Color and Effect Pigments in Powder Coatings

Recently, Pantone® revealed its Fashion Color Report Spring 2018 edition. The report identifies the 10 most popular color trends to expect in 2018. Pantone and many other color forecasters derive their list after extensive analysis of color usage on the runways of New York’s Fashion Week, home furnishings, automotive and a range of other global designer shows.

According to Leatrice Eisman, executive director of the Pantone Color Institute, Pantone’s spring color palette consists of “spring shades that show where hues are headed” and “reflects consumers’ ongoing fascination with color.” Pantone describes in detail the emotions conveyed by each color in the report. The descriptions can seem abstract and intangible without some understanding of color psychology.

The ability of color to produce a psychological impact has been confirmed through many studies, including Satyendra Singh’s 2006 study on the “Impact of Color on Marketing.” While individual reactions to a color may differ, the predominant effect that certain colors elicit is well understood. This article will focus on color psychology and how the use of effect pigments can enhance viewer perceptions of the Pantone hues in powder coating.

The Power of Effect Pigments

Color psychology is widely used in marketing to entice potential buyers and to inspire brand confidence. Consumer studies indicate visual appearance and color are determining factors for more than 85% of product purchases according to data from Secretariat of the Seoul International Color Expo 2004.

To generate the greatest customer interest, a color must be both appealing and appropriate for the product. An example of color-appropriate paint usage is in automotive paints. White and black effect-based colors have consistently ranked as the top colors for new car coatings globally.

Conversely, blue is far and away the world’s favorite hue, but only accounts for about seven percent of new automotive basecoats. The reason for the discrepancy is likely that white and black are deemed more color appropriate than blue for a car finish.

Blue communicates honesty, sincerity, tranquility and other similar positive qualities. To evoke the subconscious impression of style, fluid versatility, modern, elegant and technological advancement, both designers and consumers choose whites and blacks modified with effect pigments.

Despite 35% of Americans selecting blue as their favorite hue according to Kathy Lamancusa’s “Emotional Reactions to Color” study, effect-based black and white color’s associations appear to resonate more with buyers seeking similar attributes in their new car. The preference for effects in the white and black color space is even greater in the luxury car market according to Axalta’s 2015 Global Automotive Color Popularity Report.

Solid blacks account for 10% of luxury vehicles compared to 17% for effect-based blacks. For white the difference is even more dramatic, where solid white accounts for 4% and pearl white is 22%. Pearl whites are perceived as ‘up-scale’ and innovative, which correlates to its extensive use on devices from laptops to mobile phones.

In fairness to blue, new car buyers are overwhelmingly conservative, with a very limited palette deemed color appropriate. White, silver, black and grey are all currently more popular than any of the chromatic color offerings. A nonchromatic paint isn’t subject to color trends and is perceived to afford quicker vehicle resale down the road. Nonchromatic automotive basecoats are popular, but bland is not. The use of pearlescent and metallic effect pigments on vehicle coatings continues to grow. “Effect pigments are the fastest growing segment of the high-performance pigment market, and in 2015 were present in 70% and 65% of automotive colors for new builds in the Americas and Europe, respectively,” according to Jane Harrington, Manager of Color Styling with PPG Automotive OEM Coatings.

Pearlescent micas and aluminum pigments produce luster and brilliance to create a vibrant depth in both liquid and powder coatings. Pearlescent white micas add a soft, silky richness that creates a natural and soft impression in coatings. When used effectively, pearlescent micas in a variety of hues and particle size fractions can produce eye-catching results that draw attention without overwhelming a finish. Aluminum pigments can produce subtle shifts in brightness or dazzling brilliant sparkles depending upon the flake morphology and particle size. The reflective silver glow of aluminum pigments elicits a sense of timeless style.

The Importance of Color Harmony

Effect pigments can visually enhance the perception of almost any powder coating if used effectively. To attain the most desirable appearance with pearl micas and aluminums, color harmony and the psychological influence of color combinations should be considered. Color harmony is achieved when two or more compatible hues produce a balanced and pleasing visual experience. Harmony will not overstimulate nor underwhelm the viewer. Harmonious color combinations are agreeable or even captivating but never dull or chaotic.

Effect pigment selections to optimize color harmony should be made with consideration of the hue, value and chroma of the powder coating. Hue is defined by Merriam-Webster as “the attribute of colors that permits them to be classed as red, yellow, green, blue or an intermediate between any contiguous pair of these colors.” Hue is often commonly used interchangeably with the word ‘color.’ Hue is the proper word to use when referring to a specific pure color. Value is the quality of lightness or darkness of a color. Black has a low or dark value. White has a high or light value. Chroma is the intensity or saturation of a color. Fire engine red is a commonly cited example of high chroma while pink is low chroma and less intense.

There are multiple systematic approaches to achieve color harmony including developing complimentary, monochromatic and analogous colors. Effect pigments add a unique depth, richness and optical reflectance that that often transcends the traditional rules of powder coating color harmony.

Aluminum pigments can complement most any powder coating hue when used at the proper flake size and optimum percentage loading. From silky satin to glittering sparkle, pearlescent micas can often enhance the visual appeal of powder, even in traditionally rule-breaking combinations.

Before incorporating effect pigments, it is important to consider the end use of the powder coating. The effect pigment selection should correlate with the message of the powder coating color. For example, a coarse violet wouldn’t harmonize with a rugged brown lawnmower coating because it conveys spirituality and healing while the product message is different. The basic psychological message or theme of the powder coating hue should correlate or be enhanced by the effect pigment. Each hue can elicit a range of emotional responses. The powder coating and effect pigment should convey the same message.

Red is associated with power, passion and high energy. Red is aggressive and impulsive. Red is a great attention grabber and can stimulate impulse purchases. Red is a color of physical activity and danger.

Orange promotes a sensation of happiness, enthusiasm and determination. Orange invigorates and is a preferred color of young adults and kids. Yellow is enthusiastic and happy. The color of sunshine is energetic, spontaneous and attention grabbing. Too much yellow is disturbing and despite the common misuse, yellow does not promote safety.

Green is relaxed, peaceful and healthy. Green is natural and easy on the human eye. Blue is the natural color of both sky and sea. Blue is cool, calm, clean and intellectual. Light blue is healthy and tranquil. Dark blue is more serious and indicates power and integrity. Blue is the most universally beloved color. Purple represents royalty, luxury and mystery. Light purple is romantic while dark purple can feel gloomy.

White is light, pure and innocent. White is natural, fresh and the color of perfection. White is almost always perceived to create a positive impression. White pearlescent micas can amplify the positive appeal of a coating.

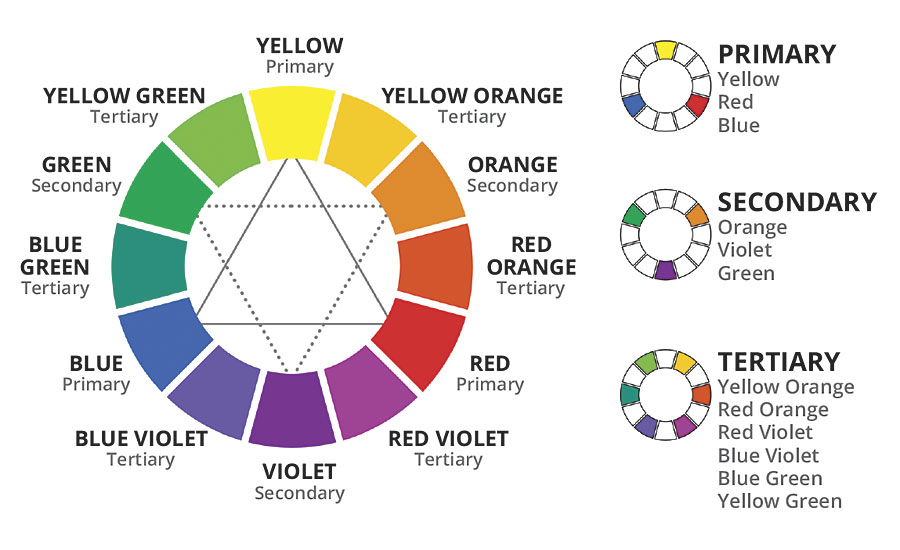

With these associations in mind, a brief overview of the color wheel is a good starting point for devising an effect pigmented powder coating color scheme. The basic color wheel shown in Figure 1 contains 12 hues chromatically arranged in a circle.

FIGURE 1 » A basic color wheel contains 12 hues chromatically arranged in a circle.

The primary colors are separated equidistant from each other, with corresponding secondary and tertiary colors filling the space between primaries on the wheel. Primary colors are pure and cannot be created by mixing others. A mixture of two primaries creates secondary colors. Primary and secondary hues are combined to form tertiary colors. Yellow-green and red-violet are examples of the two-hued tertiary colors.

Applying Color Harmony in Powder Coatings

In powder coatings, metallic pigments and pearlescent micas can be effectively combined with organic pigments using the color wheel to provide contrast or enhancement of the pigment hue used in the coating.

One common method of combining pigments is using a complementary color scheme. Complementary colors are those opposite to each other on the color wheel. Examples include red pearlescent mica and green organic or yellow mica and blue base color. This can be achieved because the effect flakes can be seen as discreet particles and flecks of color in powder paints. The opposing colors create a dramatic impact that can draw attention. This color scheme offers the greatest contrast, but effect pigmentation should generally be used sparingly to avoid an unbalanced, chaotic feel.

A monochromatic color scheme can be created by using variations in value and chroma from a single hue. This color scheme is easily incorporated and considered visually pleasing. Pearlescent micas are great accents for powder coatings in the same color family. The monochromatic color is low contrast but balanced and appealing to the eye. Examples include a white pearlescent over a white base or a blue interference mica pigment in a blue base. An analogous color scheme is similar to those found in nature.

Analogous colors are comprised of any three hues located side-by-side on the color wheel. The analogous color scheme is rich and harmonious without too much contrast. Autumn fall leaves are a prime example of analogous color schemes. Peacock and other bird colorations are other examples of analogous colors creating harmonious feelings.

These systematic approaches can be achieved because of the optical properties of effect pigments. Although there are many types of effect pigments, flake pigments typically will contribute more strongly to the face angle, the color seen close to specular reflection than at the flop angle, which is the color seen at the diffuse angles. Submicron particle size organic and inorganic pigments reflect equally at all angles but can be “overpowered” by the effect’s reflection color at the face. Because of the effect’s weaker contribution at the flop, the absorption pigment will be dominant at the down angles. This attribute, as shown in Figure 2, allows formulators to almost “independently” control face and flop color or create two or more visible colors in the same coating.

FIGURE 2 » Analogous automotive paint using effect pigment to independently control face and flop color.

Aluminum flakes create a “flash” of brightness at the face by strong reflection of all wavelengths of light (Figure 3). Pearlescent white flakes do the same but reflect only about 35% of the incident light, creating a softer, mother of pearl effect. Interference and absorption pearlescent pigment reflect bands of narrower wavelengths of specific colors.

FIGURE 3 » Aluminum flakes create a flash of brightness due to their strong reflection of all wavelengths at specular angles.

Further, flakes above about 35 microns can be seen by the naked eye and will create a textured or glittering effect. Since effects are available in a range of sizes and colors, the possible combinations of color and texture are endless.

Incorporating Effect Pigments to Align with 2018 Color Trends

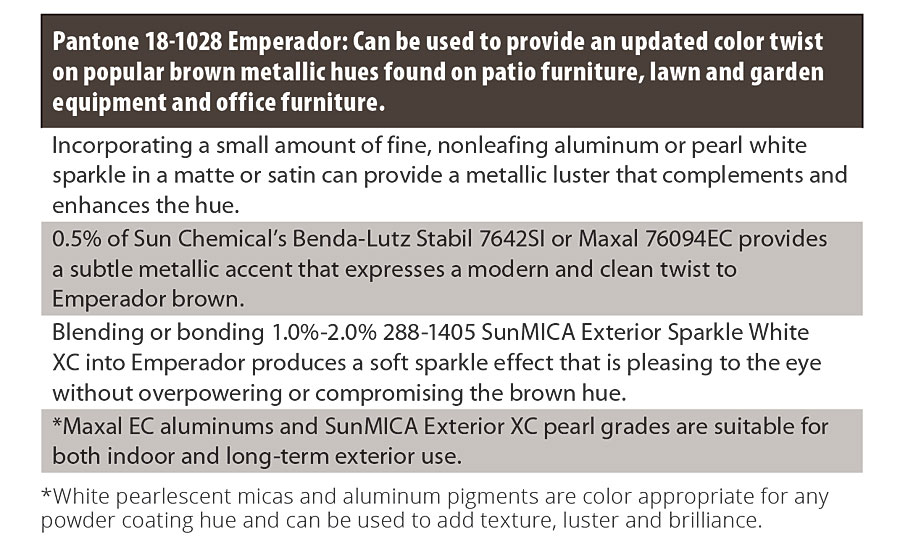

Figure 4 shows suggestions for adding metallic and pearlescent effects to work in synergy with a few of Pantone’s 10 most popular 2018 Spring Color Trends to create monochromatic, complementary or analogous color schemes.

FIGURE 4 » Suggestions for adding Sun Chemical metallic and pearlescent effects to work in synergy with one of Pantone’s 10 most popular 2018 Spring color trends.

The incorporation of metallic and pearlescent pigments is a proven method to generate interest and improve viewer perception of powder coatings. Effect pigments convey a message of premium product finish with the visual association conveyed to the coated parts or products.

Aluminum pigments and pearlescent micas create the illusion of spatial depth that differentiates the coating from noneffect pigmented offerings. Effect pigment selections are tailor made to create warmth, add energy, produce eye-catching impact or subtly draw positive attention. Effect pigments provide a simple solution to broaden the appeal and enhance the color message specific to the powder coating’s end use.

For more information, e-mail michael.venturini@sunchemical.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!