Resource-Efficient Corrosion Protection

a Life Cycle Assessment of a Silicone-Epoxy Hybrid Resin-Based Coating

The term resource efficiency is used widely in the coatings market. The aim is to offer customers the products they need in order to produce resource-efficient paints and coatings. The term resource efficiency here characterizes the bundling of the environmental and economic pillars of sustainability.1

More than any other sector, the corrosion protection market is showing the impact that the use of perfectly tailored pigments and binder systems can have on the function of the coating as a whole, and also on the protection/durability of valuable objects.

Silicone-Epoxy Hybrid Resin for Corrosion Protection

Silicone-epoxy hybrid resins, such as SILIKOPON® EF, can be used in corrosion protection applications.2 In these applications, the coating must meet different requirements to fulfill the needed corrosion resistance. The coating must protect the underlying steel by adhering well, while simultaneously preventing harmful substances from coming into contact with the substrate. The coating itself must be weather resistant. This means it must not only be resistant to rain, snow and ice, but it must also be resistant to the high-energy UV component of sunlight. Additional active protection of the steel (with a zinc primer, for example), however, cannot be avoided.

Conventional coating systems for heavy corrosion protection are based on a three-layer application system built to reach the aforementioned requirements, specified in ISO 12944 (C5 I/M, high protection). The market standard is based on an epoxy zinc-rich primer, an epoxy intermediate layer and a polyurethane (PU) topcoat.3

Silicone-epoxy hybrid resins can be used as solvent-free, ultrahigh-solids binders for resource conservation in many different industrial topcoat applications. This technology allows formulation of coating systems with significantly less than 250 g/L (sometimes even less than 100 g/L) VOC as well as permitting isocyanate-free crosslinking.3

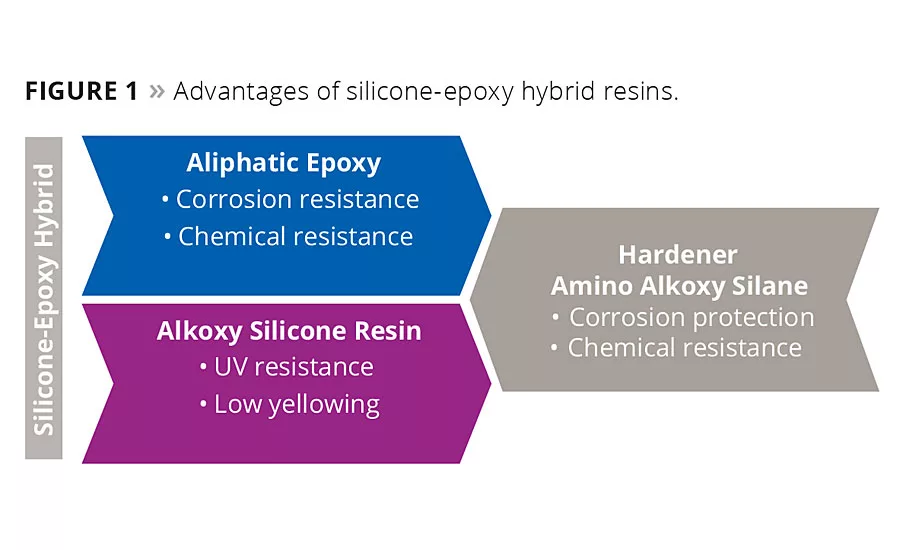

The silicone-epoxy hybrid resin technology combines the positive effects of an aliphatic epoxy resin, like corrosion protection and chemical resistance, with the UV resistance and low yellowing characteristics of an alkoxy silicone resin. Together with an amino alkoxy silane hardener, the abilities of the intermediate epoxy layer and the PU topcoat can be combined. The advantages of silicone-epoxy hybrid resins are depicted in Figure 1.

Thus, new two-layer corrosion protection systems with lower film thicknesses and the same corrosion protection abilities can be achieved. By reducing the film thickness, less coating material is required. This leads to the assumption that the two-layer systems are more resource efficient than the market-standard three-layer systems. To prove that silicone-epoxy hybrid resins support resource-efficient coating systems, the entire life cycle of a coating based on a silicone-epoxy hybrid resin was analyzed in an ISO-certified life cycle assessment.

Concept of the Life Cycle Assessment

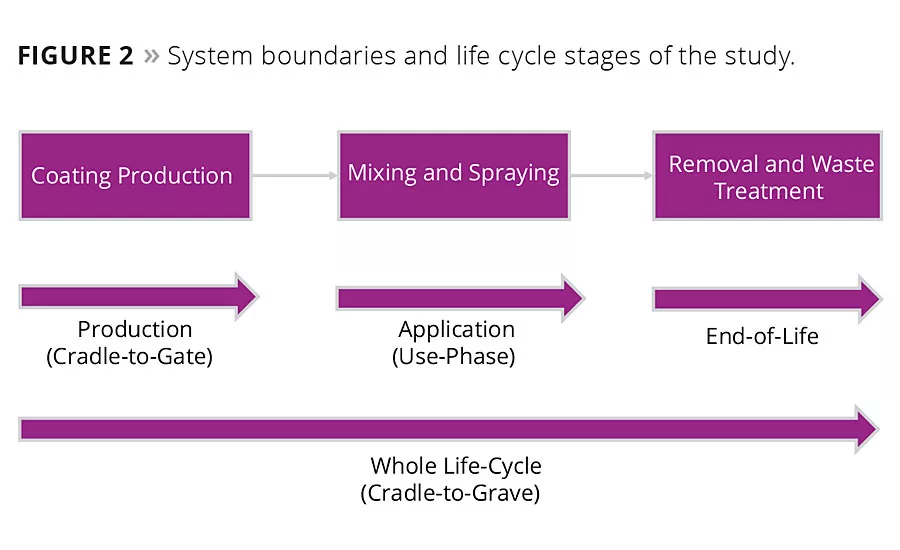

A life cycle assessment (LCA) is an evaluation of inputs, outputs and the potential environmental impacts of a product system throughout its life cycle. The life cycle depends on the boundaries of the study. A cradle-to-gate LCA investigates all environmental impacts, from feedstock through production until a product leaves the “gate” of a manufacturing site. The system boundary of a cradle-to-gate LCA defines which “gate” of multiple steps within a supply chain is meant. The cradle-to-grave approach, however, additionally investigates the application (use-phase) and the end-of-life of a product so that it covers the entire life cycle, from raw material acquisition or generation, to natural resources to final disposal.

The LCA study of the silicone-epoxy hybrid resin was conducted in accordance with ISO 14040 and 14044 and approved by an external review panel. It investigates the environmental impacts of corrosion protection coatings over their whole life cycle, from the raw material production through coating formulation and production, as well as their application and the end of life (cradle-to-grave). The system boundaries are displayed in Figure 2. The results are analyzed in a stepwise approach. First, the preliminary cradle-to-gate results of each coating layer are discussed. Then, application and end of life are added to get the final results over the entire life cycle (cradle-to-grave).

The study gives a comprehensive overview on the environmental impacts of the different coating systems. Nonetheless, special attention is drawn on the global warming potential (GWP, also known as carbon footprint), primary energy demand (PED) and photochemical ozone creation potential (POCP). The POCP (also known as summer smog) describes the change of the ozone concentration near ground level. VOC emissions from the drying process of coatings have a major impact on the POCP; hence, this impact category is of special interest in this application. GWP and PED are the most common impact categories, and therefore, they will generate a good understanding of the overall results. Other categories are not as closely analyzed even though qualitative and quantitative results are also given in the study.

The environmental performance of two different coating systems were compared.

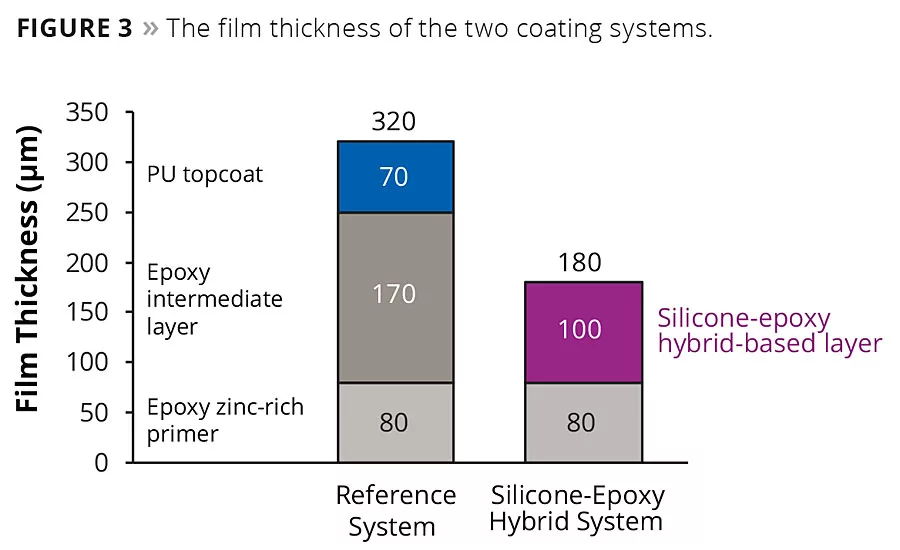

Reference System

The reference system had three different layers and represents the market standard for a heavy-duty corrosion protection coating. Each layer was applied in a different thickness. The nominal dry film thickness (NDFT) of epoxy zinc-rich primer is 80 µm, which is the same in both coating systems. The intermediate layer of this reference system was an epoxy-based layer with the average coating thickness of 170 µm. The two-pack PU topcoat of this system was based on a hydroxy functional acrylic resin with a film thickness of 70 µm.4

The international standard ISO 12944 (C5-I/M, high protection) describes not only the tests that need to be fulfilled to reach a certain level of corrosion protection, but it prescribes the film thickness that is mandatory to achieve a desired durability class at chosen corrosion category. The reference system, which was chosen here, fulfills all the specifications concerning the total NDFT according to ISO 12944 (C5-I/M, high protection).4

Silicone-Epoxy Hybrid System

The second system was a two-layer system with an epoxy zinc-rich primer and a topcoat that was based on the silicone-epoxy hybrid resin. The silicone-epoxy hybrid resin-based topcoat was applied with a nominal dry thickness of 100 µm. Polysiloxane-based paints are not included in ISO 12944 (C5-I/M, high protection), so no recommendations for NDFT are available. Therefore, the topcoat was applied as thinly as possible, while still achieving the same corrosion protection performance as the reference system. For the topcoat of the silicone-epoxy hybrid system, the formulation from the article “Silicone-Epoxy Hybrid Binders – a Strong Network Against Rust” was used.3

Figure 3 compares the film thickness of the two systems. The film thickness is always the NDFT.

Testing

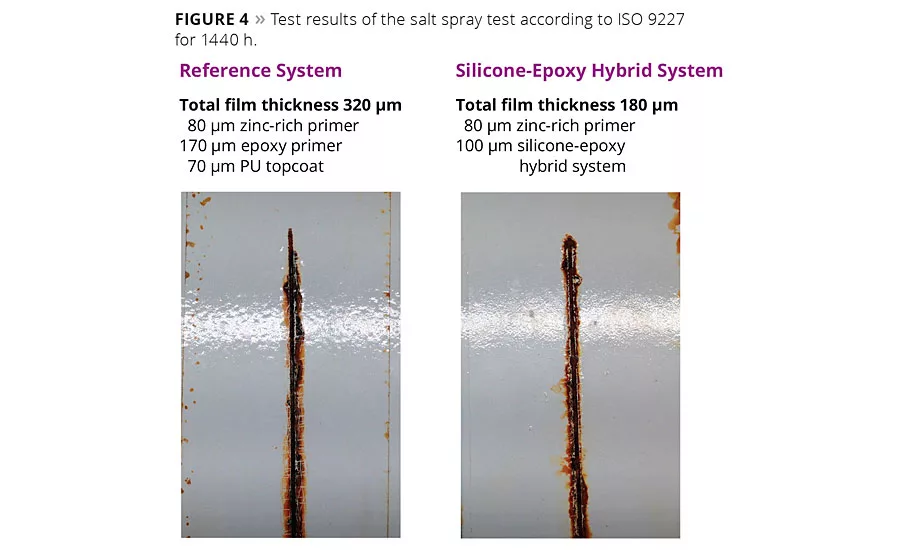

Both systems were tested according to ISO 12944 (C5-I /M, high protection). This includes exposure to chemicals in accordance with ISO 2812-1 for 168 h, determination of resistance to humidity (continuous condensation) according to ISO 6270 for 720 h, and determination of resistance to neutral salt spray (fog) according to ISO 9227 for 1440 h. The results of the salt spray test are shown in Figure 4.

Both coating systems performed comparably in the aforementioned test methods, although they differ significantly in film thickness. Hence, these tests prove that corrosion protection performance of both systems is similar. This is the basis for the comparison of the environmental impacts in the life cycle assessment of the two coating systems.5

Results of the Life Cycle Assessment

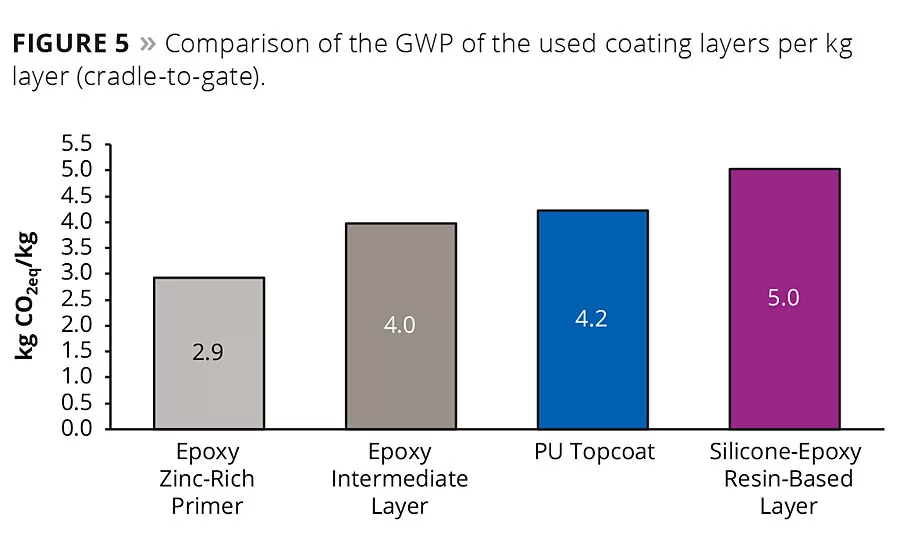

The cradle-to-gate results of each layer used for the two systems are shown in Figure 5. It shows the GWP of the four different layers up to the point where the coatings leave the site of the coating manufacturer (cradle-to-gate). The silicone-epoxy hybrid resin shows the highest carbon dioxide emissions per kg liquid coating formulation, which is mainly because of the complex production process and its silicone-based nature. The carbon dioxide emissions per kg layer, however, were just the results of a cradle-to-gate system boundary.

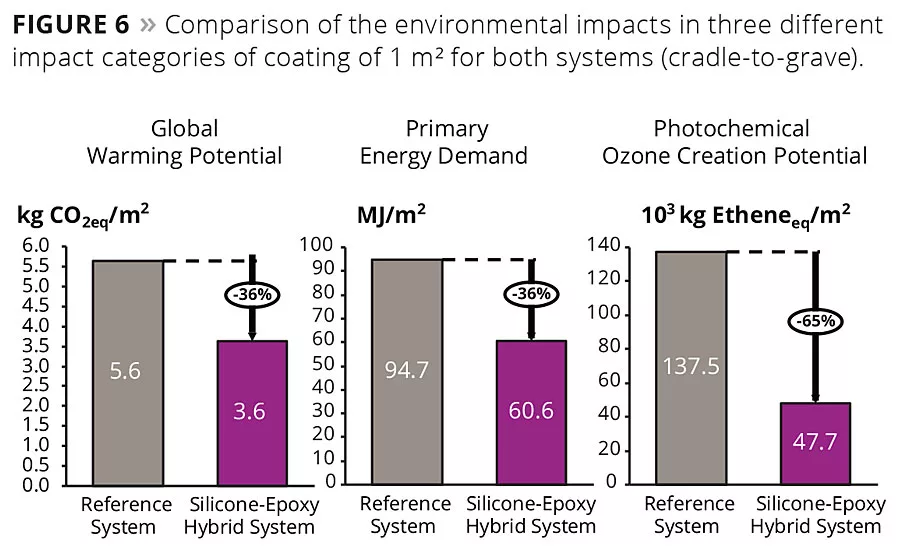

More significant results can be achieved with a system boundary over the entire life cycle. In a life cycle assessment with a cradle-to grave approach, the application phase and the end of life have to be considered as well. Also, the functional unit that is investigated is not the kg of the layer but the coating of 1 m2 of coated metal substrate. The environmental impact on the GWP of the two compared coating systems is shown in Figure 6. It shows that the CO2 emissions of the silicone-epoxy hybrid-based coating system were up to 36% lower than the market standard system. Figure 6 shows that the silicone-epoxy hybrid resin-based coating can also reduce the PED by up to 36%. A closer look at the two impact categories shows that the majority of the emissions were raw material related. Disposal of the systems is responsible for 25% of the CO2 emissions and is a function of the amount of coating that must be removed and disposed. These results prove that a reduction of film thickness reduces the environmental impact of this coating system over the entire life cycle.

The third impact category that was analyzed in detail is the POCP. It represents the VOC emissions of a coating system. Figure 6 illustrates that POCP can be reduced by 65% within the thin silicone-epoxy hybrid resin system. Almost all emissions are created in the application phase in which the coating is applied, dries and the solvent leaves the coating film.5

The life cycle assessment covers the environmental differences between the chosen systems. A coating system with just two layers provides several additional advantages over the conventional three-layer systems, which are not covered quantitatively with the LCA results. Some examples are shorter curing times, less application time and fewer raw materials to purchase, store and carry for the professional painters.

Conclusion

There is an increasing trend towards ecologically responsible business practices. Our results show that it is possible to achieve the same corrosion protection performance as the current market-standard systems with just two layers and a much lower overall film thickness with a topcoat that is based on a silicone-epoxy hybrid resin. The silicone-epoxy hybrid resin helps reduce emissions from cradle-to-grave, although they have higher cradle-to-gate emissions. The GWP and PED decreased by 36%, while the VOC emissions dropped by 65%.

References

1 Evonik Industries AG, The Big TEGO, 2013, 14-17.

2 www.tego.de, Technical data sheet TEGO “SILIKOPON® EF”.

3 Hinzmann, D.; Klotzbach, T.; Herrwerth, S. Silicone-Epoxy Hybrid Binders – a Strong Network Against Rust, PAINTINDIA; 62, 11; 83-91.

4 International Organization for Standardization, (1998). Paints and varnishes - Corrosion protection of steel structures by protective paint, ISO 12944. Berlin: Beuth.

5 Florian Böss, Björn Bröskamp, Comparative Study - Life Cycle Assessment of Corrosion Protection Coating Systems, July 2014.

For more information, contact Kirstin Schulz at kirstin.schulz@evonik.com.

By Björn Bröskamp, Florian Böss, Sascha Herrwerth and Christiane Cova-Hög, Evonik Resource Efficiency GmbH, Essen, Germany

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!