UV LED Curing

Delivering Dramatic Process Improvements

Manufacturing managers and process engineers need consistent, high-production processes that deliver quality products daily. In addition, leading manufacturers embrace lean manufacturing methods as they strive for continuous improvements to their production processes. Ultraviolet (UV) LED curing technology improves existing manufacturing processes.

UV Curing Basics

UV curing is a photochemical process that changes a liquid ink, coating or adhesive into a solid. Instead of using heat to drive off solvents or water, UV energy causes “drying” of the specially formulated photosensitive chemistry in just seconds. From its first use in the graphic arts printing industry over 40 years ago, a broad range of industrial manufacturers now use UV curing for a wide variety of processes such as wood coating, electronics assembly, medical device coating and assembly, automotive parts coating and marking, plastics decorating, and many more.

An efficient UV-curing process needs to match the output of the UV-curing lamps to the absorption characteristics of the UV chemistry. Typically, the formulator will recommend the energy density (mJ/cm2) and wavelengths (nm) needed for curing. Often, lab testing confirms chemical performance and UV lamp specifications. UV chemistries are available for nearly any application as single-component formulations that do not require mixing. Depending on the specific application, the UV formulator can adjust viscosities to meet the needs of the ink, coating or adhesive application method such as screen-printing, roller coating, spraying, or precision adhesive dispensing. Sometimes, if there are shadow areas where the UV energy cannot reach (UV curing is line-of-sight), a process can still gain many of the advantages of UV curing by using a dual-cure chemistry that combines UV and heat or moisture to cure.

Advantages of UV LEDs for Manufacturing

UV LED embraces many of the advantages of traditional UV curing for manufacturing processes. It offers advanced capabilities beyond traditional UV curing. First is low heat. UV LEDs do not generate any infrared output that is translated into heat. This is extremely important on manufacturing lines where the introduction of heat changes the chemical properties of the adhesive or coating. This heat can lead to material warping, lack of adhesion and eventually scrap. UV LEDs are a ‘cool’ light source; the only heat is due to UV energy being generated.

The second major improvement is process stability. Manufacturing companies need consistent, stable output. This is now possible with UV LED curing. Traditional UV bulbs degraded over time, which meant their UV output was not stable. Manufacturers dealt with this by over specifying the amount of energy needed, (which could lead to over-cured, brittle adhesives) or by implementing a maintenance schedule to remove bulbs as a precaution. With UV LED, both of these issues are removed, as they will provide stable UV output consistently over time, leading to better process control and stability.

UV LED Lamps

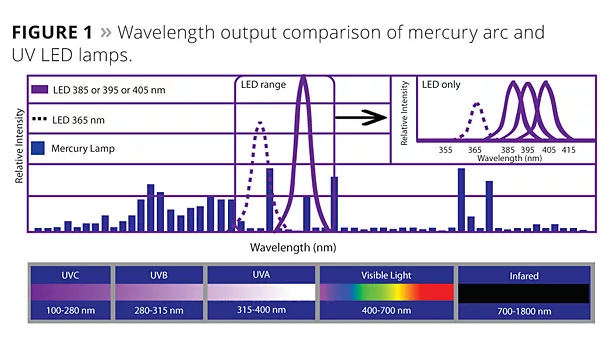

Commercially available for over 10 years, a UV LED generates UV energy by applying an electric current to a semiconductor device called a diode, causing it to emit UV energy. The specific materials in the diode determine the wavelength of the output, which is typically in a very narrow band +/- 10 nm. Figure 1 compares the output of various UV LED lamps with a typical mercury arc lamp. UV LED lamps are provided in single-wavelength configurations, typically centered on a specific wavelength +/- 5 nm.

Typically, an array of UV LEDs are packaged into a single unit or lamp head with a power supply to provide control. A UV LED unit can weigh as little as 0.4 lb (0.2 kg). Their size and weight generally increases with energy output or as the emitting window size increases. Suppliers typically specify the emitting window size and peak irradiance in W/cm2. When comparing UV LEDs, it is important to note whether the peak irradiance given was measured at the emitting window or at some distance away since peak irradiance decreases with distance from the emitting window.

LED Benefits

UV LEDs offer many advantages, including significantly longer lifetimes, consistent output, more energy efficiency, no ozone emissions, no mercury waste, much less heat onto the substrate, instant on/off, and a small-form factor ideal for incorporating into processes or machinery with little available space.

The total ownership cost of a UV LED system is significantly less due to less-frequent lamp replacements, less maintenance, better energy efficiency and small space requirements. Compared to an arc lamp’s 500- to 2,000-hour life, most UV LEDs have lifetime ratings of 10,000 hours, but can last over 20,000 hours. It is also important to note that over this lifetime, UV LED output only drops about 5%, as compared to arc lamps, which lose about 50% by the end of their life. The instant on/off capability of UV LEDs prevents damage to heat-sensitive substrates during production line stops, eliminating the need for mechanical shutters, which often require additional maintenance and costly downtime. UV LEDs are the most efficient UV-curing technology, saving between 50 and 75% over mercury arc lamps. A UV LED lamp converts electrical energy more efficiently into wavelengths useful to the curing process and wastes no energy as infrared, as is the case with both mercury arc and electrodeless lamps.

UV LEDs are a safe and environmentally friendly technology. Because UV LEDs emit UV energy in the UVA range, the lamps do not generate any ozone that needs to be exhausted from the work area. In addition, there is no mercury in a UV LED lamp, so there are no concerns about mercury spills in the work place or hazardous disposal requirements.

In a production environment, UV LEDs require significantly less space, monitoring, maintenance and down time, which translates into less scrap, higher productivity rates and higher-quality products at lower costs. Paybacks for retrofitting onto existing machines or replacing existing UV arc lamps can be as low as 12 months.

Phoseon Technology now offers the FirePower™ lamp rated at 20 W/cm2 primarily for flexographic printing and wood coating applications requiring high-intensity UV energy. In general, the higher the UV LED lamp output the more cooling required, so they use water cooling to maintain the integrity of the diode. A separate chiller provides cooled water to the UV LED units. Lower-output units, such as the 12 W/cm2 FireJet™ unit, use ambient air cooling (Figure 2).

Practical Considerations

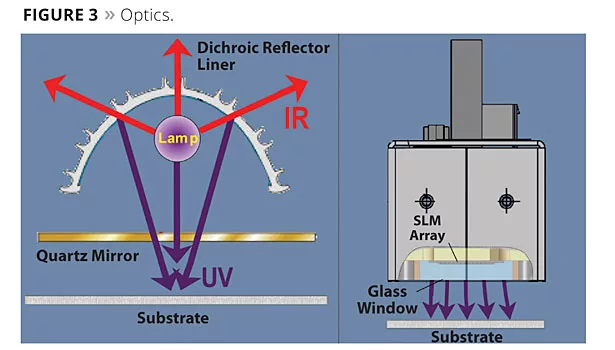

The working distances of UV LED lamps can range from 2 mm up to 50 mm, and the output is more like a flood pattern, as shown in Figure 3. Mercury arc or electrodeless lamps typically have a working distance of approximately 2 inches (50 mm) or further from the substrate, and use parabolic or elliptical reflectors behind the bulb to either collimate or focus the energy onto the substrate.

For some applications, such as three-dimensional parts, a larger working distance is desirable, and machine builders and others are finding ways to compensate for the loss in irradiance by using advanced optics. Some UV LED lamps use advanced optics to deliver consistent high-peak irradiance UV energy over a specific area, larger or smaller. For example, light guides concentrate the UV LED output into a very small area. The FireEdge™ UV LED lamp has specialty optics for use in edge-curing/banding applications while directing the exhaust air away from the substrate surface (Figure 4).

To cure larger parts, the unique scaling feature enables joining UV LED units ‘end to end’ to provide contiguous, uniform UV output (Figure 5). For example, both the FireJet and FireEdge UV LEDs are scalable. The UV LED lamps utilize power supplies that easily integrate with manufacturing line process controls. Since UV LED power supplies are solid state, they easily adapt for a given line voltage (100 to 240 volt AC) and frequency (50 or 60 Hz). For added flexibility and energy savings it is possible to turn off individual UV LEDs in multiple unit installations. For example, turning off one or more UV LED units when processing narrower products across a wide wood coating line saves energy without compromising production rates or quality.

Commercial Applications

Some of the earliest UV LED commercial applications were small-area adhesive and bonding applications such as medical device assembly, low-end thermal inkjet printing applications (including marking, coding and variable printing), and field repair of fiberglass composites. These early applications took advantage of UV LEDs’ form factor (lightweight and small), through cure capabilities, and increased safety inherent with longer wavelengths. UV-curing applications previously thought impossible are now possible due to UV LEDs’ small size, light weight and cool curing capabilities. For example, UV LED curing now dominates wide-format inkjet printing; the UV LED lamp is ideal for this application because it easily fits into a small carriage that quickly moves the lightweight lamp from side-to-side across the width of the printer to cure the inks. This “moving head” application was simply not possible with mercury arc and electrodeless lamps because of their heavy weight, cooling mechanisms and large size. Today, as the energy density has increased and costs have decreased (especially for 395 nm output), UV LED is commercial in the graphic arts, wood coatings, electronics, composites, textiles, glass, plastics, household products, pharmaceutical and other markets.

Conclusion

UV LED curing offers many advantages for improving manufacturing processes and product quality. Manufacturing managers and process engineers should evaluate UV curing as a way to reduce floor space, energy costs and environmental emissions while increasing production rates. UV-curing formulators and lamp manufacturers often work with manufacturers to specify the chemistry and lamps for their specific process. Manufacturers should consider UV LED lamps to take advantage of the additional benefits they offer such as no ozone or mercury, small-form factor, reduced maintenance, and consistent and reliable operation for a stable process. UV LEDs offer manufacturers the lowest total cost of ownership compared to other UV lamp technologies. As shown, many formulators and machine builders are actively involved in developing applications using UV LED curing, and many manufacturers are already reaping the benefits.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!