Sustainable Painting

High-End EV Manufacturer Equips New Paint Shop for Sustainable Production Process

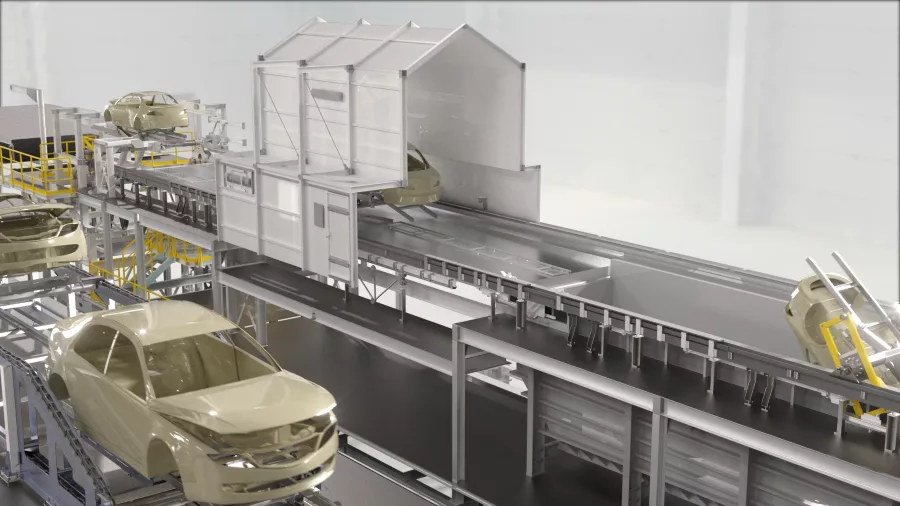

Dürr’s RoDip® M rotational process for pretreatment and cathodic electrocoating.

The high-end new energy vehicle manufacturer SERES not only focuses on intelligent electric drive technology, but also on sustainable production processes. The company therefore commissioned Dürr to equip a new paint shop in the Liangjiang plant in Chongqing in southwestern China to optimize the production process for energy and resource efficiency. Just nine months after receiving the contract, Dürr installed the plant and exhaust air purification technology as well as the software.

SERES electric cars have been on the market since 2018, and the company has shipped vehicles to over 70 markets since then. They aim to become a major player in the European electric vehicle market. The new paint shop in the Liangjiang plant in Chongqing can complete 60 jobs per hour. “To meet the requirements of a production process that saves both resources and energy, we used especially sustainable products from plant and environmental engineering and installed our DXQ energy management solution,” explains Yu Lin, Vice President of the paint and final assembly business at Dürr China.

Savings with Smaller Tanks

The RoDip® M mechanical rotational process is well known for conserving energy and resources during the pretreatment and cathodic electrocoating of vehicle bodies. While RoDip is a classic in the market, its sustainability benefits remain remarkable: Its 360° rotational movement, which spins the bodies around their own axes, eliminates the need for an inclined exit section in the immersion tanks. This innovation saves up to six meters in length per tank compared to pendulum conveyor technology, reducing water, chemical, and energy usage.

Cardboard Instead of Water and Chemicals

In the future, SERES will use the EcoDry X dry separation system for overspray removal, a solution that saves energy. This cost-effective system relies on easily replaceable disposable cardboard filters, eliminating the need for water and chemicals. Dry separation minimizes fresh air requirements by recirculating nearly 90 percent of the air. This substantial reduction in energy consumption within the paint booth sets it apart from traditional wet scrubbing methods.

EcoDry X is based on easily replaceable and disposable cardboard filters for fast filter changes, even during production.

Heating Ovens with Exhaust Air

SERES is also setting standards when it comes to emissions control. To eliminate solvents (VOCs) from exhaust air, paint booths are equipped with a compact air pollution control system from Dürr. Exhaust air from the paint booths, which has already undergone adsorptive concentration through the recirculation process, undergoes further purification using a highly efficient VOC concentration system in combination with the downstream Oxi.X TR TAR recuperative thermal oxidizer. This results in up to 15 percent reduction in energy consumption. Additionally, exhaust air from the ovens is purified via the integrated Oxi.X TR TAR afterburning system with heat recovery and then reintroduced into the oven heating system.

Smart Factory Thanks to DXQ Software

Dürr’s DXQ software products play a significant role in enhancing sustainability within SERES’ new paint shop. DXQcontrol is employed for higher-level plant control, seamlessly tracking each body’s life cycle. The DXQenergy.management tool provides a transparent overview of energy and media consumption across the entire production plant or for specific areas, like individual process lines. In this way, Dürr’s energy management solution makes it possible to quickly identify primary energy consumers at the plant level. Additionally, DXQequipment.maintenance monitors when individual components like pumps, valves, or filters need to be maintained.

Dürr’s certified energy management solution DXQenergy.management enables production to save resources.

Modular Design Offers Many Advantages

Dürr’s plant technology is designed with a modular structure. This allowed them to efficiently complete the SERES project in just nine months – from receipt of the contract to the start of production. Moreover, the modular approach offers advantages to the customer as well: The ideal layout of the individual modules, from pretreatment to sealing processes to paint booths and ovens, makes production more flexible and eliminates unused space within the paint shop. In response to SERES’ request, Dürr also factored in space for a future primer line within the layout.

“We’re very happy that we were able to impress SERES with our modular equipment and fast completion time, and look forward to a long-term partnership,” says Yu Lin.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!