The Case for Two-Component Waterborne Polyurethane Coatings

The desire to use waterborne instead of solventborne coatings is driven by tighter government regulations on VOCs, which are moving to 50-100 g/L. In addition, consumers are demanding low odor in coatings, especially those used in interior applications. The challenge has been to make a low-VOC, low-odor paint system that offers the performance properties of a two-component solventborne polyurethane paint.

Two-component waterborne polyurethane coatings have been under development for decades and now meet the requirements for low odor and low VOC. In addition, the quality of these coatings has steadily improved to the point where their performance properties compare favorably with two-component solventborne polyurethane coatings. However, to date there have been few scientific studies done specifically to document the performance comparison of these two coating systems.

This article describes a designed set of experiments that were carried out in Bayer MaterialScience’s laboratory to do just that: compare the coatings properties of two-component waterborne polyurethane coatings and two-component solventborne polyurethane coatings. The study used paints developed for use as metal coatings in the agricultural, construction and earthmoving (ACE) market.

Experimental

Paints were made containing the three most prominent colors in the ACE market – green, yellow and red. Once these paints were formulated, they were sprayed on treated steel panels and allowed to cure at ambient temperature. First the colored coat was applied and allowed to flash off and a clear topcoat, using the same resins as the colored paint, was applied. Each resin combination was made in each color to provide three readings for each resin system.

Paint Formulation

Paints were formulated in each color using a standard clear formulation and adding pre-dispersed pigments in the appropriate color. A formulation typical of the clear waterborne formulations used in this study is shown in Table 1. Table 2 shows the solventborne clear formulation.

Description of Resins

The paint systems used in this study were all two-component coatings. They consisted of a hydroxyl-functional acrylic that contained the additives, including pigments (if pigmented), and a polyisocyanate. A standard commercial solventborne polyurethane coating was used along with eight waterborne systems. These systems are described below.

The solventborne polyurethane coating (SB) consisted of a hydroxyl-functional polyacrylate crosslinked with a low-viscosity isocyanurate-type polyisocyanate. The polyisocyanate was 100% solids, had a viscosity of 700 and contained 24.0% NCO.

The waterborne polyurethane coatings consisted of the following waterborne polyacrylates mixed with one of the polyisocyanates described below:

1. W PAC A = a product that yields hard but flexible films when crosslinked. It has 45% solids, a hydroxyl content of 3.9% and 3% co-solvent.

2. W PAC B = a product that yields hard, glossy and chemical-resistant films when crosslinked. It has 50% solids, a hydroxyl content of 5.4% and 1% co-solvent.

3. W PAC C = a product that dries quickly to yield hard, glossy, chemical-resistant films when crosslinked. It has 45% solids, a hydroxyl content of 3.9% and 8% co-solvent.

4. W PAC D = a product that yields high-gloss clear and pigmented films when crosslinked. It has 45% solids, a hydroxyl content of 3.3% and 8% co-solvent.

The waterborne polyurethane coatings contained one of the following water-dispersible polyisocyanates:

1. Iso A = A high-functionality, easily dispersed, anionically modified HDI-based polyisocyanate. It is 100% solids, has a viscosity of 3,500 and contains 21.8% NCO.

2. Iso B = a high-functionality, non-ionically modified HDI-based polyisocyanate. It is 100% solids, has a viscosity of approximately 4,000 and contains 18.2% NCO.

Table 3 lists the coatings that were tested in this study.

Paint Application

The polyisocyanate was mechanically mixed into the formulated hydroxyl-functional resin and then let stand for one half hour to allow bubbles to escape. This formulation was then applied within the next hour.

The formulated paints were sprayed onto phosphate-treated steel panels (Bonderite 1000) using a gravity-fed HVLP spray gun with 10 psi pressure at the tip. The DFT of a single application of the coating was 1.5 - 2 mils. Once the panels were sprayed, they were allowed to cure at ambient conditions.

Test Regimen

Following 14 days of cure at ambient temperatures, the coated panels were tested for: DOI, flexibility (by conical mandrel bend), pendulum hardness, impact resistance, chemical resistance, xenon arc and Florida weathering. The test procedures used are given in Appendix I.

Results and Discussion

Distinction of image (DOI)

The DOI of each coating was tested using Bayer method 05-008. These results varied from 90 to 97, with the waterborne coatings being slightly higher than the standard solventborne coating.

Conical Bend

Next the flexibility of each coating was tested by conical mandrel bend using ASTM 0522. All coatings, both waterborne and solventborne, passed this test.

Hardness

Hardness was tested using a pendulum hardness tester with test method ISO 1522. The results show that the waterborne coatings are slightly harder than the standard solventborne coating, and vary by composition. Those resins that contain Iso B have higher hardness. This is due to the higher amount of crosslinking delivered by Iso B compared to Iso A. These results are shown in Figure 1.

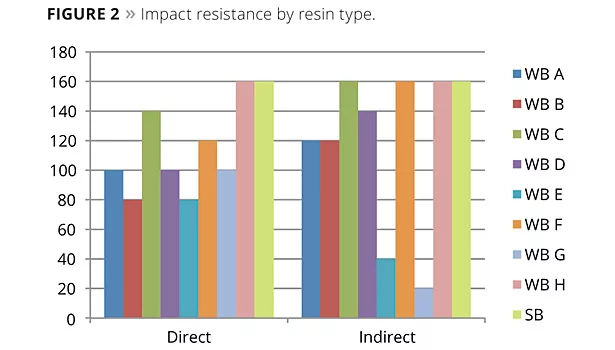

Impact Resistance

Impact resistance was tested using ASTM D 2794 to determine the coating’s flexibility and adhesion on metal. This test shows that the solventborne coating has outstanding impact resistance when hit directly or from behind, and only one of the waterborne coatings (WB H) matches it. This result is not surprising since WB H is chemically the closest waterborne formulation to the solventborne formulation. The other waterborne coatings have impact resistance from 80 to 160 foot-pounds, which is considered acceptable by general ACE paint standards. These results appear in Figure 2.

The chemical resistance of each coating was tested using a 24-h spot test. Since this study was done with the ACE market in mind, the testing consisted of vehicular fluids such as gasoline, diesel fuel, engine oil, transmission fluid and engine coolant. Table 4 shows that all coatings stand up to diesel fuel, engine oil and trasnsmission fluid. Gasoline softens some of the waterborne coatings and the standard solventborne coating. Two waterborne coatings (WB A and WB C) demonstrate better resistance to gasoline than the standard solventborne coating. These waterborne coatings have the highest level of crosslinking.

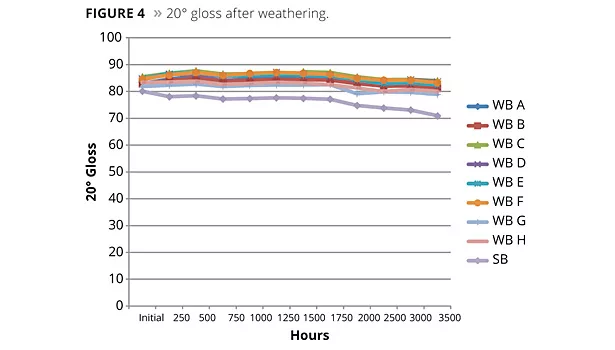

All coatings were tested for weathering using ASTM D2244, in which the panels were placed in a Xenon Arc weatherometer. Each panel was removed and tested for gloss (using ASTM D533) from 250 h through 3500 h (146 days). The results are shown in Figure 3 and Figure 4. The gloss at 60° changes very little with any of the formulations. The waterborne coatings are all slightly higher gloss than the standard. The solventborne standard coating drops from 89 to 85. All waterborne systems start between 90 and 93 and finish between 89 and 92. The gloss at 20° shows the same trend with slightly lower gloss values. Again all waterborne coatings are slightly higher than the standard solventborne coating, indicating that the waterborne polyurethanes weather as well as the standard solventborne polyurethane tested.

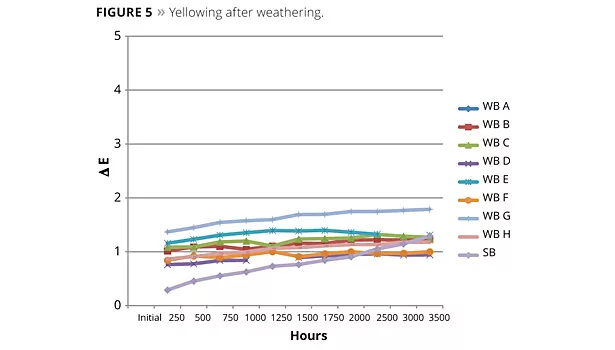

Each time the panels were removed for gloss testing they were also tested for yellowing using method SAE J2527 C2; results are shown in Figure 5. The change in color (ΔE) of the standard solventborne polyurethane is more than 1 by the end of the study, and rates about average for all the waterborne coatings. This shows that the waterborne polyurethane coatings are as light stable as solventborne polyurethane coatings.

Florida weathering trials involving all coatings in the larger study are underway. The results are too preliminary to report on, but will be the subject of a future paper.

Conclusions

This study has shown that low-VOC waterborne polyurethane paints can be formulated that are the equal of soventborne polyurethane paints when used on metal. These coatings are two-component waterborne polyurethanes consisting of a waterborne polyacrylate with a water-dispersible polyisocyanate. The waterborne polyurethane coatings show results equal to, or better than, standard solventborne polyurethane coatings in hardness, impact resistance and solvent resistance. In addition, these waterborne polyurethane coatings show accelerated weathering results that are the equal of standard solventborne polyurethane coatings. Waterborne polyurethane coatings WB C and WB H exhibit the best combination of properties and can be used to replace the standard solventborne polyurethane tested.

This article was presented at The Waterborne Symposium, Feb. 24-28, 2014, New Orleans, LA.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!