Evaluation of PDO-Based Polyols in Cast Elastomer Protective Liners

Image courtesy of typo-graphics, iStock / Getty Images Plus, via Getty Images.

Cast polyurethane elastomers are usually two-component (2K) systems composed of an NCO-pre-polymer (or quazi-pre-polymer) and a curative defined as either a di-hydroxyl chain extender or a hindered diamine chain extender. Some of the major applications of cast elastomers include protective liners for pipes for slurry transportation, coatings for mining screens, various types of wheels, electrical potting, electrical insulators, crack sealants, gaskets, and pipeline pigs.

PU-lined steel pipe are used for transportation of abrasive slurries over vast distances and can experience a broad range of temperatures. The composition of slurries can greatly vary and can include water-based slurry from mining and drilling applications, heavy oil, salt water, petroleum, and mixtures thereof. The slurries frequently carry abrasive particles that can include sand, gravel, rocks, and other particles of varying sizes.

Polyurethane-cast elastomer for pipe-lining application needs to have the following combination of properties:

- Good physico-mechanical properties;

- Excellent hydrolytic and solvent resistance (a mixture of water and oil);

- Excellent adhesion to metal;

- Good heat resistance;

- Good abrasion resistance.

Most PU systems currently used in a pipe-liner application are cast elastomer based on a NCO-pre-polymer and a hindered diamine (e.g. Ethacure 300) as a curative. The NCO-pre-polymer is based on Toluene diisocyanate (TDI) and a polyol. Polyols typically used in this demanding application environment include PTMG and polycarbonate polyols due to their high-performance qualities and contributions to the overall cast elastomer system. NCO-pre-polymers and hindered diamines are typically applied onto interior of the pipes via a spin-coating process, whereby evenly distributing the cast elastomer on the inner surface of the pipe.

PDO-sebacate polyester polyols and PO3G polyether polyols could potentially be candidate in cast-polyurethanes applications, including a protective pipe-lining application. PDO-Sebacic polyols in particular had produced 2K-PUDs with a good combination of metal adhesive properties, hydrolytic resistance, corrosion protection, and solvent resistance, which in some instances outperformed 2K-PUD controls based on PTMG and polycarbonate polyols (3-5). Therefore, it is anticipated that PDO-based polyols could provide similar benefits in cast elastomer applications where wear resistance, adhesion to metal, and solvent resistance to a broad range of media constitute critical performance properties.

Experimental

Urethane-urea cast elastomers based on PDO-sebacate 2000 and PO3G 2000 polyols and reference cast elastomers based on PTMG 2000, PPG 2000 and polycarbonate 2000 polyol were prepared and tested. NCO-pre-polymers were prepared from TDI isocyanate (80/20) and the following polyols:

- PDO-sebacate 2000 polyester polyols;

- PO3G 2000 polyether polyol;

- PPG 2000 polyether polyol (reference);

- PTMG 2000 polyether polyol (reference);

- Polycarbonate 2000 polyol (reference).

The blend of 50:50 by weight of PPG/TDI and PO3G/TDI pre-polymer was prepared as well and was used in cast elastomer preparation. Cast elastomers were prepared by polymerization of TDI NCO-pre-polymers with a hindered diamine Ethacure 300.

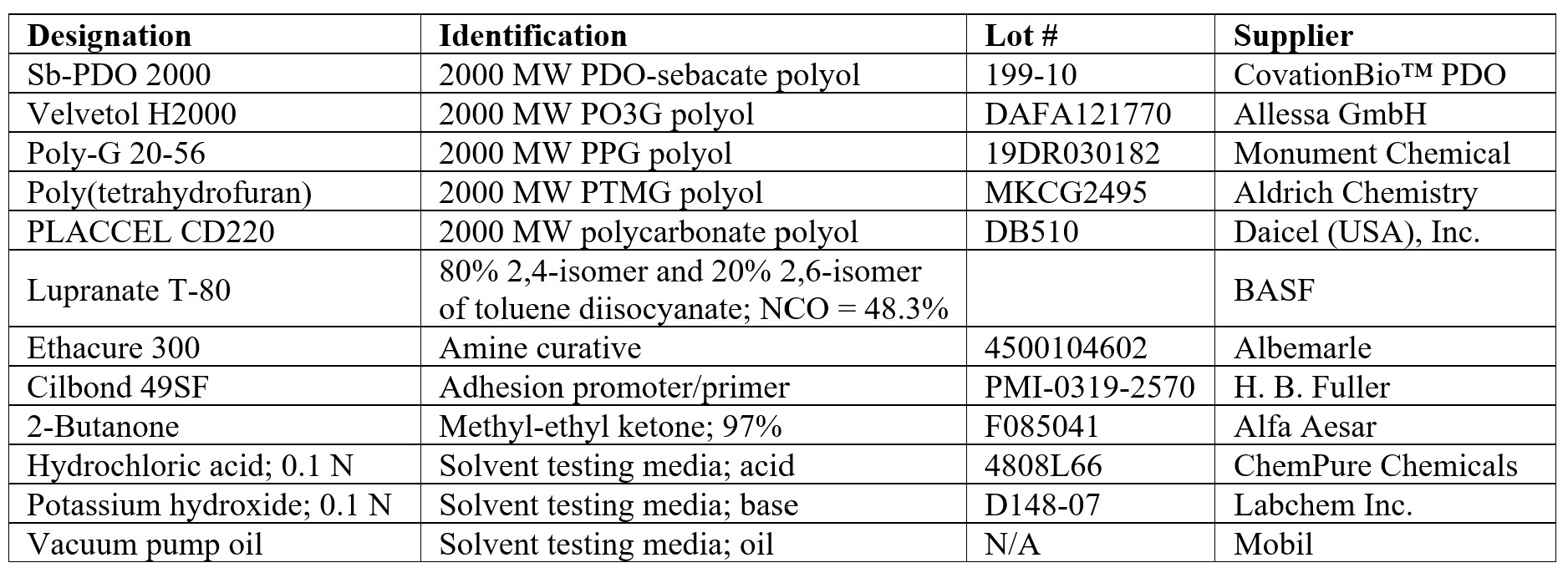

Materials

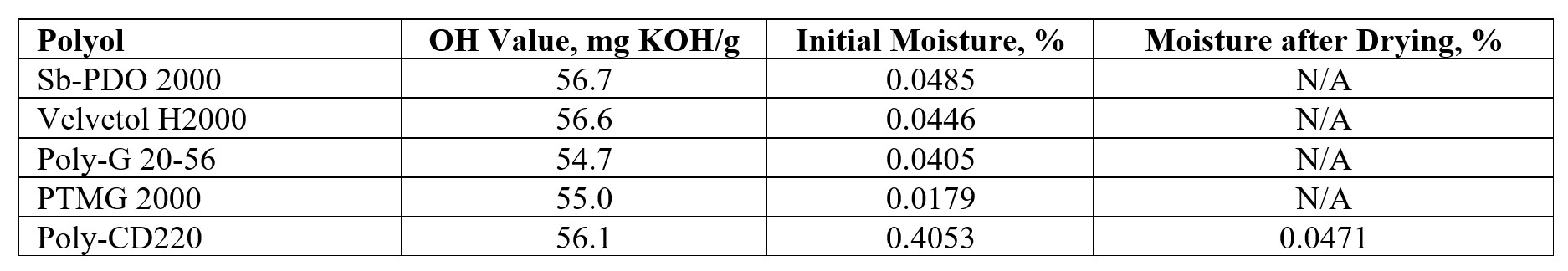

Materials used in this study are listed in Tables 1 and 2. The water content of the polyols was checked by Karl Fisher method (ASTM D-4672). If water content was higher than 0.06%, the polyol was de-moisturized for 24 hours at 75-80 °C under vacuum of 1-3 mm Hg and continuous mixing by magnetic stirrer (Table 2). Isocyanate was used as received from the suppliers. Prior to use, isocyanate content was checked by di-n-butylamine titration method (ASTM D-5155).

TABLE 1 ǀ Materials.

TABLE 2 ǀ Properties of polyols.

Preparation of NCO-Pre-Polymers

NCO-terminated pre-polymers, based on TDI 80/20 and selected polyols, were prepared at NCO/OH equivalent ratio of 2/1, according to the following procedure: calculated amount of TDI was placed in a 1L glass reaction kettle equipped with agitation and continuous nitrogen flow. The reactor was heated via temperature-controlled heating mantle. When the temperature of isocyanate reached 70 oC, polyol was added to the reactor under continuous stirring and temperature at 65-75 oC. The reaction was monitored via NCO% titration. After the theoretical NCO% value was reached, the reaction was stopped by cooling to room temperature. The pre-polymer was stored in a sealed glass bottle under nitrogen at room temperature.

The following properties of TDI NCO-pre-polymers were measured:

- NCO%;

- Viscosity at 70 °C;

- Tg, DSC analysis.

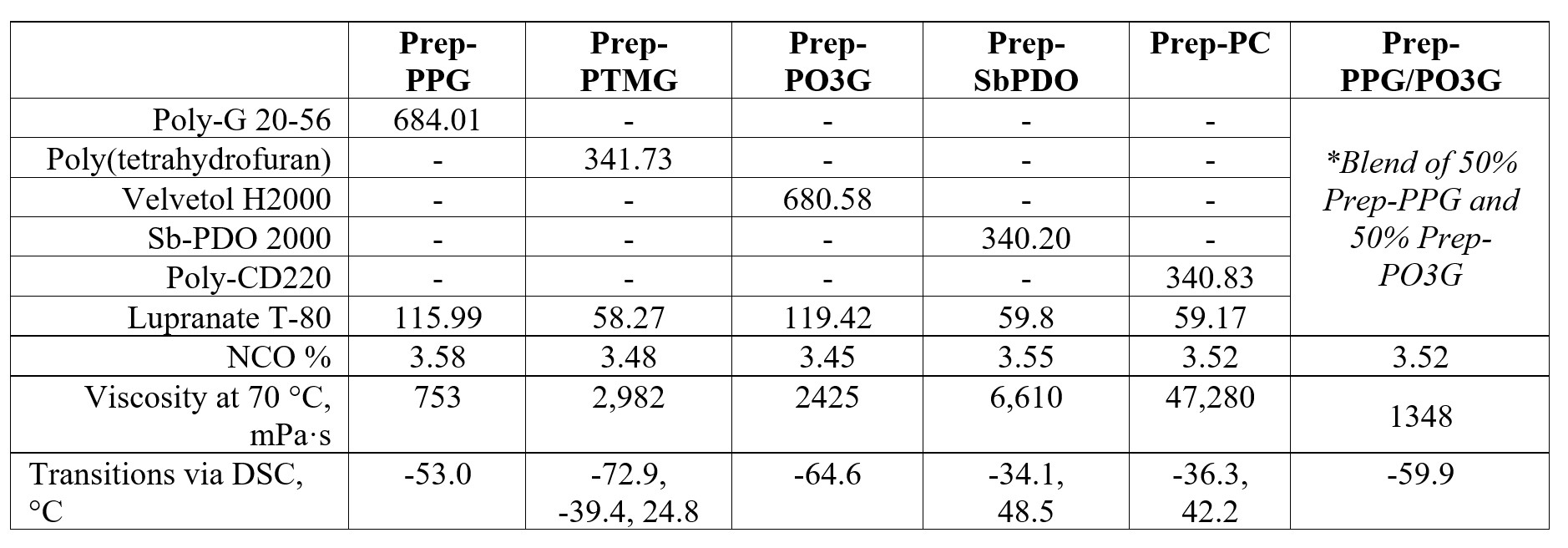

The formulation of NCO-pre-polymers and their properties are presented in Table 3.

TABLE 3 ǀ Formulation and properties of TDI pre-polymers.

Preparation of Cast Elastomers

Cast elastomers were prepared at NCO/NH2 equivalent ratio 2.05 as presented in Table 4. Cast elastomers were prepared using the following procedure: calculated amount of pre-polymer was weighed into a 100g cup (suited for a speed mixer) and heated in an oven at 80 °C for 1 hour. Calculated amount of Ethacure 300 was added to the pre-polymer and mixed by a speed mixer (FlackTek Inc.) for 1 minute. The resin was placed in the oven at 80 °C until gel time and then dispensed into Teflon-lined molds preheated to 80 °C. The mold was closed and placed in a Carver press pre-heated at 80°C, pressed to 20,000 psi, cured for 1 hour, and then removed. The cast elastomers were post-cured for 7 days at room temperature before testing. Cast elastomer sheets (6x6 inches and 3 mm thickness) and cylindrical sample “buttons” (D=1 in, H= ½ in) were prepared for testing.

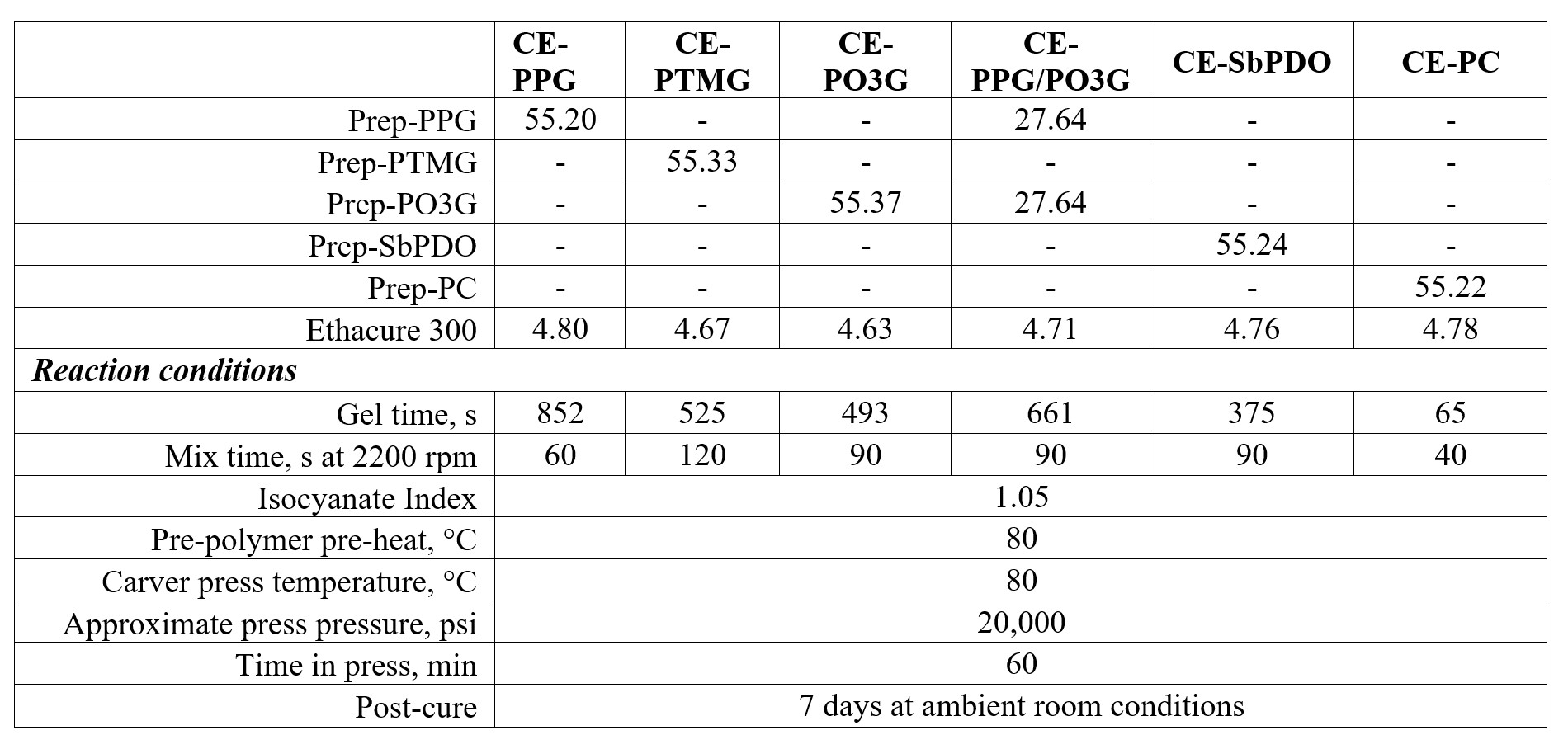

TABLE 4 ǀ Curing conditions in preparation of cast elastomers.

Testing of Cast Elastomers

The following properties of cast elastomers were measured:

- Hardness, Shore A, ASTM D-2240;

- Tensile stress-strain properties at RT, ASTM-412 (tensile strength at break, 100% and 300% modulus, elongation at break);

- Tear resistance, Graves die C, ASTM D-624;

- Resilience, Bayshore rebound, ASTM D-430;

- Heat resistance (tensile properties at 50 and 70 °C);

- Hydrolytic stability (weight change and change of stress-strain properties with exposure to 95% RH at 60 °C for 5 days). The retention of tensile properties was calculated;

- Abrasion resistance, ASTM D-1044;

- Oil resistance in selected hydraulic oil (weight change after three days of immersion at RT);

- Resistance in water solution at two pH values (higher than pH 7 and lower than pH 7), (weight change after three days of immersion at RT);

- Glass transition temperatures (Tg) via DSC.

Adhesion Properties of Cast Elastomers

The adhesion test specimens were prepared using steel panels RS-14 (Q-Lab Corporation) of substrate. Steel panels were pre-treated with the adhesion promotor, which was utilized to enhance the adhesion of cast elastomers to steel as is conventionally done in production of protective urethane liners for pipe protection.

Preparation of Adhesives

Steel panels (RS-14, 1x4 inches) were immersed for 30 seconds in solution of 50 g Cilbond 49SF and 30 g methyl-ethyl ketone and then dried in a vertical position at room temperature for 1 hour. Panels were then transferred to an oven preheated at 110 °C and baked for 2 hours. After cooling the panels to room temperature, NCO-prepolymer and Ethacure 300 curative were mixed at specified weight ratio via speed mixer and allowed to thicken in an oven pre-heated to 60 °C. Resin was applied to the panels at 0.15g per 0.5” of one end of panels, and panels were clamped overlapping at 0.5 inches. Test samples were then oven cured at 60 °C for 1 hour and aged 3 days at room temperature before testing or transferring to humidity chamber for hydrolytic aging.

The adhesion properties were tested via ASTM D1002 adhesive lap joint test. The adhesion samples were also humid aged (95% RH at 60 °C for 5 days) and tested after aging. The retention of adhesion properties was calculated.

Results and Discussion

TDI-Based NCO-Pre-Polymers

NCO-pre-polymers were prepared from TDI isocyanate and following polyols:

- PDO-sebacate 2000 polyester polyols;.

- PO3G 2000 polyether polyol;

- PPG 2000 polyether polyol (reference);

- PTMG 2000 polyether polyol (reference);

- Polycarbonate 2000 polyol (reference).

The blend of 50:50 by weight of PPG/TDI and PO3G/TDI pre-polymer was prepared as well and was used in cast elastomer preparation.

The pre-polymers based on PPG 2000 and PO3G 2000 were liquid at room temperature, while those based on PTMG 2000, PDO-sebacate 2000, and polycarbonate polyol were solid at room temperature. The viscosity of NCO-pre-polymers at 70 oC based on polyether polyols was lower than that based on PDO-sebacate 2000 polyol at 6610 cps (Table 3). However, the viscosity of NCO-pre-polymer based on Polycarbonate 2000 was much higher at 47,280 cps (Table 3). In general, lower viscosity of NCO-pre-polymers is desirable property in cast elastomers applications.

DSC analyses indicates crystallinity of NCO-pre-polymers based on PTMG polyol with melt transition at 24.8 oC, PDO-sebacate polyol with melt transition at 48.5 oC, and polycarbonate polyol with melt transition at 42.2 oC (Table 3). The remaining NCO-pre-polymers appear to be non-crystalline.

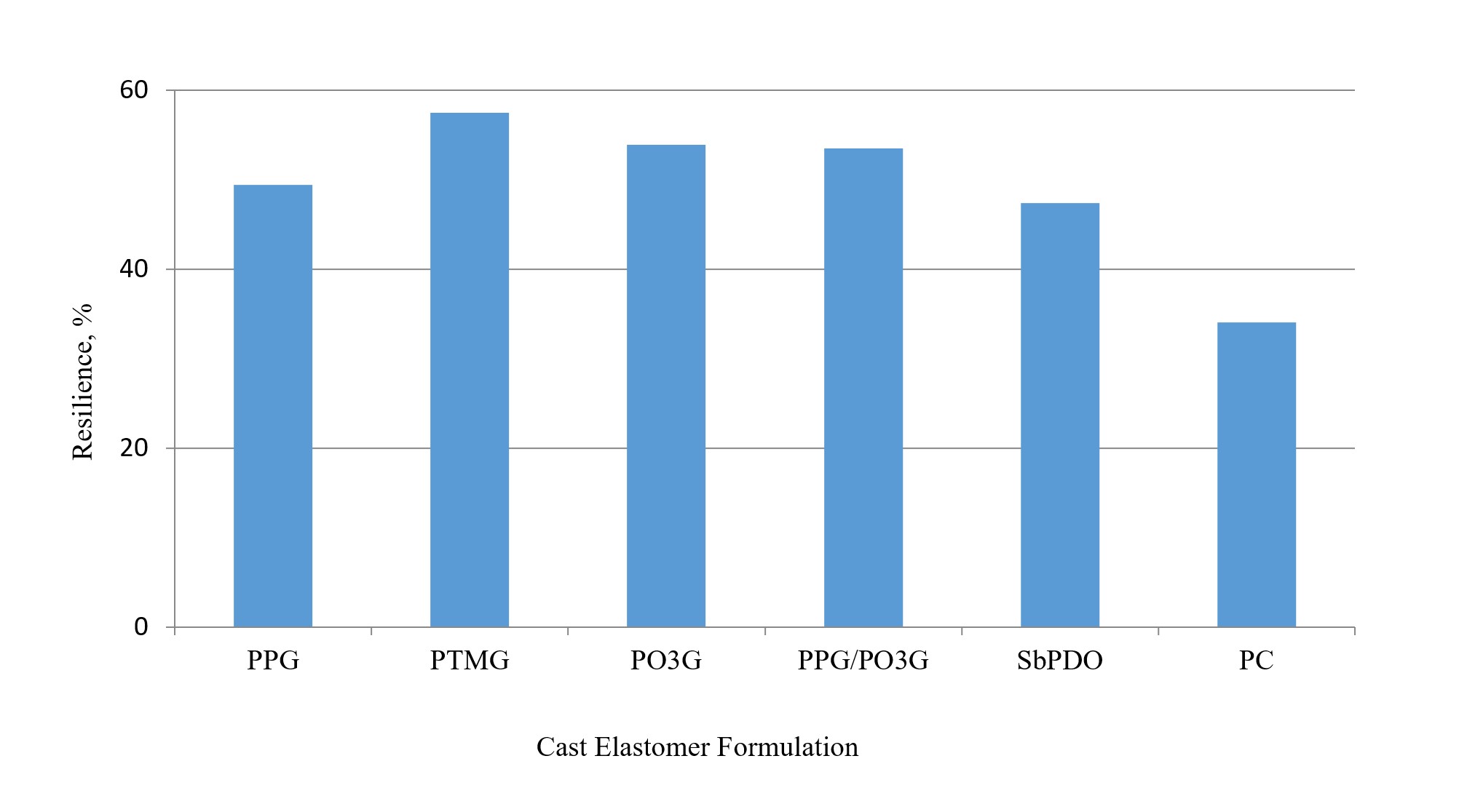

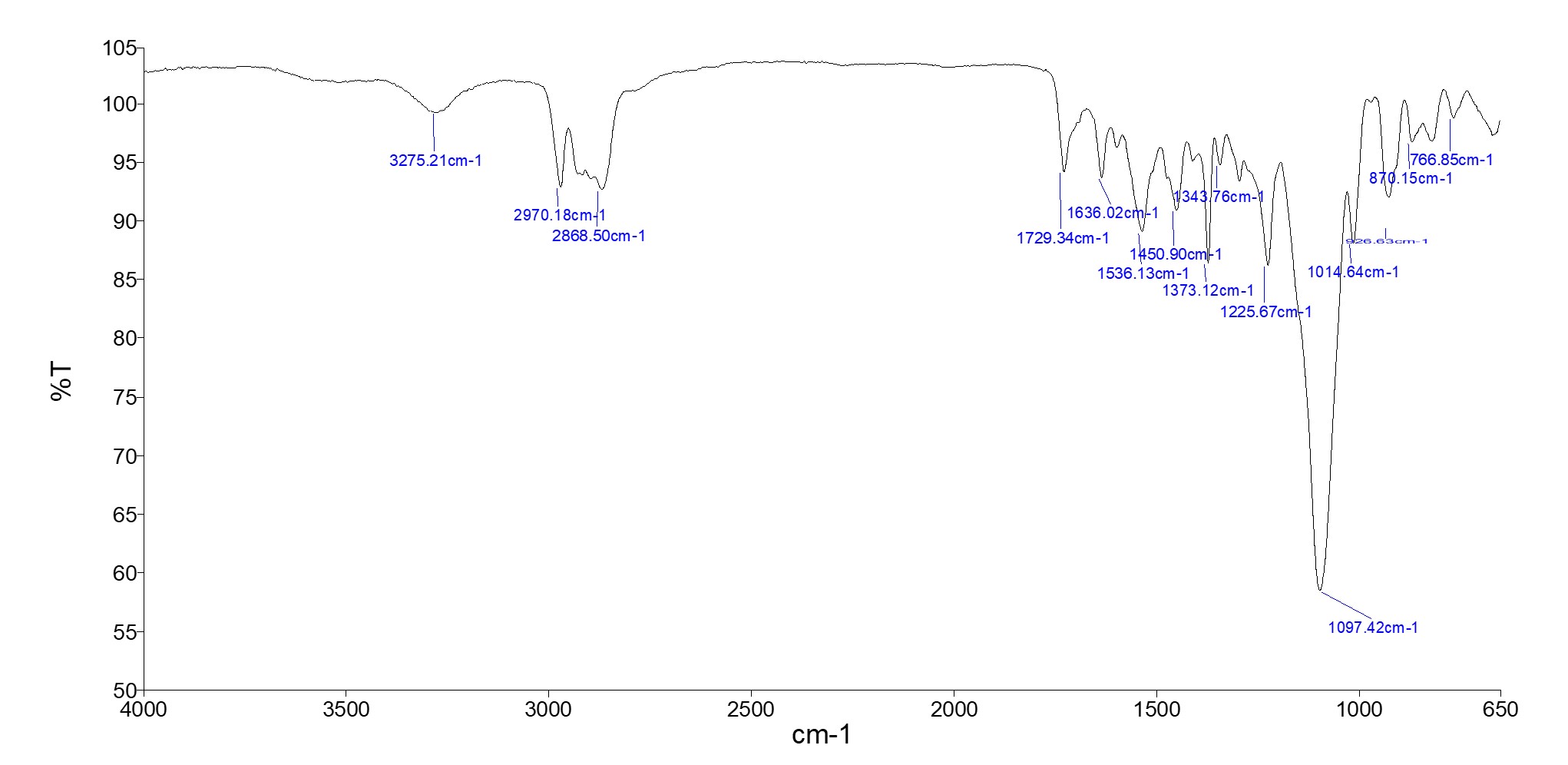

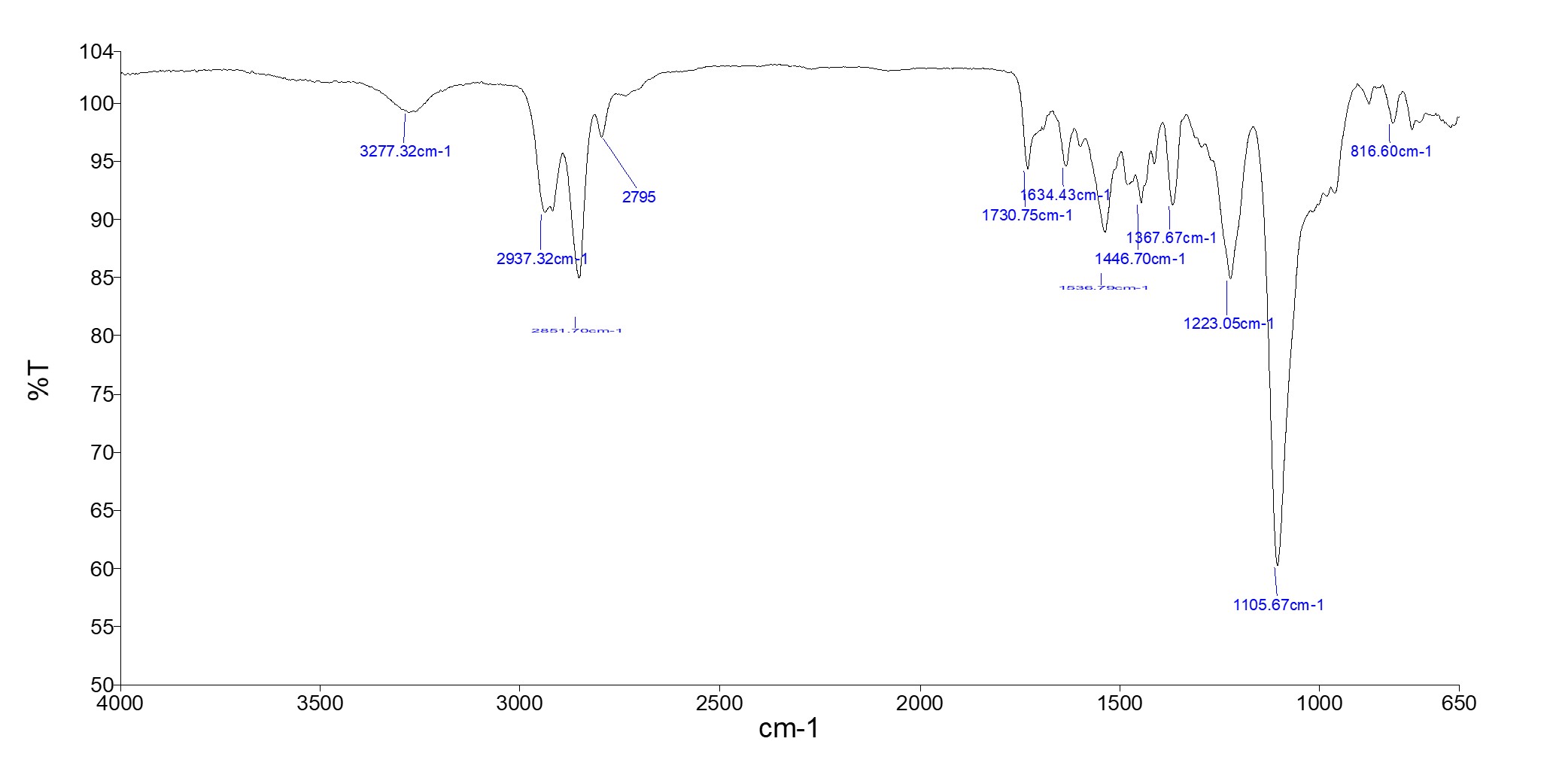

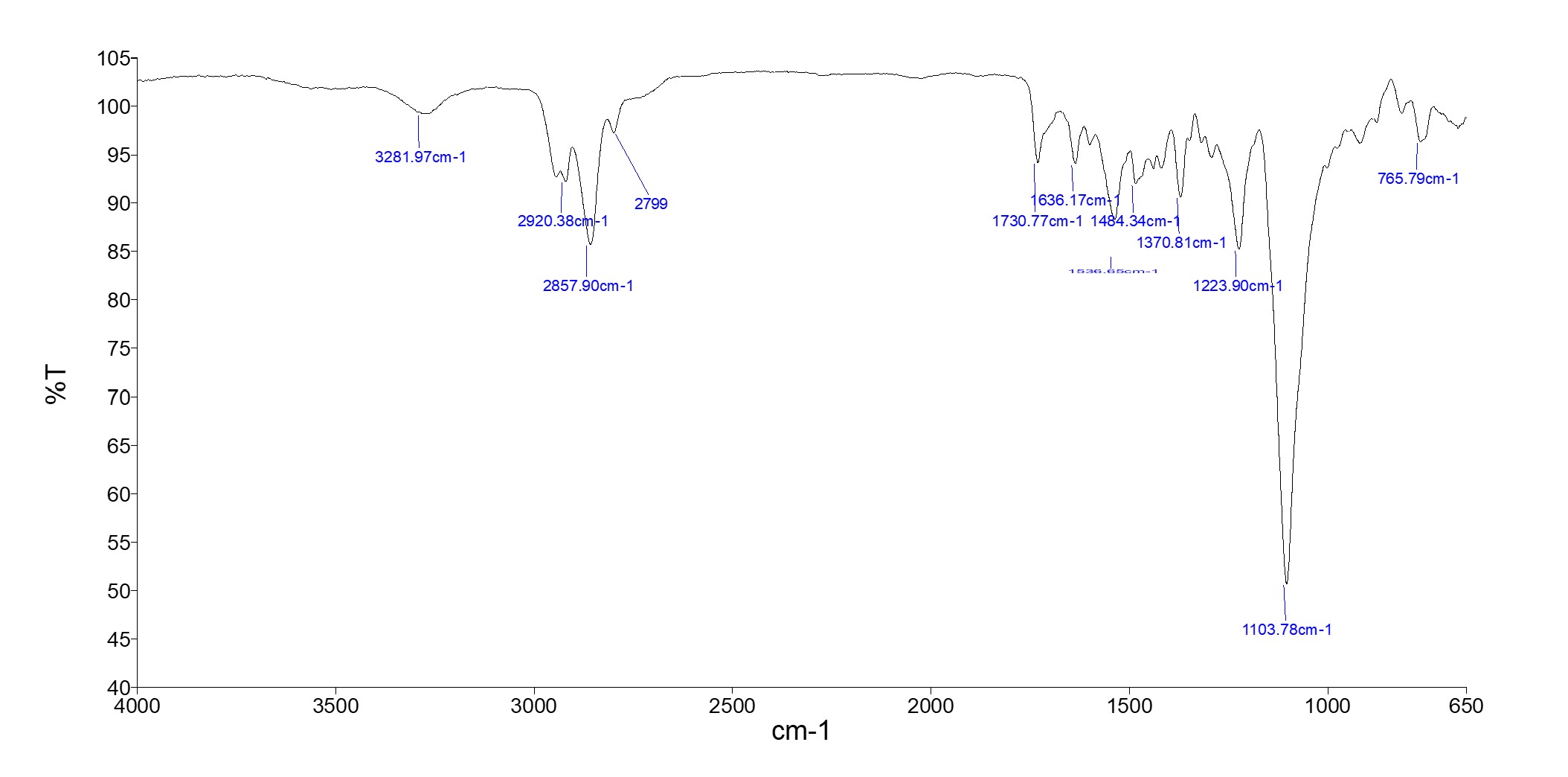

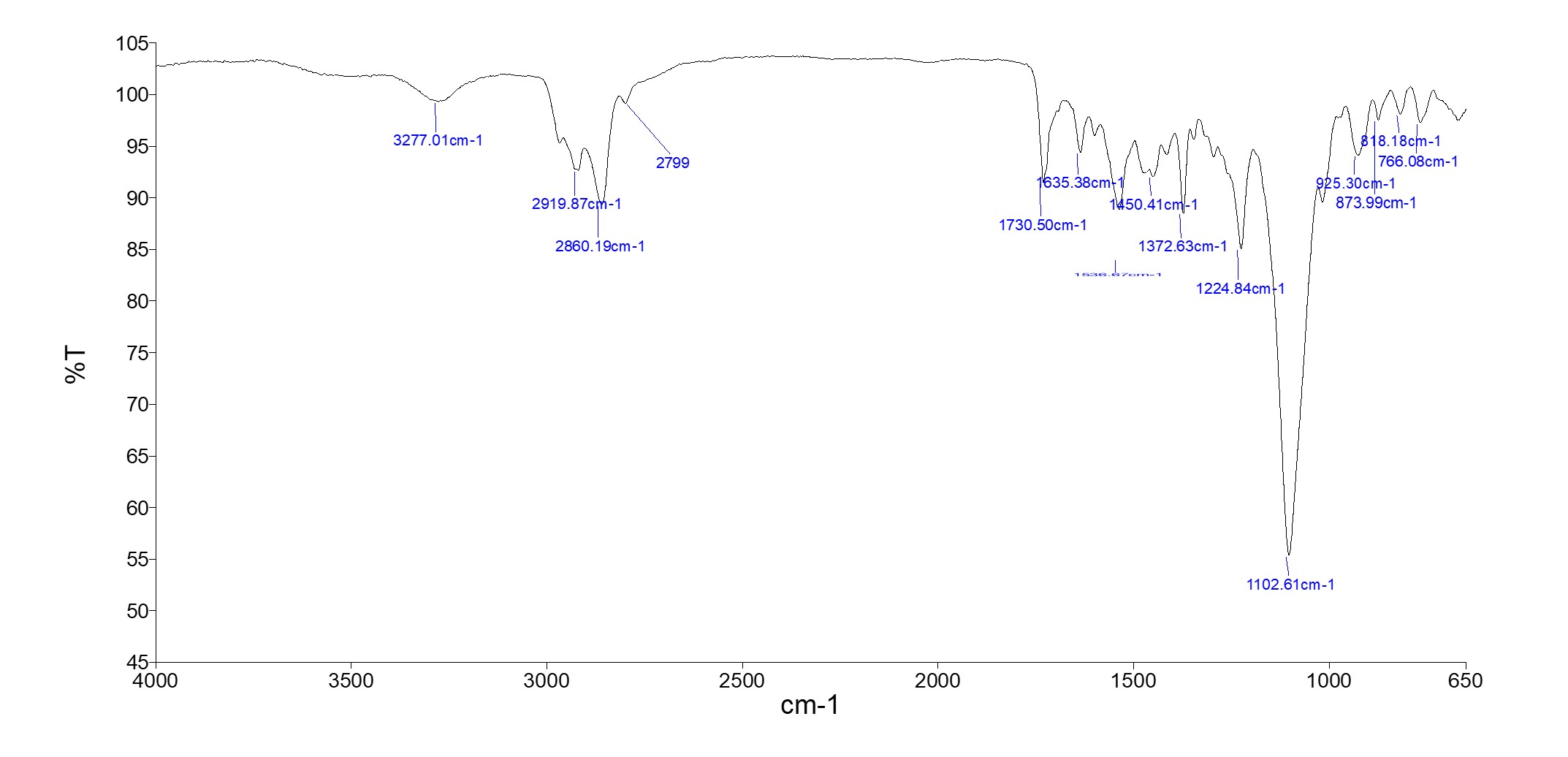

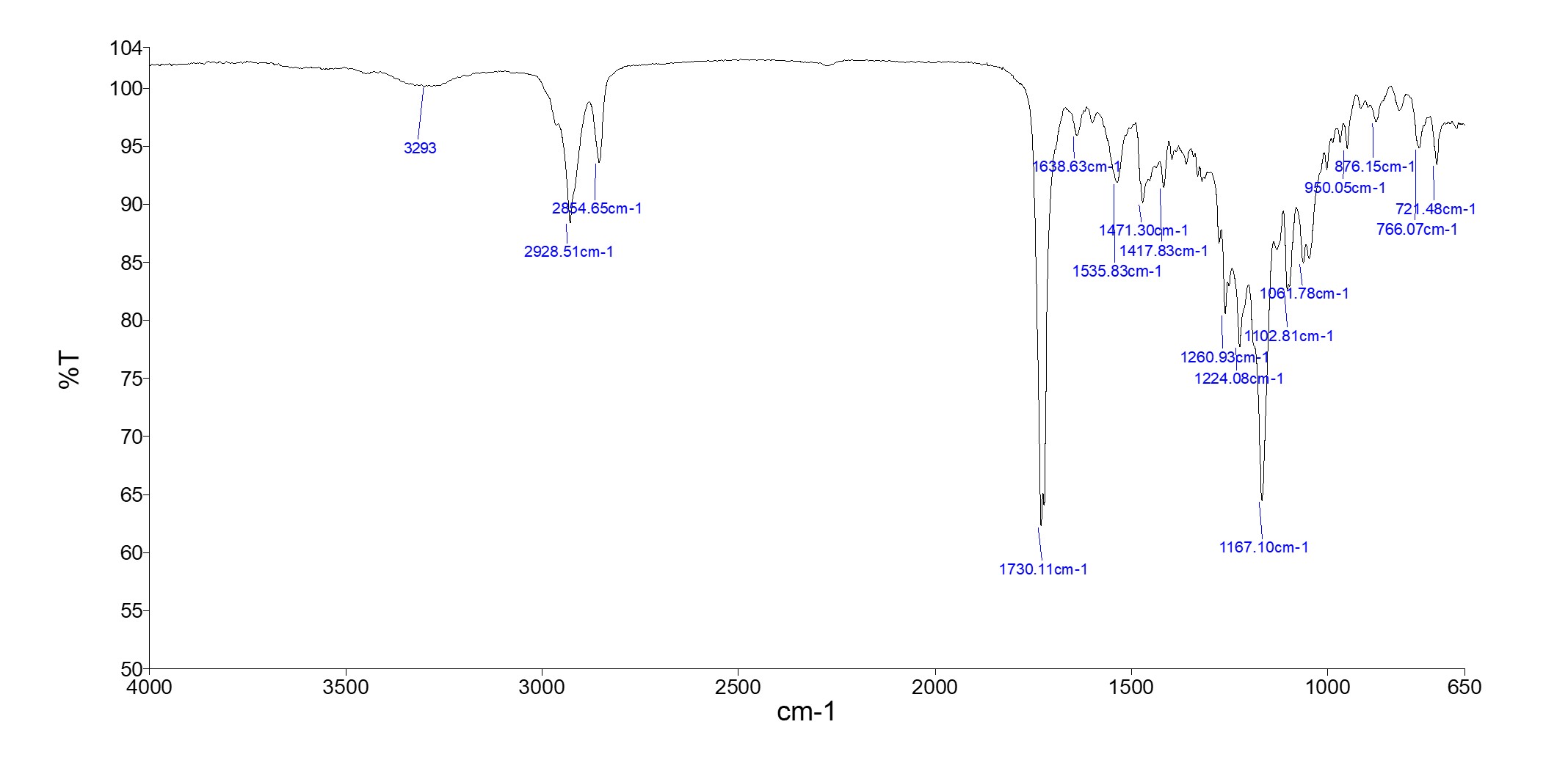

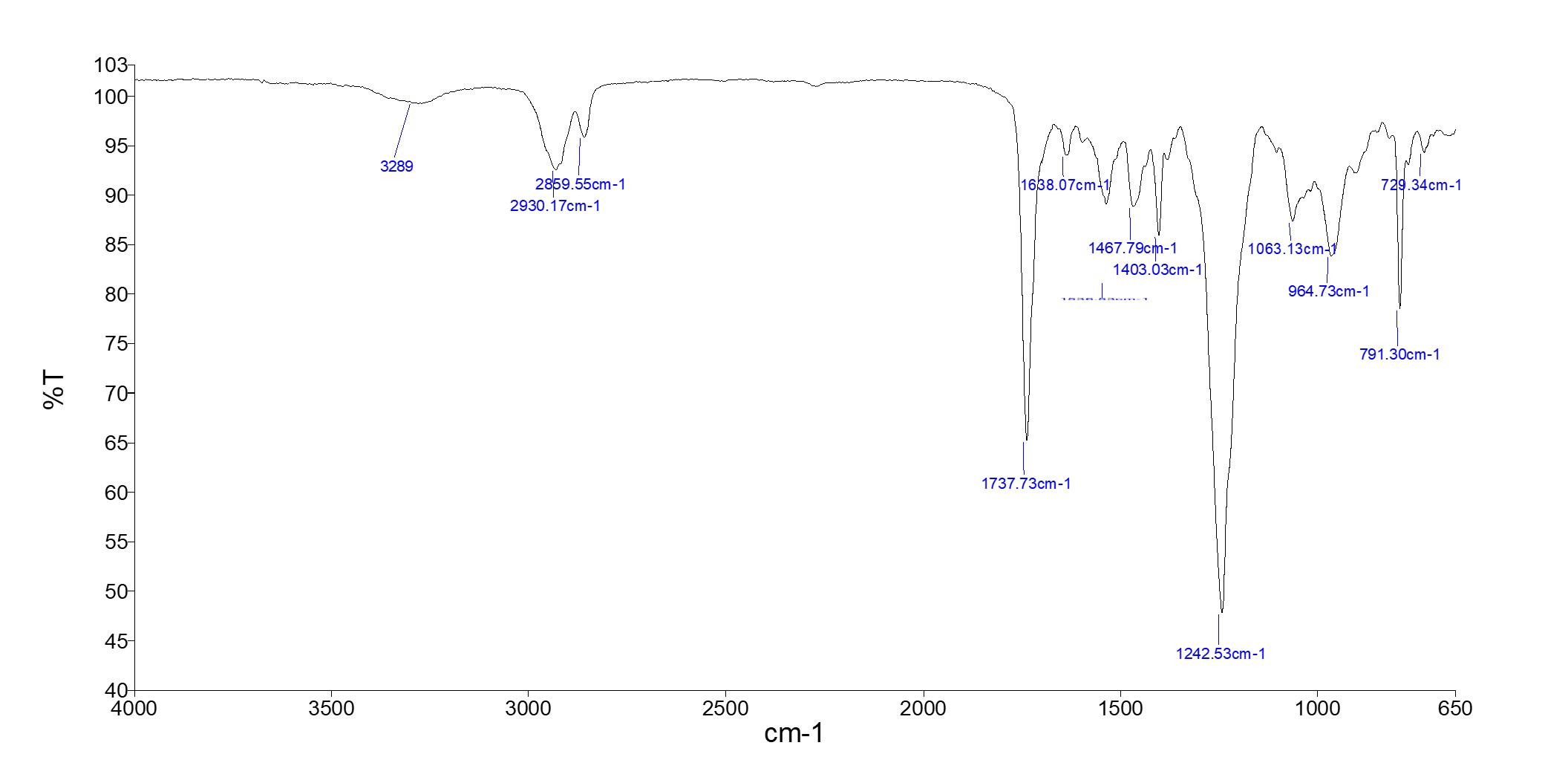

Cast Elastomer Performance

Cast elastomers were prepared by reaction of NCO-pre-polymer with Ethacure 300 at isocyanate index of 1.05 (Table 4). Gel time (80 oC) of cast elastomer resins based on polyether polyols was longer than that based on polyester PDO-sebacate 2000 and polycarbonate polyol. Gel time in urea forming reaction can be adjusted with temperature of pre-polymer, as needed. Cast elastomers were completely polymerized, after-cured and post-cured for seven days at RT, as indicated via FTIR analysis (Appendix A, Figures 1-6). All cast elastomers samples were transparent at room temperature.

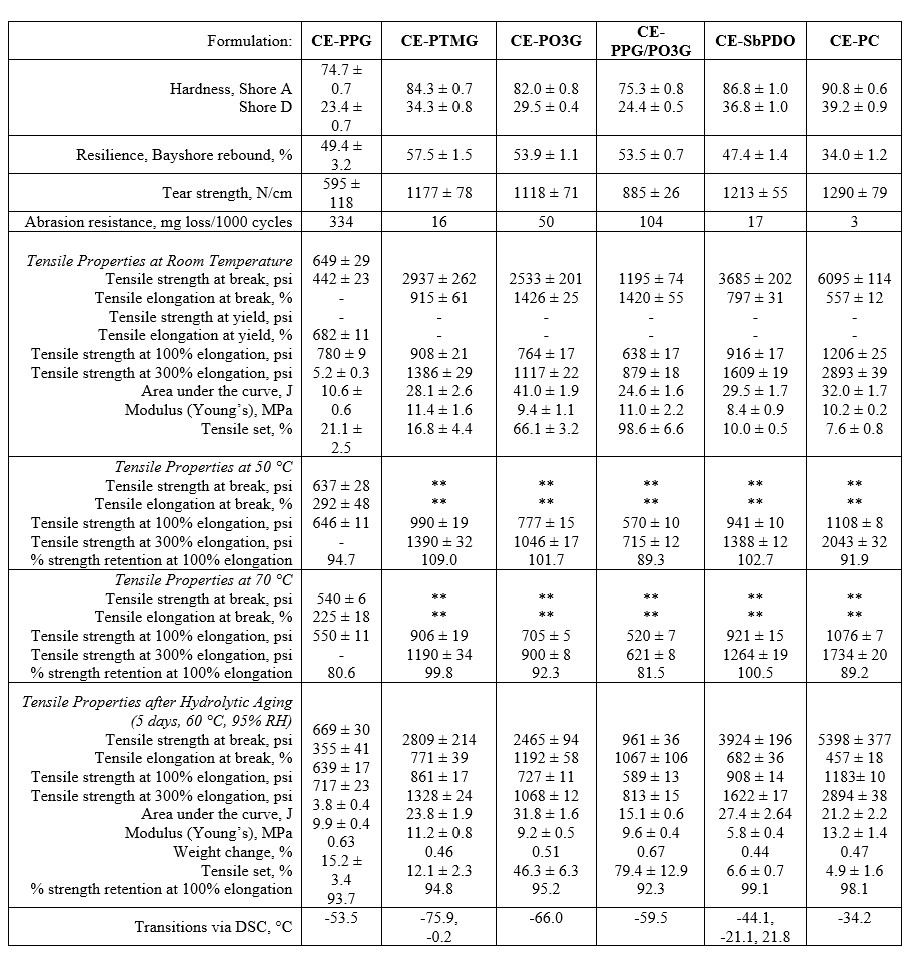

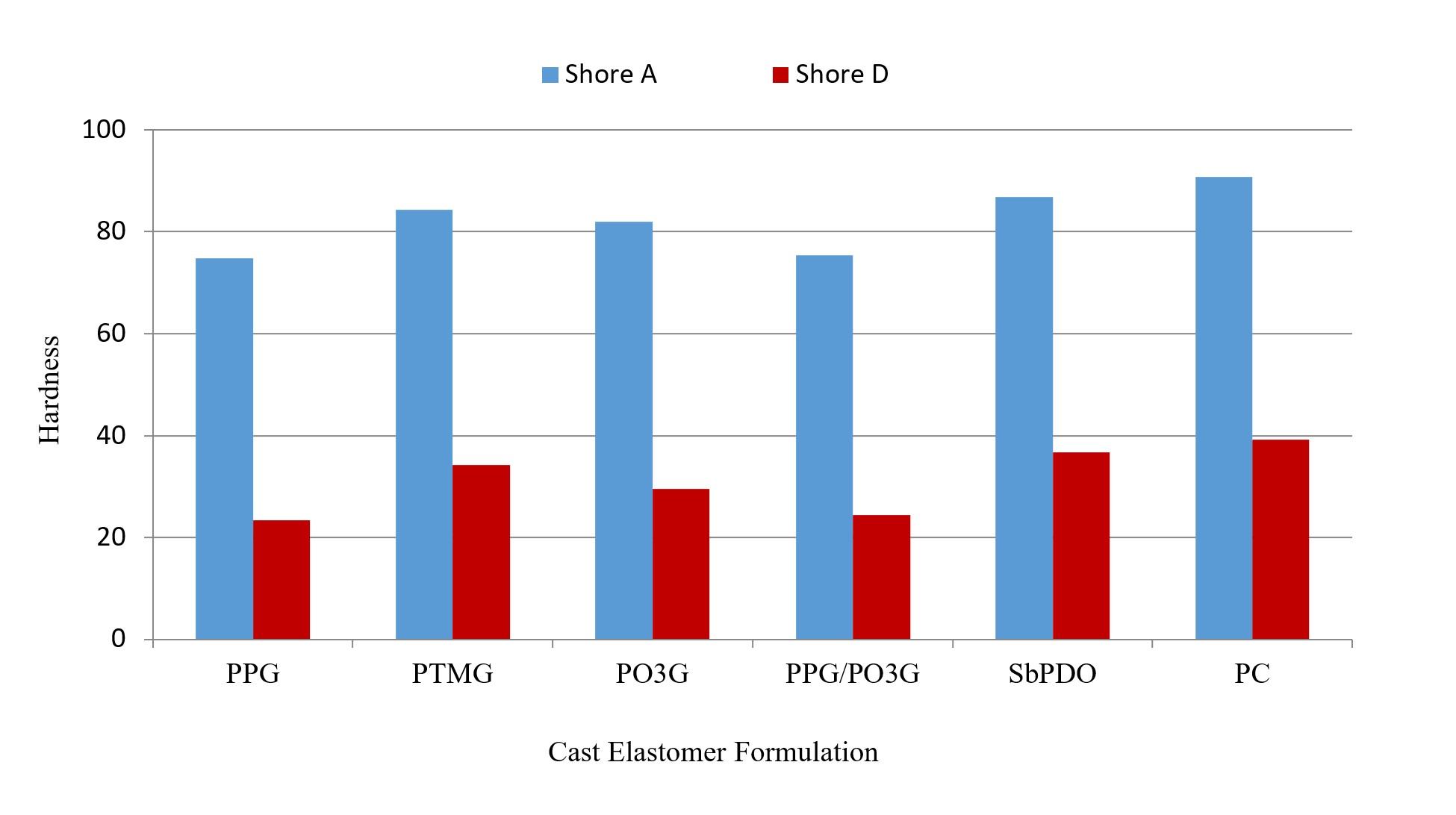

Hardness and Resilience

Cast elastomers based on PPG 2000 exhibited lower hardness (Shore A 74.7) than those based on PTMG 2000 and PO3G 2000 (Shore A 84 and 82, respectively). The hardness of cast elastomer based on PDO-sebacate 2000 (Shore A 86.8) and Polycarbonate 2000 (Shore A 90.8) was higher (Table 5, Figure 1).

TABLE 5 ǀ Properties of cast elastomers.

FIGURE 1 ǀ Hardness (Shore A and D) of cast elastomer prepared with various polyols.

The resilience of cast elastomers based on polyether polyols was higher than of cast elastomers based on polyester and polycarbonate polyols (Table 5). It should be noted that resilience of cast elastomer based on PDO-sebacate polyol was somewhat higher than that based on polycarbonate polyol. The resilience of cast elastomers was found to corelate with their elasticity (elongation at break %) as shown in Table 5 and Figure 2.

FIGURE 2 ǀ Resilience of cast elastomers prepared with various polyols.

Thermal Properties

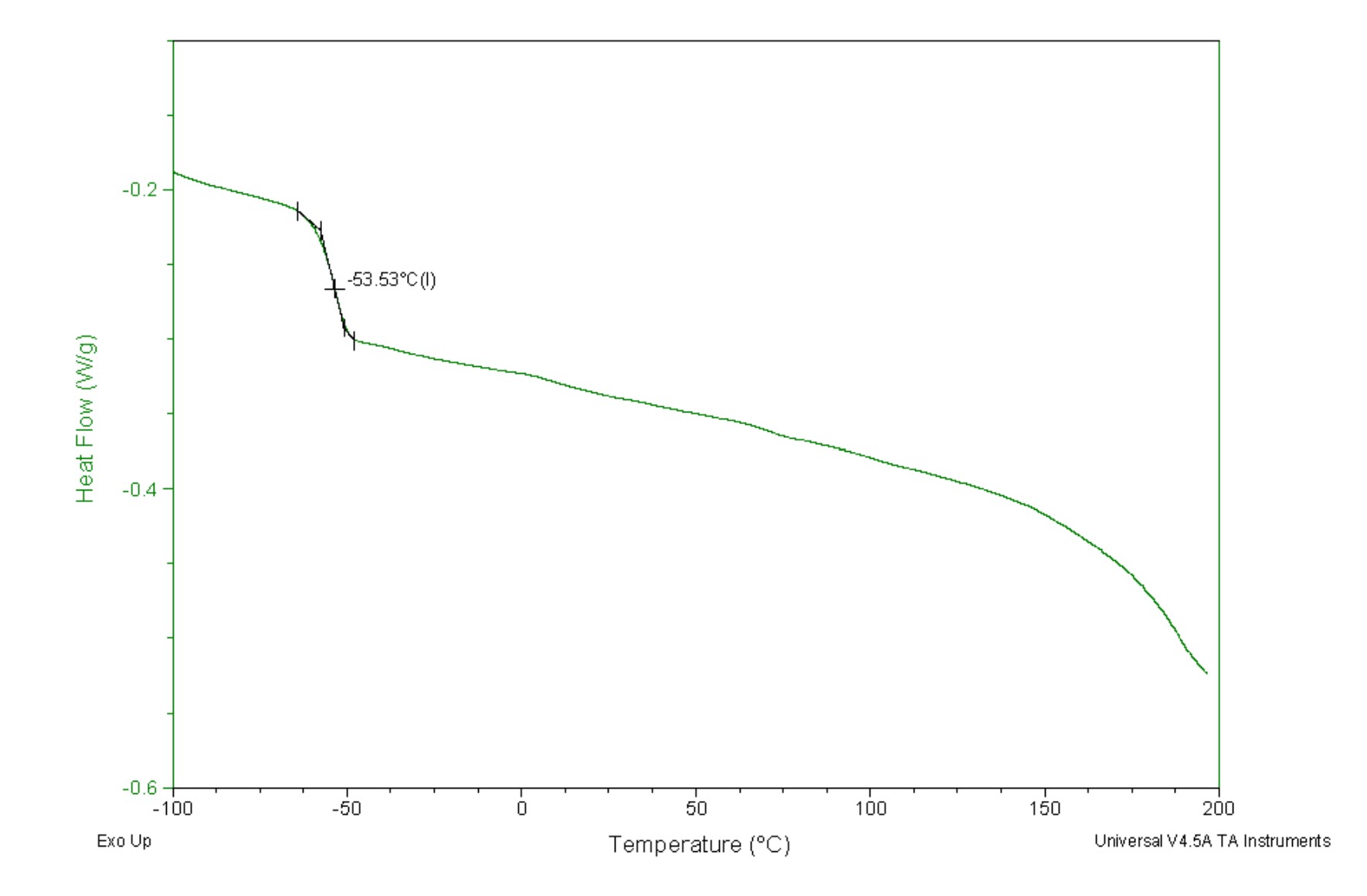

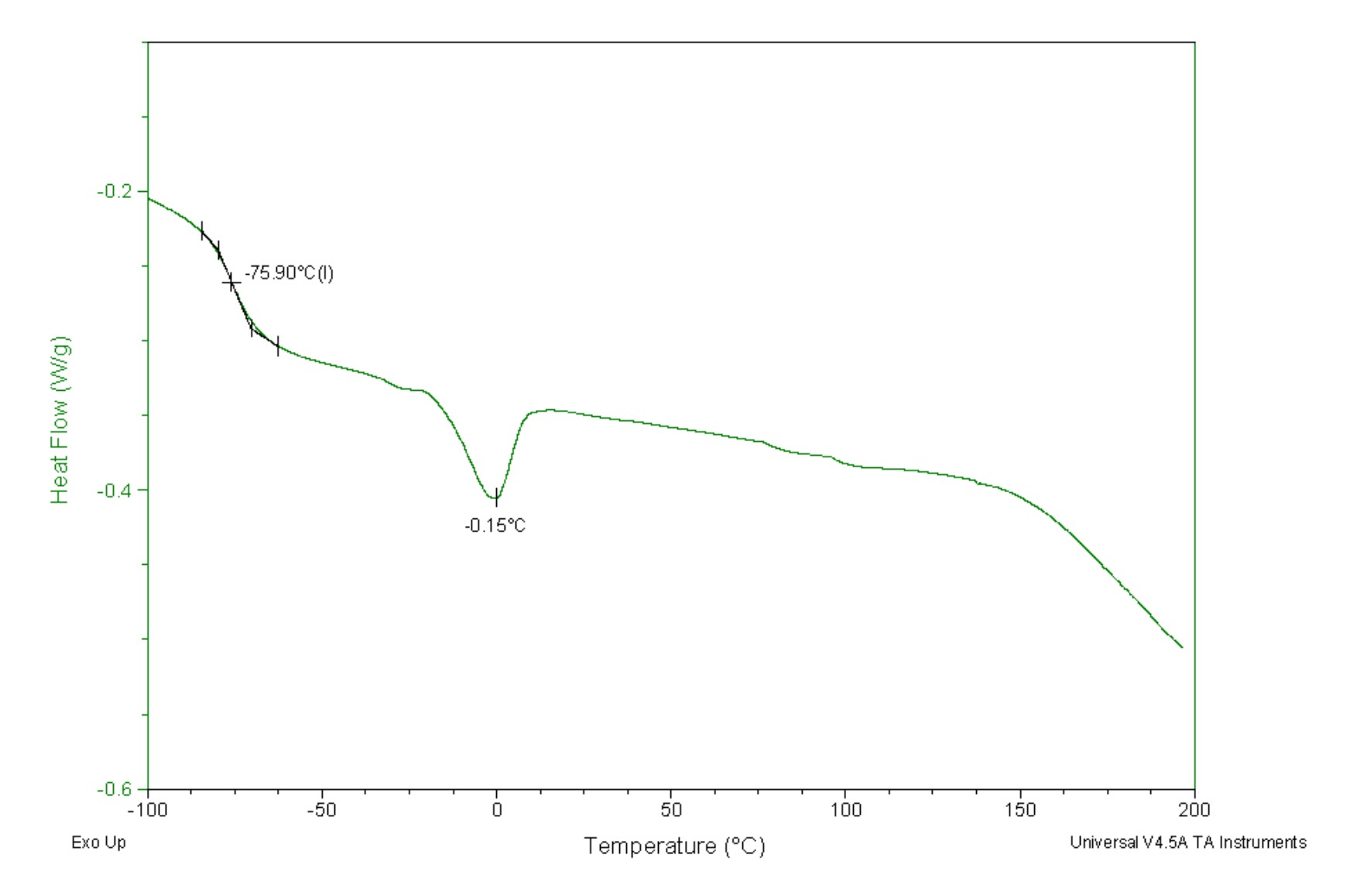

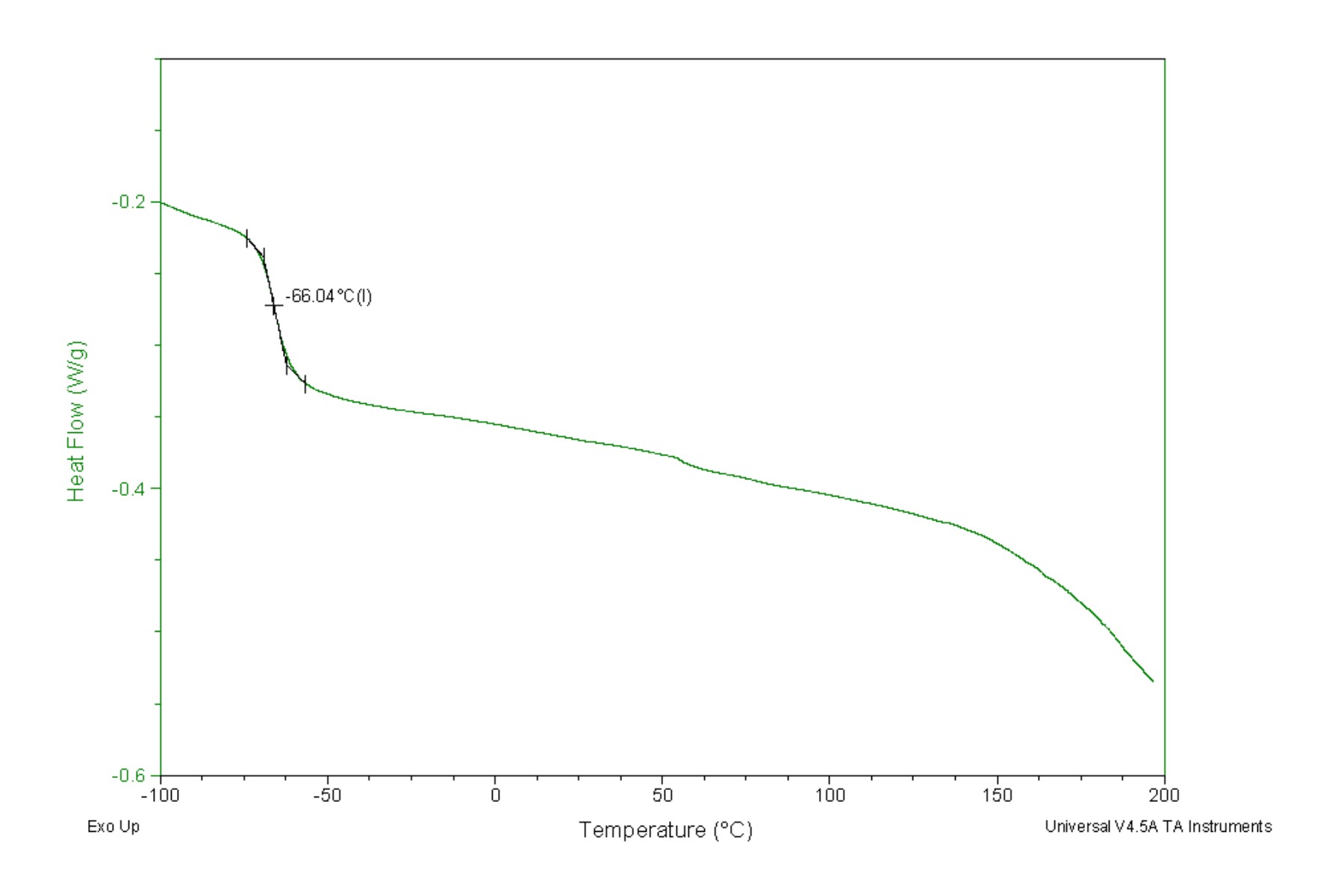

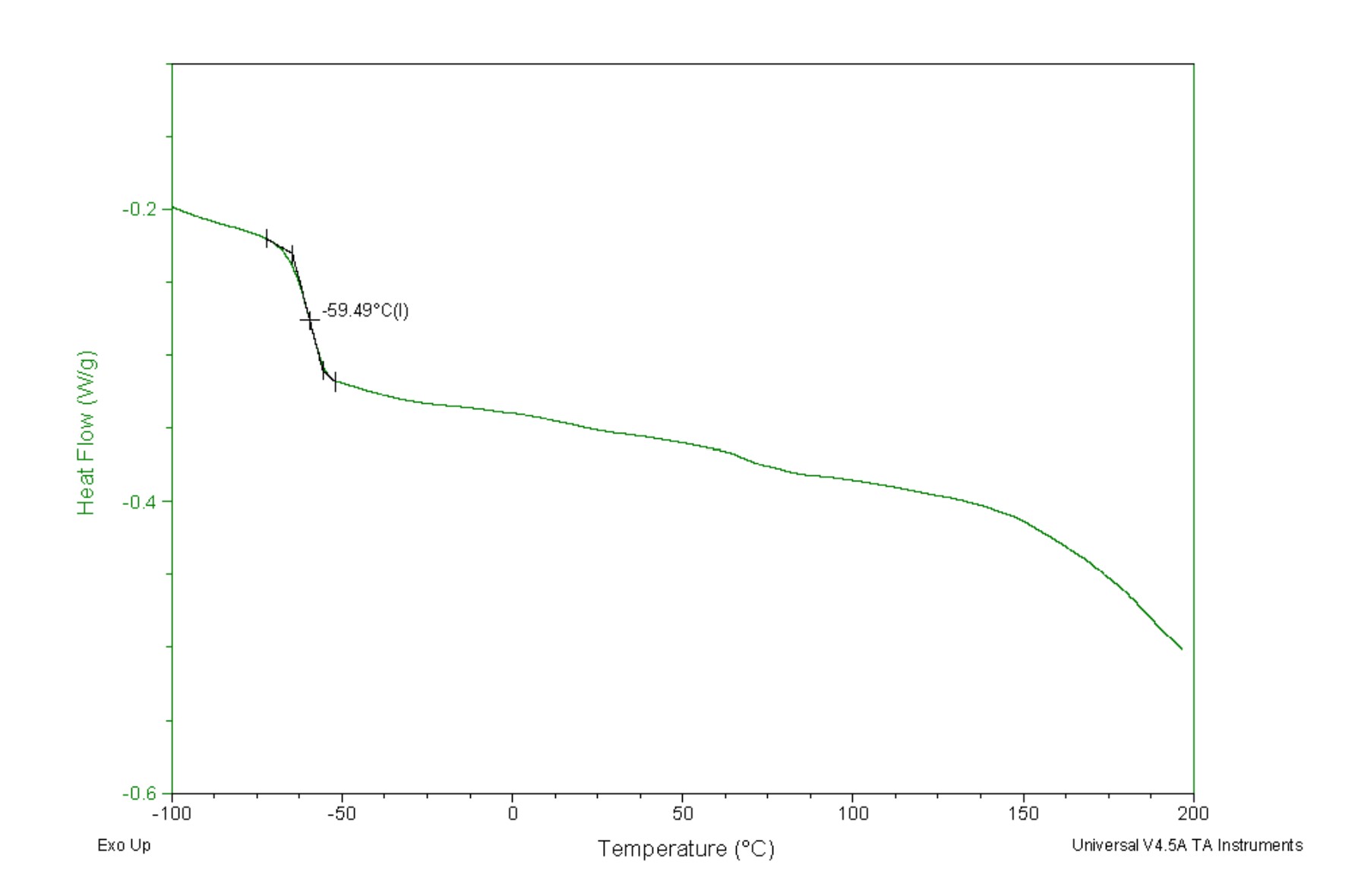

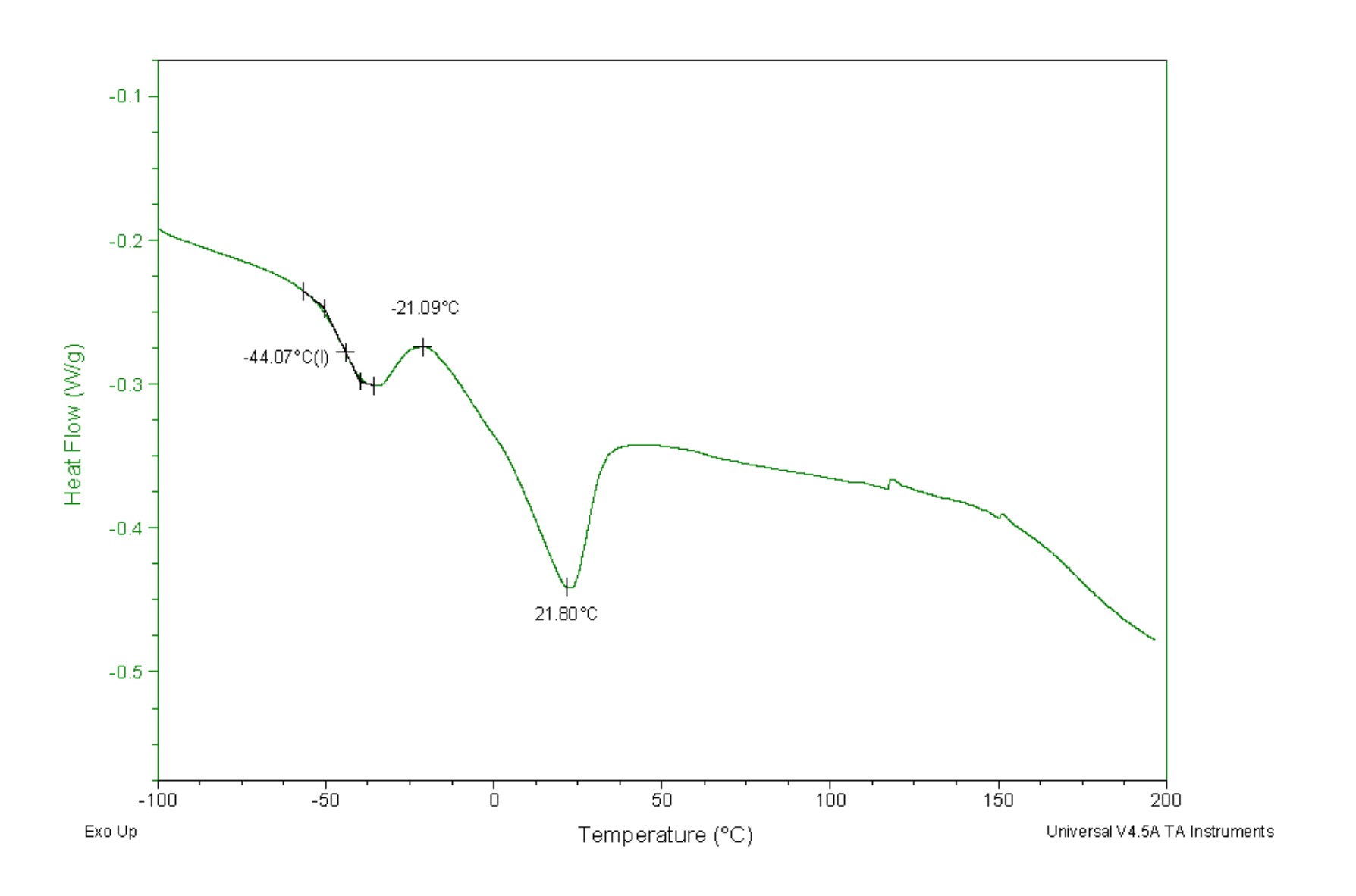

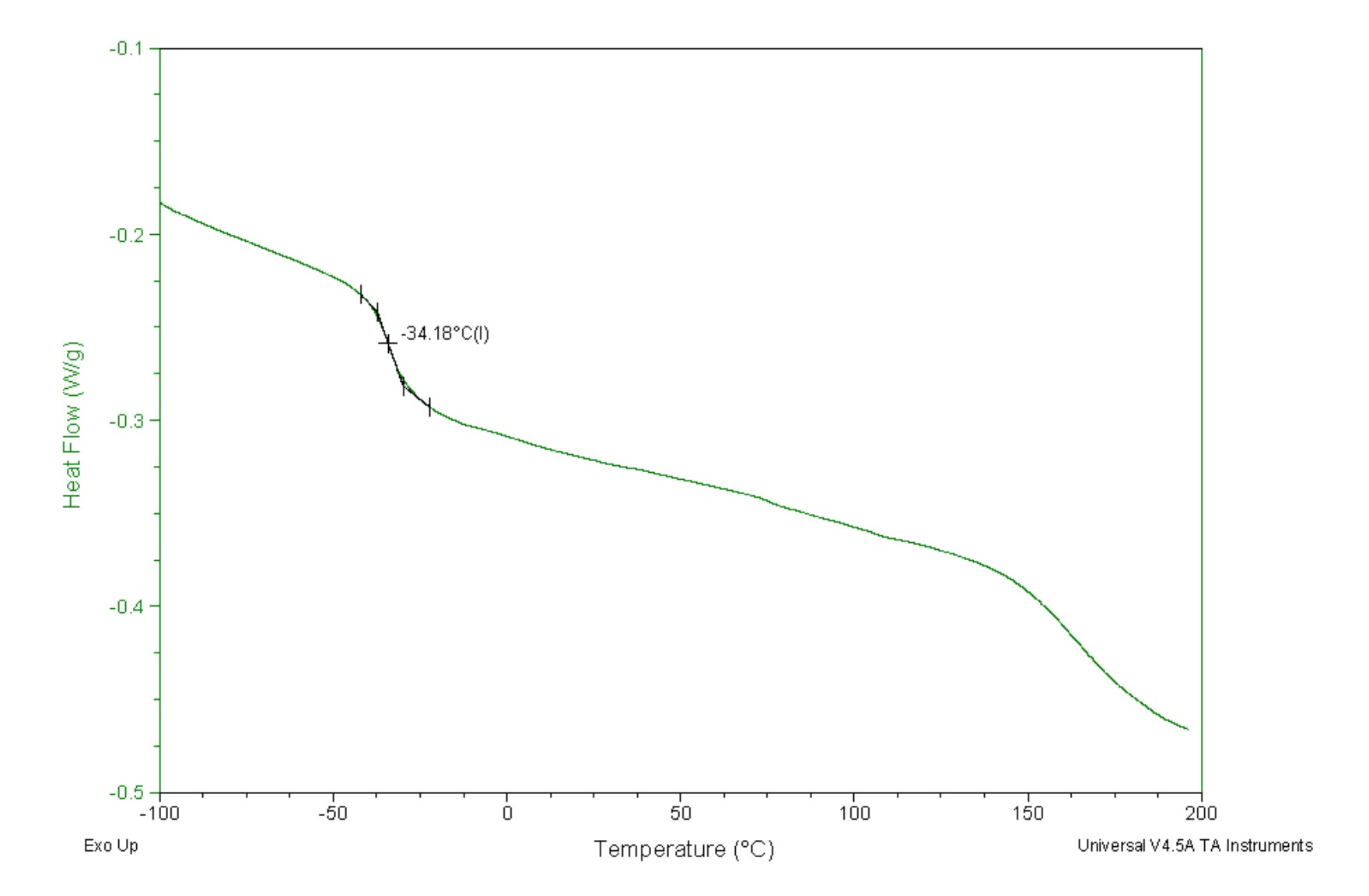

The thermal transitions of cast elastomers were measured via DSC over a temperature range from -100 oC to 200 oC (Table 5, Figures 3-8). The glass transition temperature was found to depend on type of polyol in cast elastomers. The glass transition temperature of cast elastomers based on polyether polyols (from -55 oC to -75.9 oC) was lower than for cast elastomers based on Polycarbonate 2000 (-34.2 oC) and PDO-sebacate 2000 (-44.1 oC). DSC graph of cast elastomers based on PTMG 2000 indicate a crystalline transition at -0.15oC and cast elastomer based on PDO-sebacate 2000 at 21.8oC.

FIGURE 3 ǀ DSC thermal analysis of cast elastomer based on PPG 2000 polyol.

FIGURE 4 ǀ DSC thermal analysis of cast elastomer based on PTMG 2000 polyol.

FIGURE 5 ǀ DSC thermal analysis of cast elastomer based on PO3G 2000 polyol

FIGURE 6 ǀ DSC thermal analysis of cast elastomer based on 50/50 pbw polyol blend PO3G2000/PPG2000.

FIGURE 7 ǀ DSC thermal analysis of cast elastomer based on PDO-sebacate 2000 polyol.

FIGURE 8 ǀ DSC thermal analysis of cast elastomer based on Polycarbonate 2000 polyol.

Tensile, Tear, and Abrasion

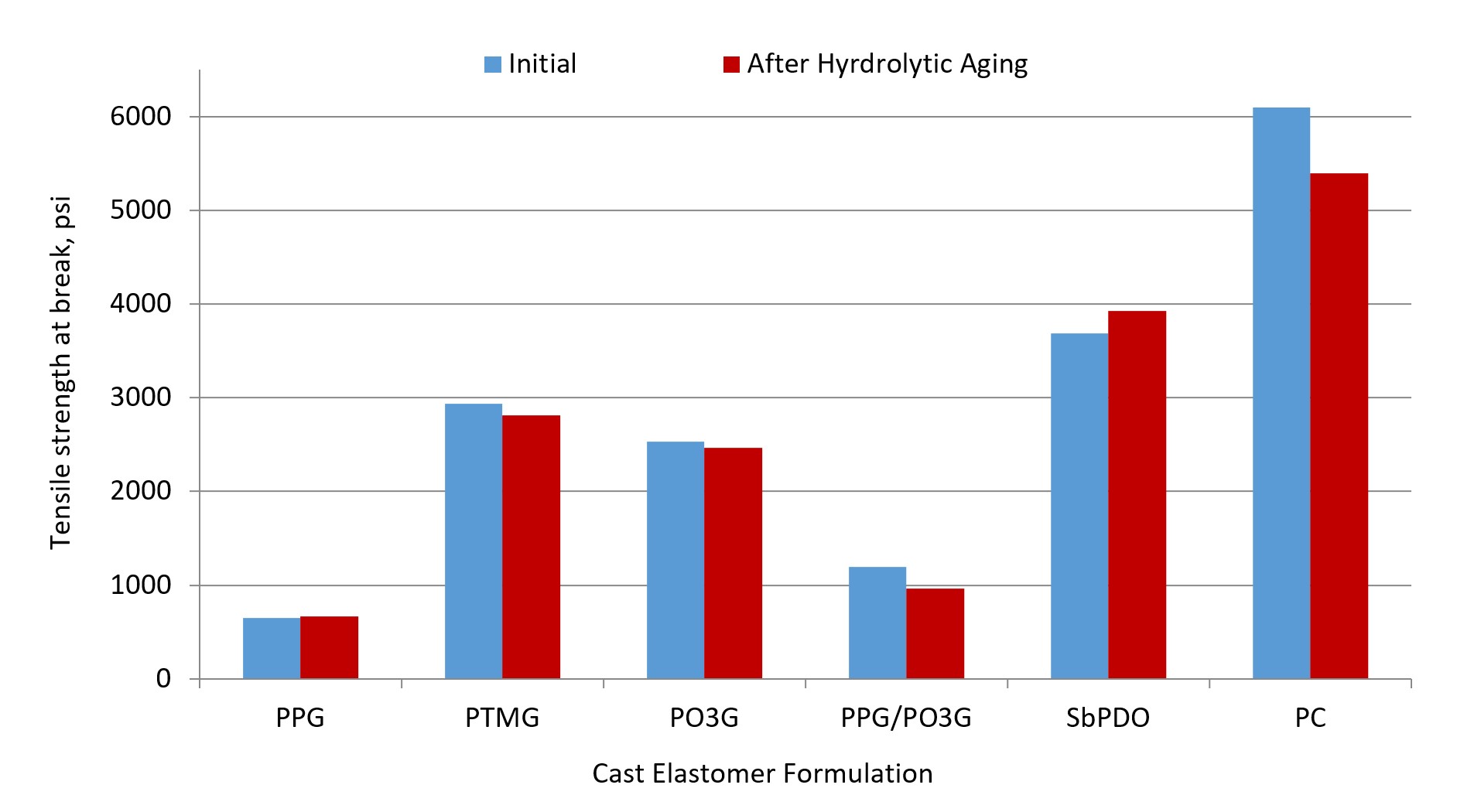

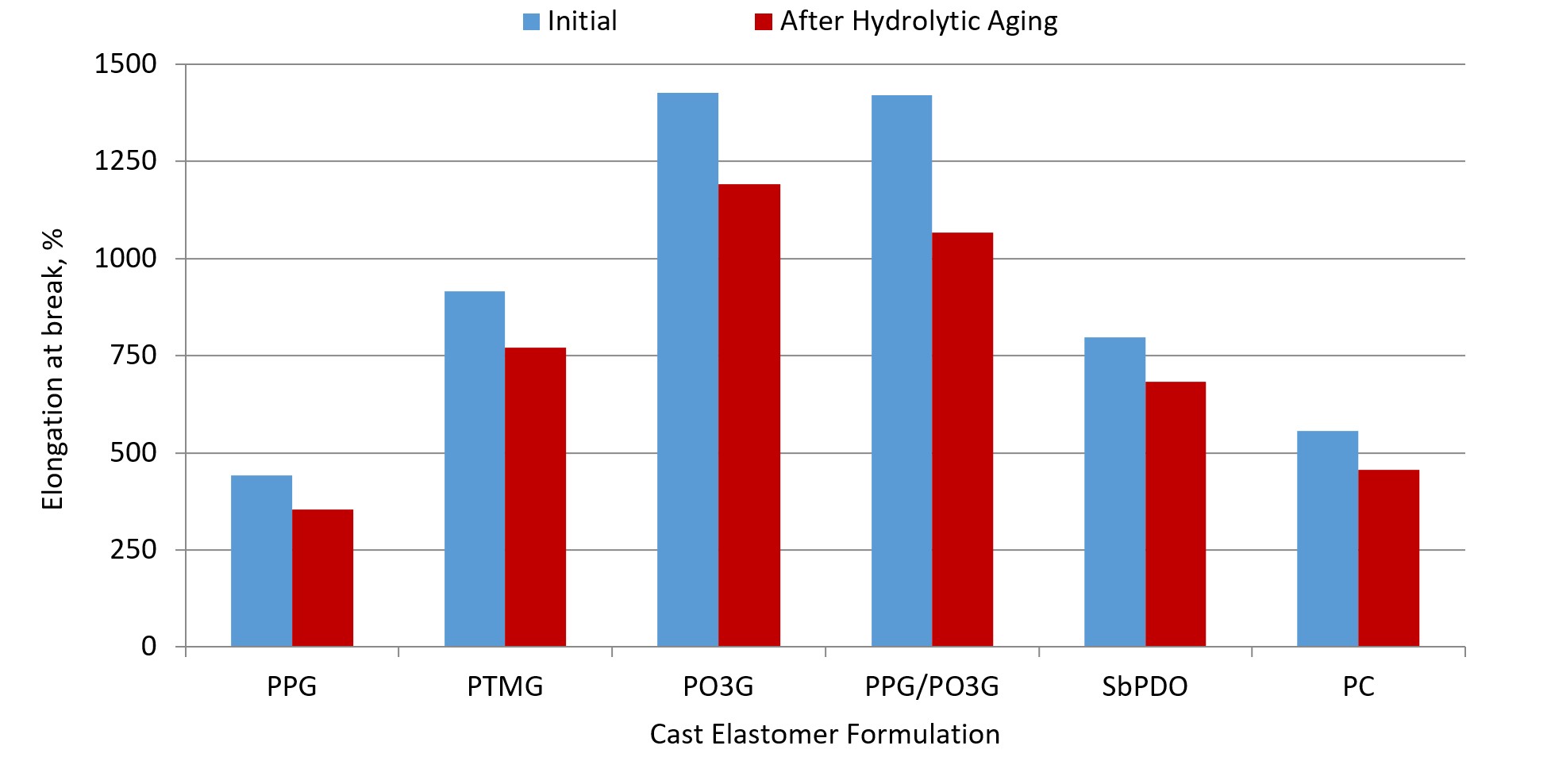

Tensile strength of cast elastomers based on PDO-sebacate polyol was higher than for cast elastomers based on polyether polyols, including PTMG, which is a high-performance cast elastomer (Table 5, Figures 9 and 10). Tensile strength of cast elastomer based on polycarbonate polyol was notable higher at 6055 psi, but its elongation at break was substantially lower. Thereby, cast elastomers based on PDO-sebacate, PTMG, and polycarbonate polyols exhibited comparable toughness as measured by the area under the tensile curve (Table 5). It should be noted that cast elastomers based on PO3G exhibited the highest toughness due to its very-high elongation at break. Overall, cast elastomers based on PPG polyol had the lower toughness, associated with low tensile strength and elongation at break.

FIGURE 9 ǀ Tensile strength at break of cast elastomers before and after hydrolytic aging.

FIGURE 10 ǀ Elongation at break of cast elastomers before and after hydrolytic aging.

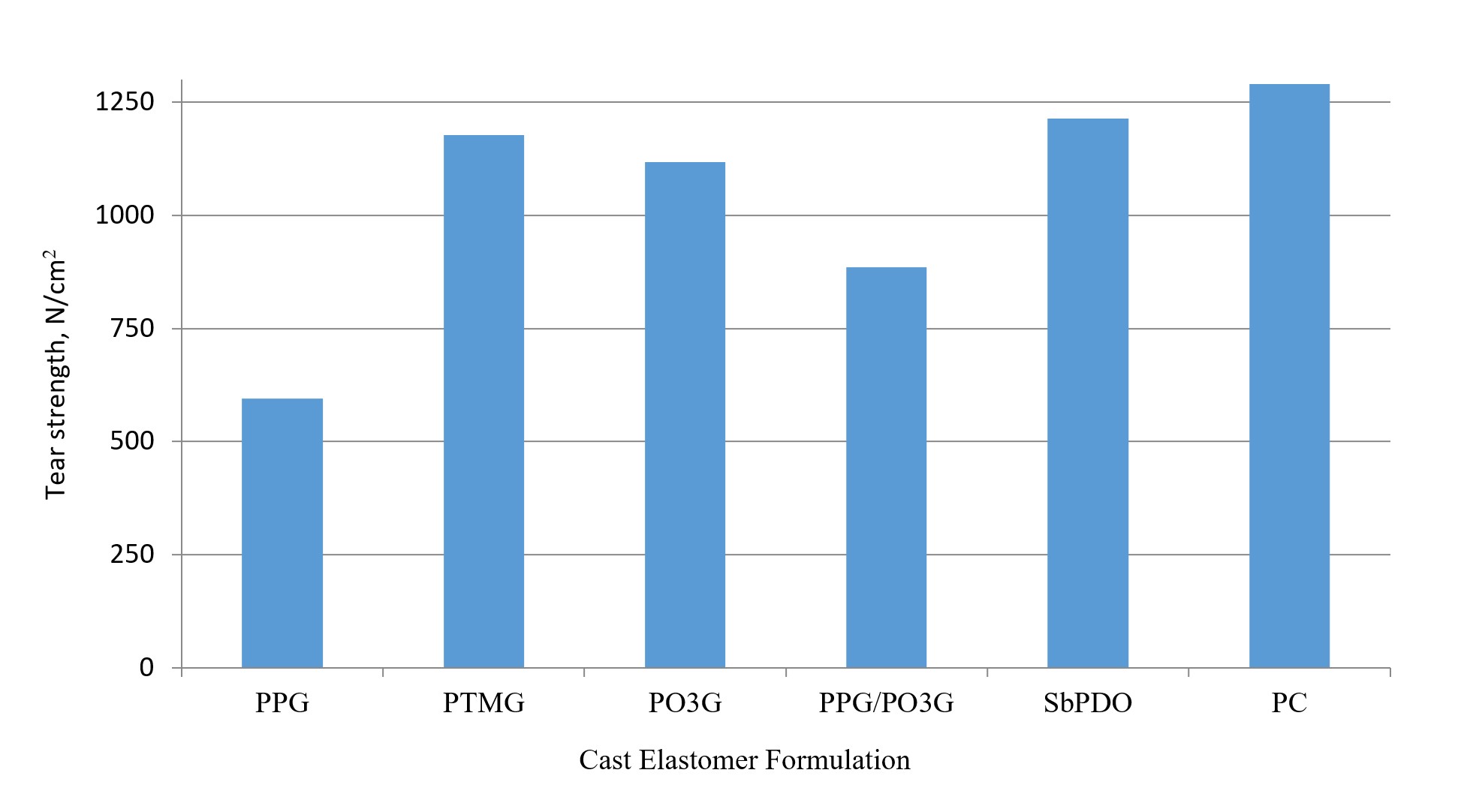

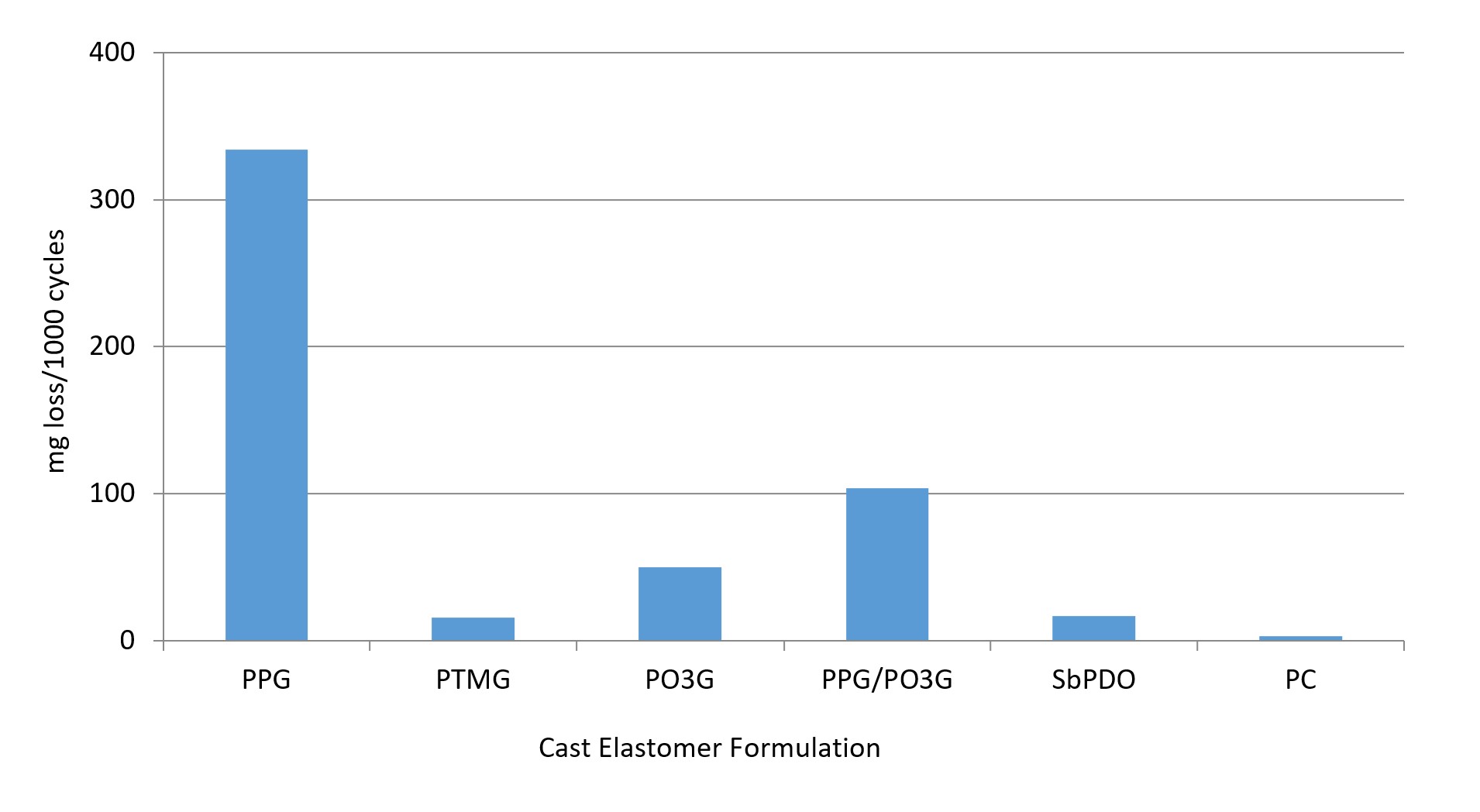

Perhaps a better indicator of wear performance is tensile modulus, which was highest for the cast elastomers base on polycarbonate polyols, followed by the cast elastomers based on PDO-sebacate and PTMG polyols. A similar trend was observed in tear strength and abrasion resistance (Table 5, Figures 11 and 12). Abrasion resistance is very important property in many cast elastomer applications, including as protective liners for pipes for slurry transport or protective coating in sieves in drilling application. Therefore, based on abrasion resistance results, cast elastomers based on PDO-sebacate are comparable to those based on PTMG polyols and slightly lower in performance than polycarbonate polyol-based cast elastomers.

FIGURE 11 ǀ Tear strength of cast elastomer prepared with various polyols.

FIGURE 12 ǀ Abrasion resistance of cast elastomers prepared with various polyols.

Tensile set of cast elastomers based on PDO-sebacate and polycarbonate polyols were low (10% and 7.6%, respectively), which should correlate with good recovery upon stretching or resistance to shear forces. Tensile set of cast elastomers based on PTMG and PPG polyols was similar at 16.8% and 21.1%. Tensile set for cast elastomers based on PO3G 2000 was high at 66.1%.

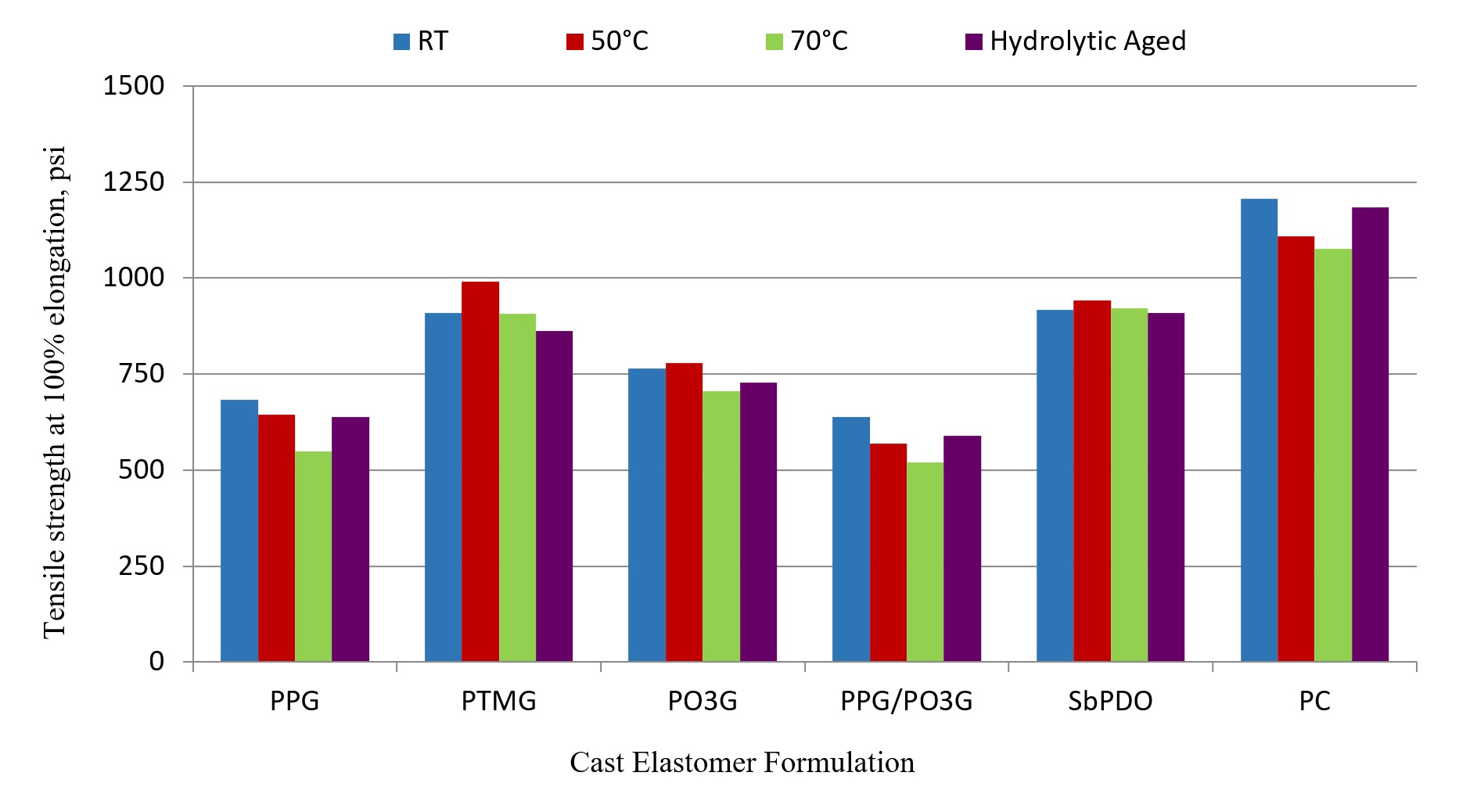

Temperature and Hydrolytic Resistance Performance

The effect of temperature on properties of cast elastomers was evaluated via determination of change in tensile properties. Tensile properties of cast elastomers were measured at 50 °C and 70 °C, and compared to performance at room temperature (Table 5). Mainly, the retention of tensile modulus at 100% was used as the key benchmark property. It was determined that cast elastomers based on PDO-sebacate and PTMG polyols essentially completely retained their modulus at 50 and 70°C (Table 5). Cast elastomers based on polycarbonate polyols and PO3G experienced an approximate 10% reduction in the modulus at 70 °C, while those based on PPG experienced a 20% loss in modulus.

All cast elastomers performed well in hydrolytic aging test (60 °C, 5 days and 95% relative humidity). Water absorption in hydrolytic aging test was the lowest for cast elastomers based on PTMG, PDO sebacate, and polycarbonate polyols (Table 5). The weight increase was somewhat higher for cast elastomers based on PPG 2000 and PO3G 2000 polyols. The retention of tensile properties (tensile modulus at 100%) was very good with 90% or greater retentions in all cases (Table 5). However, cast elastomers based on PDO-sebacate and polycarbonate polyols did slightly better than the rest, with essentially no change in modulus.

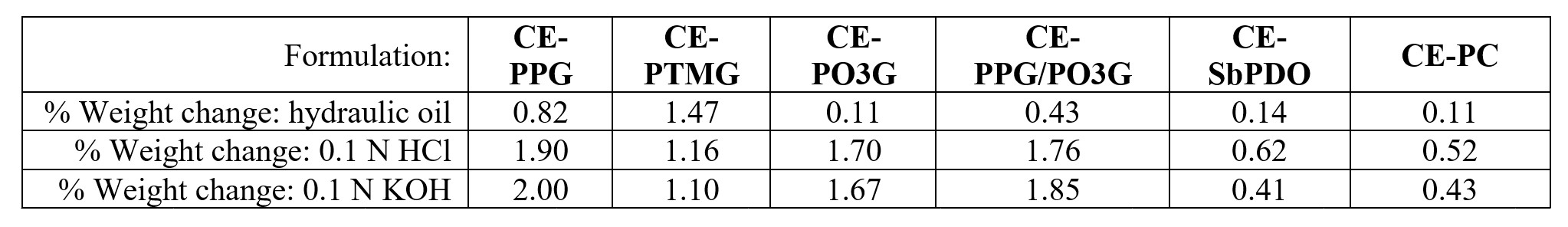

Solvent and Moisture Resistance

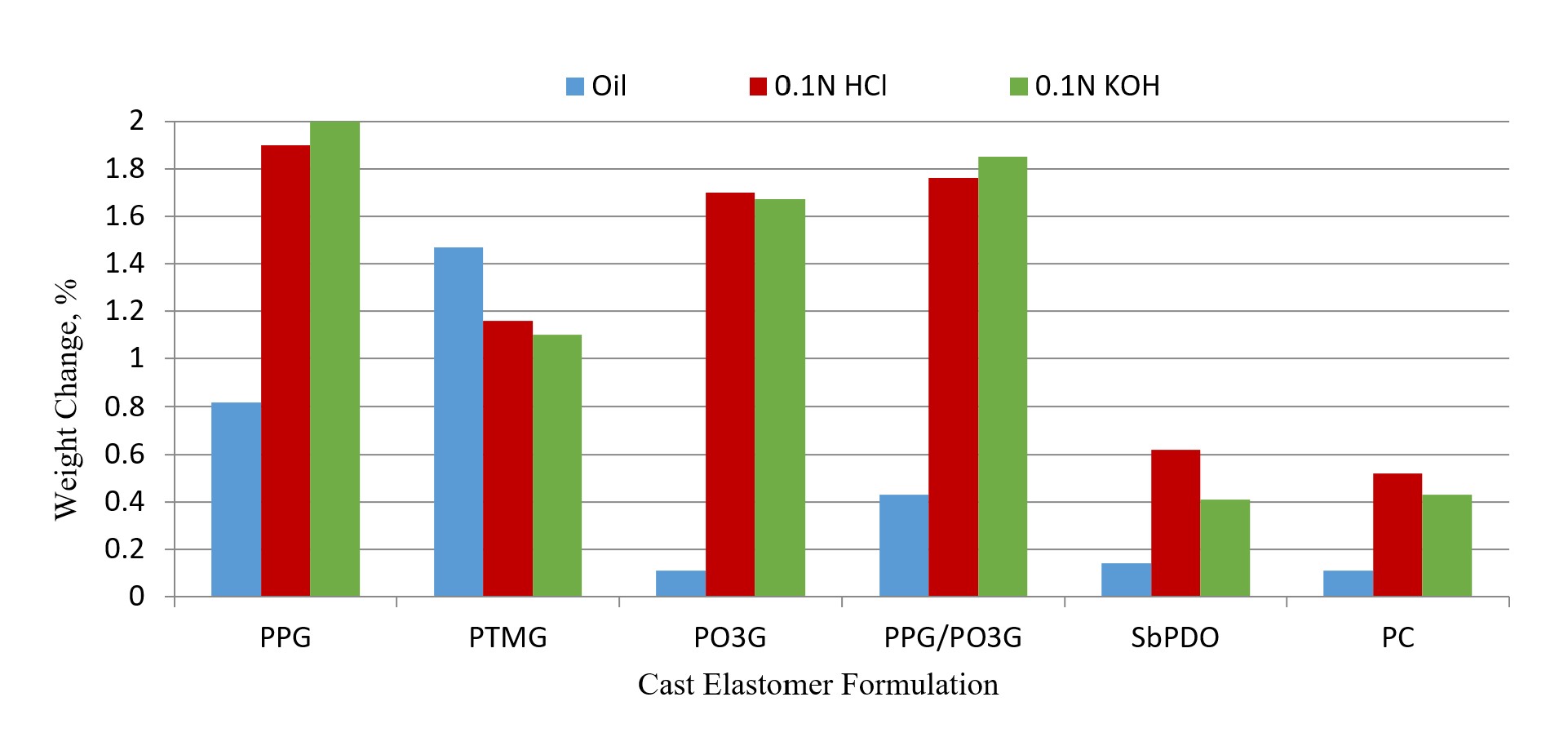

The solvent resistance of cast elastomers based on polycarbonate polyol and PDO-sebacate polyol in non-polar hydraulic oil and alkaline and acidic aqueous solutions was very good (weight gain by immersion low), and notable better than that for cast elastomers based on PTMG and other polyether polyols (Table 6, Figures 13 and 14). Good resistance of cast elastomers to both non-polar polar materials is very important in an application that includes a harsh environment such as exposure to water and chemicals found in crude-oil transport, drilling, and mining applications.

TABLE 6 ǀ Resistance of cast elastomers in various solutions upon 3 days of immersion.

FIGURE 13 ǀ Tensile modulus at 100% elongation of cast elastomers under different conditions.

FIGURE 14 ǀ Resistance of cast elastomers by immersion to various solutions.

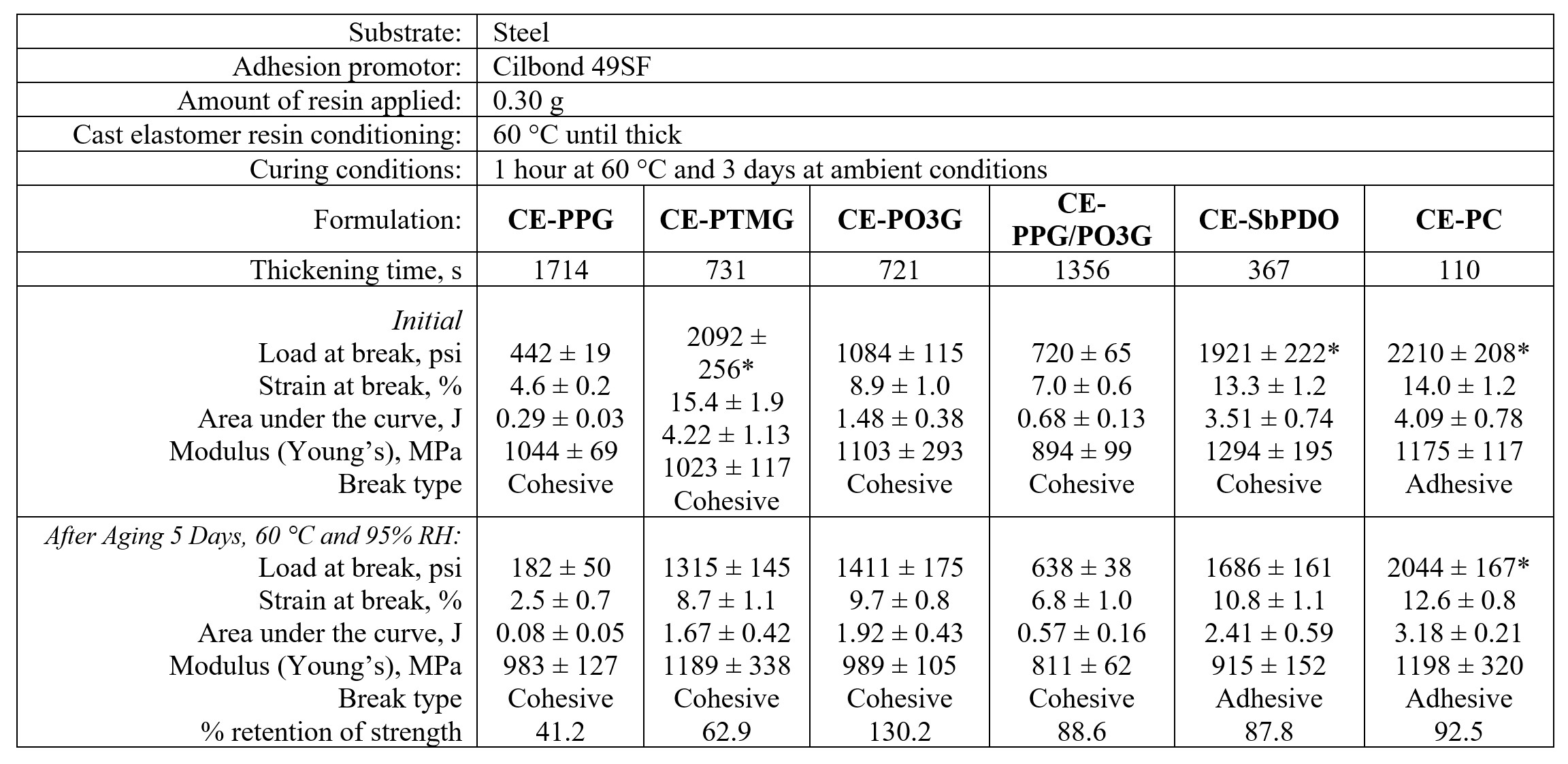

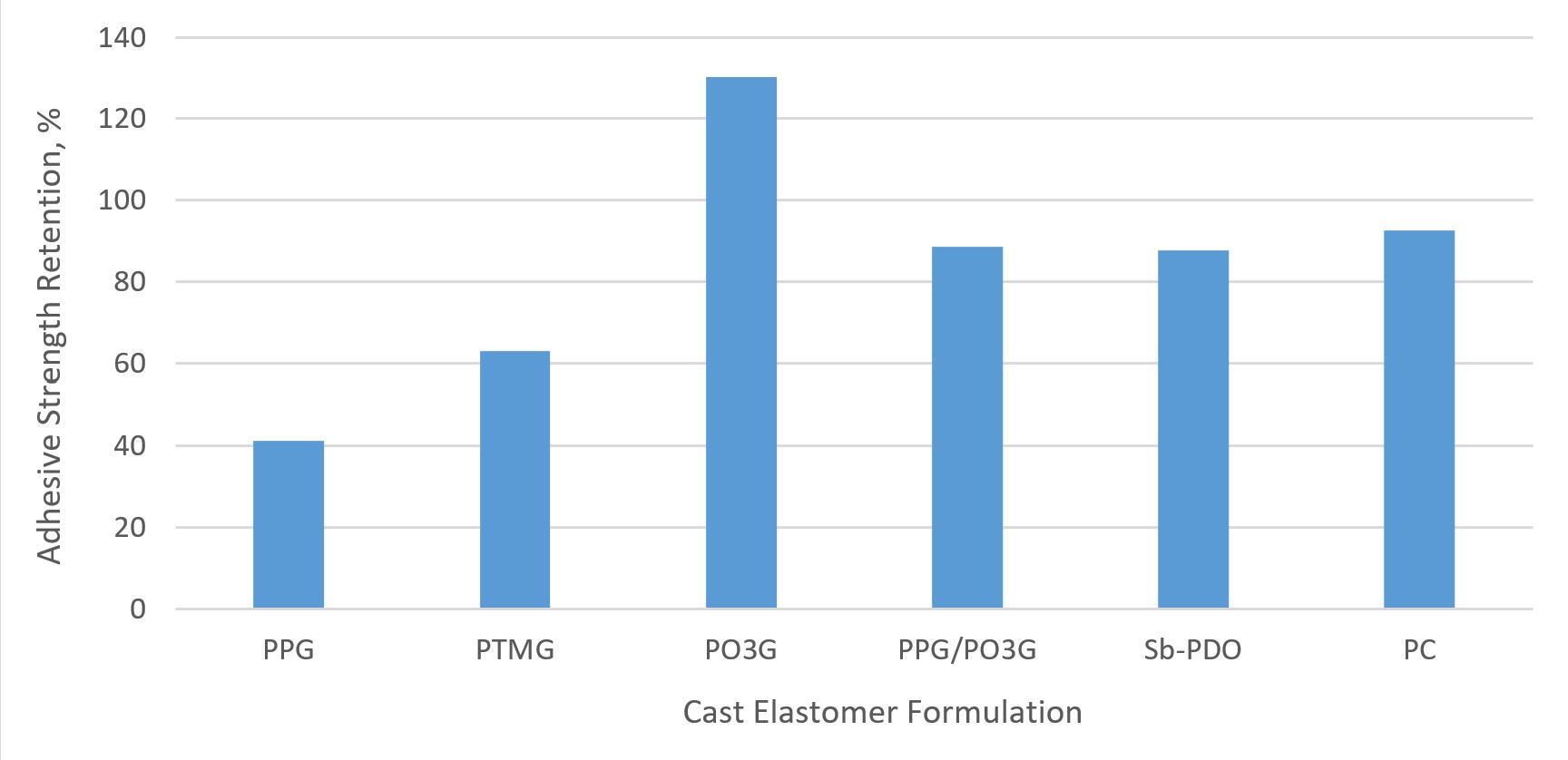

Adhesion Properties

The adhesion properties of cast elastomers were evaluated using stainless steel substrate (Table 7, Figure 15). Cast elastomers based on PTMG, PDO-sebacate, and polycarbonate polyol polyols exhibited similar, very-good adhesion strength, which was significantly higher than for cast elastomers based on PPG and PO3G polyether polyols.

TABLE 7 ǀ Adhesive properties of cast elastomers.

FIGURE 15 ǀ Retention of adhesive strength, load at break (psi), for cast elastomers of various polyols for before and after hydrolytic aging.

The adhesion properties of cast elastomers changed upon hydrolytic aging (60 oC, 5 days, 95% relative humidity). PDO-sebacate and polycarbonate polyol-based elastomers retained well the adhesion strength (87.8% and 92.5%, respectively), while cast elastomer based on PTMG 2000 decreased significantly (62.9%). The adhesion strength of cast elastomer based on PO3G improved significantly, which could indicate additional annealing. The adhesives based on blend PO3G2000/PPG 2000 exhibited much better retention (87.8%) of adhesion strength compared to that based on PPG 2000 (41.2%).

The adhesion strength is very important in cast elastomer applications such as coating inside the pipes for transport of slurries. It is also important in spray cast elastomers, such as truck bedliners. Good adhesion properties combined with good moisture as well as heat resistance are important in most cast elastomer application.

Conclusions

Two-component-polyurethane cast elastomers based on 1,3-Propanediol polyester polyols (PDO sebacate 2000), polyether polyols (Velvetol H 2000, Allessa), and a 50/50 blend of PPG 2000 polyol and PO3G 2000 were prepared via NCO-pre-polymer (or quazi-pre-polymer) using toluene diisocyanate (TDI, 80/20, BASF) and a hindered diamine-chain-extender curative (Ethacure 300, Albemarle) to evaluate their performance and commercial viability as steel pipe liners. The commercial reference PUDs were based on PPG 2000, poly(oxytetramethylene) glycol 2000 (PTMG 2000), and polycarbonate diol 2000 (PLACCEL CD220, Daicel USA, Inc.)

Overall, based on the performed analyses, it appears that cast elastomers based on PDO-sebacate 2000 exhibit an excellent combination of tensile properties, abrasion resistance, thermal, hydrolytic, and solvent resistance, as well as adhesion to metal substrates. These are desirable properties for cast elastomers intended for applications as protective coatings for pipes, and coatings for sieves typically used in drilling and mining applications. In terms of overall performance, cast elastomers based on PDO-sebacate polyol appear to be comparable or exceeding the properties of those based on PTMG and polycarbonate polyols. Cast elastomers based on PTMG polyols and polycarbonate polyols are both considered performance materials as internal protective coatings in pipe protection applications.

PO3G 2000 cast elastomers performed better than referent PPG 2000 cast elastomers. The properties of cast elastomers based on the blend of these two polyols improved as compared to those based on PPG 2000. PPG polyols are also used as protective pipe coatings when applications requiring lower levels of protection and overall performance.

Acknowledgements

CovationBio™ PDO would like to thank Aisa Sendijarevic and Ibrahim Sendijarevic from Troy Polymers, Inc., for their dedication to this project and the ultimate preparation, synthesis, and analyses.

References

- Oertel, G. Polyurethane Handbook, 1985.

- Case Studies/Polycarbonate diol Eternacoll, UBE

- Hurff, S.J.; Shen, M.; Sendijarevic, I.; Sendijarevic, A. Advances in the Use of Bio-Based Components in Aqueous Polyurethane Dispersions for Coating and Adhesive Applications. CPI Polyurethanes 2018 Technical Conference, 2018.

- Gahan, S.L.; Shen, M.; Sendijarevic, I.; Sendijarevic, A. Evaluation of 1,3-Propanediol-Based Polyester and Polyether Polyols in Polyurethane Water Dispersions (PUDs) for Textile Coating Applications. CPI Polyurethanes 2019 Technical Conference, 2019.

- Gahan, S.L.; Shen, M.; Sendijarevic, I.; Sendijarevic, A. Evaluation of 1,3-Propanediol-Based Polyester and Polyether Polyols in Polyurethane Water Dispersions (PUDs) for Direct to Metal Applications. CPI Polyurethanes Technical Conference, 2020.

Appendix A: FTIR Spectra

APPENDIX FIGURE 1 ǀ FTIR spectra of cast elastomer based on PPG 2000 polyol.

APPENDIX FIGURE 2 ǀ FTIR spectra of cast elastomer based on PTMG 2000 polyol.

APPENDIX FIGURE 3 ǀ FTIR spectra of cast elastomer PO3G 2000 polyol.

APPENDIX FIGURE 4 ǀ FTIR spectra of cast elastomer based on a blend of PPG2000/PO3G2000 (50/50 pbw).

APPENDIX FIGURE 5 ǀ FTIR spectra of cast elastomer base on PDO-sebacate 2000 polyol.

APPENDIX FIGURE 6 ǀ FTIR spectra of cast elastomer based on Polycarbonate 2000 MW polyol.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!