An Evaluation of Controlled-Release Preservatives in Europe

EIFS panel preparation. Image courtesy of Arxada.

Field testing, also known as outdoor exposure testing, assesses the expected performance of exterior paint and coatings applied to houses and commercial structures. This long-term testing has proven to be the best indicator of performance in real-world applications. Laboratory evaluations are beneficial in preliminary stages of product development as a screening tool. However, while laboratory evaluations are faster and less costly, they have considerable limitations. They do not account for numerous variables such as the nature and condition of the substrate, microorganisms encountered in actual use, or the coating's lifespan. Additionally, laboratory testing makes it difficult to simulate the migration and depletion patterns that occur in actual use. As a result, outdoor exposure testing is a necessary element in evaluating dry-film preservative efficacy in exterior paint and coatings.

Worldwide Field Testing Sites

Over the past several decades, Arxada has invested in properties worldwide for field testing sites, selecting locations based on numerous criteria, foremost among them the variety of microbial growth and climatic conditions. These sites represent both extreme conditions and typical use environments representative of the geographic marketplaces into which customer coatings are sold. Long-term field testing is conducted for Polyphase®, Troysan® and Fungitrol® dry-film preservatives, including innovative TIME controlled-release preservatives, at these locations. Arxada customers are in more than 100 countries, and the products they manufacture are subject to many different climates and types of microbial attack. As a result, the breadth of exposure scenarios offered by these testing sites is important. Arxada has also recently expanded its network of field testing sites, reaching a present count of 15 sites worldwide.

Test Fence Procedures

Scientific and consistent field test procedures are essential to obtain a reliable assessment of the biological performance of paints and coatings in actual use conditions, which can include the growth of mold, mildew, staining and rot fungi, algae and/or lichens. Scientific field test procedures ensure an optimum breadth of eventualities is accommodated and substantially reduce the possibility of field failure. With this in mind, the protocol developed is based on four important elements:

- Panel preparation and exposure

- Paint preparation

- Test design

- Site selection

Panel Preparation and Exposure

Pine, cedar, stucco, Hardie board panels and exterior insulation finishing system (EIFS) are most often used, reflecting the most common substrates worldwide. Test panels are typically exposed vertically (90°), facing north. This orientation promotes mold and algae growth and corresponds to the most common application, wood siding. For accelerated exposure, panels can be exposed at approximately 45° for faster dirt pickup and more exposure to rain. Figure 1 shows EIFS panel preparation at Arxada’s Germany site. Other panel orientations and angles can be used to evaluate different applications and conditions. For decking materials, exposure is usually done at a horizontal (180°) angle.

Paint Preparation

In a typical Arxada test procedure, the front of the panel is divided into several equal segments. One of the segments serves as the control, consisting of an unpreserved paint with no film preservative. The same paint with different dose levels of Arxada and competitor film preservatives is applied to the other segments of this same panel. The locations of the control and preserved coatings on each panel are random to negate environmental effects from panel to panel.

Test Design

The basic principle of experimental design is randomization and replication. Large-scale panel exposure tests are planned using replicated and randomized designs. In this type of design, panels representing each paint and dose level are replicated several times. Panels are placed on exposure racks in random order to minimize environmental effects such as proximity to the ground. Randomization also minimizes any influences of adjoining panels on each other.

Site Selection

Arxada maintains test fence sites in climatically and microbiologically diverse areas such as the Northeastern United States (temperate climate with wet, humid summers and cold, dry winters); the Pacific Northwest (temperate climate with dry summers and wet, humid winters); Southeastern United States (wet springs and falls, humid summers and very dry, chilly winters); and Northern Europe (temperate climate with mild, wet winters and warm, wet summers). These test sites provide test results for geographies that represent significant markets for paint and coatings applied over various substrates and where mildew growth is prevalent but algae are also problematic. Arxada also maintains test fence sites in tropical regions, which are hot, wet and humid year-round. Rainfall and temperature play a significant role in promoting microorganism growth. Algae are the predominant threat in these regions, which represent large markets for stucco and masonry coatings. Arxada has several tropical and subtropical field testing sites located in India and Southeast Asia.

Areas Most Vulnerable to Fungal and Algal Attack

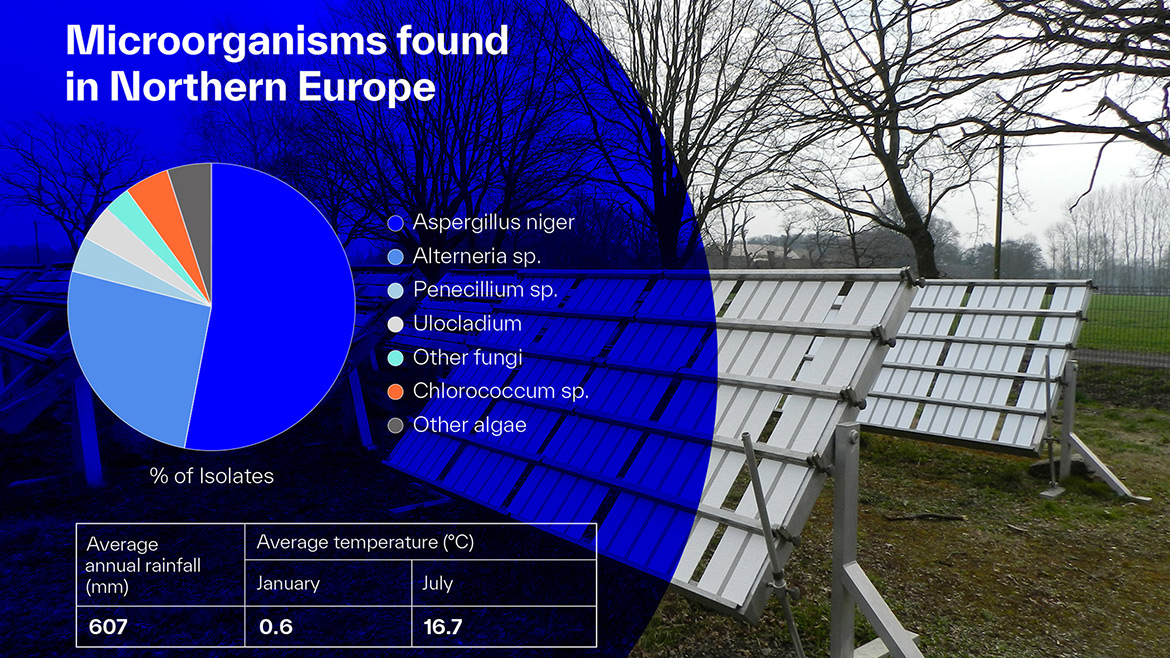

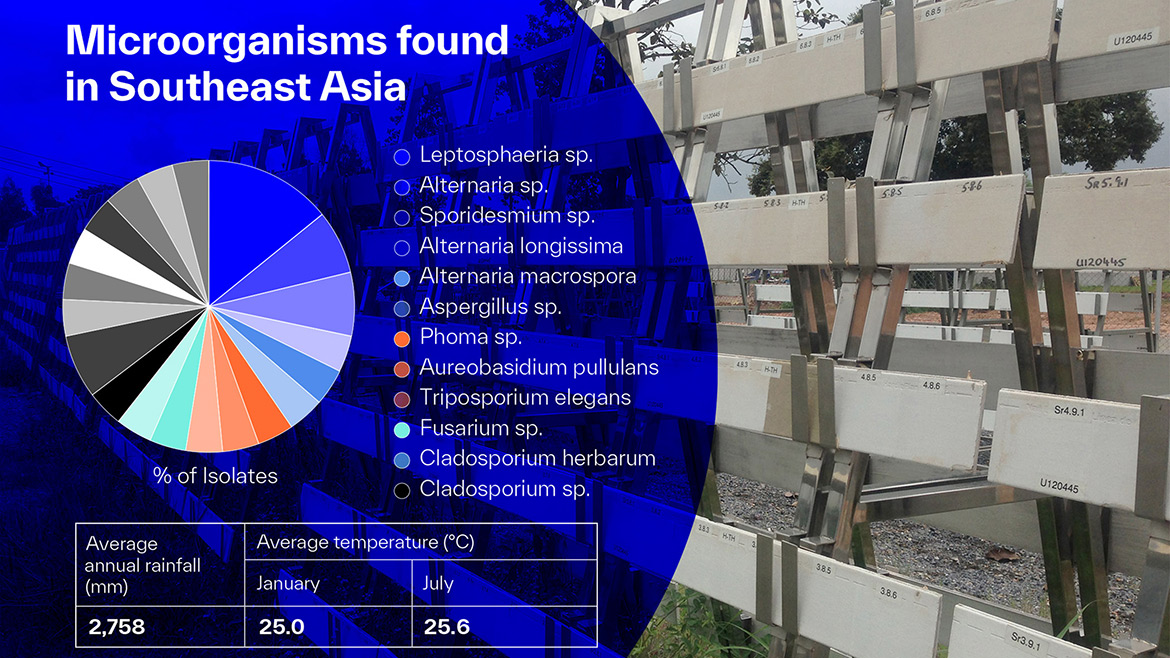

Arxada’s field testing sites are in areas subject to a full spectrum of microbiological attack and a wide range of climates. In many regions, and in some of the world’s most heavily populated areas, coatings are subjected to both fungi and algae. Figures 1 and 2 show the considerable differences in microbial species and climate conditions in two of the test sites that represent significant markets for exterior coatings — Northern Europe and Southeast Asia.

Field Evaluations of TIME CR Preservatives

New and ongoing evaluations are carried out at all Arxada field testing sites worldwide according to a predetermined schedule for the preservatives being tested. Every one to three months, the test panels are visually inspected and rated in accordance with ASTM D3274 for mildew or algae growth. The grading scale runs from 0 to 10, with 0 indicating complete mildew or algae coverage and 10 indicating a complete absence of growth. Test panels are typically exposed for two years for pine substrates and three to five years for cedar and masonry substrates.

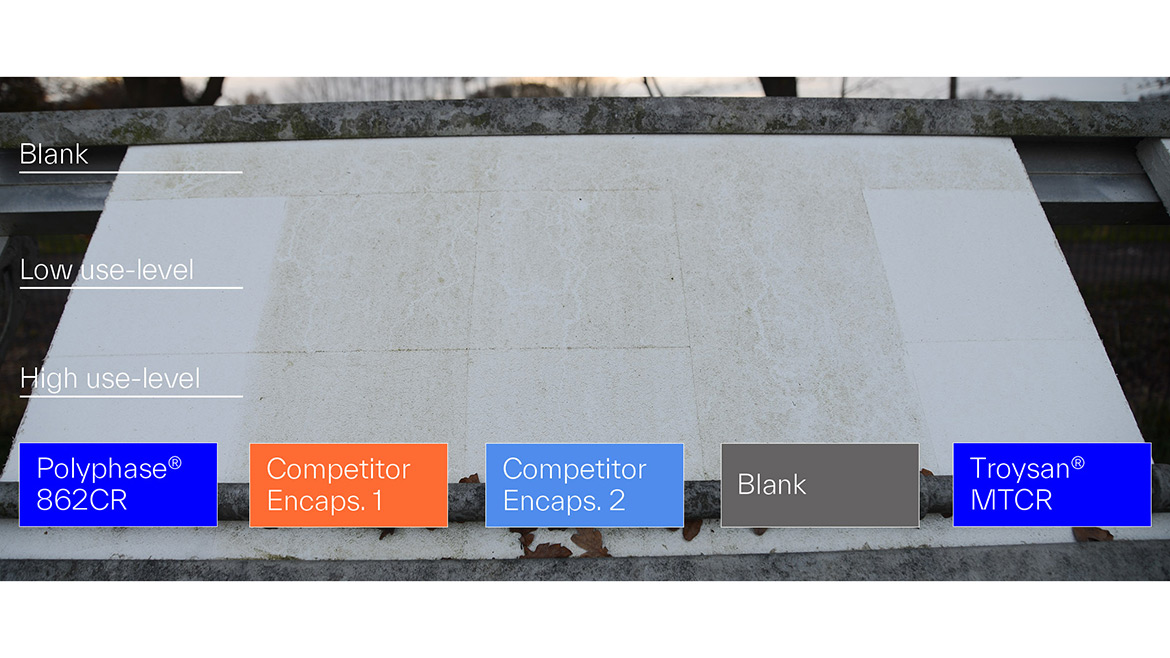

Recent outdoor exposure results from Arxada’s Germany test site demonstrate the performance of TIME (Technology for Innovative Micro-Encapsulation) CR products in real-world conditions against competitor encapsulated products. In these evaluations, TIME CR and competitor algaecide-free preservatives were incorporated into various acrylic paint samples on EIFS in randomized samples amidst blanks (unprotected panels). All products in this evaluation are commercially available to coatings manufacturers in Europe.

Polyphase 862CR, a new dry-film preservative, was the focus of the exposure testing. It features a unique combination of encapsulated anti-fungal and Diuron-free anti-algal actives. It contains encapsulated IPBC, a leading anti-fungal active, along with encapsulated algaecides Terbutryn and Isoproturon, preferred for performance and compliance. Polyphase 862CR enables label-free paints and coatings.

In Figure 3, Polyphase 862CR’s IPBC-based formulation, with its synergistic Isoproturon/Terbutryn algaecide combination, outperformed competitor encapsulated preservatives. While the panels treated with the new dry-film preservative exhibited negligible microbial growth, competitor-treated panels showed significant growth. Even at a lower biocide level (1,200 ppm), the new preservative outperformed competitor products tested at 2,400 ppm.

Further, results from this microbiologically and climatically diverse test site indicate that while competitor samples initially exhibited adequate protection, their performance declined significantly within the first few months. This deterioration aligns with the algaecide-free composition of these preservatives, which limits their long-term efficacy in environments prone to both fungal and algal growth. In contrast, broad-spectrum preservatives, particularly encapsulated formulations, have consistently demonstrated superior protection in this study and in additional evaluations conducted at Arxada’s global field testing sites.

The findings reinforce that TIME CR products exhibit robust performance in real-world conditions by resisting active ingredient leaching and maintaining long-term protection against fungal and algal contamination. These results hold significant value for formulators marketing exterior coatings across Europe and beyond, providing essential insight into product durability across varied environmental conditions. Moreover, coatings manufacturers should recognize that while a macroclimate may predominantly foster mold and mildew growth, microclimates within the same region can present heightened risks of algal contamination.

Arxada’s experience in developing and field-testing dry-film preservatives confirms that a broader spectrum of microbial control leads to greater reliability for both formulators and end users. By selecting preservatives designed to combat a wide array of microorganisms, coatings manufacturers can ensure more consistent, long-term protection for their products, offering peace of mind in an increasingly demanding market.

Summary

Coatings are exposed to a wide variety of microorganisms worldwide, including fungi, algae, lichen and yeast. While laboratory testing serves as a useful preliminary screening tool, long-term outdoor exposure testing remains the most accurate predictor of real-world product performance. For this reason, Arxada’s field testing sites are strategically located to evaluate coatings under diverse climatic and microbiological conditions, ensuring their relevance to key global markets.

Arxada’s approach to testing and formulation focuses on providing coatings manufacturers with the most effective preservative solutions tailored to their target markets. Through rigorous field trials, preservative options are assessed across multiple sites, allowing the company to recommend formulations that offer the broadest and most reliable protection for end-use products.

TIME CR preservatives have demonstrated long-term efficacy at Arxada’s outdoor testing sites, effectively safeguarding coatings against a vast spectrum of fungal and algal species. The results further validate that algaecides play a critical role in dry-film preservation, as formulations lacking algaecidal components exhibit higher failure rates in field conditions. Algal contamination is more prevalent than often assumed, making a comprehensive preservation strategy essential for coatings longevity.

For more information on Arxada TIME CR preservatives, field testing capabilities and additional services, visit the website.

Use biocides safely. Always read the label and product information before use. All information in this article corresponds to Arxada’s knowledge on the subject at the date of publication, but Arxada makes no warranty as to its accuracy or completeness and Arxada assumes no obligation to update it. All information in this article is intended for use by recipients experienced and knowledgeable in the field, who are capable of and responsible for independently determining the suitability of ingredients for intended uses and to ensure their compliance with applicable law. Republication of this information or related statements is prohibited. Information provided in this article by Arxada is not intended and should not be construed as a license to operate under or a recommendation to infringe any patent or other intellectual property right. All trademarks belong to Arxada or its affiliates or to their respective third parties and are used here only for informational purposes. Copyrighted material has been produced with permissions or under license, all other materials © 2025 Arxada.

References

1. Weatherbase.com. CantyMedia, 2018.

2. American Society for Testing and Materials, Number D3274. ASTM, 100 Barr Harbor Drive, West Conshohocken, Pa., USA.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!