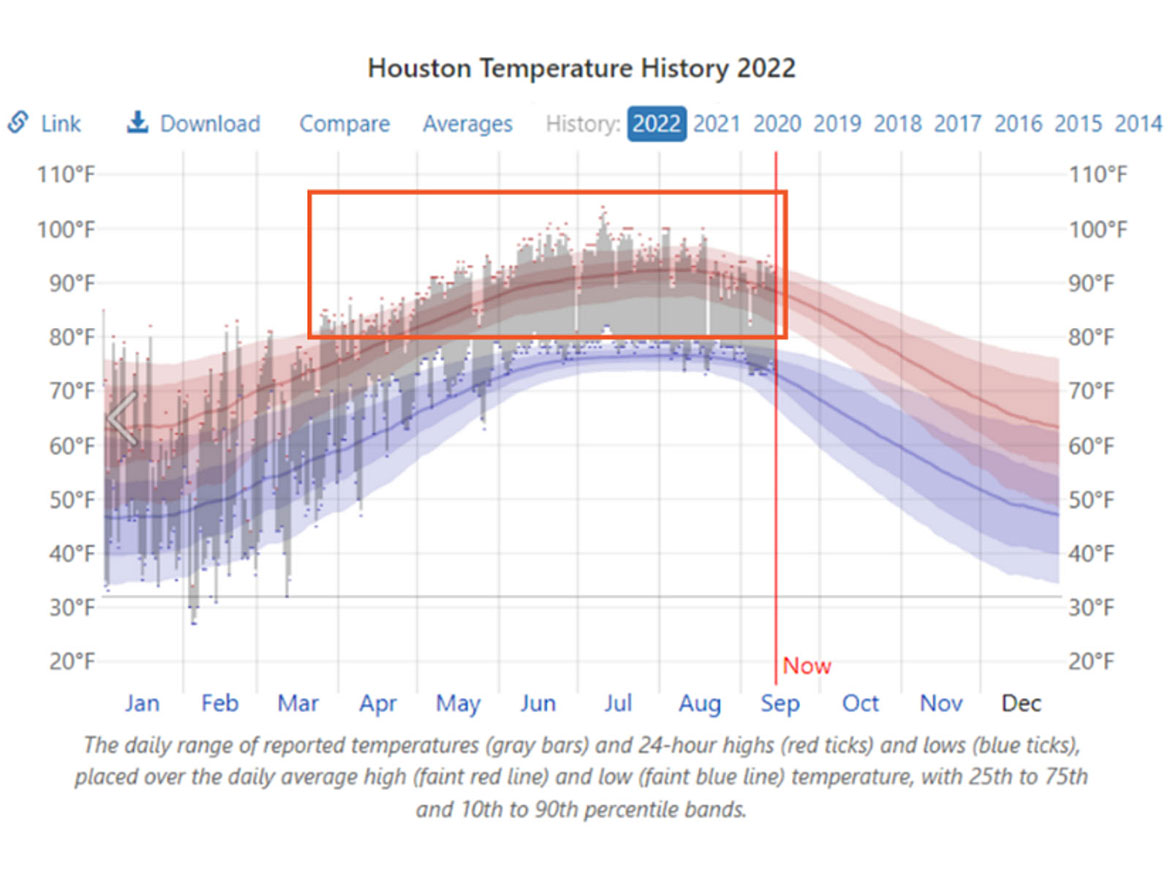

To determine if the LY epoxy system might be suitable for exterior use, these two epoxy systems, as well as a clear version of the LY epoxy system, were placed on a southern-facing exterior testing fence in the greater Houston area. Figure 6 shows that for the six months period between March and August 2022, there were a significant number of hot, sunny days (>30 total) that were above the 90th percentile of the typical temperature historical range. So, the weathering results shown in Figures 7 and 8 were caused by a significant amount of intense sunlight exposure.

Based on the exterior testing results, the clear formulation of the LY epoxy system performed extremely well in that after 6 months of exterior testing, the Delta E was only 2 units, and the gloss retention was 100%. Exterior testing will continue for another 6 months on the test fence. The white enamel formulation used for the testing fence study was modified with some wetting and dispersing additives, however, the significant gloss reduction shows that further optimization work is needed.

Conclusions

Based on this study, we find that a lower yellowing (LY) epoxy system can be used as a single-layer coating system to replace a traditional two-coat system (epoxy primer / polyurethane topcoat) for protection of concrete substrates. This single-layer coating saves time for the applicator because it eliminates the topcoat layer. A standard epoxy coating layer can require up to 24 hours to achieve cure so that the topcoat layer can be applied to the floor. The LY epoxy system has significantly faster dry times (only 10 hours), enabling faster return to service; saving 60% of the overall drying time.

Solvent-free epoxy coatings based on this LY epoxy system are potentially suitable for applications ranging from floor coatings for warehouses, automotive or aerospace hangers, as well as bar or countertop coatings.

A critical aspect of this unique epoxy system is that it has significantly better yellowing resistance and gloss retention than a standard Bis-A epoxy system even when combined with a lower yellowing cycloaliphatic amine. This improved yellowing resistance means that a discrete topcoat layer can be eliminated from the application. This improves worker safety by avoiding potential exposure to isocyanate monomer and eliminates the amount of material, time, and energy used to manufacture and transport the topcoat. Therefore, the Scope 1 and Scope 2 carbon dioxide emissions from the topcoat are eliminated by using this single-layer coating approach.

Most importantly, when compared side-by-side with a traditional epoxy system, the lower yellowing (LY) epoxy system provides the typical performance expected from an epoxy floor coating system. It offers superior hardness and abrasion resistance, while at the same time, offering comparable adhesion to wet or dry concrete and equivalent chemical resistance.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!