New Biocidal Active

Effectively Preserves Paint, Latex, Colorants and Mineral Slurries

Preventing microbial contamination in waterborne paint is a problem faced by manufacturers across the United States and around the world. Bacteria are the primary threat against product quality, but some yeasts and mold can also cause spoilage without an effective preservation package. Contamination impacts paint and paint performance in obvious ways such as bulging cans, foul odor, viscosity changes and color changes, as well as in more subtle ways such as pH drift.1

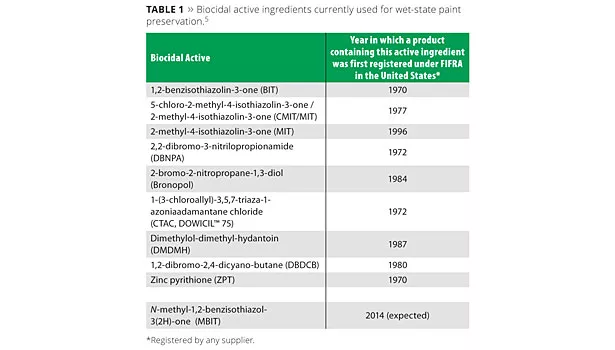

Biocides, including those used for paint preservation, must be registered in the United States under the Federal Insecticide, Fungicide and Rodenticide Act (FIFRA), which was first enacted in 1947, revised in 1972, and further amended in 1996 (7 U.S.C § 136 et seq.). The EPA states, “All pesticides distributed and sold in the United States must be registered by the EPA based on scientific data showing that they will not cause unreasonable risks to human health, worker or the environment when used as directed on product labeling.”2 Shown in Table 1 are some of the commonly used FIFRA-registered biocidal actives for in-can (wet-state) paint preservation against microbial attack. A large portion of biocidal actives used in modern paint formulations have been registered for more than 40 years. It is important to note that registered biocides are reviewed by the EPA every 15 years, and in each review more and more data regarding the environmental fate, ecological toxicity and exposure data for the biocides is required to maintain registrations.

Meanwhile, over the course of four decades, paints have undergone a metamorphosis. One notable change early on was the ban on lead-containing paint announced in September 1977 by The United States Consumer Product Safety Commission, which went into effect in 1978 (16 CFR 1303).3 Other significant changes include the transition from solventborne paints to waterborne paints. Further, the reduction in VOCs and increased use of both recycled water and naturally derived raw materials have impacted today’s sophisticated paint formulations. All of these positive changes have unfortunately made paints a more hospitable environment for microorganisms to survive – and more importantly – thrive.4

A Substantial Undertaking

Paint manufacturers are seeking more effective long-term preservation of paints against common contaminants, especially resilient bacterial strains present in manufacturing facilities. However, the process of developing, testing and registering a new biocidal active ingredient is not trivial – it can require several years and millions of dollars. To be considered a valuable addition to the current range of preservatives on the market, a new preservative product would need to be: efficacious against a broad range of industrially relevant contaminants including resilient manufacturing isolates, free of formaldehyde-releasing chemistries as well as bronopol, compatible with paint and raw materials, acceptable with major ecolabels, and appropriate for use in low-VOC paint formulations.

There are several other factors to consider when discussing the feasibility of introducing a new paint preservative. Biocides are highly regulated by the EPA under FIFRA. EPA requirements include: acute, chronic, and ecological toxicity; environmental fate; physical/chemical properties; and efficacy of the proposed preservative product. Even new combinations of previously registered active ingredients (Table 1) brought into the market require extensive review before registrations are granted. The standard timeline for review of a product dossier can be as little as five months for a new product that contains an active that has previously been approved for that same end use (i.e., BIT for paint preservation). However, the timeline for a new active ingredient, as well as products containing the new active ingredient, is much longer – typically 18 months. Meeting the data requirements has a significant financial impact on the registrant, and requires a large investment of time to complete all the necessary scientific studies.

This Century’s First New Biocidal Active for Coatings Preservation

The Dow Chemical Company anticipates US EPA registration of a new active ingredient N-methyl-1,2-benzisothiazol-3(2H)-one (MBIT) in 2014. The registration process demanded a multimillion dollar commitment over a multi-year timeframe. As anticipated, the largest financial investment for the registration of MBIT in the United States was the toxicology data package, which accounted for more than 90% of the costs.

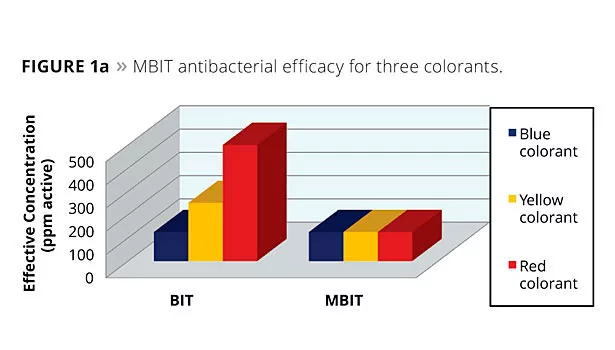

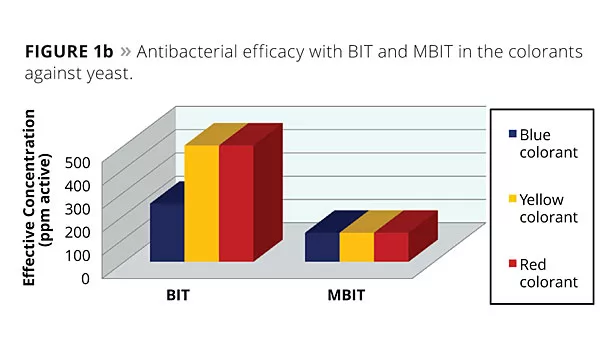

Prior to pursuing EPA registration, extensive MBIT efficacy testing was conducted in a variety of paint, colorant, latex and mineral slurry formulations against industrially relevant bacteria, yeast and mold. Of particular interest were the results of MBIT performance against the structurally similar biocidal active 1,2-benzisothiazolin-3-one (BIT), which is commonly used in paint preservation. In colorant preservation tests, MBIT demonstrated enhanced activity against yeast when compared to BIT and exhibited equivalent or superior efficacy against bacterial insults. In Figure 1a, the antibacterial efficacy is shown for three colorants after four challenges with laboratory bacterial strains (5 x 106 CFU/mL). The blue colorant was successfully preserved with equivalent concentrations of BIT and MBIT (125 ppm total active). Additionally, 125 ppm of MBIT alone effectively protected the yellow and red formulations from bacterial spoilage, whereas elevated concentrations of BIT (250 to 500 ppm) were required to preserve these particular colorants. Evaluations with BIT and MBIT in the colorants against yeast (Figure 1b) demonstrated similar results, with MBIT demonstrating efficacy at 125 ppm total active. The BIT concentration required for the same level of efficacy was two to four times greater for the blue colorant (250 ppm) and the yellow and red colorants (500 ppm), respectively. In five out of the six colorant tests conducted, MBIT demonstrated superior results with lower active ingredient concentrations and, in the remaining test, equivalent performance was observed.

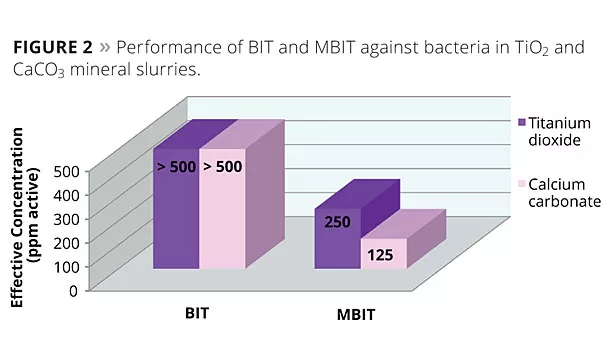

he exceptional efficacy of MBIT was not limited to colorants. Performance of the two actives was evaluated against bacteria in titanium dioxide (TiO2) and calcium carbonate (CaCO3) mineral slurries. The difference in efficacy after four bacterial inoculations was dramatic, with 500 ppm (0.05%) BIT failing to protect either of the two mineral slurries, while 250 ppm and 125 ppm MBIT was sufficient for preservation of the TiO2 and CaCO3 slurries, respectively (Figure 2).

MBIT Launch in the United States

Dow Microbial Control will launch the preservative product BIOBAN™ 557 Antimicrobial in 2014 once EPA registration has been granted. BIOBAN 557 contains the new active ingredient N-methyl-1,2-benzisothiazol-3(2H)-one (MBIT) in combination with 5-chloro-2-methyl-4-isothiazolin-3-one (CMIT) and 2-methyl-4-isothiazolin-3-one (MIT). Rather than blending MBIT with an existing preservative product, such as a 1.5% CMIT/MIT product, the new formulation was designed as a unique blend of 10% total active ingredient with an adjusted ratio of the three actives for optimal broad-spectrum protection against industrially relevant bacteria, yeast and mold, including resilient environmental strains. The final MBIT/CMIT/MIT formulation was determined through extensive testing in paints and other matrices with Dow Microbial Control’s proprietary TAUNOVATESM High-Throughput Testing (HTP) system (Figure 3a). The system utilizes a robot to assist with sample analysis and can provide 13,000 data points for simultaneous tests in one day. A calculation of efficiency determined that the same amount of laboratory work by standard, non-robot methods involving Petri dishes and sample cups (Figure 3b) would require 15 eight-hour days.

Protection Against Bacteria and Fungi

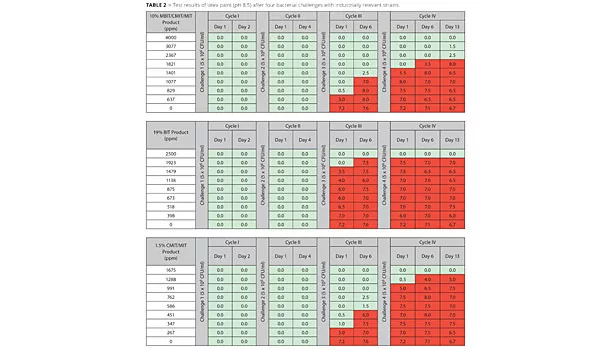

As the prevalence of low-VOC paint formulations increases, so does the demand for robust preservation strategies. Manufacturers are reporting increased incidences of microbial contamination in their facilities, particularly in low-VOC products and products containing naturally derived raw materials. These factors, coupled with the timing of the United States painting season in the warm summer months, can provide the ideal growth conditions for microorganisms. To deal with the microbial onslaught, manufacturers are often forced to use multiple single-active preservative products in order to successfully preserve paints. To demonstrate the efficacy of the new 10% MBIT/CMIT/MIT product versus the single-active products such as those containing 1.5% CMIT/MIT and 19% BIT, the TAUNOVATE HTP system was used in a four-cycle bacterial challenge test of a difficult-to-preserve latex paint (pH 8.5). The HTP testing results are shown in Table 2. After four bacterial challenges with industrially relevant strains, the 10% MBIT/CMIT/MIT product demonstrated enhanced efficacy over the single active BIT and CMIT/MIT products. Green-shaded cells indicate passing scores, while red-shaded cells indicate failing scores after each inoculation with 5 x 106 CFU/mL of bacteria. The MBIT/CMIT/MIT product passed the month-long challenge test at 2,367 ppm product, which delivered 236.7 ppm of MBIT/CMIT/MIT. Both the BIT and CMIT/MIT single-active products passed the test at their EPA maximum use levels of 2,500 ppm (475 ppm BIT) and 1,675 ppm (25 ppm CMIT/MIT) for paints, respectively. While effective in this test, manufacturing conditions –particularly issues with industrial hygiene – could cause the single-active preservatives to fail. There is no margin of error given the reported results in Table 2. Conversely, there is a comfortable margin between the passing level of 2,367 ppm MBIT/CMIT/MIT product and the anticipated upper limit of 3,700 ppm for the MBIT/CMIT/MIT product (once EPA registered), which would deliver 370 ppm active MBIT/CMIT/MIT.

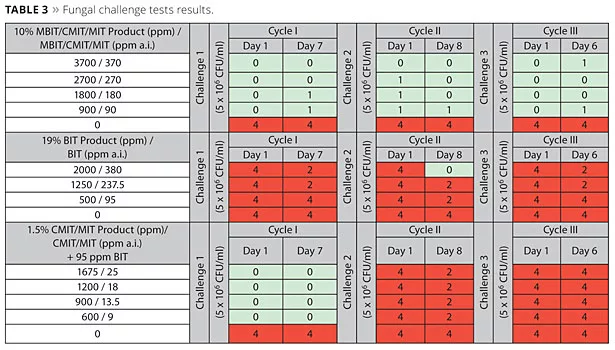

Exceptional efficacy of the MBIT/CMIT/MIT blend against fungi has also been documented. While fungal contamination of wet-state paint is not as prevalent a problem as bacterial contamination, manufacturers are reporting an increased rate of occurrence. The MBIT/CMIT/MIT product was evaluated against the single active BIT product as well as a combination of 95 ppm BIT and varying CMIT/MIT levels provided by a 1.5% CMIT/MIT product in a three-cycle fungal challenge test of a difficult-to-preserve latex paint (pH 9.0). The samples were inoculated weekly with a combination of a paint manufacturer-specific yeast and industrially relevant laboratory mold strains. The results are shown in Table 3. MBIT/CMIT/MIT passed at the anticipated lower limit use rate for paints (once EPA registered) of 900 ppm (0.09%) product, which delivers 90 ppm total MBIT/CMIT/MIT. BIT alone failed at 380 ppm. Most significantly, the combination of 25 ppm CMIT/MIT (provided by 1,675 ppm of the 1.5% CMIT/MIT product) and 95 ppm BIT, for a total of 120 ppm active, failed. These results further demonstrate the effectiveness of the unique ratio of MBIT to CMIT to MIT in the MBIT/CMIT/MIT product.

Rapid Kill and Long-Term Preservation

Microbial contamination events can occur during the paint manufacturing process, and these events tend to be more frequent during the summer season. Product remediation (rework) is an important practice due to the susceptibility of low-VOC waterborne products and the exorbitant cost associated with disposal of contaminated product batches. Typically, the remediation process involves a rapidly acting sanitizing biocide, for example a product containing DBNPA. Following the addition of the sanitizing biocide, there is a period of mixing, holding, microbial monitoring and finally incorporation of the reworked material into a new production batch with a long-term preservative. This time-consuming process requires several steps, and paint manufacturers are always seeking ways to streamline the process.

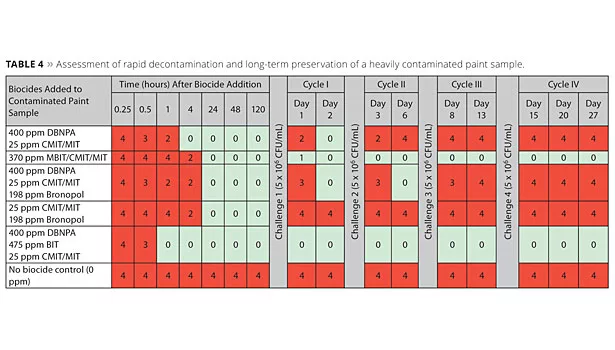

Evaluations early in the development of the MBIT/CMIT/MIT product showed rapid decontamination of heavily contaminated samples. More studies followed, including the study shown in Table 4 in a heavily contaminated paint sample supplied by a manufacturer seeking recommendations for effective remediation and long-term preservation of a highly susceptible paint formulation after challenge with the resilient Pseudomonasstrain isolated from the facility. The one-time use of 370 ppm MBIT/CMIT/MIT successfully decontaminated the paint and provided effective long-term preservation through four additional challenges. Combinations of DBNPA/CMIT/MIT, CMIT/MIT/bronopol and DBNPA/CMIT/MIT/bronopol could not provide both decontamination and long-term preservation. The combination of DBNPA/CMIT/MIT/BIT successfully decontaminated and then preserved the paint, but the total biocidal concentration required of 900 ppm active (6,175 ppm product) was significantly higher than the 370 ppm MBIT/CMIT/MIT (3,700 ppm product) required for nearly equivalent performance.

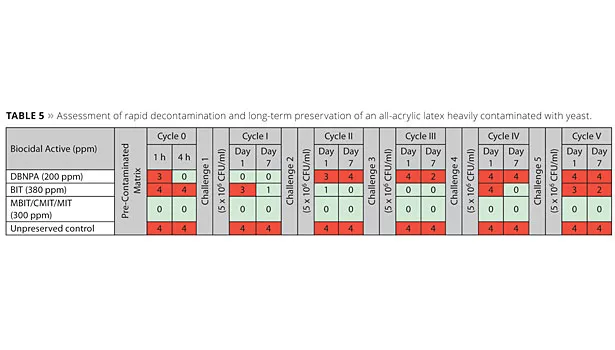

The combination of rapid kill and long-term preservation was measured in other formulation types and against a variety of microorganisms. Table 5 displays the results of a study conducted in an all-acrylic latex that was heavily contaminated with yeast. The one-time use of MBIT/CMIT/MIT at 3,000 ppm (delivering 300 ppm MBIT/CMIT/MIT) successfully decontaminated the latex more rapidly than 200 ppm of DBNPA and then provided effective long-term preservation through five additional challenges. BIT is not considered to be a fast-acting biocidal chemistry, but 380 ppm was not sufficient for long-term preservation of the latex.

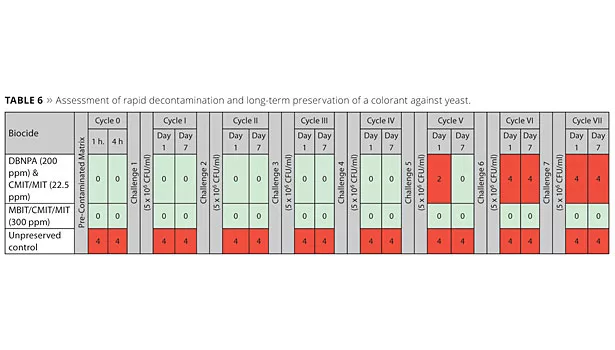

The CMIT/MIT chemistry is considered the fastest-acting isothiazolone chemistry. A study was performed in a contaminated colorant in which CMIT/MIT was paired with a moderate dose of the rapid-sanitizing chemistry DBNPA. The MBIT/CMIT/MIT combination at 300 ppm provided equivalent speed of kill and then outperformed CMIT/MIT/DBNPA over the course of seven challenges with (5 x106 CFU/mL) yeast. The results are shown in Table 6.

Laboratory Trials Are Underway

Waterborne product manufacturers within the United States may contact Dow Microbial Control to request an experimental sample of the MBIT/CMIT/MIT formulation for laboratory studies. Alternatively, manufacturers may discuss efficacy testing with the company and continue to provide their environmental isolates of bacteria, yeast and mold for challenge testing.

An Important Part of the Larger Picture

Successful preservation of waterborne products, particularly the highly susceptible low-VOC products generated from naturally derived raw materials, involves many factors. Having a variety of EPA-registered biocidal actives in different preservative products is important, as no single biocidal active (or product) will work in every product formulation. Efficacy testing is critical to determine the performance of biocides used in accordance with their EPA labels. Care must also be taken to avoid exposing preservatives to extreme conditions, such as combining two different concentrated (neat) biocide products together. This action can deactivate the biocidal actives before they are mixed into a paint formulation. In contrast, preservative blends offered by biocide suppliers are formulated in such a way as to maintain the stability of the active ingredients with appropriate ratios and the use of stabilizers. Additionally, factors such as heat and extreme pH can negatively impact the stability of a preservative, and altering the order of addition can extend the longevity of a preservative. Industrial hygiene is also a significant part of effective product preservation. A preservative package cannot be expected to counteract the effects of a poor or non-existent industrial hygiene program in a manufacturing facility. By taking these factors into consideration, preservatives can be effectively and sustainably used to prevent product contamination. Cost-to-treat calculations must be balanced against the potential expenses of product recall and loss of brand equity.

Developing a new biocidal active in today’s environment requires significant commitment and expertise. Paints and raw materials are becoming ever more sustainable, increasing their susceptibility to microbial contamination. Even once a solution has been identified, bringing a new active to market requires a multi-year, multimillion dollar commitment to secure registration with the EPA. The scale of investment required highlights the importance of MBIT for paint manufacturers, as the first new active for paint preservation to be introduced in the United States this century.

References

1 Browne, B.A. 2010. The Influence of Global Regulatory Requirements and Pressures on Preservative Choices for Consumer Products. May 6, 2010. Consumer Specialty Products Association Mid-year Meeting. Chicago, IL.

2 US EPA Registration Review. http://www.epa.gov/oppsrrd1/registration_review/.

3 Consumer Product Safety Commission website. http://www.cpsc.gov/en/Recalls/1977/CPSC-Announces-Final-Ban-On-Lead-Containing-Paint/.

4 Browne, B.A.; Geis, P.; Rook, T. 2012. Conventional vs. Natural Preservatives. happi 49(5): 69-73.

5 National Pesticide Information Retrieval System (NPIRS).

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!