Innovative, Multifunctional Additives

for Water-Based Coatings

Wetting refers to the dynamics of how a liquid, when deposited on a solid (or another liquid) substrate, is able to spread. This wetting of solid substrates by liquids is a basic element in many natural and commercial processes. Understanding the wetting phenomenon enables us to explain why water spreads nicely on clean glass, but does not spread on a sheet of polypropylene.

A wetting agent is a compound that causes water to spread over the surface of another material. A common observation is that the addition of a surface active agent (or surfactant) to water will enable a solution to wet.1

With the regulatory arena becoming more and more restrictive, the move to water-based coatings has reached a high point and has necessitated the development of additives to assist the formulator in overcoming the required regulations. The result, however, can be the inclusion of more additives than the formulator would like to use.

An innovative technology has been developed that will give the formulator the choice to use a family of additives that are multi-functional, thus limiting the number of additives necessary to successfully produce the desired coating properties. Although these materials are wetting agents, they also serve at least one other purpose, such as being an excellent dispersant, being biodegradable or having a very low critical micelle concentration (CMC). The properties and characteristics of these products are highlighted in numerous testing regiments that follow. The materials are designated MW (multifunctional wettings agents) followed by A, B, C, D or E.

Evaluation and Discussion

Basic Characteristics

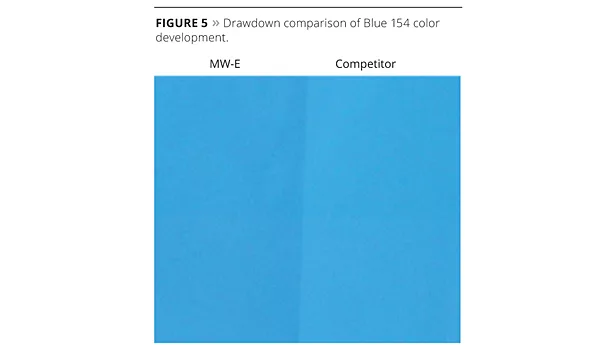

Initial laboratory studies were conducted to determine the basic properties of these multifunctional wetting agents. Table 1 shows the results and a comparison with an anionic additive that is used in coating applications. Surface tension studies, both static and dynamic, were completed and show excellent values of surface tension reduction for materials that are non-silicone and non-fluorinated. Product MW-E is the exception to these low values, but does have other interesting capabilities. The critical micelle concentration of the MW-A and MW-D are particularly low and yield some interesting results. Of the five materials, only MW-D and MW-E show any propensity to foam.

Substrate Wetting

The proper wetting of the chosen substrate is generally thought to be the most important factor in coating application. Improper substrate wetting will cause a number of issues, including adhesion failure, corrosion, lower gloss and in general a poor appearance of the final coating. It is, therefore, of utmost importance to understand the capability of the wetting agents used in the formulation.

A number of evaluations were carried out to identify the substrate wetting properties of the MW series on various low-energy substrates. In addition, a comparison was done on clean versus dirty, or unprepared, surfaces.

Contact angle comparisons on styrene and washed PTFE are shown in Figure 1. As can be seen from the data, MW-B, MW-C and MW-D have low contact angle measurements on both of the low-energy substrates tested. MW-A and MW-E are competitive, but not quite as low. These results indicate very good wetting capability on difficult-to-wet substrates for use in coatings and related applications.

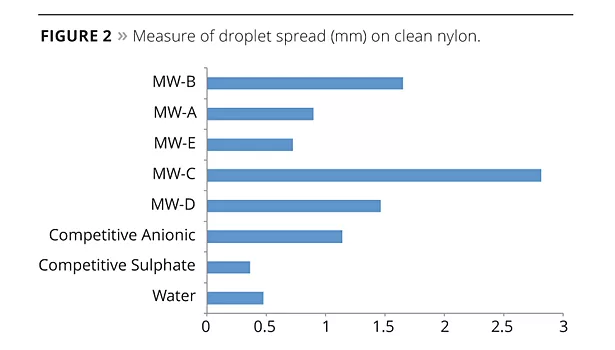

The data in Figure 2 demonstrates the ability of the MW series to wet out clean or prepared substrates. Another low-energy substrate, nylon, was used as the test material for the spreading of a droplet. A drop is placed on the surface of the nylon, and the spreading of that droplet is measured after 30 sec. In this case, MW-C spreads the most by far, followed by MW-B and MW-D. As was seen in the contact angle testing, the same three materials are the leading candidates.

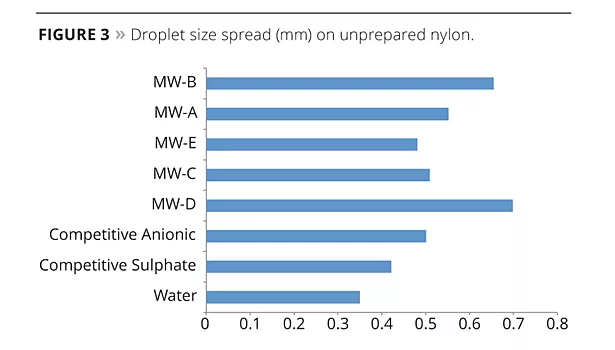

In contrast to the results of droplet spread on clean nylon, the data in Figure 3 shows a different range of the MW series yielding a larger spreading effect when unprepared nylon is the test substrate. In this case, MW-A, MW-B and MW-D are the leading spreading agents. This data does correspond to data in Table 1, as these are the three materials with the lowest CMC. The ability of these three materials to form micelles at very low concentrations could indicate possible emulsification of the impurities on the substrate.

Solids Wetting and Dispersion

Evaluations were also completed that tested the capability of the MW series to wet out and aid in the dispersion of solid particles. To maximize the utilization of a pigment, proper wetting and dispersion of the pigment are of utmost importance.2 The color development that can be attained by a pigment can be enhanced by improving the quality of the dispersion process. A proper wetting and dispersing agent can provide that advantage.

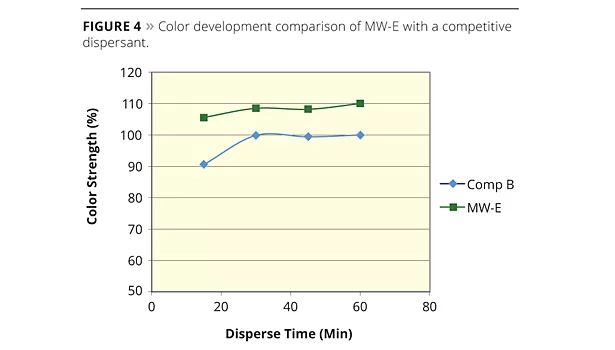

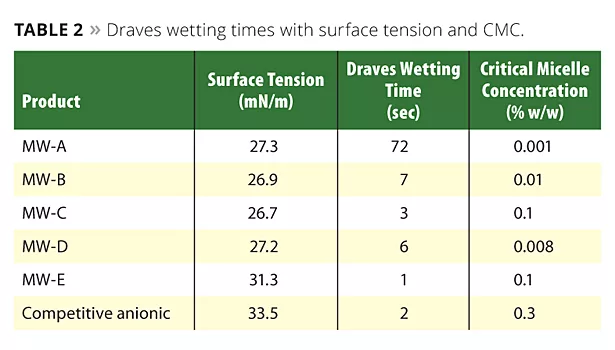

Figure 4 shows a comparison of MW-E and a competitive high-profile dispersing agent. A 40% solids dispersion of Blue 154 was ground by high-speed mixing for a total of 60 min. The 60-min grind color developed with the competitive dispersing agent is set as 100%, and all other data is compared to it. As can be seen in Figure 4, the color developed by MW-E when used as the wetting and dispersing agent is dramatically better than that developed by the competitive material. In fact, after 15 min of grinding, the MW-E dispersion offers improved color development over the competitive material after 60 min of grind. This ability of MW-E to yield a color advantage as well as perform very well as a wetting agent is very unique.

The visible comparison of color development depicted in Figure 4 can be seen in Figure 5. A substantial difference can be seen in the color of the two drawdowns. The 60-min grind was used in this comparison. To be visible to the naked eye, the difference in color development needs to be at least 5%.

Draves Wetting Test

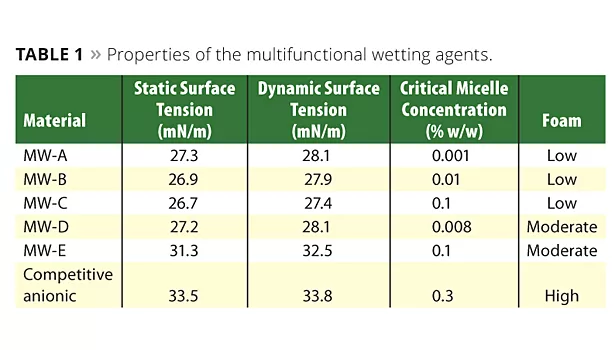

The Draves wetting time is the time required for a weighted cotton skein to sink in a solution of wetting agent. It is a test typically used in the textile industry. The evaluation completed used all wetting agents at a 0.1% concentration based on solids. Table 2 shows the resultant data with the surface tension and CMC. It would be expected that all of the MW would have very low Draves wetting times. However, MW-A has a relatively long Draves wetting time when compared to the other materials in the MW series.

The most plausible hypothesis to explain this result is that MW-A has a very low CMC and therefore is forming micelles, while the other materials are moving to the cotton/water interface to wet the cotton. Therefore, MW-A will prove to be very efficient in use due to its low CMC.

Regulatory Data

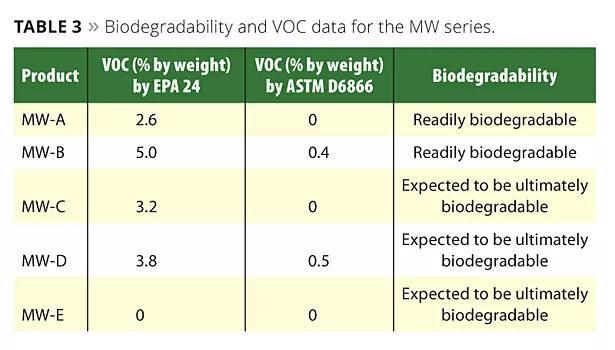

The MW series also shows a very good environmental profile. As can be seen from Table 3, all MW products are biodegradable in some form. Additionally, these materials have low VOC, particularly when determined by ASTM D6866. This allows the use of the MW series in formulations without a substantial increase in VOC.

Paint Formulation

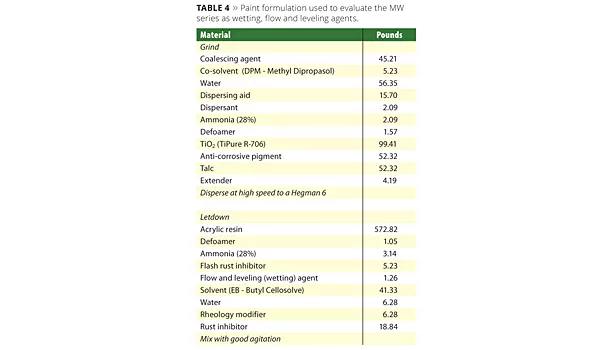

The final evaluations of the MW series were conducted in a paint formulation. The formulation is designed for use as a direct-to-metal paint that can be used without a primer. This paint typically uses a silicone wetting, flow and leveling agent. The MW series products were substituted for the silicone additive directly on an “as is” basis.

The paint formulation in Table 4 was used to evaluate the MW series as wetting, flow and leveling agents. The MW products were used as direct replacements for the silicone additive.

Paint Properties

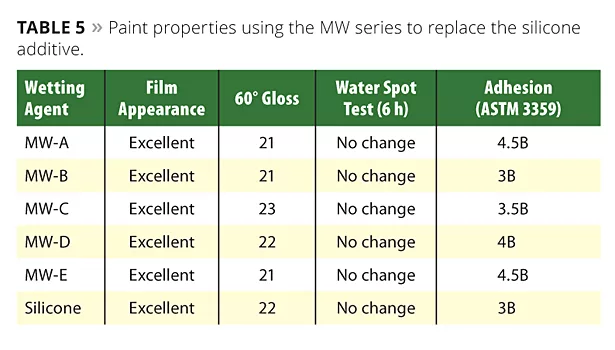

Table 5 highlights the ability of the MW series to replace the silicone additive without any loss of properties, and in fact, potentially provide some adhesion advantage.

Conclusions

• The MW series of multifunctional wetting agents produce paint with properties equal to or better than the competitive silicone flow and leveling additive.

• These APE-free, low- or no-VOC materials offer very good surface tension reduction as well as excellent low-energy substrate wetting capability.

• MW-C performed best as a low-energy substrate wetter when using clean substrates. MW-A, with the lowest CMC, was among the best when wetting unprepared substrates.

• MW-E is an excellent solids wetting agent and dispersant, yielding dispersions that show dramatic improvement in color development when compared to a typical wetting agent. n

Summary of Multifunctional

Wetting Agents’ Capabilities

• MW-B for biodegradability and substrate wetting;

• MW-A for most efficient wetting (lowest CMC) and lowest foaming;

• MW-E for solids wetting and dispersion;

• MW-C for excellent wetting of low-energy substrates and low foaming;

• MW-D for most versatile wetter, including unprepared and low-energy substrates.

References

1 Patton, T.C. Paint Flow and Pigment Dispersion, John Wiley and Sons, 1979.

2 Napper, D. H. Polymeric Stabilization of Colloidal Dispersions, Academic Press, 1983.

This paper was presented at the 40th Annual Waterborne, High-Solids and Powder Coatings Symposium, February 2013, in New Orleans.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!