Ceramic Media with Improved Efficiency

Fine media horizontal mills are becoming the standard for particle dispersion equipment in many branches of industry (paint pigments, magnetic coating, pharmaceutical, etc.), due to the increasing demand for fine (<1 mm) product particle size and shorter processing cycles. To meet current requirements for smaller particle size, tighter particle size distributions, improved dispersion efficiency, and minimum wear contamination in the dispersed product, the media used in these mills should satisfy certain criteria. Media selection criteria and the operation of horizontal media mills have been discussed in several professional publications.1-4

This article compares different media materials in terms of their wear resistance and impact on mill wear. Also discussed is the effect of individual media shape and media size distribution on the dispersion efficiency. A recently developed modification of wear resistant media material (Ce-TZP) (Mill Mates®/ Mill Mates Plus®) will be introduced and its properties compared with the other types of zirconia ceramics currently used as media material (Y-TZP and Mg-PSZ).

Media/Mill Wear Resistance

Extensive research conducted on wear mechanisms of different materials5 has shown that for wear resistance, media material should have a certain combination of structural and mechanical properties, which can be summarized as follows.- High hardness/fracture toughness

- Fine grain structure and higher surface stability

- Low friction coefficient

Mill wear is inherently related to media wear resistance due to the abrasive nature of media wear debris. Media breakage can potentially generate fine particles, which can cause significant damage for internal mill components. A high friction coefficient between media and mill materials will lead to excessive heat generation and will have a detrimental effect on the mill wear.

Table 1 shows a comparison of mechanical properties between different engineering materials commonly used as media in horizontal mills. Among them, steel has the highest density. Its cost and wear resistance varies significantly depending on the grade of steel. Steel, because of its density, offers certain advantages by allowing the dispersion of high-viscosity products. However, steel usage is declining due to product contamination and discoloration issues as well as corrosion resistance of the dispersed products (automotive waterborne topcoats, for example). Low-cost glass beads offer certain advantages for dispersing low-viscosity products due to their low density and tight size distribution. However, they have poor wear resistance and cannot be used for dispersion of high-viscosity products or for products that cannot tolerate silicate contamination.

Among ceramic media, zirconia-based engineering ceramics offer a combination of properties (high hardness, fracture toughness, and chemical stability) that make them very attractive for wear resistant components. The lowest grade is zircon (zirconium silicate) beads. They have relatively low density, hardness and strength and have a tendency for breakage and accelerated wear after prolonged use.

Two types of zirconia ceramics have been used for demanding dispersion applications: magnesia partially stabilized zirconia (Mg-PSZ) and yttria stabilized tetragonal zirconia polycrystals (Y-TZP).

They differ in mechanical properties and microstructure. Figure 1 compares the microstructures of Mg-PSZ and Y-TZP ceramics. Mg-PSZ (see Figure 1a) has relatively large grains (15–50 mm); Y-TZP material consists of much smaller grains (< 0.5 mm). Due to its fine grain structure, Y-TZP demonstrates very high hardness and fracture toughness. It is well known that Y-TZP provides one of the best choices for ceramic media so far developed. The only disadvantages of this material are its fast degradation in moist environments at ~200–300ºC, and its high cost due to elaborate manufacturing conditions. Figure 1 / Microstructure Comparison between Mg-PSZ (a), Y-TZP (b) and Ce-TZP (c)

Figure 1 / Microstructure Comparison between Mg-PSZ (a), Y-TZP (b) and Ce-TZP (c)Recently, a different type of TZP material was developed, by replacing yttria with ceria as a stabilizing element. Figure 1c shows the microstructure of Ce-TZP ceramic. Its microstructure is fine, but slightly coarser (<1 mm) than Y-TZP. This material also has some additional advantages — lower production costs and it is stable in moist elevated temperature environments.

Figure 2 / Fluidization Conditions During Mill Operation [a] Optimum Feed Rate and [b] Hydraulic Packing

Figure 2 / Fluidization Conditions During Mill Operation [a] Optimum Feed Rate and [b] Hydraulic PackingMedia Criteria for Horizontal Mills

An optimum combination of media material properties is important for efficient operation of the horizontal mill. However, other media parameters have significant impact on the mill performance, such as media sphericity and size distribution.It is commonly accepted that fine media mill processes are based on the assumption that the mill is operated under conditions of full media fluidization, e.g., the individual media are uniformly distributed throughout the mill (see Figure 2a). The media charged to the mill usually occupies 75–90% of the mill void volume. The product flow through the mill will carry the media toward the mill exit unless counteracted by the internal flow patterns induced by the agitator system. If the media concentration at the exit end of the mill rises — even locally — to about 94%, the media will assume a non-flowable interlocked configuration known as hydraulic packing (see Figure 2b). Hydraulic packing leads to significant temperature and/or pressure increases, and can result in excessive mill and media wear.

Fluidization conditions are determined by a combination of media properties (density, size, and mill volume), product properties (density and viscosity at processing conditions), and mill operating conditions (product feed rates and agitator speed).

In a fine media mill, media flow in layers following the liquid flow induced by the pumping action of the agitator. In a disc mill, these media layers flow parallel to the rotating disc surface (see Figure 3). The liquid velocity is the highest adjacent to the disc surface and diminishes as the distance from the disc surface increases, due to the effect of product viscosity. The difference in the average liquid velocity for each of the media layers will result in the media layers passing each other and creating shear zones in the intervening space. The difference in the liquid velocity at the top and bottom of each media layer also results in a media rotation, which intensifies the shear zones between the passing media (see Figure 3a). Extensive testing has confirmed that shear is the predominant dispersion mechanism in fine media milling. Figure 3 / Media Flow Pattern in a Horizontal Mill

Figure 3 / Media Flow Pattern in a Horizontal MillSmooth spherical media with narrow size distribution and high density will allow the most efficient use of the media charge in a mill. High-density media allows higher product feed rates to be used before hydraulic packing occurs. Media roundness and narrow size distribution result in the most effective energy transfer from the rotating agitator system to the media. This is achieved by allowing both a uniform gap between media layers and an unobstructed maximum velocity difference between adjacent media layers, resulting in a constant and maximum shear rate. On the other hand, media with poor roundness and a wide size distribution leads to nonuniform gaps between media layers and the reduction in the velocity differential between adjacent media layers, thereby reducing the shear obtained between passing media (see Figure 3b). In extreme cases, oversized media acts to “dam” the local flow differential between the adjacent media layers, thus eliminating the shear completely in the affected areas. With wide media size distributions, the finer media could, theoretically, have a tendency to migrate to the exit end of the mill and hydraulically pack.

High density and narrow size distribution are particularly important for very fine media (< 0.8 mm), due to the fact that smaller media is more difficult to keep in the mill and significantly more prone to hydraulic packing.

Figure 4 / Shape Comparison between Mill Mates (Ce-TZP) and Y-TZP Beads

Figure 4 / Shape Comparison between Mill Mates (Ce-TZP) and Y-TZP BeadsCe-TZP vs. Y-TZP

The high quality and high priced Y-TZP media satisfy the above described criteria for media selection and have established a clear benchmark among different types of media used in horizontal mills due to their narrow size distribution, spherical shape, excellent mechanical properties, surface smoothness, and wear resistance. However, due to advances in material development and manufacturing practices, a significantly less expensive Ce-TZP based media (Mill Mates) was developed, which can successfully compete with the Y-TZP product in demanding applications. Figure 4 shows a comparison in the shape factors between two commercial media types. Although Mill Mates (Ce-TZP) does not show a “perfect” spherical shape, its roundness factor (ratio between the smaller and larger bead axis) R> 0.95 is very close to Y-TZP media (R~ 0.98).As seen from Figure 5, the size distribution for Mill Mates (Ce-TZP) beads is slightly narrower than that for Y-TZP beads. Figure 5 / Size Distribution of Ce-TZP and Y-TZP BeadsIn a case study for milling calcium carbonate in a 1.5-liter laboratory horizontal mill, using 85% mill loads of Mill Mates (Ce-TZP) and Y-TZP media and identical mill operating procedures, the narrower size distribution of the Ce-TZP beads yielded superior dispersion performance than that of the Y-TZP beads (see Figure 6). This was reflected in a more rapid particle size reduction with the Mill Mates (Ce-TZP) beads than was attained with Y-TZP beads. After 75 minutes of circulation milling, the product particle size with both media was essentially equal, as anticipated when equivalent particle size and identical mill operating conditions are used. The point is that the media with a narrower size distribution Mill Mates may reach a given particle size in less grinding time.

Figure 5 / Size Distribution of Ce-TZP and Y-TZP BeadsIn a case study for milling calcium carbonate in a 1.5-liter laboratory horizontal mill, using 85% mill loads of Mill Mates (Ce-TZP) and Y-TZP media and identical mill operating procedures, the narrower size distribution of the Ce-TZP beads yielded superior dispersion performance than that of the Y-TZP beads (see Figure 6). This was reflected in a more rapid particle size reduction with the Mill Mates (Ce-TZP) beads than was attained with Y-TZP beads. After 75 minutes of circulation milling, the product particle size with both media was essentially equal, as anticipated when equivalent particle size and identical mill operating conditions are used. The point is that the media with a narrower size distribution Mill Mates may reach a given particle size in less grinding time. Figure 6 / 50% Particle Size Reduction Comparison for Calcium Carbonate Using Mill Mates (Ce-TZP) and Y-TZP Media

Figure 6 / 50% Particle Size Reduction Comparison for Calcium Carbonate Using Mill Mates (Ce-TZP) and Y-TZP Media Table 2 / Mechanical Properties and Wear Resistance Comparison for Commercial 1mm Mg-PSZ, Ce-TZP and Y-TZP Beads

Table 2 / Mechanical Properties and Wear Resistance Comparison for Commercial 1mm Mg-PSZ, Ce-TZP and Y-TZP BeadsZirconia Media — Laboratory Tests

Comparative mechanical properties and wear resistance between three types of commercial beads (Mg-PSZ, Ce-TZP and Y-TZP) are shown in Table 2.Two types of Ce-TZP material have been developed. Figure 7 shows an optical image of the Mill Mates (a) and Mill Mates Plus (b) beads. By proprietary modification of the structure and composition of Ce-TZP, a better wear resistant material (Mill Mates Plus) has been obtained. The wear resistance tests were conducted in a 0.3-liter horizontal laboratory mill under conditions of hydraulic packing for one hour. The mill was charged with ~85% media, and water was used as a lubricant. The mill was equipped with an agitator shaft with pins, and the mill operated at 3,500 RPM. Figure 7 / Comparison between Two Types of Ce-TZP beads. Mill Mates (a) and Mill Mates Plus (b)Table 2 shows that the Ce-TZP beads have the highest density. Among these three materials, Y-TZP beads show the best combination of mechanical properties (hardness, fracture toughness and strength) followed by Ce-TZP and then Mg-PSZ beads. Among Ce-TZP compositions, Mill Mates Plus shows higher fracture toughness than Mill Mates.

Figure 7 / Comparison between Two Types of Ce-TZP beads. Mill Mates (a) and Mill Mates Plus (b)Table 2 shows that the Ce-TZP beads have the highest density. Among these three materials, Y-TZP beads show the best combination of mechanical properties (hardness, fracture toughness and strength) followed by Ce-TZP and then Mg-PSZ beads. Among Ce-TZP compositions, Mill Mates Plus shows higher fracture toughness than Mill Mates. Figure 8 / Surface Finish for Mill Mates Plus Beads after Short Period in the Mill

Figure 8 / Surface Finish for Mill Mates Plus Beads after Short Period in the MillAs seen from impeller wear rate data in Table 2, the Ce-TZP beads yield the least mill wear. Mill wear for the Ce-TZP beads is about 30 times better than the Mg-PSZ beads and seven times lower than that of Y-TZP beads.

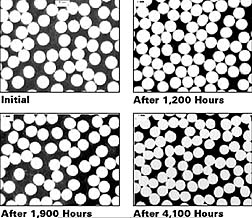

Optimum combination of surface structural stability, high hardness and fracture toughness, produces very fine surface polish for both types of Ce-TZP beads, with the surface smoothness of Mill Mates Plus beads being exceptionally good (see Figure 8). Low friction coefficient associated with smooth surface is responsible for very low mill wear in the case of the Mill Mates Plus. Figure 9 / Ce-TZP 1 mm Bead Images vs. Operation Time in 200 Liter Horizontal Mill

Figure 9 / Ce-TZP 1 mm Bead Images vs. Operation Time in 200 Liter Horizontal Mill Figure 10 / Effect of Milling Time on Size Distribution of Ce-TZP Media Major and Minor Axis

Figure 10 / Effect of Milling Time on Size Distribution of Ce-TZP Media Major and Minor AxisCe-TZP Bead Case Study of Pigment Dispersion in 200-Liter Horizontal Mill

To confirm results of the laboratory tests on Mill Mates beads, a case study was done in a 200-liter horizontal mill producing automotive waterborne topcoats. The mill was charged with ~85% of 1 mm Mill Mates. Traditionally, the media wear rate is evaluated by measuring media level in the mill, or by removing media and weighing it after a certain operational time. Image analysis was used as an alternative approach to evaluate media wear and predict the maintenance schedule requirements for the mill user. This mill operated for more than a year and small samples of media were taken from the grinding chamber and analyzed after 440, 1,200, 1,900 and 4,100 hours of mill operation. Figure 9 shows optical images of beads after different operational time. Bead wear is very uniform and small. No broken/fractured beads were detected in operation or in the test.Figure 10 shows the results of bead size distribution throughout the trial. The size distribution is narrow even after 4,100 hours in use, which confirms the results of uniform bead wear. Figure 10 / Effect of Milling Time on Size Distribution of Ce-TZP Media Major and Minor AxisFigure 11 shows time dependence for the average major and minor bead axis, as well as for minimum bead size. Bead wear can be described by a linear time dependence. There are no signs of accelerated bead wear even after prolonged usage. The average wear for the media major and minor axes is about 12% in 4,100 operating hours or about 0.0029% per hour.

Figure 10 / Effect of Milling Time on Size Distribution of Ce-TZP Media Major and Minor AxisFigure 11 shows time dependence for the average major and minor bead axis, as well as for minimum bead size. Bead wear can be described by a linear time dependence. There are no signs of accelerated bead wear even after prolonged usage. The average wear for the media major and minor axes is about 12% in 4,100 operating hours or about 0.0029% per hour. Figure 11 / Operational Time Dependence of Ce-TZP Bead Measurements

Figure 11 / Operational Time Dependence of Ce-TZP Bead MeasurementsFigure 11 provides a useful predictive tool for evaluating the time required between scheduled maintenance for the mill. It shows that even after 4,100 hours in operation, bead minimum size is still above 0.7 mm, and there is no danger of finer beads passing through the screen and causing significant damage.

This particular mill continuously operated in excess of 4,100 hours on original media charge without any significant loss in efficiency. After 4,100 hours, mill wear was minimal. Prior to this trial, the mill operated with larger size steel media. By switching to 1mm Ce-TZP beads with their narrow size distribution and round shape a significant efficiency gain was realized.

Conclusion

- Ceramic media with high hardness, high fracture toughness, fine grain structure, spherical shape and narrow size distribution give the best performance.

- Mill Mates/Mill Mates Plus media provide a cost effective alternative to Y-TZP products for demanding dispersion applications and a significant improvement on Mg- PSZ media.

- Image analysis can be used as a very useful predictive tool for evaluation of media and mill wear.

Acknowledgements

The authors would like to thank Mr. W.H. Edwards for discussions and providing illustrations for mill operation conditions.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!