The Corrosion Challenge

and the Rise of Plant-Based Solutions

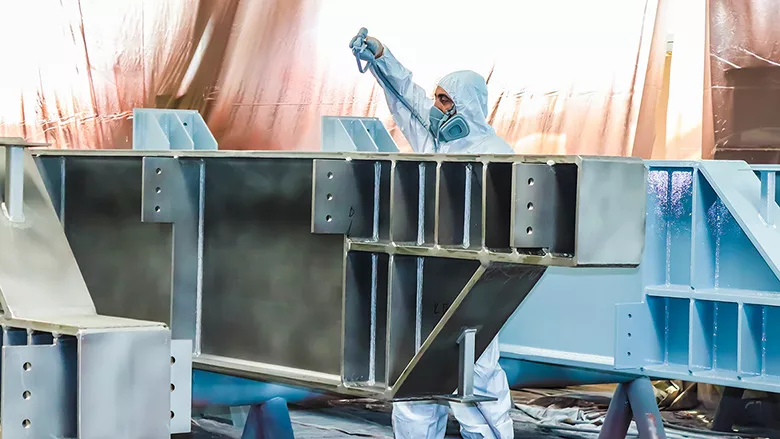

Corrosion quietly erodes bridges, ships, tank farms and factory assets every hour, yet the traditional cure — heavy-metal pigments and solvent-rich primers — often exposes workers and the ecosystem to lead, hexavalent chromate and high-volatile organic compound (VOC) solvents. With regulatory pressure mounting and increased demand for healthier jobsites, the coatings world is looking to nature's chemistry for an answer.

Plant-based technologies are bio-derived molecules that latch onto metal surfaces and block oxygen-water attacks without the toxic baggage. Explore how plant-based additives reshape corrosion protection, why the shift matters and where the market is headed.

From spalling concrete car parks and rusting rebar to chloride spray-pitted offshore platforms, corrosion claims an estimated 3–4% of the global gross domestic product per year.ⁱ Large users — marine, oil and gas, and pulp and paper — have long relied on chromate primers and amine-cured epoxies.

Over the past decade, researchers have begun screening botanical extracts rich in alkaloids, tannins, flavonoids and polysaccharides. Their tests show that compounds from orange peels, henna leaves and green tea could adsorb onto steel and cut corrosion by at least 80%.² Over 300 plant species have been assessed as green corrosion inhibitors.

Manufacturers blended these extracts into waterborne epoxy and polyurethane binders to create today's bio-based coatings.³ The tipping point came when multinationals started chasing “zero hazardous air pollutants” labels for infrastructure paint specifications. By 2023, reports valued the global corrosion-inhibitor niche — water treatment and organic segment — at roughly $8.5 billion and estimate the market will reach $11.6 billion by 2031.⁴

This rise is not merely regulatory box-ticking. In oil field brine, plant-based additives tolerate wide pH swings,⁵ and in potable water tanks, they remove the need for chromate passivation. In marine topcoats, they double as ultraviolet (UV) stabilizers. Such synergies accelerate the transition from pilot projects to having bio-based coatings in mainstream product ranges.

The Payoffs of Plant-Based Additives

Plant-derived chemistry translates into real-world value. Here are five advantages that consistently tip the scales in favor of bio-based additives:

-

Built-In Barrier Layer

Natural polyphenols and sugars bond to metal while linking with the paint resin, creating a dense coat that keeps water and oxygen out.⁶ The film survives salt spray and coastal weather better than many other solvent-borne components, meaning parts stay rust-free and glossy for longer. -

Worker- and Eco-Friendly

Because the additives come from food or farm by-products, they are non-toxic and biodegradable. Crews handle fewer hazmat warnings and spent blast media is easier — and more cost-effective — to dispose of at the end of a project.

-

Stable, Local Supply

Extracts from sugarcane bagasse, orange peel, or forestry waste can be sourced locally. Contractors are not bound by price swings in mined components like zinc chromate. -

Cleaner Air During Application

Plant-based molecules dissolve readily in high-solids or waterborne binders, enabling formulators to hit low-VOC levels. This means less solvent smell in confined spaces and easier compliance with “no hazardous air pollutants” guidelines on public works sites. -

Small Scratches Self-Seal

Certain plant sugars and components form weak bonds that break and reform. If a coating gets nicked, moisture triggers those bonds to reconnect and knit over hairline scratches,⁷ extending the interval between touch-ups.

The Applications of Plant-Based Additives

Steel turns reddish-brown when it rusts, but many everyday structures rely on metals that do not contain iron, like aluminum, brass and zinc. However, these nonferrous materials can still corrode as salt spray, high-pH cleaners and chemicals slowly pit the surface once they breach the natural oxide skin.⁸ Plant-based additives make a difference because the same molecules that cling to iron latch as firmly onto aluminum and copper, laying an invisible yet durable shield.

Real-world examples show the payoff. Factory-applied polyvinylidene fluoride (PVDF) finishes on aluminum curtain-wall panels often have long color-fastness warranties. Field-applied maintenance paints do not last quite as long, but a good topcoat on aluminum siding can stay intact for five to 10 years,⁹ and a well-maintained PVDF system may keep its gloss for up to 40 years.

Achieving such numbers also hinges on the weather. When relative humidity increases, drying slows to a crawl. Most waterborne or high-solid coatings stay sticky and collect dust at a higher humidity level instead of forming a tough film. Keeping jobsite humidity low or scheduling work during drier periods gives bio-based additives the best chance to lock in and protect materials for the long haul.

Another promising application involves everyday outdoor metal fixtures — such as patio furniture, handrails, street signs and rooftop solar panels — that face sun, rain and salty breezes. A clearcoat enriched with plant-based additives forms a tough barrier that slows fading and rust, helping these items stay sturdy far longer before they need a fresh coat of paint.

A Greener Future

Green corrosion inhibitors have moved from an interesting idea to a line item in market forecasts. Three forces do most of the heavy lifting in their rise — new test methods that recognize plant inhibitors, easier access to fermentation-made tannins and tax breaks or grants to those using or developing bio-based chemicals in different parts of the world.¹⁰

Even the mainstream corrosion inhibitor market is tilting toward waterborne and plant-derived options. Major coating suppliers are already retooling pilot lines to accommodate bio-stocks and locking in contracts with agricultural partners to secure supply. Investment, customer demand and regulation give plant-based paints a clear runway to grab a larger share of the premium protection space over the next few years. These combined pressures are turning green inhibitors from a sustainability bonus into a competitive requirement.

Toward Tailored, High-Performance Green Coatings

Plant-based additives let formulators cut out heavy metals without sacrificing durability by delivering corrosion protection, antimicrobial action, UV shielding and self-healing. Research teams are matching natural ingredients to the needs of each plastic or metal, testing how long coatings last in rain, heat and air and adjusting the formula as needed.

The next frontier likely involves tailoring and creating routes that design green inhibitors for specific materials and service conditions. The coatings industry's plant-based future is sprouting and set up to deliver performance at a much lower environmental cost.

References

1 Iannuzzi, M.; Frankel, G. S. The carbon footprint of steel corrosion. Nature, December 29, 2022. https://pmc.ncbi.nlm.nih.gov/articles/PMC9797878/

² Hamidi, N.; et al. Potential application of plant-based derivatives as green components in functional coatings: A review. Cleaner Materials, June 2022. https://www.sciencedirect.com/science/article/pii/S2772397622000570

³ Verified Market Research. The rise of water-based coatings. Paint & Coatings Industry Magazine, April 9, 2024. https://www.pcimag.com/articles/112266-the-rise-of-water-based-coatings

⁴ Corrosion inhibitors market size, share, trends and growth report — global opportunities & forecast, 2024–2031. GMI Research, February 2024. https://www.gmiresearch.com/report/corrosion-inhibitors-market-analysis-industry-research/

⁵ Holla, B.; et al. Plant extracts as green corrosion inhibitors for different kinds of steel: A review. Heliyon, June 27, 2024. https://pmc.ncbi.nlm.nih.gov/articles/PMC11304013/

⁶ Sesia, R.; et al. Natural polyphenols and the corrosion protection of steel: Recent advances and future perspectives for green and promising strategies. Metals, June 3, 2023. https://www.mdpi.com/2075-4701/13/6/1070

⁷ Choi, K.; et al. Properties and applications of self-healing polymeric materials: A review. Polymers, November 14, 2023. https://pmc.ncbi.nlm.nih.gov/articles/PMC10674826/

⁸ Elsher, O. How to remove rust from metal: 6 natural remedies. Renovated, February 22, 2024. https://renovated.com/how-to-remove-rust-from-metal/

⁹ The ultimate guide to painting siding. Aboff’s Paints, September 5, 2023. https://aboffs.com/blogs/resources/painting-siding

¹⁰ U.S. Department of Energy. Biodiesel laws and incentives. Alternative Fuels Data Center, n.d. https://afdc.energy.gov/fuels/laws/BIOD?state=US

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!