Measuring Effect Pigments

Coatings that contain effect pigments change appearance as the illuminating and viewing angles change. This phenomenon is called gonioappearance, and the changes in appearance can be very dramatic. While designers love the visual effects achieved by using these effect pigments, the very aspects that make these pigments so visually appealing also make them uniquely difficult to characterize and control. As the development time from concept color to finished product becomes shorter, the challenge to formulate, correct and evaluate gonioapparent pigments grows.

Metal-Flake Pigments

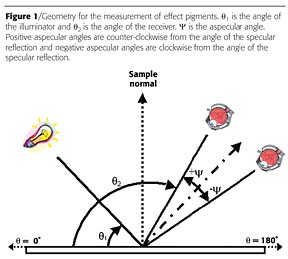

Automotive paint was the first industrial coating to use gonioapparent effect pigments. Initially, only metal-flake pigments were used. These pigments achieve their appearance characteristics by behaving like opaque mirrors, which are layered throughout the cured coating film. Formulations containing only metal-flake and conventional pigments vary most noticeably in lightness, as the viewing angle is changed. This change in lightness is called flop or travel, and the greater the lightness change, the more dramatic the visual effect. The most striking visual effects achieved with these pigments occur when the flakes are aligned parallel to the surface of the coating. The larger the flake, and the more consistent its alignment, the greater is the flop.Researchers have found that the angle of illumination is not critical when measuring colors containing only metal-flake and conventional pigments. This has led to the specification of the "aspecular" angle for measuring coatings containing metal flakes. The aspecular angle is the difference between the viewing angle and the specular (mirror-like) reflection angle of the illuminator. Figure 1 illustrates the aspecular angle concept. The first generation of multiangle spectrophotometers was developed to accommodate this specification. Some of these instruments had a single illuminating angle (45°) and from three to five aspecular viewing angles. Others had from three to five illuminating angles with a single viewing angle (0°).

Two international standards have been adopted for measuring metal-flake pigments. Each includes the specification of aspecular angles for measuring and evaluating these materials. The angles in these standards are referred to as "metallic" angles.

In Germany, the Deutsches Institut für Normung e. V. published DIN 6175-2 Farbtoleranzen für Automobillackierungen - Teil 2: Effektlackierungen (Tolerances for automotive paints - Part 2: Goniochromatic paints). That standard specifies measurements at aspecular angles of 25°, 45°, 75° and 110°.

In the United States, ASTM International published E 2194 Standard Practice for Multiangle Color Measurement of Metal Flake Pigmented Materials. That practice recommends making measurements at aspecular angles of 15°, 45° and 110°, and provides the option for substituting two additional aspecular angles.

The DIN standard even includes a color difference equation with different specifications for manufacturers and users of automotive paints.

Interference Pigments

While conventional pigments produce color by absorbing selected wavelengths of light, metal-flake pigments generally reflect all wavelengths of light. The special visual effect achieved through their use is due to the layering of the pigments throughout the coating. This effect can be measured by changing only the aspecular angle. Since only the aspecular angles are important, a first-generation multiangle spectrophotometer having only one illuminating or viewing angle can adequately capture this effect. In contrast to conventional and metal-flake pigments, interference pigments selectively reflect light as the illuminating and viewing angles are changed. As a result, interference pigments vary most noticeably in hue and chroma. Adding interference pigments to a formula containing metal-flake pigments produces coatings that change not only in lightness, but also in hue and chroma.

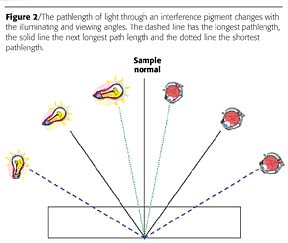

The wavelengths of light reflected by the interference pigment depend upon the thickness of the pigment and the distance the light travels through the particle (pathlength). The reflected light is seen at, or very near to, the angle of the specular reflection. The thickness controls the range of hues that can be seen for a given particle. For a given interference pigment, as the illuminating angle increases, the pathlength decreases, and a range of colors is seen (see Figure 2). Two types of mica-based interference pigments have been developed for commercial applications. While the first generation of interference pigments produces subtle changes in the hue of the coating, the latest generation of these materials produces striking hue changes.

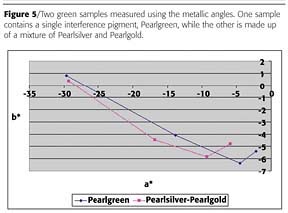

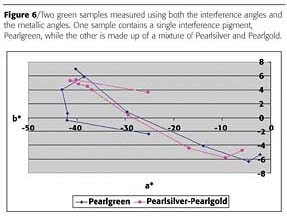

Research done by several pigment suppliers has shown that three illuminating angles (q1 = 25°, 45° and 75°) and two near-aspecular viewing angles for each of the illuminating angles (Y = +15° and Y = -15°) are sufficient for the practical measurement of industrial coatings containing interference pigments. These are referred to as the "interference" angles. Each set of these angles measures a different pathlength of light through the pigment and thus a different color. Ideally, interference pigments are also oriented parallel to the coating's surface. If all of the pigment particles were perfectly aligned, only light reflected at, or very near to, the specular angle would be seen. However, since the ideal is rarely achieved, measurements made at medium and far-aspecular angles are indicative of the flake orientation.

Measuring Coatings Containing Interference Pigments

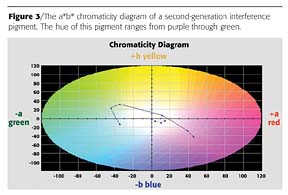

In order to accurately evaluate a coating containing interference pigments, data about the chromaticity (hue and chroma) of the coating is required.Figure 3 is an a*,b* chromaticity diagram plotting the measurements made of a second-generation interference pigment. The solid line in Figure 3 connects the six sets of interference angles in the order in which they were measured. The data points move through all four quadrants of the plot as the illuminating and viewing angles change. This confirms the visual perception that the hue of this sample ranges from purple through green. The resulting horseshoe shape of the connected interference angles is a general characteristic of second-generation interference pigments.

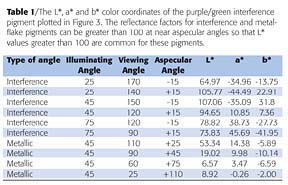

The dotted line in Figure 3 connects the four sets of metallic angles specified in the DIN standard. The origin of the dotted line is the interference point having an illuminating angle of 45° and an aspecular viewing angle of +15°. This is one of the aspecular angles allowed in the ASTM standard. Since the interference reflection is only at, or very near to, the specular angle, the metallic angles are measuring flake orientation. For this particular sample, most of the flakes are parallel to the surface, and the metallic measurements spiral in towards the black color of the substrate. Table 1 contains the L*, a* and b* color coordinates of the points plotted in Figure 3. The table shows that the lightness also decreases rapidly as the metallic aspecular angle increases. If a coating containing only metal-flake and conventional pigments was plotted on an a*b* chromaticity diagram, the chromaticities measured at the interference angles would all cluster around the same a*, b* point.

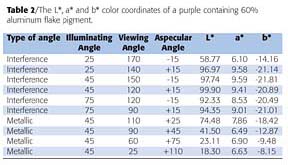

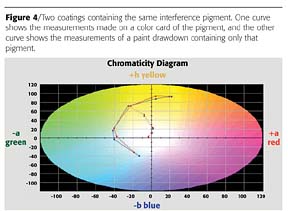

Multiangle spectrophotometers are mostly used for quality-control applications, and the evaluations are typically color difference evaluations. However, the spectral data provided can be used as a tool for matching samples containing interference pigments. Figure 4 illustrates the measurement of two samples containing the same interference pigment. One curve shows the measurements made of the pigment manufacturer's color card, and the other curve shows the measurements of an opaque paint drawdown containing only that pigment. The differences between these curves can be used to quantitatively judge how to adjust a formula to match a standard. For this particular set of samples, the vehicle and solvent package are most likely different.

Conclusion

Effect pigments will continue to be used in formulating coatings, and their use is expected to grow. Consumers and product designers demand the eye-catching effects that can be obtained with the use of these pigments. Coatings with only metal-flake and conventional pigments can be controlled with instruments having only one illuminating angle and several aspecular angles. However, to control coatings containing interference pigments, a multiangle spectrophotometer offering three illuminating angles with two near-aspecular angles at each of the illuminating angles, is necessary for evaluating and controlling interference pigments.Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!