Premium Metallic Effects

for Architectural Powder Coatings

In many ways, architectural design is comparable to crafting a fine piece of artwork. The goal is generally to produce a unique building or structure with enduring beauty. Color allows architects to truly make their designs stand out. Much like fine art, the beauty produced by architectural design needs to be timeless. Architects generally produce permanent structures, and thus require decorative finishes with long-term durability. This article highlights the aesthetic and functional properties of a new range of aluminum pigments designed specifically for architectural powder coatings.

Introduction

Aluminum flake pigments are particularly suited for architectural applications. First and foremost, they produce stunning silver finishes that invoke a sense of quality and sophistication. Typical applications include facade profiles and window frames. Besides straight silvers, aluminum pigments also work very well in tinted color shades. In most cases, architects prefer more subtle shades rather than highly chromatic colors. Aluminum pigments can add sophistication to neutral tones commonly used in architecture.

In terms of functional properties, aluminum pigments provide excellent hiding at low pigment concentrations and are inherently stable in terms of weather fastness. One key issue with standard aluminum powders is chemical resistance. Architectural powder coatings are generally applied in a single coat, and therefore require the highest level of chemical stability. Given that there is no protective topcoat, the surface of the coating is constantly exposed to external stimuli such as high- or low-pH conditions, human interactions (finger touch) or cleaning agents. Under these conditions, untreated aluminum flake will corrode, leading to visible or dark marks, discoloration or loss of gloss.

Single-coat applications require the use of encapsulated aluminum pigments to achieve the necessary level of chemical resistance. By encapsulating the flake, the aluminum is essentially protected from the surrounding environment. Most aluminum products for exterior powder coatings are based on either silica or polymer encapsulation. These encapsulation technologies can be used separately or in combination. The key is to protect the pigment without detracting from the optical properties of the base aluminum flake.

The benefit of silica encapsulation is that it protects the flake with a transparent layer that has minimal impact on optical properties. Standard silica-encapsulated grades available commercially are fine for most exterior applications but are unable to meet the stringent requirements of single-coat architectural powder coatings set forth by Qualicoat or AAMA.

Polymer encapsulation can improve chemical resistance but tends to negatively impact metallic brilliance, even at relatively low levels. To improve the performance of standard silica-encapsulated grades, some manufacturers offer hybrid silica-polymer-coated aluminum flakes. These advanced deposition technologies improve chemical resistance, however, the polymer layer can still detract from the optical properties, and the multiple deposition steps add significant manufacturing cost.

Chemical-Resistant Technology

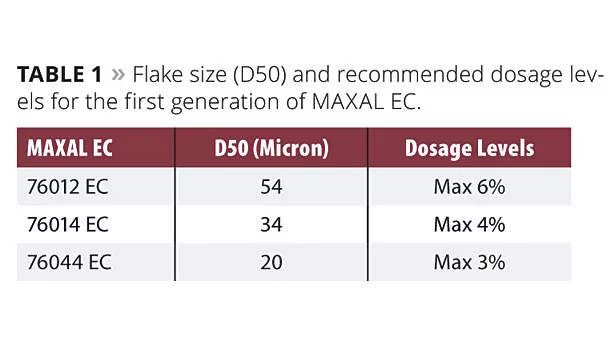

Benda-Lutz® MAXAL EC technology provides chemical resistance in a single encapsulation step. These products give outstanding metallic brilliance and sparkle while achieving a level of durability that far surpasses Qualicoat and AAMA requirements for architectural powder coatings. The flake size (D50) and recommended dosage levels for the first-generation MAXAL EC products are shown in Table 1. In general, metallic brilliance and sparkle increase when particle size and opacity decrease.1

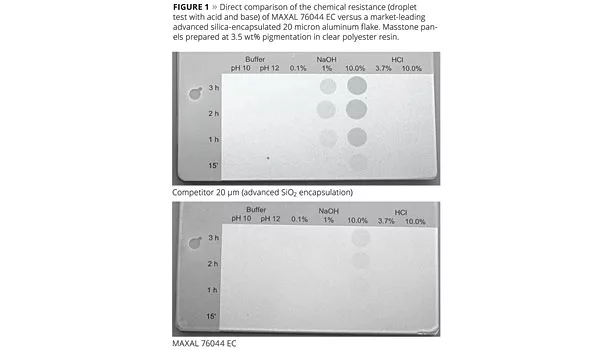

Figure 1 illustrates the chemical resistance of MAXAL 76044 EC versus a market-leading, advanced silica-encapsulated 20-micron aluminum flake. In this test, masstone panels were prepared at 3 wt% pigment loading in a clear polyester resin. Each panel was exposed to droplets having various levels of acidity and alkalinity for 15 min, 1 h, 2 h and 3 h. After the time interval, the droplet was removed and compared to the unexposed regions. As shown, both products performed equally well when exposed to HCl. However, under alkaline conditions, the chemical resistance of MAXAL 76044 EC far exceeds the competition.

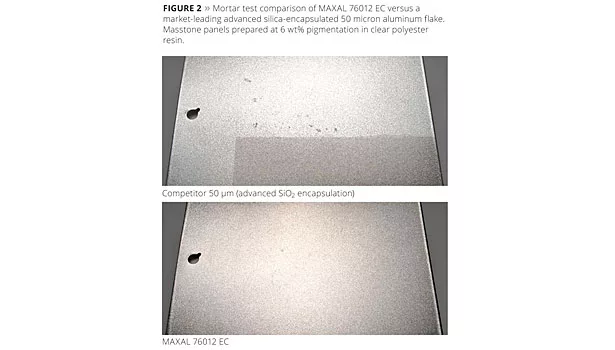

Figure 2 displays the performance of MAXAL 76012 EC versus a competitive advanced silica-encapsulated 55-micron aluminum flake. This test is used to measure the resistance of aluminum pigments used in powder coatings against mortar. It is an internal test based on AAMA 2605-05 and Qualicoat specifications. The mortar for the test represents type N according to ASTM C207. The powder-coated Q-panel samples were exposed to the prepared mortar for 24 h at 40 °C and 100% relative humidity. Afterwards, the panels were rinsed with dilute acid and evaluated against the unexposed region of the panel. As shown in Figure 2, MAXAL 76012 EC demonstrates outstanding stability in the mortar test. The competitor grade showed a marked discoloration in the exposed region.

Figures 1 and 2 also show the general appearance of the MAXAL EC range in straight silver formulations. As shown in Figure 1, the finer grade has significantly better hiding at lower dosage. This pigment is commonly used to produce architectural powder coatings with an anodized silver appearance. In contrast, MAXAL 76012 EC is characterized by a pronounced metallic sparkle effect with a significant reduction in hiding;76014 EC has a particle size (D50 = 34 micron) in between these two grades. Therefore, it provides intermediate sparkle with more hiding than 76012 EC.

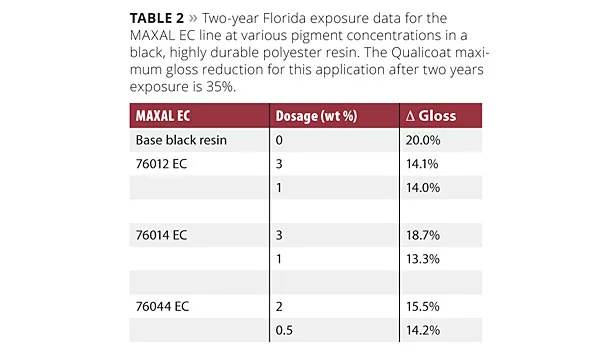

Results of two-year Florida exposure tests for the complete product range are given in Table 2. Powder-coated panels were prepared at various loadings in a customer-supplied, black, highly durable polyester base resin. The Qualicoat maximum gloss reduction for this application after two years Florida exposure is 35%. As shown in Table 2, all MAXAL EC grades greatly exceed the specifications set forth by Qualicoat. In all cases, panels containing these pigments exhibited less gloss reduction than the base resin control.

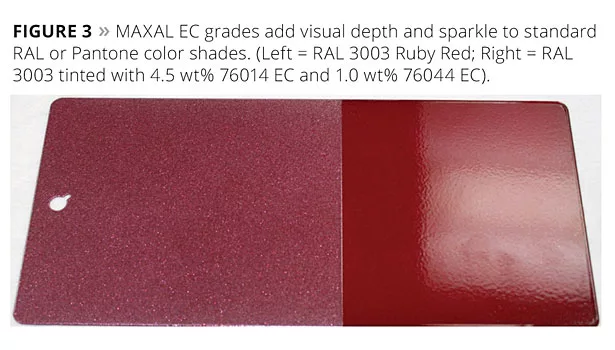

In addition to silver, the pigments can be used in a variety of chromatic shades. Figure 3 shows the impact of these non-leafing aluminum flakes in a high-gloss red (RAL 3003 Ruby Red base). The appearance of the base resin is shown on the right of the panel. In this example, 4.5 wt% of MAXAL 76014 EC and 1.0 wt% of 76044 EC transform this opaque solid red coating into a sophisticated shade with unique sparkle and depth.

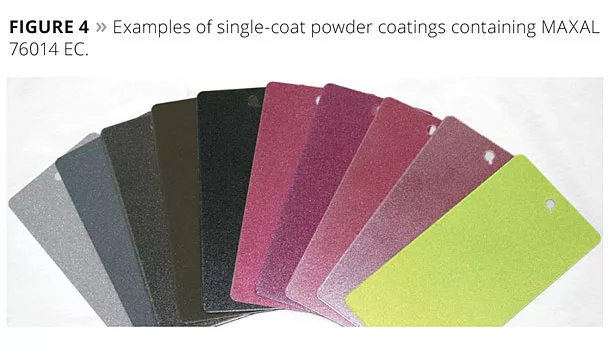

As shown in Figure 4, adjusting the base resin color (RAL or Pantone color shades) can be used to generate a wide variety of sophisticated colors and effects.

Figure 5 shows a variety of color shades that can be produced using MAXAL 76012 EC by varying the color of the base resin. As shown, 76012 EC adds a unique, sparkling metallic effect and is particularly suited for polychromatic shades. While 76012 EC is used to impart sparkle, 76044 EC is generally used to give a more continuous metallic look.

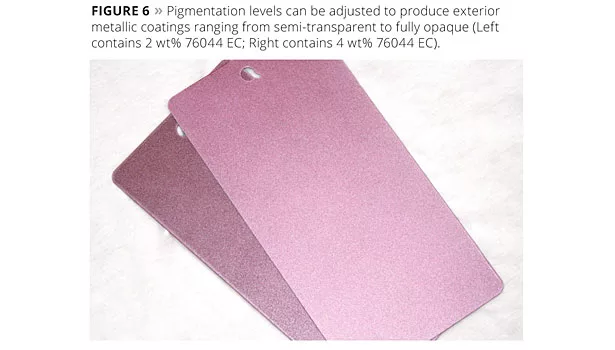

Figure 6 shows the impact of pigment loading for 76044 EC in a magenta base resin. At higher loading, the opacity of 76044 EC transitions the base magenta color from a darker metallic tone (shown at 2 wt% loading) to a bright silver with magenta undertone (at 4 wt%).

Conclusion

Benda-Lutz MAXAL EC technology provides metallic effects with outstanding optical properties and industry-leading chemical resistance for architectural powder coatings. These unique pigments will give architects unlimited styling potential combined with unsurpassed performance properties. n

References:

1 Hollman, A.M. Decorative and Functional Metallic Effect Pigments, PPCJ2012, 203(4583) 27.

For more information, email aaron.hollman@sunchemical.com.

Note: All images courtesy of Heidi Leonard, Sun Chemical.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!