Pioneering Coating Additives for a Greener Future

alvarez, E+, via Getty Images

Reducing the CO2 footprint, using renewable raw materials, and addressing microplastic pollution through biodegradable products are key considerations in the industry. MÜNZING shares high sustainability goals and provides a comprehensive portfolio of green additives to support paint manufacturers in achieving their objectives, without compromising performance.

This endeavor requires the discovery and utilization of new raw materials and technologies, presenting an opportunity to develop products with unique properties not previously explored in the sector. The challenge lies in creating sustainable formulations that match or exceed the performance of standard fossil additives.

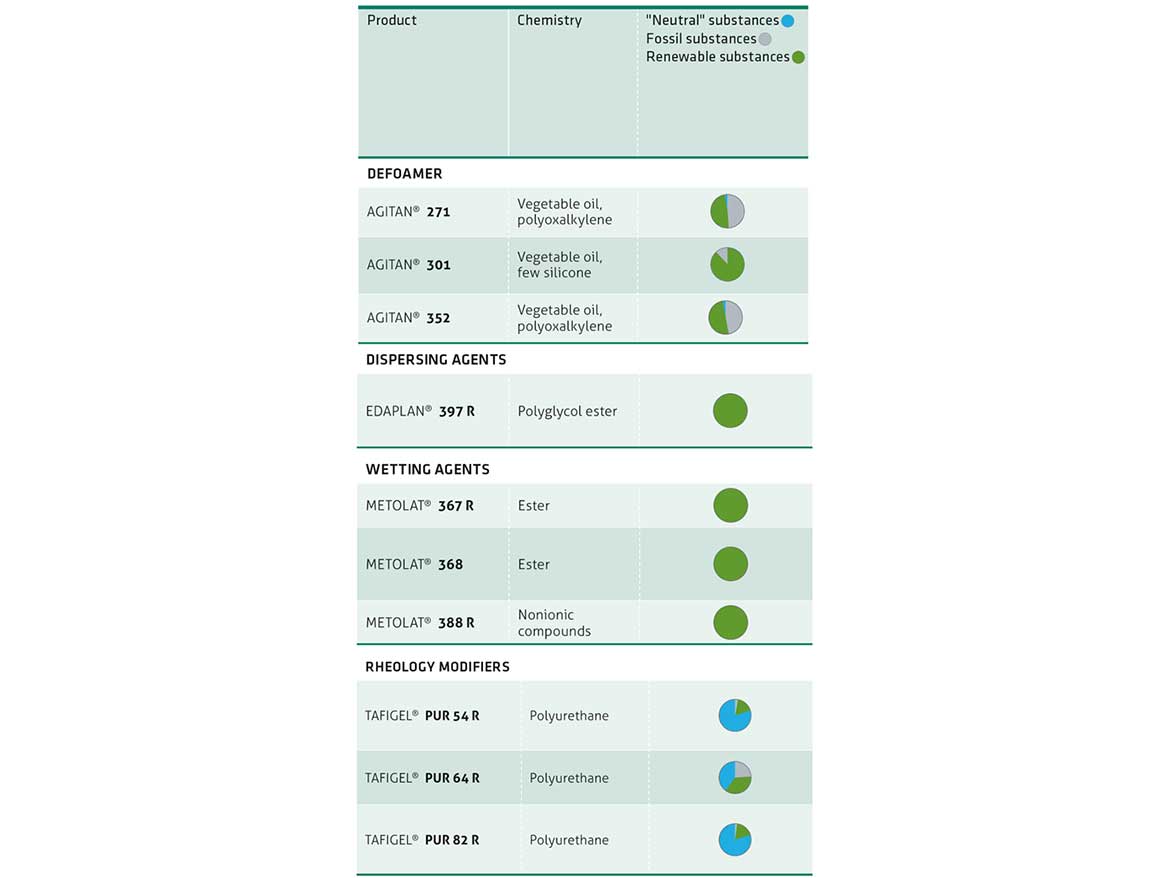

Our additive development focuses on two primary green parameters. Firstly, the renewable fraction is determined by ASTM D 6866 and indicated in the product composition. By utilizing renewable feedstock, we reduce dependence on finite fossil sources while benefiting from the CO2 absorption and energy-efficient synthesis of renewable raw materials. As a result, renewable products exhibit a significantly lower CO2 footprint compared to their fossil-based counterparts.

Secondly, we prioritize biodegradability according to OECD guidelines, addressing the growing concern surrounding microplastics. While coatings typically aim for long-lasting protection, there are applications where rapid degradability is desired, such as disposable packaging materials. We consider specific conditions under which biodegradation occurs, ensuring compatibility with the environment.

Furthermore, our company continually evaluates and incorporates additional green parameters into our internal guidelines for the development of environmentally friendly products.

By embracing sustainability and pushing the boundaries of innovation, we aim to contribute to a greener future for the coatings industry, while maintaining a focus on performance excellence.

Chemistry and Research Efforts

Our research focuses on utilizing renewable raw materials across the entire spectrum of additive synthesis. For instance, petroleum-based polyols typically used in thickeners are being replaced with renewable polyols derived from renewable feedstocks. By incorporating these renewable polyols into the polymeric backbone, we can replace up to 100% of the fossil fuel-derived polyols, achieving desired rheological properties through careful control of stoichiometry and reaction conditions.

In the realm of dispersants, our emphasis lies in incorporating renewable feedstocks into our synthesis processes. We have explored the use of biopolymers as potential drop-in solutions for conventional dispersants. These renewable polymers exhibit excellent adsorption onto pigment surfaces, providing stability and preventing agglomeration.

The chemistry involved in this development includes the modification of biopolymers through derivatization or grafting of functional groups onto their backbone. This modification enhances the dispersing capability by creating hydrophilic and hydrophobic regions, facilitating effective adsorption onto pigment particles. By precisely controlling the degree of substitution and molecular weight of the renewable dispersants, we can optimize their dispersing efficiency and compatibility with various paint and coatings systems.

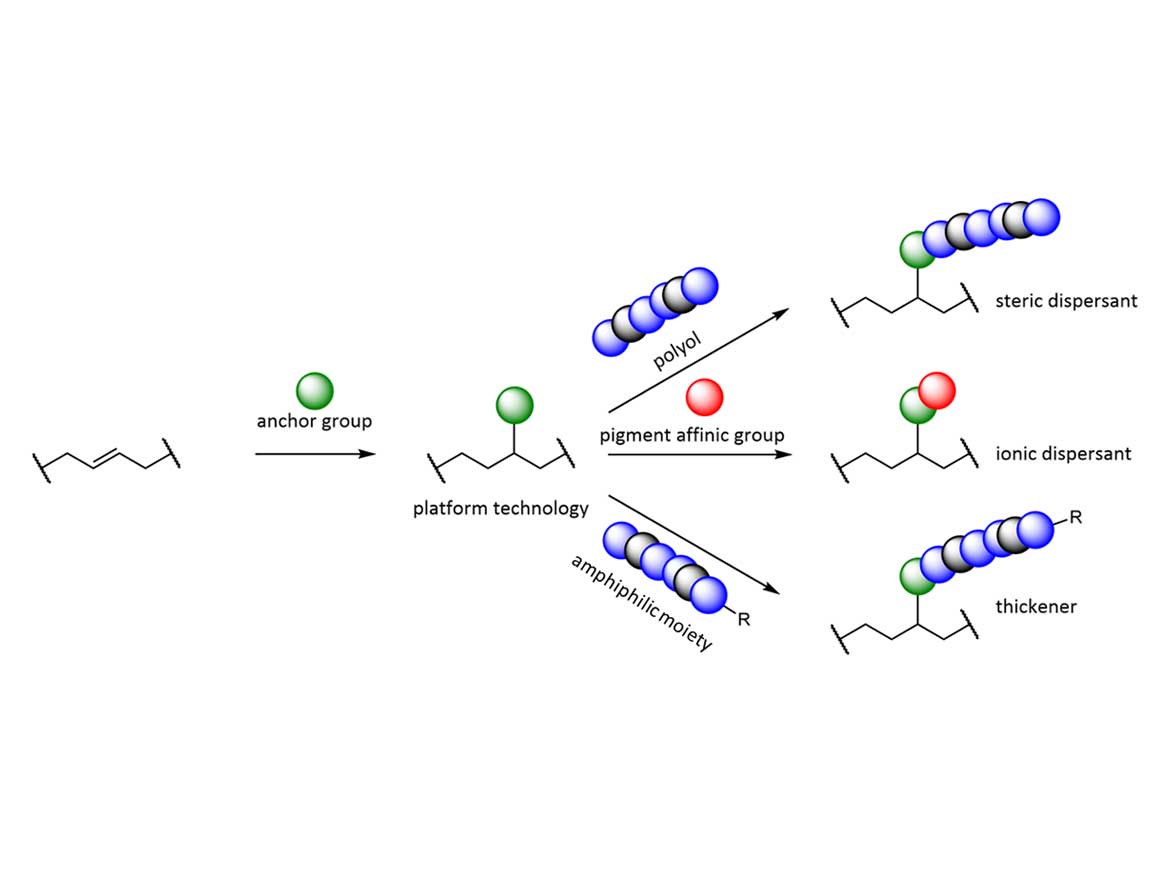

In addition to drop-in solutions, our research efforts are dedicated to the development of specialized renewable products. These endeavors require the exploration and establishment of new technologies. Modification of double bonds stands as one of our primary focus areas in this regard. Here, starting from renewable backbone polymers, a platform technology is accessible, which can be used to address multiple additive technologies. However, this research area is still in its infant stages, and clearly more effort needs to be invested before achieving high-quality products. The general rationale for this approach is represented in Figure 1.

To improve properties like matting, scratch resistance, and anti-blocking, waxes like PE-wax or FT waxes made from synthesis or fossil feedstock are often in use. Our novel additives, mainly based on plant-based feedstock, are mostly biodegradable and provide similar coating properties through a special combination of plant-based materials and new technologies. For such coating effects, additive properties like particle size, melting point, hardness, and polarity are important factors. With our technology, it is possible to adjust similar properties, or to use new materials that influence properties like melting point and hardness in a positive way for the final application.

Paraffin emulsions are well known as strong hydrophobing agents for different systems. However, there are also some disadvantages. Paraffin is made of crude oil, which means it is based on fossil feedstock. The melting point of this material is usually 45-66 °C, which results in a soft surface and could lead to a problem with dirt pick up, especially in exterior applications in hot regions.

Our new technology, based on plant-based material, is from renewable feedstock. It shows a melting point of 75-85 °C, which makes it much harder, and results in less dirt pick up, as well as better mechanical resistance in the final application, while improving the hydrophobic effect.

Usually PE/paraffin emulsions are used in exterior heat-sensitive systems to increase the melting point, anti-blocking, and hardness of pure paraffin emulsions. Also, for such applications the new technology can be used as a sustainable alternative.

Wood Coating

Hydrophobing Agents

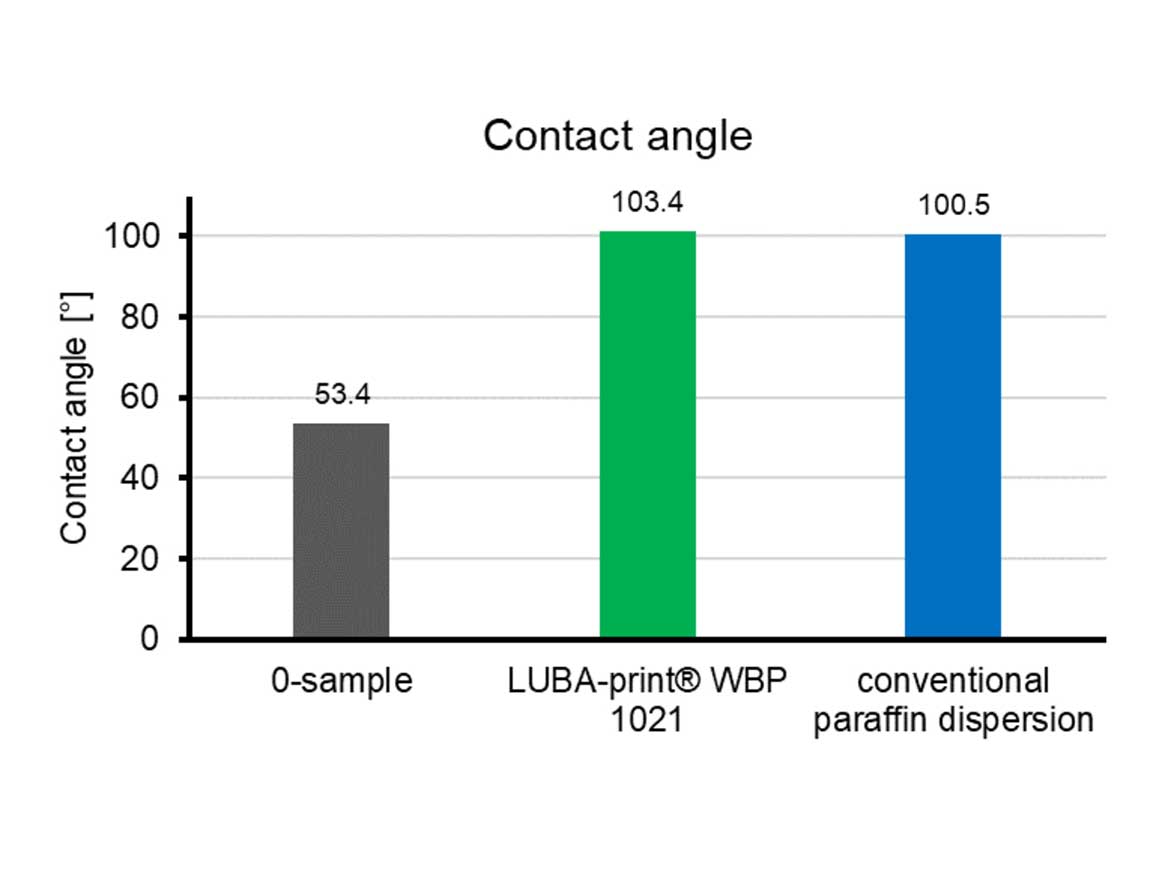

To assess the influence on the hydrophobic effect, the sustainable additive LUBA-print® WBP 1021 and a conventional paraffin emulsion were both incorporated with a dosage of 2% (calculated on solid content of the emulsion). The test system was a water-based clear wood coating system. After drying at room temperature, the coated substrates were put in the oven for 10 minutes at 60 °C to improve the hydrophobic effect, additionally. The determination of the hydrophobic effect was carried out by means of contact angle. The higher the values for the contact angle, the better the hydrophobic effect. It was found that both products improved the hydrophobic effect significantly. The contact angle of the additive samples was over 100°, whereas the blank sample was just at 53.4° (Figure 2). Due to the fine particle size of the emulsions, there was no impact on the gloss when adding those additives.

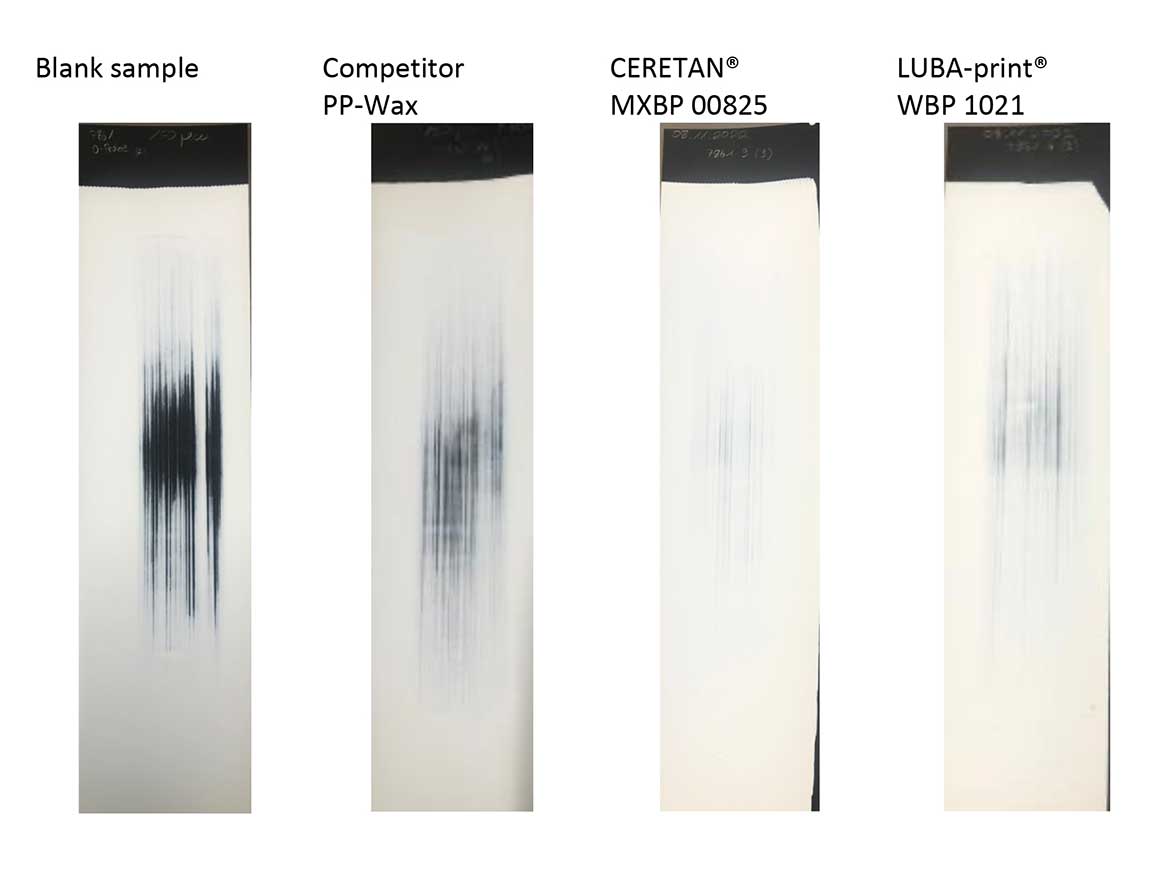

Slip, Scratch Resistance, Matting

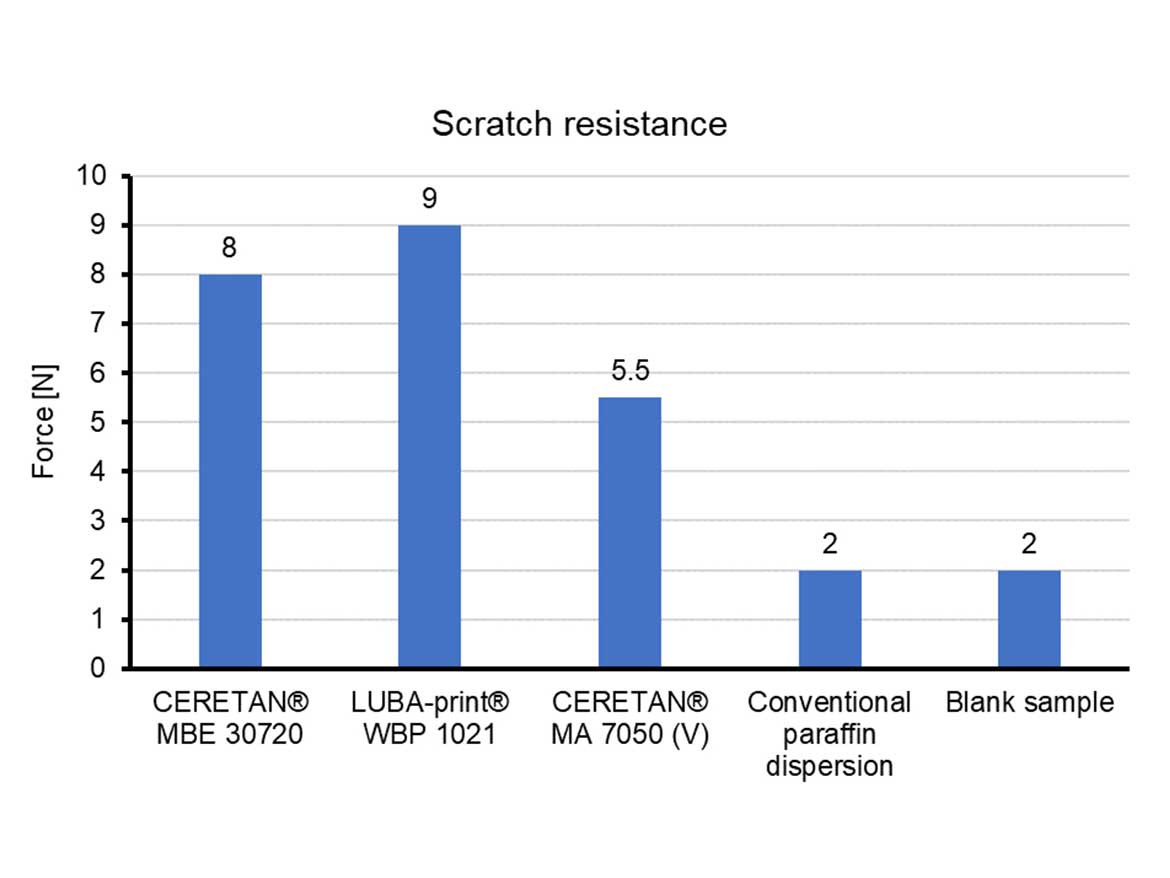

To test the performance of the sustainable products, 2% of the additive was incorporated in a clear wood coating formulation. The application was done with a bar coater with 100 µm wet film thickness on a PVC card. The coated substrates were conditioned at room temperature for two days before testing. Scratch resistance was determined with a linear tester. Here, scratches are applied with different forces. The value indicates the force required to scratch down to the substrate. It was found that all the waxes improved the scratch resistance of the surface significantly. The highest rating was 9 Newton (N), which was achieved with the LUBA-print WBP 1021, a product that was developed as paraffin alternative. Figure 3 shows that the conventional paraffin dispersion did not enhance the scratch resistance due to its rather soft characteristics. CERETAN® MBE 30720, a PE wax based on renewable raw material, increased the value to 8 N, and CERETANMA 7050 (V) to 5.5 N.

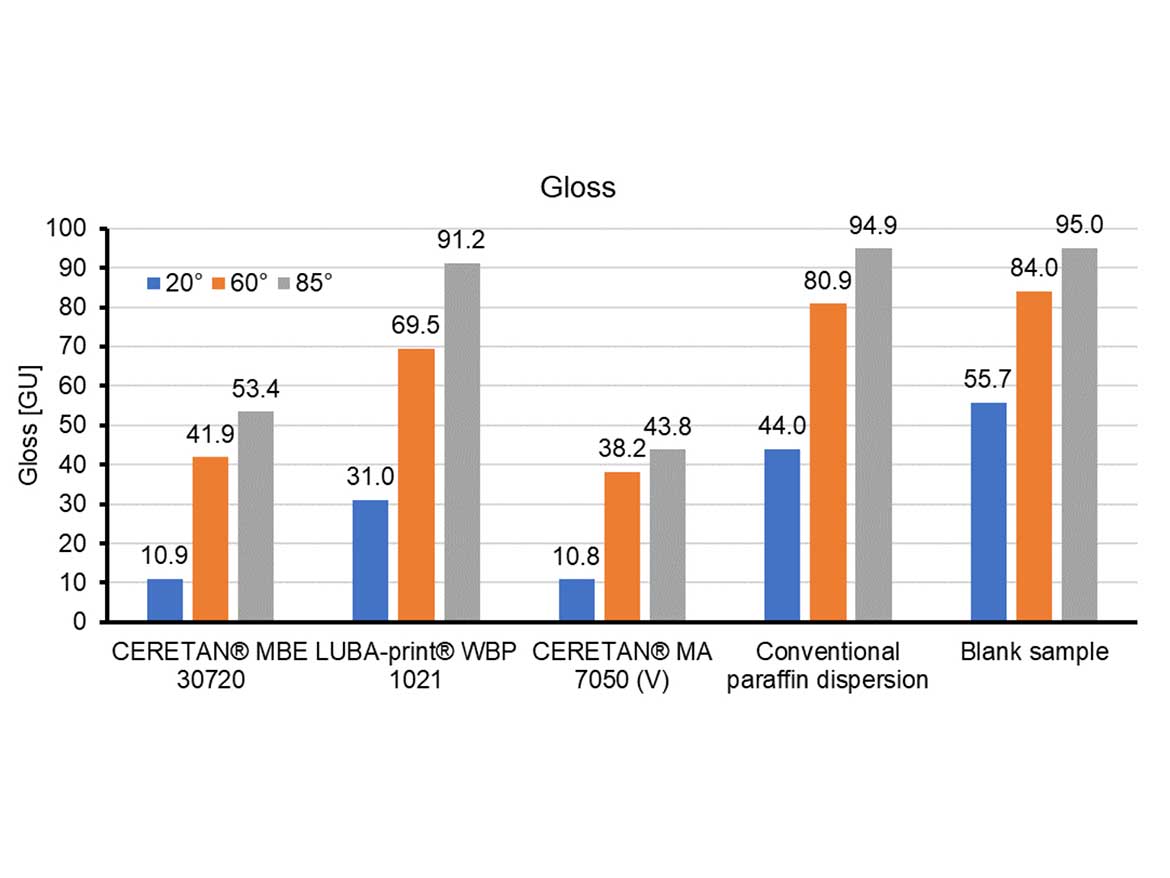

Depending on the particle size in relation to the film thickness, wax additives can also be used for matting effects. In Figure 4 it is visible that the CERETAN MA 7050 (V), which is an amide wax based on vegetable raw material, reached the strongest matting effect because of its dv99 < 50 µm. Due to particles protruding from the surface, diffuse light scattering occurs and results in matting effects.

LUBA-print WBP 1021 and the conventional paraffin dispersion show a very fine particle size due to the manufacturing in an emulsification process. Because of that there is nearly no influence on gloss.

Architectural Coating

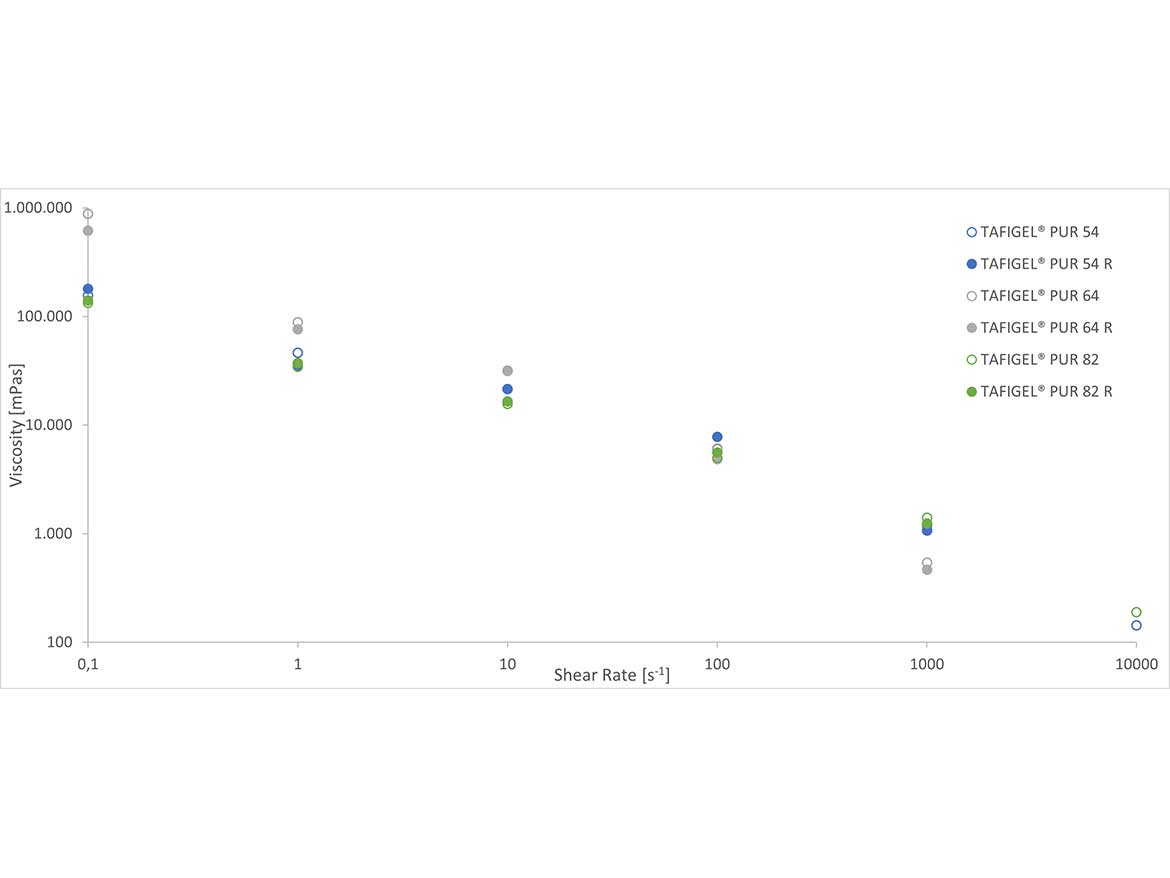

The initial step in substituting petro-based products with renewable alternatives involves replicating their desired characteristics. In this regard, our research endeavors have expanded to encompass multiple renewable products that closely emulate the performance of their petro-based counterparts. For instance, our range of renewable PUR thickeners exhibits rheological properties comparable to conventional products. These thickeners have undergone extensive testing in various formulations, including dispersion paints, coating applications, dispersion varnishes, and parquet varnishes, to gather their comprehensive rheological profiles. To illustrate, Figure 5 displays exemplary results obtained from a dispersion paint formulation.

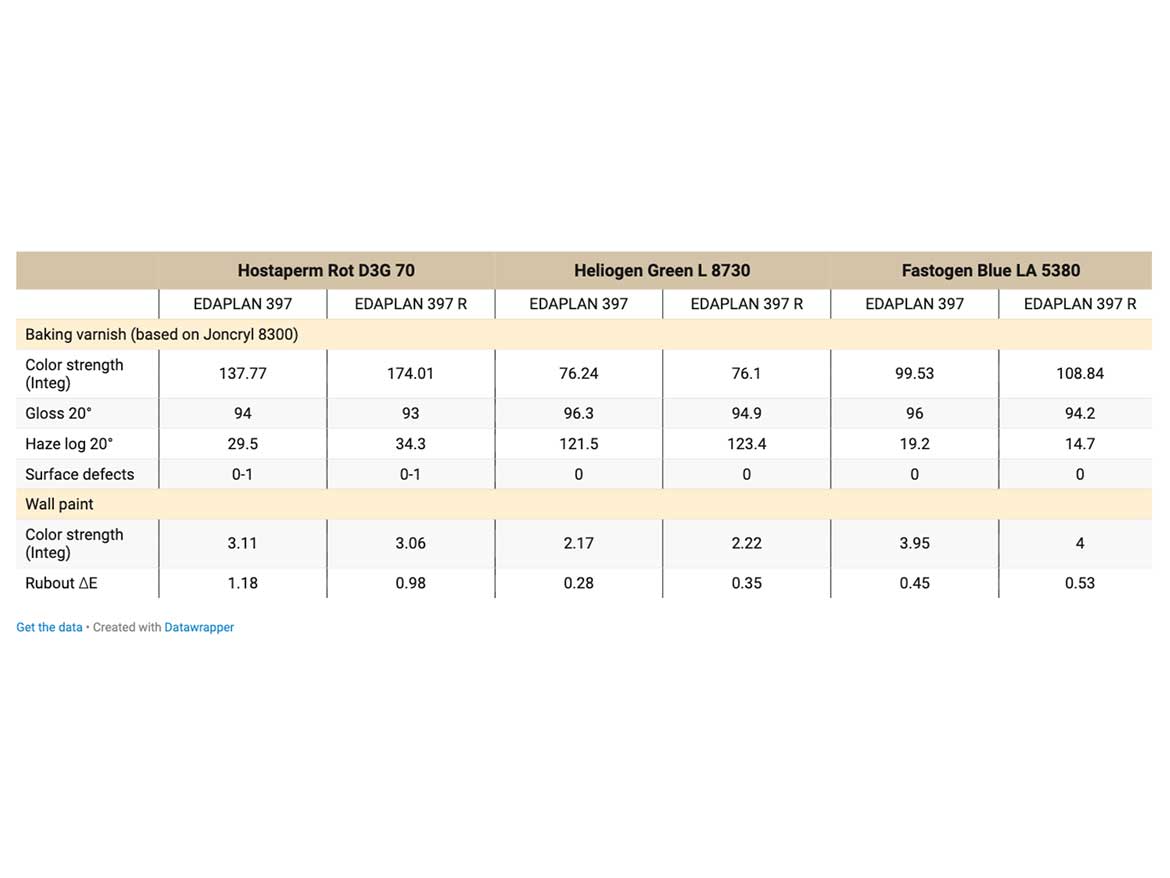

In addition to our renewable PUR thickeners, our range of renewable products also encompasses a high-performance dispersing agent, EDAPLAN 397 R. This dispersing agent successfully replicates the dispersing power of its fossil-based counterpart and delivers outstanding results, particularly when used with organic pigments. A comparison of the dispersing performance is presented in Table 1, highlighting the efficacy of our dispersing agent in achieving optimal dispersion of organic pigments. Furthermore, our portfolio includes renewable defoamers. These defoamers are inherently formulated with a significant proportion of renewable materials, eliminating the need for any adjustments to the original formulation.

The subsequent step involves the integration of our developed renewable products into actual coating formulations. In this regard, we have successfully completed several projects focusing on architectural and wood coatings, wherein paint formulations were developed utilizing renewable additives. Our portfolio offers various options depending on the additive group required. To illustrate the impact of these renewable additives, a formulation for brush- and roller-applicable white paints has been created and is presented in Table 2. A comparative analysis was conducted between this formulation and a non-renewable formulation from a competitor. Upon examination of the results, it is evident that the use of additives with a high renewable content leads to enhancements in key aspects such as brush drag, brush marks, and spattering. Notably, these improvements are achieved while maintaining a similar hiding power, ensuring that the desired level of opacity is maintained.

The successful implementation of these renewable additives in coatings demonstrates their efficacy in delivering superior application performance compared to non-renewable alternatives. By incorporating additives with a high renewable content, the coatings industry can move closer towards sustainable practices without compromising on the quality and performance of the final product. Furthermore, it is worth noting that the aforementioned renewable additives are also applicable in wood coating formulations, expanding their versatility and potential for sustainable solutions in the wood coatings industry.

Wet Scrub Resistance and Hydrophobicity

To assess the impact of wax additives on wet scrub resistance and hydrophobicity, we conducted a comparison test involving sustainable additives, of which ours is a micronized hybrid wax blend based on a natural biopolymer combined with a hard, high-melting polyethylene wax.

These wax additives were compared against a blank sample without wax, and a conventional competitor wax, based on high melting, tough polypropylene wax, as recommended by the supplier for enhancing wet scrub resistance. The test system was a water-based acrylic wall paint, with the additives being incorporated at a dosage of 3% (calculated based on solid content), using a Cowles disc disperser.

The coating formulation was applied onto a PVC card using a coating rod, resulting in a wet film thickness of 150 µm. The samples were then allowed to dry for 7 days at 21 °C with a relative humidity of 24%. Wet scrub resistance was assessed using a Zehntner rub testing device (ZAA 2600). The dried, coated samples were affixed to the device, and a sponge soaked in a 5 mL cleaning solution (0.25% Marlon A 350 solution in demineralized water) was used to scrub the coated surface at a speed of 40 cycles per minute (with a stroke length of 100 mm) for 350 cycles. Subsequently, any remaining solution was rinsed off with water. After the surface dried, the weight loss was measured, and a visual assessment of the surface was also conducted.

The results revealed that our hybrid wax exhibited the highest level of wet scrub resistance. The combination of a tough-elastic natural biopolymer with a hard polyethylene wax displayed a synergistic effect, resulting in outstanding performance. The second-best performance was achieved by the renewable-based additive.

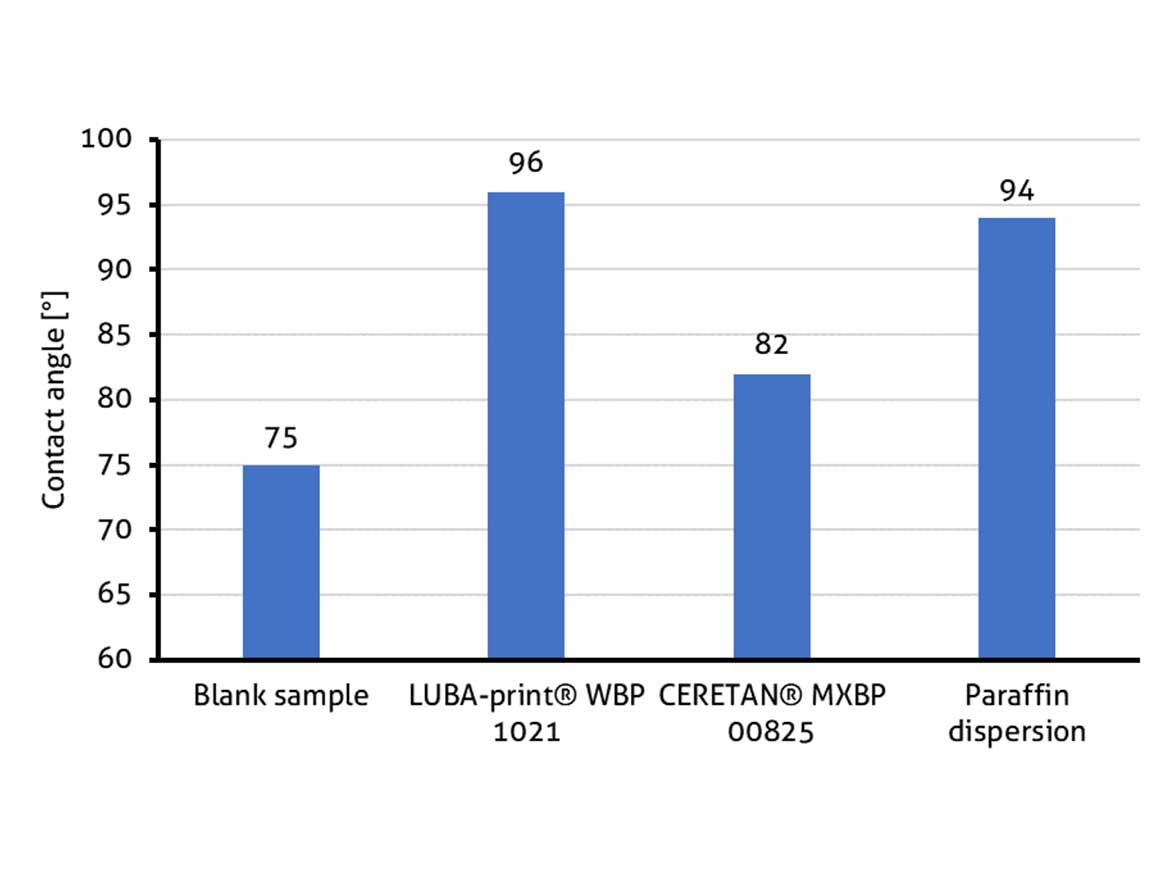

Furthermore, the hydrophobic effect was determined by measuring the contact angle of a water droplet applied to the coated surface. A higher contact angle indicates better water repellency.

It was found in terms of hydrophobicity that LUBA-print WBP 1021 exhibited the largest contact angle, surpassing even the tested paraffin wax dispersion. This superiority can be attributed to the fine particle size distribution of these two products, with a Dv50 value in the range of several hundred nanometers. The small particle size allows for a greater surface area coverage, resulting in the highest observed contact angle during the test.

On the other hand, a micronized wax, characterized by an average particle size between 6-8 µm, does not provide the same extensive surface coverage. Consequently, it cannot achieve the same level of hydrophobicity as the as before mentioned products. The particles of this micronized wax are only locally embedded into the surface matrix, failing to cover the entire surface area and limiting its hydrophobic performance.

In conclusion, our research efforts in the development of renewable additives for the paint and coatings industry have yielded promising results. We have successfully replicated the characteristics and performance of traditional petro-based additives using renewable alternatives. Through comprehensive application testing, we have demonstrated the efficacy of these renewable additives in various formulations, showcasing improved application properties, without compromising performance. The integration of renewable additives offers a sustainable pathway for the industry, contributing to a greener future without sacrificing quality or functionality. Our commitment to innovation continues as we strive to provide sustainable solutions for the evolving needs of the paint and coatings sector.

Disclaimer: Results depend on the coating system. We can provide guide formulations on request. We would like to express our sincere appreciation to our application technology team for gathering the data that has greatly contributed to our article.

For more information, click here.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!