High-Performance Titanium Color Pigments

TicosTM are a new class of high-performance yellow, orange and red pigment preparations. These titanium-based colorants exhibit maximum gloss, opacity, strength and durability, which cannot be achieved with today's blends between organic High Performance Pigments (HPPs) and white or yellow titanium or bismuth vanadate pigments. Ticos are low-dusting pigments and are as easily dispersed as inorganic pigments. Their use is recommended for coatings and plastics requiring high color saturation and good hiding power.

Introduction

In the past, chrome and cadmium pigments were the preferred choice for opaque and full-shade coatings that call for brilliant colors of yellows, oranges, reds, browns and greens. Since the regulation of these pigments1, formulators had the choice between several alternative non-toxic options. Five of these options are described in the sidebar.Today's preferred option is blending organic and titanium white pigments. This has the disadvantage of "whitening" the brilliant chroma of the organic pigment component. Furthermore it is well known that in the presence of titanium white, the weathering stability of these expensive colorants rapidly decreases.2 Blends between high-performance organic pigments and titanate yellows overcome this problem in theory, but do not develop the full potential of these two different pigment classes using today's conventional blending methods. Such blends suffer from separation, which creates stability problems. Additionally, the high abrasion of titanate yellows often prevents the development of a shear stable color. Rutile yellows have limited use then due to the insufficient color development and unsatisfying dispersion properties.

For these reasons, blends between titanium white or titanium yellow cannot match the excellent coloristic and processing properties of lead- and cadmium-based pigments, which has been an ongoing challenge since the regulation of these colorants began.

The Challenge

The deficiencies that were necessary to overcome can be summarized as follows:- avoid the whitening effect of titanium white;

- avoid the photocatalytic (burning glass) effect of titanium white;

- improve the color cleanliness of titanate carrier pigments;

- improve the gloss of titanate carrier pigments;

- reduce the high abrasiveness and improve shear stability of final color;

- improve the opacity and strength of titanate carrier pigments;

- avoid the separation between the heavy inorganic and the light organic color components and consequently the floating, metamerism and insufficient color development.

The Idea Behind Tico - Bonding Instead of Blending

An essential task of this R&D challenge was the search for titanium carrier pigments, which combine lower abrasiveness with optimal gloss, opacity, chroma and UV protection. As a second building block, a process for a special pre-treatment of high-performance organic color pigments had to be found that would allow this component to attach easily to the inorganic carrier by a novel bonding technique. A firm link such as the one created by this bonding technique is needed before the two pigment components can perform like one. This contributes considerable value in use with respect to color saturation, gloss, opacity, strength and stability, and allows the users to produce shear stable final colors. Ticos offer a better cost-to-performance ratio than any of the traditional options.

Tico Advantages

Color Saturation

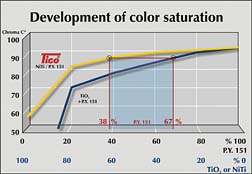

The unique effect of the Ticos' bonding technology on color saturation is illustrated in Figure 1. Ticos achieve identical saturation at only 38% PY 151 loading compared to 67% for blends between titanium white and PY 151. It is obvious that a 67% loading of organic pigment in such blends leaves too little space for gaining sufficient opacity from the titanium component. The reverse is true for Tico pigments, which allow high loadings for the new titanate carrier pigment without compromising full color saturation. This explains why Ticos combine maximum opacity with full color saturation.

Improved Fastness Properties

A further benefit of the Tico bonding technology is a significant improvement in light and weather fastness. Unlike titanium dioxide, which has been known to exhibit photocatalytic activity3,4, accounting for weather-induced degradation mechanisms, the new titanium carrier pigments of Tico act like UV absorbers and protect the sensitive organic pigment. The effect is similar to the method by which sunglasses protect our eyes - a.k.a. the sunglass effect.Figure 2 illustrates the improved durability of Ticos in contrast to the hidden costs imposed by the destructive effect of titanium dioxide on the light and weather fastness of the highly valuable organic HPP.

Note the fact that the weather resistance of TiO2/PY 151 blends falls within a comparable range with highly stabilized chromate and bismuth vanadate pigments, whereas Tico Yellow 594 (also based on PY 151) sets new standards for durability.

Improved Processing Characteristics

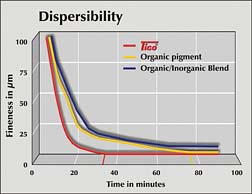

High-performance organic colorants and inorganic pigments differ significantly with respect to their surface characteristics and their specific weights. This is the underlying reason why inorganic pigments incorporate much easier into coating systems than their organic counterparts. As Figure 3 illustrates, the difference in dispersion properties becomes even more problematic when blends of inorganic and organic pigments are incorporated into coating systems.

The new bonding technology resolves this problem by preparing a pre-dispersed form of the two pigments. This provides significantly shorter grinding times compared to those for pure inorganic pigments (Figure 3).

Low Dust and Low Oil Absorption

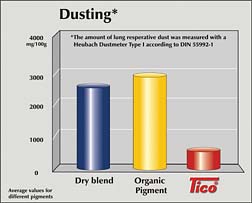

The new bonding technology offers two further advantages compared with straight blends:- 1. The oil absorption can be greatly decreased, allowing for higher pigment loadings in colorant pastes.

2. The tendency for dusting is significantly reduced (Figure 4).

Universal Applicability

Ticos qualify for the requirements of nearly all demanding applications in the coatings and plastic industries, such as:- OEM and automotive refinish coatings;

- Industrial coatings;

- Architectural coatings;

- Exterior decorative coatings;

- Powder coatings;

- Marine coatings;

- Can coatings;

- Plastic applications for PVC, PE, Polyolefins and engineering plastics.

Price and Value-In-Use

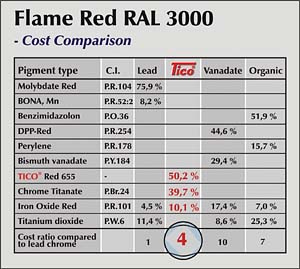

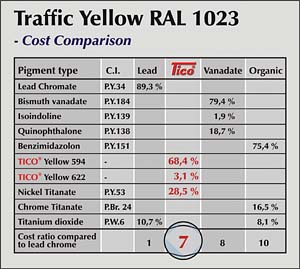

Looking at the favorable properties of Ticos raises the question for the price and the value, at which these new colorants come to the market. The answer is summarized in Tables 1 and 2, showing the relative formulation costs of alternative pigmentations at equal opacity for two typical brilliant RAL-colors, i.e., Flame Red (RAL 3000) and Traffic Yellow (RAL 1023). Ticos do not match the cost of chromate pigments, but offer both a lower cost alternative and higher performance than the other lead- and chrome-free options available.Ecology

Ticos are non-toxic and environmentally friendly alternatives to cadmium- and lead-containing pigments, and match the following EU-regulations:1. Ticos are non-hazardous under Council Directives 67/548/EEC and 1999/45/EC and latest amendments as well as their national implementations.

2. Ticos need not be classified as "hazardous waste".

3. Ticos comply with the purity requirements of EN 71-3:1994 for safety of toys.

Summary

The advantages of Ticos can be summarized as follows.Fastness Properties: Ticos show the best fastness properties compared to blends between HPP organics/TiO2, bismuth vanadates and lead chromate/molybate pigments.

Opacity and Chroma: Ticos are highly opaque and sufficiently saturated to cover important full shade industry colors as defined in the RAL register, but also branded shades like Coca-Cola Red, Shell Yellow or John Deere Green.

Processing: The processing and handling characteristics are superior to those of typical organic colorants and provide easy dispersibility combined with low dusting properties.

Fields of Application: Ticos are recommended for opaque and brilliant full shade or close to full shade applications, which demand high-performance characteristics.

Value in Use: Formulation costs with Ticos are lower if compared to alternative high-performance color solutions.

Contact information:For Europe: Heubach GmbH, Dr. Yvonne Brussaard, Heubachstraße 7, 38685 Langelsheim, Germany; Phone: (+49) 5326 52259; Fax: (+49) 5326 52215; E-mail yvonne.brussaard@heubachcolor.de.

For USA: Heucotech Ltd., Dave L. Keenan, 99 Newbold Road, Fairless Hills, PA 19030; Phone: 215/736.0712 ext. 115; Fax: 215/736.2249; E-mail davekeenan@heubachcolor.com.

For Asia: Heubach Colour Ltd., Dr. Roy, 2nd Floor, Landmark, Race Course Circle, Vadodara 390 007, India; Phone (+91) 2652-300 134; Fax (+91) 2652-235 4827; E-mail roy@heubach-india.com.

References

1 European Economic Community Guideline No. 91/338/EWG (1991).2 Hugh M. Smith (ed.), High Performance Pigments, pp. 44-46, (VCH, Weinheim, 2002).

3 Swaraj Paul, Surface Coatings Science and Technology, pp. 324-326, (Wiley&Sons, New York, 1985).

4 Peter A. Lewis (ed.), Pigment Handbook, Vol. 1 pp. 22-24, (Wiley&Sons, New York, 1988).

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!