Eco-Friendly Upcycling Chemistry Meets Innovative Luxury Coatings

Bio-based color particles for decorative coatings.

The coatings industry has adopted a steady pace on its transition towards more bio-based, carbon-friendly and resource-efficient solutions. Whereas this journey can be somewhat challenging in the field of technical coatings, there is certainly a myriad of opportunities in the decorative market segment. Binder systems from plant-based sources have replaced a great deal of fossil-derived resins, and a variety of degradable, natural pigments have gained presence beyond niche applications.

As far as texturing and reinforcement are concerned, the industry has conventionally used mineral particles. Hardness and resistance paired with appealing white shades and competitive pricing have made them an unquestioned top choice for most manufacturers. Only recently, plant-based alternatives have awakened innovators’ curiosity. “Creating a fully bio-based particle that meets—and even exceeds—the requirements of modern coatings, both in terms of technical features and value for money has been quite a process, says Kathrin Schilling, Founder and Director, BioPowder.

BioPowder specializes in upcycling a unique raw material: olive stones, a by-product of the olive oil industry. Over the years, the team has experimented with a wide range of raw materials, all leftovers from fruit processing such as almond and pistachio shells, apricot stones, ginger fibers, rice husk and avocado peel.

Olive stones, when used in superior quality, are an excellent raw material for resistant light-weight particles with an appealing shape and color. In addition, they originate from a carbon-neutral ecosystem in which foodstuff and by-product value chain emissions are offset by the olive trees’ carbon capture. Essentially a source of bio-carbon, olive stone particles are multifunctional. In coatings, they are compatible with different resin systems (i.e. conventional and bio-based epoxy, polyurethane, and acrylic formulations), and can improve a product’s carbon footprint, lifespan, impact and abrasion resistance, and curing times. “Our mission consists in identifying applications where olive stone particles can add maximum value to an end product, both in technical and environmental terms,” says Schilling.

To achieve this goal, customization is key. Particle ranges can be adjusted to meet diverse requirements with regard to viscosity, texture, and surface effects of coating formulations. The lignocellulosic composition of olive stone particles and the associated reactivity can be adjusted/suppressed by way of surface functionalization. This can reduce the need for compatibilizers and boost hydrophobicity for barrier or protective coatings, for instance. A line of bio-based color particles to amplify the aesthetic options for decorative applications is also available.

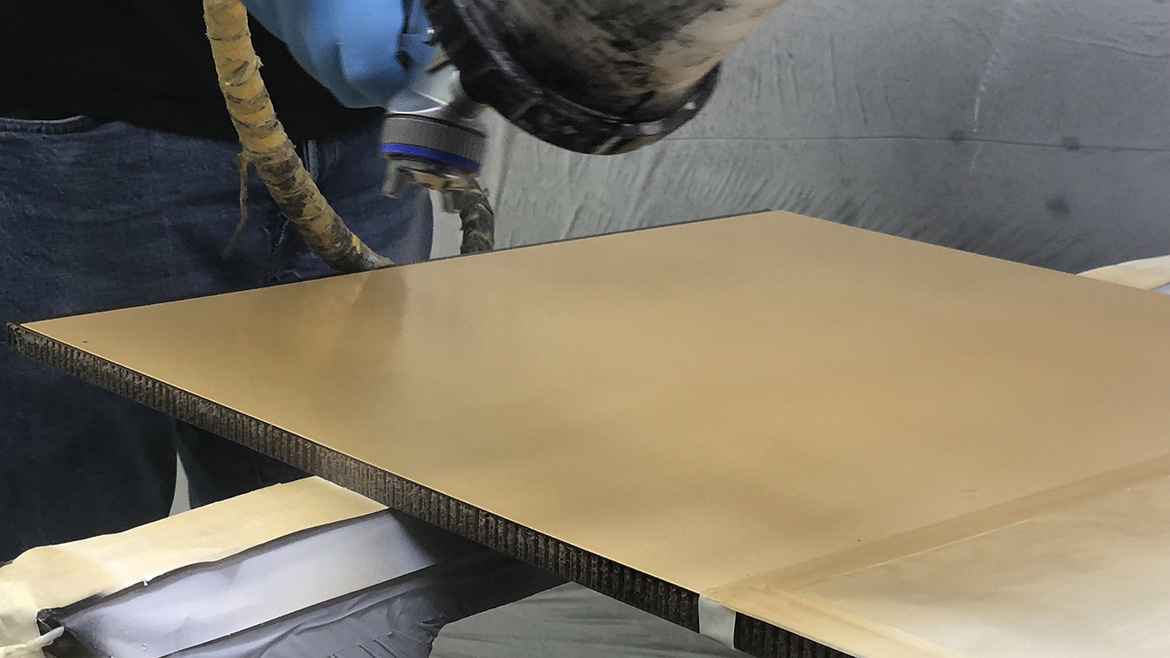

In an attempt to promote bio-based innovation, BioPowder recently unveiled its collaboration with F/LIST, an Austrian manufacturer of decorative high-performance coatings. The company serves the luxury business jet, private jet and residential markets with a unique combination of traditional craftsmanship and cutting-edge material science. The R&D experts and in-house future lab called F/LAB at F/LIST developed the product line that includes decorative coatings with customized pattern engraving and sustainable pigment finish. The bio-based laminate is created from the fusion of traditional jewelry techniques, aerospace technology and cutting-edge chemistry. Diverse materials such as plant-based pigments, up-cycled olive stone or mother-of-pearl are brought together and given a new life.

With its plant-fiber-based carrier substrate, the new line immobilizes approximately 400 liters of CO2/m² material from the atmosphere and stores it as biogenic carbon. Possible applications range from wall and divider coverings over inlays and furniture fronts.

The F/LAB project showcases the potential of carbon-friendly innovation in coatings and high-quality decorative applications. Available guide formulations for VOC-free, bio-based coatings can accelerate product design, shorten the time-to-market of new developments and ultimately contribute to “eco” being the norm, not a niche.

To read more on this topic, read Olive Stone Powders: A Natural, Sustainable Option for the Paint & Coatings Industry.

Learn more from BioPowder here.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!