2K Waterborne Epoxy-Fortified Technology

For Increased Cure Speed of Institutional Coatings

In buildings that experience high traffic volumes, walls require high abrasion and scuff resistance. These walls are usually painted with a 2K epoxy-fortified coating system that can take 7-14 days to reach full cure properties. A new 2K epoxy-fortified resin system has been developed that reaches full performance in 3 days. This system exhibits accelerated dry-to-touch and dry-through time, decreased recoatability time, and high scratch and abrasion resistance. These characteristics lead to increased throughput, lower maintenance costs and quicker turnaround time for contractors.

This article focuses on the development of a novel 2K epoxy-fortified waterborne system that is less than 100 g/L VOC and that exhibits full cure within 3 days. This coating is compared to other 2K epoxy-fortified waterborne systems that are currently on the market.

New Acrylic Latex

Pliotec SA60 acrylic latex is used in conjunction with a water-based epoxy to form a 2K coating system. This coating system can be used on interior vertical walls in institutional locations such as schools, hospitals, warehouses, office buildings and correctional facilities. It can be applied to a wide variety of substrates; the most common is cement block. Other substrates include primed metal, wood, drywall and plaster. The coating can be formulated to flat, matte or gloss finishes, and it has a high film build, which typically reduces the need for a second coat. It exhibits excellent resistance during frequent cleaning with abrasive cleaning products.

Coatings formulated with Pliotec SA60 acrylic latex reach full performance after 72 h of curing. The coating composition allows an 8 h pot life during application. Current commercial 2K systems do not show full performance until 7-14 days after application. The quick cure of a 2K system based on Pliotec SA60 latex allows for recoat (if needed) in one hour versus 1-2 days, thus allowing the contractor to spend less time at a job site.

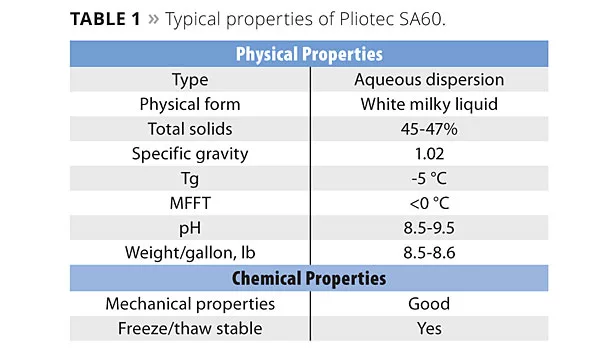

Pliotec SA60 institutional coatings offer low VOC, low odor, accelerated dry-to-touch and dry-through time, decreased recoatability time, high scratch-resistant finishes, improved performance over current commercial products and are APE free. Table 1 shows typical properties of the new resin system.

VOC and Stability Test Results

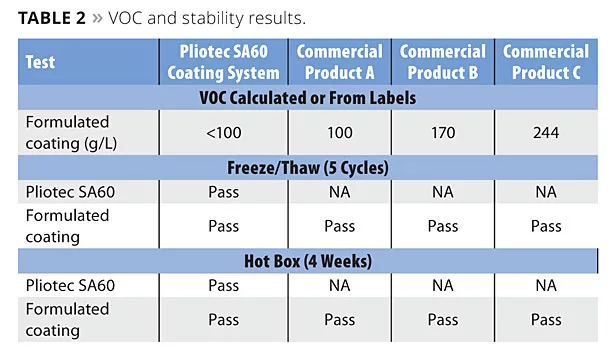

The VOC levels listed in Table 2 were noted from the labels of widely available commercial products and calculated for Pliotec SA60 formulation. Pliotec SA60 latex was tested for both freeze/thaw and oven (120 °F) stability. In addition, the formulated coating (without epoxy) for Pliotec SA60 and the commercial products were also tested for freeze/thaw and oven stability.

Pot Life and Cure Time Results

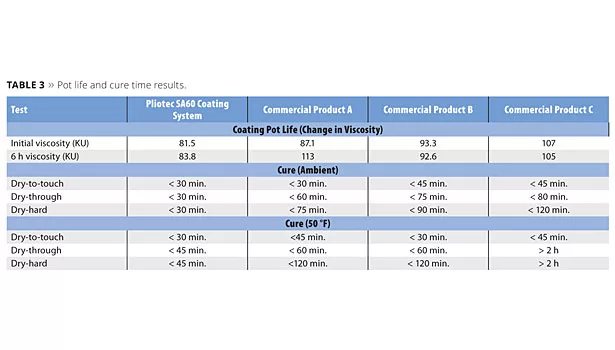

Pliotec SA60 formulated coating and the commercial product coatings were mixed as directed, and the pot life (useable work time) and cure times were determined. Dry-to-touch, dry-through and dry-hard were evaluated according to ASTM D1640 (Table 3).

Cured Film Characteristics

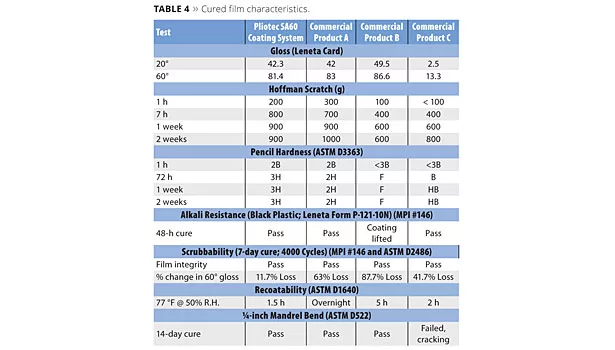

Cured films of the 2K coating systems were tested for film characteristics using the following methods. Results are shown in Table 4.

- Gloss at 20° and 60° was tested using a BYK Gardner micro-TRI-gloss meter.

- The Hoffman Scratch Hardness Tester indicates the comparative scratch resistance and adhesion of coatings. Weight loads are added until the tool cuts through to the substrate. Scratch hardness is the force necessary to cut through the film to the substrate. Higher weights correlate with harder films.

- Pencil hardness was rated using a Pencil Hardness Gage. The “Gouge Hardness” was evaluated as the hardest pencil that will not cut through the film to the substrate. Rating grades 6B (softest) to B/F (middle) to 9H (hardest).

- Alkali resistance was tested with 2% sodium hydroxide for 30 min and examined for disintegration or deterioration.

- Scrubbability was tested according to ASTM D2486 with slight exceptions listed per MPI #146 — Master Painters Institute Detailed Performance Standard MPI #146 Latex, Interior, Institutional Low Odor/VOC, ("satin-like'-MPI Gloss Level 4) White and Tints.

- Recoatability or dry-to-recoat according to ASTM D1640.

- Mandrel bend of 6 mil films according to ASTM D522.

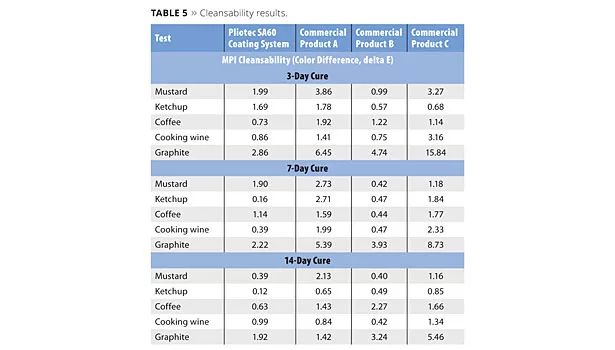

Cleansability Performance of 2K Coating Systems

Cured films of Pliotec SA60 and commercial products were tested for cleansability according to section 7.11 in MPI #146 (Table 5). Color difference was determined by using a HunterLab spectrometer and noting results as delta E (dE). Delta E takes into account the differences between L, a* and b* of the original film sample and the standard after staining and cleaning. The idea is that a dE of 1.0 is the smallest color difference the human eye can see. Delta E is a single number that represents the difference between two colors. Theoretically any dE that is less than 1.0 is visually imperceptible.

Conclusion

These test results show that systems formulated with Pliotec SA60 have faster dry-to-touch and dry-through times, which reduces time needed for recoatability. Generally, this resin exhibited a higher scratch-resistant finish than current commercial coatings, which allows the occupant to spend less time on maintenance. Pliotec SA60 can facilitate lower VOCs in the workplace, low odor, less time spent for contractors on the jobsites and faster turnaround time on coating projects. The building owner has faster reoccupancy and benefits from lower maintenance costs.

For more information, visit www.omnova.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!