Improving Water Resistance of Water-Based Coatings Using Reactive Surfactants, Part 3

Davizro / iStock / Getty Images Plus, via Getty Images.

Continuing from the previous two articles, we will look at the first polymerization process, how the reactive non-ionic surfactant was incorporated, and how it affected the properties of the emulsion. In next month’s article we will look at additional processes and conclude.

Process 1

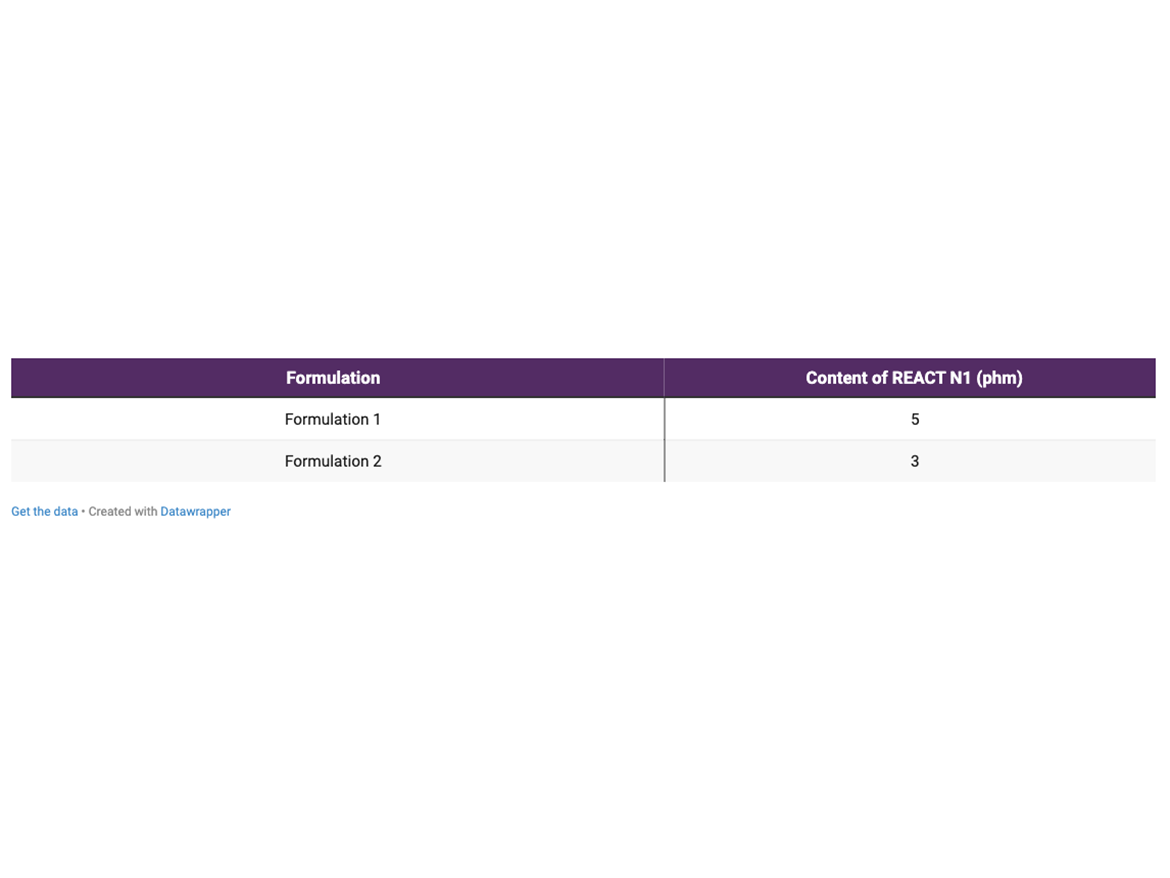

Process 1 is a typical semi-batch used in the production of styrene-acrylic emulsions. Formulations 1 and 2 were performed according to this process and contain a conventional anionic surfactant and REACT N1 in a ratio of 1:2. Formulation 1 contains 5 phm (parts per hundred of monomer) of REACT N1, while Formulation 2 contains 3 phm of REACT N1 (Table 1).

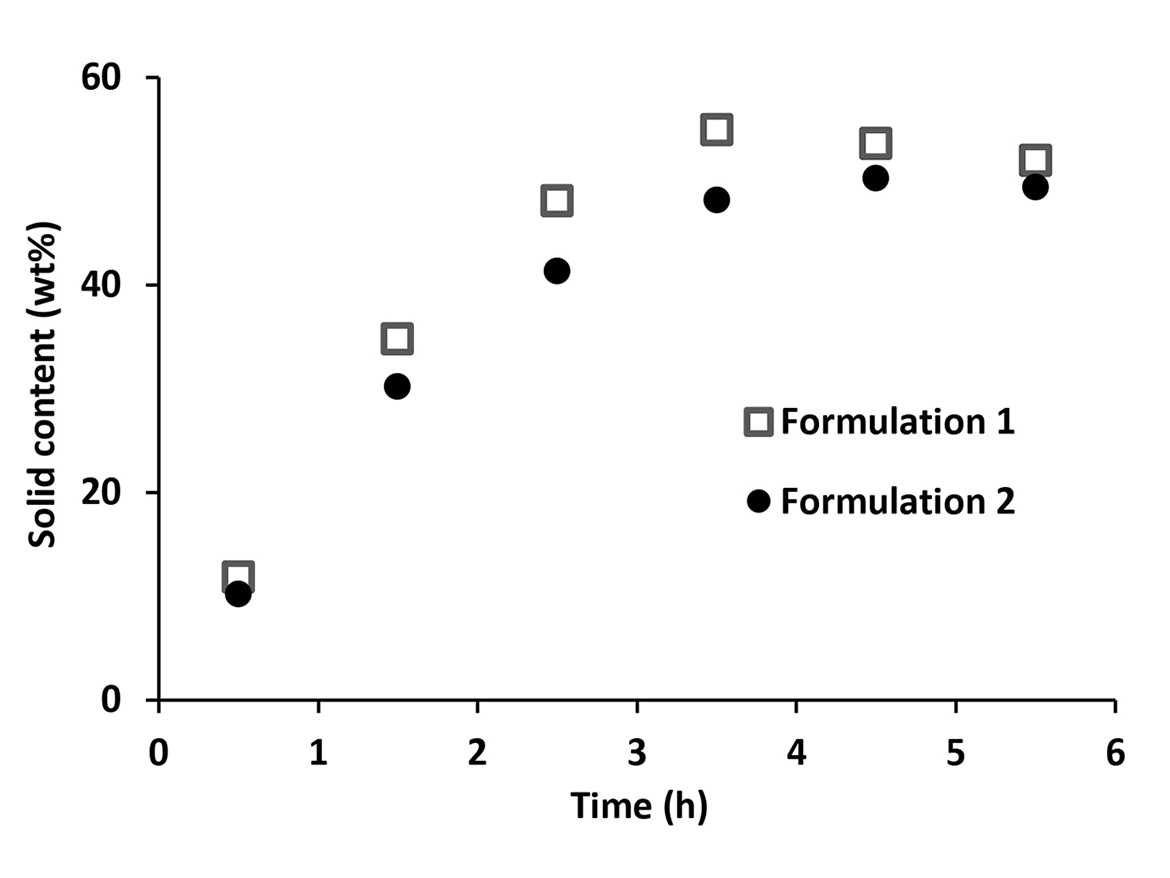

The evolution of solid content, particle size, and particle number of Formulations 1 and 2 are presented in Figures 1, 2, and 3, respectively. Figure 1 shows that both formulations containing REACT N1 presented an evolution of solid content typical of styrene-acrylic latexes, suggesting that REACT N1 performed as well as a conventional non-ionic surfactant and did not hamper the conversion of monomers into polymer.

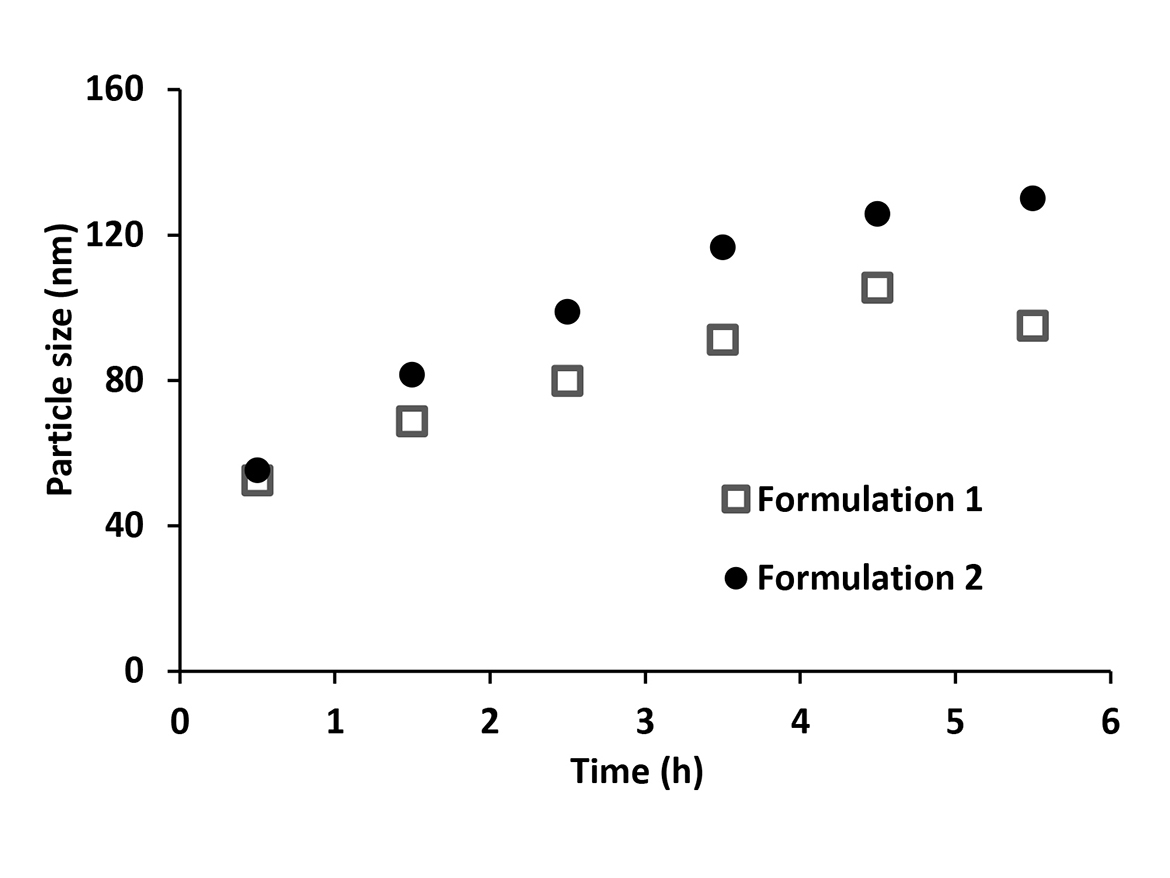

Figure 2 shows that both formulations containing REACT N1 presented particle size evolution typical of latexes nucleated through micellar mechanism. Due to this, Formulation 1, which has higher content of surfactant, generated emulsions with particle size smaller than Formulation 2.

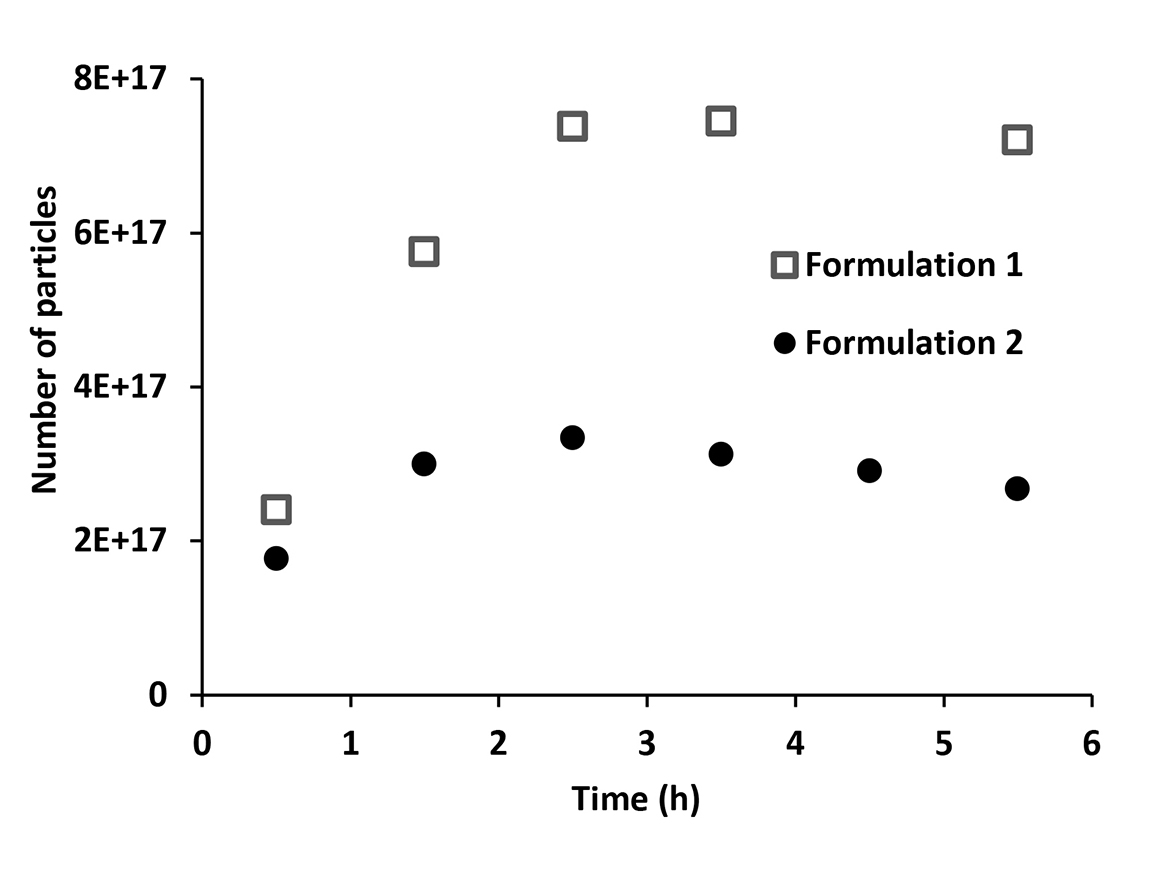

As expected, according to Figure 3, Formulation 1 generated more particles than Formulation 2. These results of evolution of particle number suggest that REACT N1 was effective for stabilizing the latex particles along the polymerization.

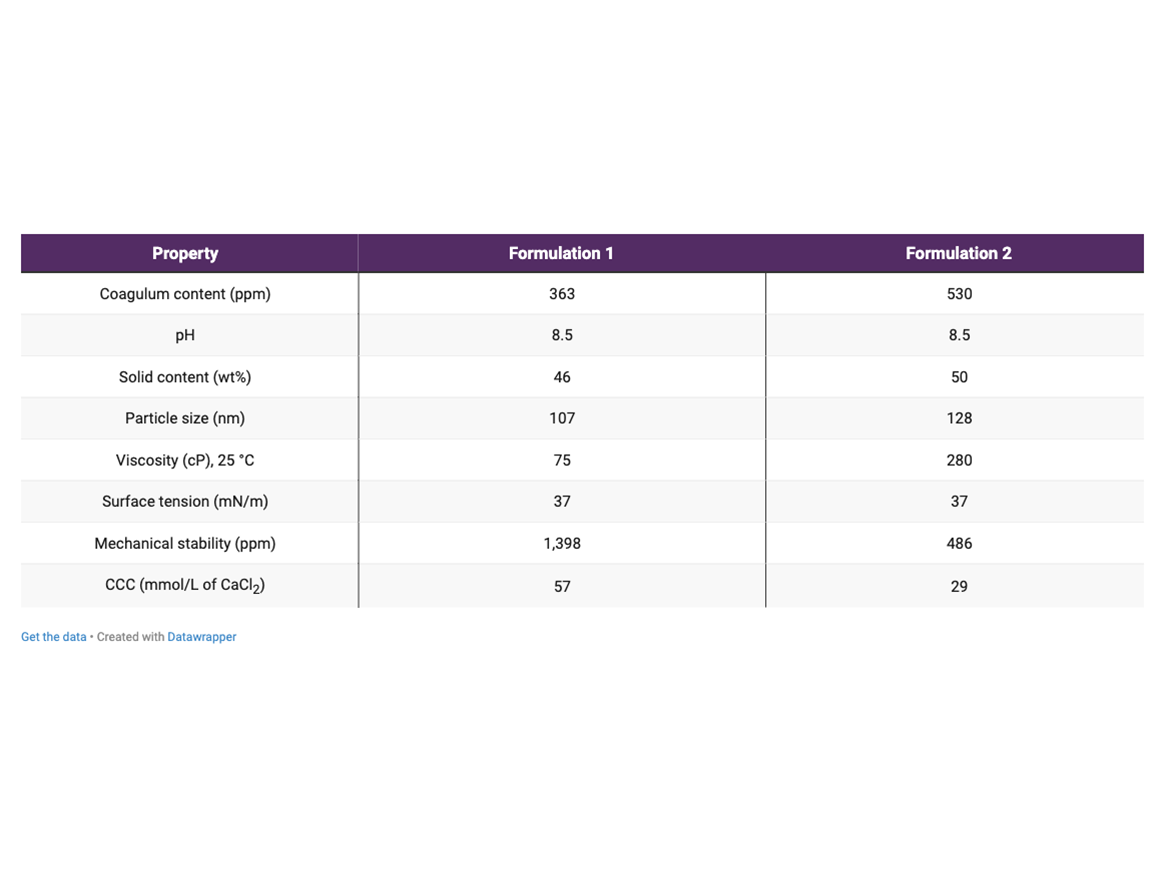

The main properties of latexes generated from Formulations 1 and 2 are presented in Table 2. The table shows that the latexes obtained from Formulations 1 and 2 presented similar pH, solid content ranging from 46 to 50 wt%, viscosity lower than 300 cP at 25 °C, and surface tension of about 40 mN/m. As expected, the latexes containing 5 phm of REACT N1 obtained from Formulation 1 had particle size close to 100 nm while the emulsion containing 3 phm of REACT N1 obtained from Formulation 2 had particle size about 130 nm.

The latex with 5 phm of REACT N1 (obtained from Formulation 1), and the latex polymerized with 3 phm of REACT N1 from Formulation 2 formed similar level of coagulum in the reactor during the polymerization. However, the latex from Formulation 1 formed more coagulum in the mechanical stability test than the one polymerized from Formulation 2.

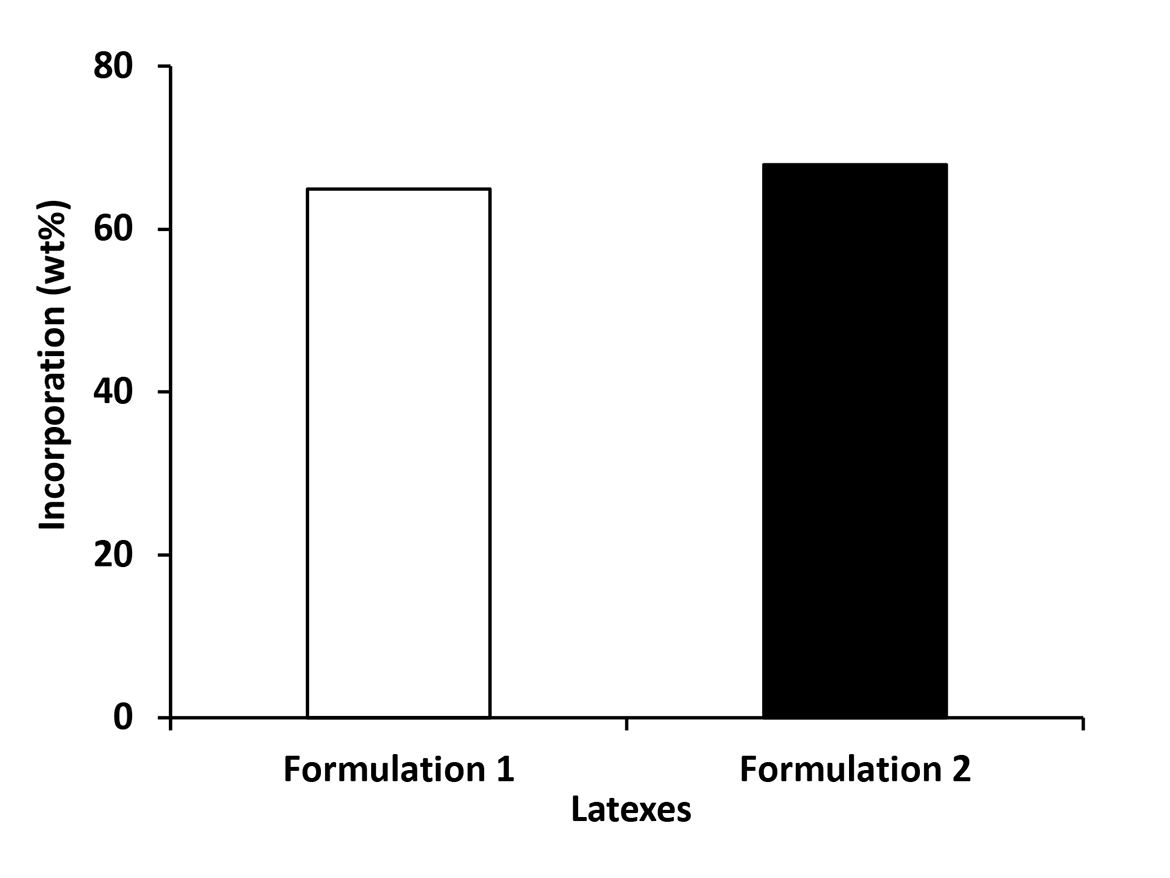

On the other hand, based on CCC data, the latex polymerized with 5 phm of REACT N1 presented higher electrolytic stability than the one polymerized with 3 phm of REACT N1 suggesting that the former latex had higher content of non-ionic surfactant on particle surface than the later latex. Figure 4 shows the content of REACT N1 incorporated into latex particles.

Figure 4 shows that both emulsions of Formulation 1 and Formulation 2 had an incorporation of REACT N1 close to 70 wt%. This level of incorporation is very good and similar to the ones observed for reactive non-ionic surfactants used in combination with conventional anionic surfactants.2 - 4 However, for all types of reactive surfactants, it is known that its incorporation will be lower than 100%. Due to this, REACT N1 was also designed for being more compatible with emulsions used in architectural coatings than the conventional non-ionic surfactants typically used in emulsion polymerization.

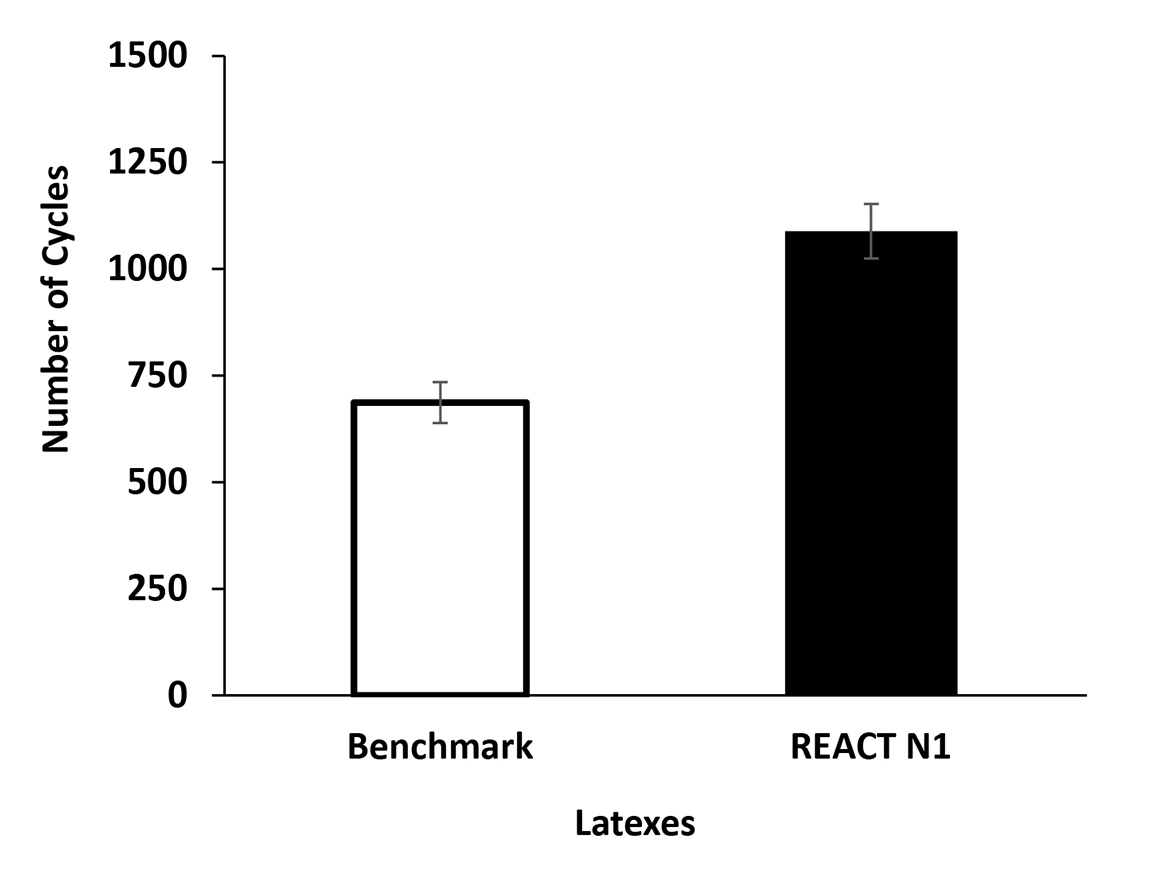

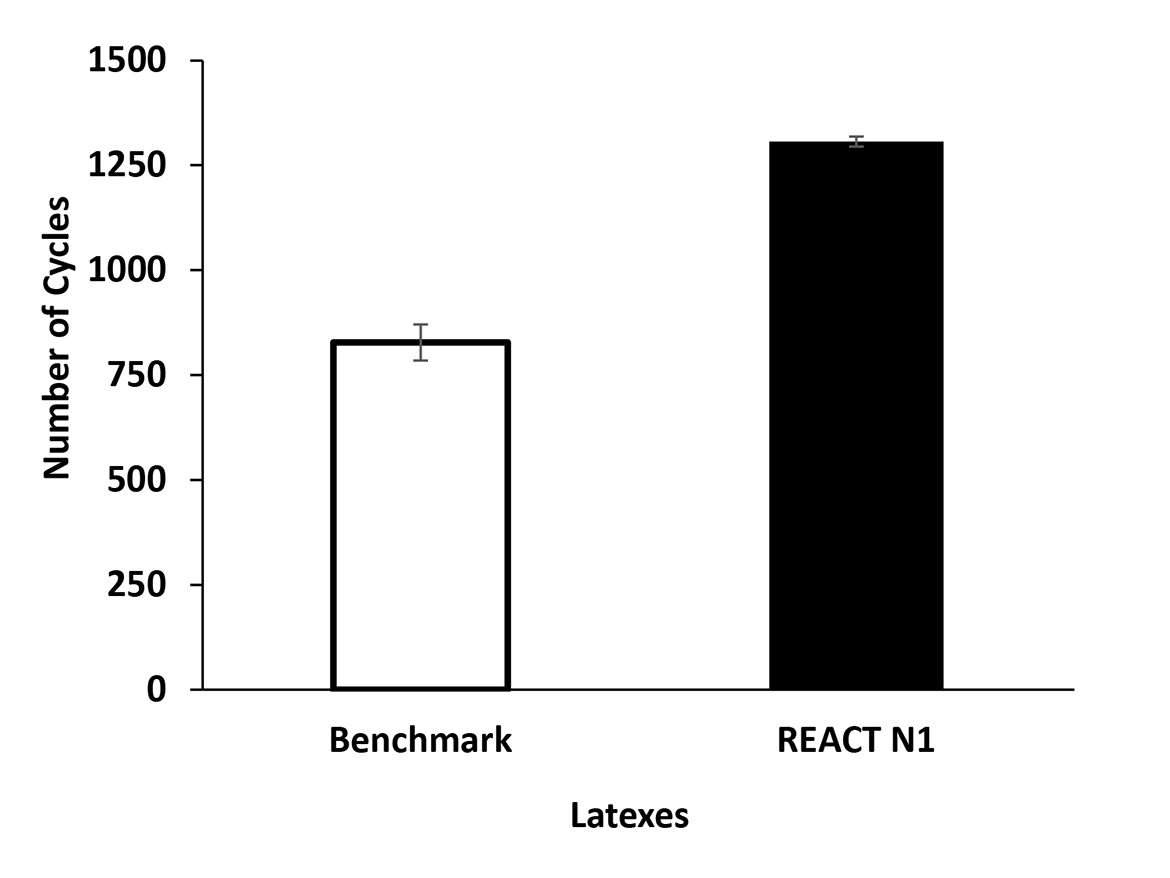

The wet scrub resistance of paints with PVC of 30% formulated with latexes containing 5 phm of REACT N1 (Formulation 1) and 3 phm of REACT N1 (Formulation 2) is presented in Figures 5 and 6, respectively. Paints formulated with latexes from Formulation 1 and Formulation 2 presented wet scrub resistance 60% higher than the styrene-acrylic latex (considered a benchmark in water resistance among styrene-acrylic latexes). These results are interesting because they showed that the wet scrub resistance of those paints was not only up to the content of surfactants used in the emulsion polymerization, but other factors such as quality of film formation, distribution of hydrophilic species such as additives, conventional anionic surfactant, and molecular weight may be affecting the wet scrub resistance.

References

1 Vanderhoff, J. W.; Bradford, E. B.; Carrington, W. K. The Transport of Water through Latex Films, J. Polym. Sci. 1973, 41, 155 - 174.

2 Aramendia, E.; Mallégol, J.; Jeynes, C.; Barandiaran, M. J.; Keddie, J. L.; Asua, J. M. Distribution of Surfactants near Acrylic Latex Film Surfaces: A Comparison of Conventional and Reactive Surfactants (Surfmers), Langmuir 2003, 19, 3212 - 3221.

3 Aramendia, E.; Barandiaran, M. J.; Grade, J.; Blease, T.; Asua, J. M. Improving Water Sensitivity in Acrylic Films Using Surfmers, Langmuir 2005, 21, 1428 - 1435.

4 Noyes, N. Non-Leaching Reactive Surfactants for Architectural Latex Binder, PCI, 2018, 34, 36 - 41.

5 Fithian, P.; O’Shaughnessy, M.; Lubik, M.; Mark, S. Redox for Main Polymerization of Emulsion Polymers, PCI, August2017.

All information contained herein is provided "as is" without any warranties, express or implied, and under no circumstances shall the author or Indorama be liable for any damages of any nature whatsoever resulting from the use or reliance upon such information. Nothing contained in this publication should be construed as a license under any intellectual property right of any entity, or as a suggestion, recommendation, or authorization to take any action that would infringe any patent. The term "Indorama" is used herein for convenience only, and refers to Indorama Ventures Oxides LLC, its direct and indirect affiliates, and their employees, officers, and directors.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!