How Industry 4.0 Technologies are Revolutionizing Paint and Coatings Manufacturing

Photo by KJ Brix: https://www.pexels.com/photo/close-up-of-modern-robotic-mechanism-16544054/

Industry 4.0 represents the fourth industrial revolution, characterized by the fusion of advanced technologies like the Internet of Things (IoT), artificial intelligence (AI) and automation to create smart factories. This paradigm shift is significantly transforming manufacturing landscapes, including the paint and coating sector, where competitiveness hinges on operational efficiency and innovation. However, paint and coating manufacturers face key challenges: optimizing processes while safeguarding sensitive data against increasing cybersecurity threats.

These new technologies provide powerful solutions, enabling real-time monitoring, predictive maintenance and data-driven decision-making. By leveraging these innovations, manufacturers can streamline production, reduce waste and enhance quality control. Ultimately, embracing Industry 4.0 not only positions paint and coating companies at the forefront of manufacturing excellence but also helps them navigate the evolving market landscape with resilience and agility.

Industry 4.0: A Game Changer for Paint and Coating Manufacturers

Industry 4.0 signifies the fourth industrial revolution, where traditional manufacturing processes are enhanced through advanced technologies, creating smart, interconnected production environments. This new era leverages the capabilities of the following core technologies:

- Internet of Things (IoT): This technology connects machines and devices, allowing for real-time data exchange and monitoring.

- Artificial Intelligence (AI): AI algorithms analyze vast datasets to predict maintenance needs and enhance operational decision-making.

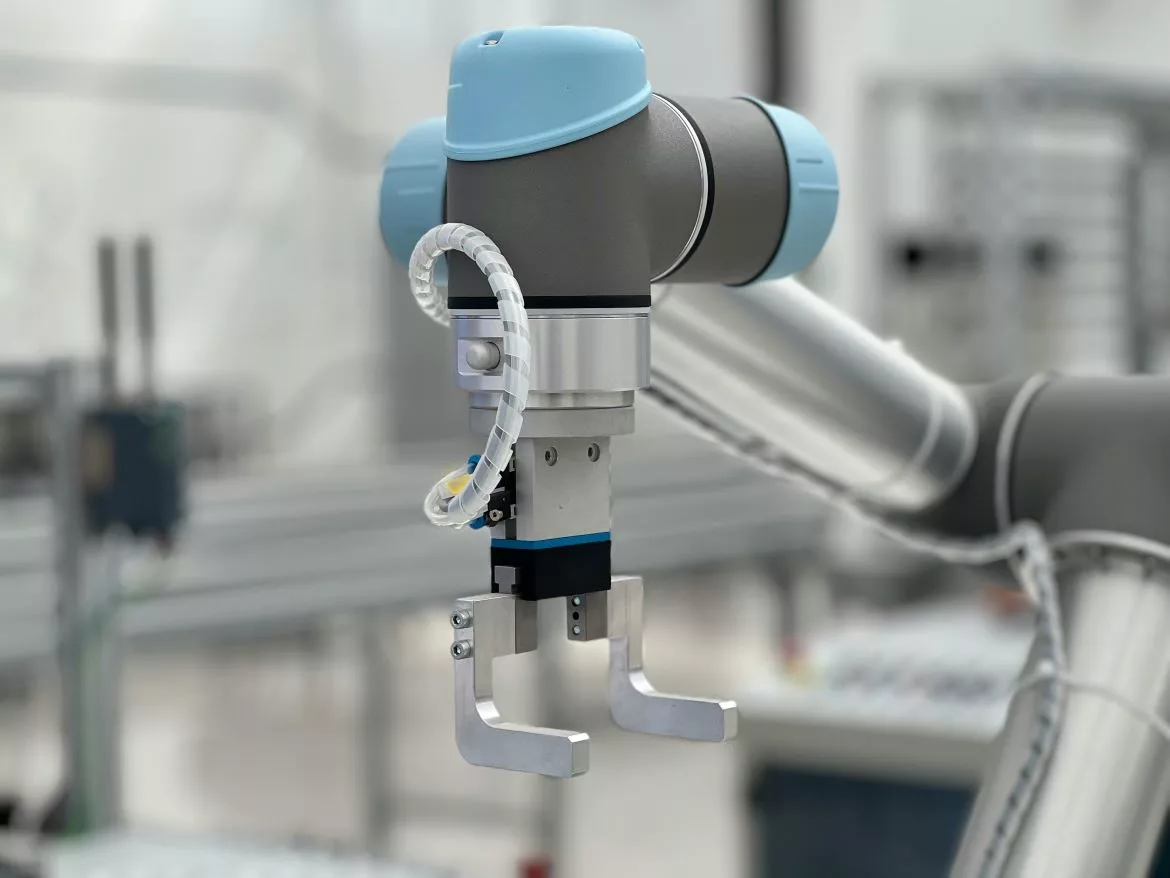

- Robotics: Automated systems perform repetitive tasks with high precision, increasing speed and efficiency.

- Big Data: The analysis of large datasets enables manufacturers to identify trends and optimize processes.

The integration of these technologies into paint and coating manufacturing represents a substantial shift from traditional methods.

- Precision: IoT devices monitor variables like temperature and humidity during the coating application, ensuring optimal conditions for quality.

- Customization: AI-driven systems enable the production of tailored formulations based on customer specifications, enhancing product offerings.

- Sustainability: Advanced analytics can identify waste patterns and inefficiencies, allowing for more sustainable practices and reduced environmental impact.

As manufacturers move from conventional production lines to smart, connected systems, the dynamics of the paint and coatings industry will change. Real-time data insights will facilitate agile responses to market demands and automated processes will minimize human error, boosting overall quality.

Industry 4.0 technologies significantly improve warehouse operations by implementing automated inventory management, predictive analytics for stock levels and IoT-enabled tracking systems. These innovations ensure timely supply chain responses, reducing lead times and enhancing overall operational efficiency.

Embracing Industry 4.0 technologies enables paint and coating manufacturers to innovate, meet customer demands and establish a more sustainable future.

Driving Efficiency in Paint and Coatings Manufacturing

IoT-enabled devices improve quality control and minimize material waste in paint and coating manufacturing. By providing real-time monitoring of production processes, these devices ensure that variables such as temperature and viscosity remain within specified ranges, thereby maintaining consistent product quality. Additionally, IoT analytics help identify inefficiencies, allowing manufacturers to adjust processes on the fly and reduce excess material usage.

AI and machine learning applications further enhance manufacturing efficiency. In smart factories, these technologies analyze historical data to optimize formulations for different coatings, ensuring superior performance with less resource consumption. Furthermore, AI can improve production scheduling, dynamically allocating resources based on demand forecasts and machine availability, which leads to streamlined operations.

Predictive maintenance powered by AI significantly reduces downtime by anticipating equipment failures before they occur. For instance, sensors can gauge the health of machinery in real-time, sending alerts when maintenance is needed. This proactive approach minimizes unplanned outages, ensuring consistent production and enhancing overall operational reliability.

Strengthening Physical and Digital Security With Industry 4.0

IoT sensors and connected systems are integral for monitoring facility access and physical security. These sensors provide real-time data on who enters and exits, facilitating an efficient access control system. Smart surveillance systems equipped with AI offer advanced analytics, detecting unusual activities and alerting security personnel instantly. When integrated with robotics, these systems enhance real-time security management by patrolling areas autonomously, creating a comprehensive surveillance network.

Moreover, integrating blockchain and AI-driven tools ensures data integrity, safeguarding sensitive information against breaches. Blockchain technology enhances transparency and accountability, while AI analyzes patterns to identify potential security threats, proactively mitigating risks.

Smart factories face unique security challenges, such as cyber threats and network vulnerabilities. Therefore, combining physical and digital security strategies is essential for a comprehensive approach to facility protection. Implementing layered security measures that include IoT, AI and blockchain establishes a robust defense framework, effectively safeguarding assets while promoting operational resilience.

Addressing Barriers to Adoption

Common barriers to Industry 4.0 adoption include cost concerns, resistance to change and a lack of skilled workforce. To integrate new technologies without disrupting operations, factories should take a phased approach, starting with pilot projects demonstrating quick wins and validating innovations.

Investing in workforce training is essential. Tailored programs can enhance employees' skills and boost their confidence in using advanced technologies. Encouraging collaboration between IT and operational teams fosters a culture of innovation and ensures that technological solutions align with production needs.

Additionally, management should communicate the long-term benefits of Industry 4.0, emphasizing improved efficiency and competitiveness. By addressing these barriers and committing to ongoing training and collaboration, factories can successfully transition to Industry 4.0 and unlock their potential for increased operational excellence.

Conclusion

The adoption of Industry 4.0 technologies in paint and coating manufacturing offers significant advantages that enhance efficiency, security and competitive positioning. Automation and IoT solutions make production and manufacturing streamlined and efficient, thereby reducing waste with higher output. This leads to higher productivity and cost savings, enabling manufacturers to deliver quality products faster.

In terms of security, integrating AI and blockchain fortifies systems against cyber threats and data breaches, ensuring the integrity and safety of sensitive information. Such robust security measures protect valuable intellectual property and maintain customer trust.

Furthermore, embracing digital transformation helps manufacturers differentiate themselves in a competitive market, allowing them to respond swiftly to changing demands and innovate continuously.

By investing in Industry 4.0, paint and coating manufacturers can foster long-term growth and resilience, equipping themselves to navigate future challenges. Embracing these technologies is no longer an option but a strategic imperative for success in today’s manufacturing landscape.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!