Baker Perkins Exhibiting Powder Coating Extrusion Technology

The MPX24 Integra pilot-scale machine is on display at Baker Perkins’ Stand 6-418. Also highlighted are the new MPX19 laboratory scale extruder; the range of twin-screw MPX production extruders and details of a new Innovation Centre.

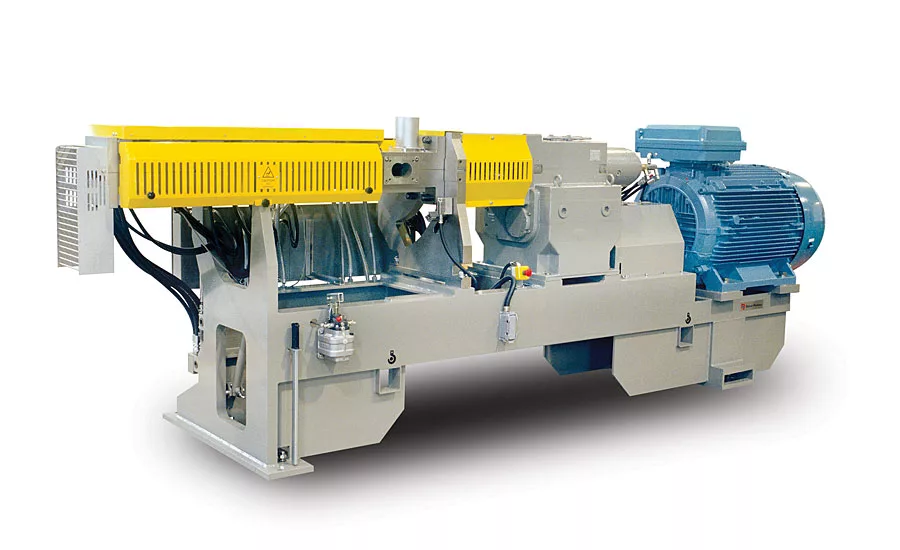

MPX24 Integra Pilot-Scale Machine

Feeding, twin-screw extruding, cooling and flaking operations are integrated in the MPX24 Integra. This flexible machine meets the demand for a rapid-response system capable of fulfilling batch production needs with simple, rapid product changeover. It is also used for color matching, and new product development in the laboratory.

The unit can be re-configured, without the need for tools, to enable production of color matching samples that can be consistently reproduced, first time, on high-output production machines.

Color matching is facilitated by bypassing the belt cassette, which disables the flaking unit and permits safe running of the product through the cooling rolls. This eliminates the need for cleaning of the belt and flaking unit between samples.

Start and shutdown sequencing cuts waste at the beginning and end of each run: production does not start until the machine has warmed up, and the extruder does not shut down until product is completely ejected from the barrel.

Data trending/logging and network connection for data acquisition support improve short- and long-term efficiency and improvement programs.

Production-Scale MPX Extruders Upgraded

Baker Perkins’ MPX production extruders provide continuous production at outputs from 100 to 2,900kg/hour. These systems are specifically designed for all types of powder coating formulations, including epoxy, hybrids, polyester, acrylics and fines recycling.

A gearbox condition monitoring system that reduces unexpected downtime is available on all new MPX extruders and can also be fitted to existing machines. This simple system continuously monitors the frequency and amplitude of vibrations within the gearbox, allowing the ongoing condition of vital components to be measured. The principal benefit is elimination of unforeseen loss of production due to gearbox repair or replacement: maintenance scheduling is significantly enhanced.

A new control system developed for the complete range of MPX extruders is a recent innovation. The operator interface is a touch-screen HMI providing clear, at-a-glance visualization of the process, including current status of all major components and parameters. Alarm management means that the operator can immediately identify and locate problems. Automatic management of recipe settings ensures exact, unvarying replication of product, eliminating quality variations caused by operator error.

A high-intake feed port and modified screw profiles contribute to greater throughput. The feed port area has been opened up so material can enter the extruder quickly and evenly with no risk of backing up creating torque spikes. Screw profiles have been re-designed to increase intake rates, particularly of low density materials.

A water-cooled motor, quieter and cleaner than the air cooled alternative, is an option.

New Benchtop MPX19 Laboratory Extruder

A significant improvement in the extent and accuracy of information achieved in laboratory and development work is offered by Baker Perkins’ new MPX19 benchtop twin-screw extruder. It incorporates features that ensure full, reliable scale-up from batch to continuous output on the company’s range of production extruders.

A new control system – with identical functionality to production machines – includes a full formulation management system holding up to 50 formulations; historical trending of data, and connectivity to a PC or network to capture that data. Full automatic start up and shut down sequences mirror production extruders.

The MPX19 features the Baker Perkins clam-shell barrel so that the process can be stopped at any time with immediate access to view the state of material being processed. Adjusting the formulation, process settings and screw configurations are all straightforward. The screw configurations are identical in geometry to larger extruders, ensuring accuracy in scale up.

As well as ongoing development of existing extrusion processes, the MPX19 is an ideal tool for companies moving from batch to continuous processing that need to establish the processing parameters necessary to match their existing product.

New Innovation Centre for Customer Trials

Baker Perkins is opening a new Innovation Centre at Peterborough for customer trials. The Centre includes full powder coating production facilities, including an MPX24 Integra twin-screw extruder, plus grinding, spraying, curing and full analytical equipment to process results.

Powder coatings companies will be able to use the Innovation Centre to develop new products and processes using their own raw materials; produce samples; and conduct feasibility trials.

Customers are guaranteed total confidentiality, working with or without the help of Baker Perkins' experienced technologists. Companies from every part of the world will find that thorough trials provide a reliable basis for trouble-free commissioning of a new plant or launch of a new line.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!