Choosing the Right Pasta for Your Powder Coating Dish

Hey PC cooking fans, it’s time to lace up your aprons and roll up your sleeves. Today’s powder coating cooking lesson revolves around fillers, aka, extender pigments. Much like pasta, these raw materials are the unsung heroes of a powder coating formula. Although relatively low in cost, your choice of pasta can make or break a tasty dish. Similarly your choice of filler is critical to a coating’s performance.

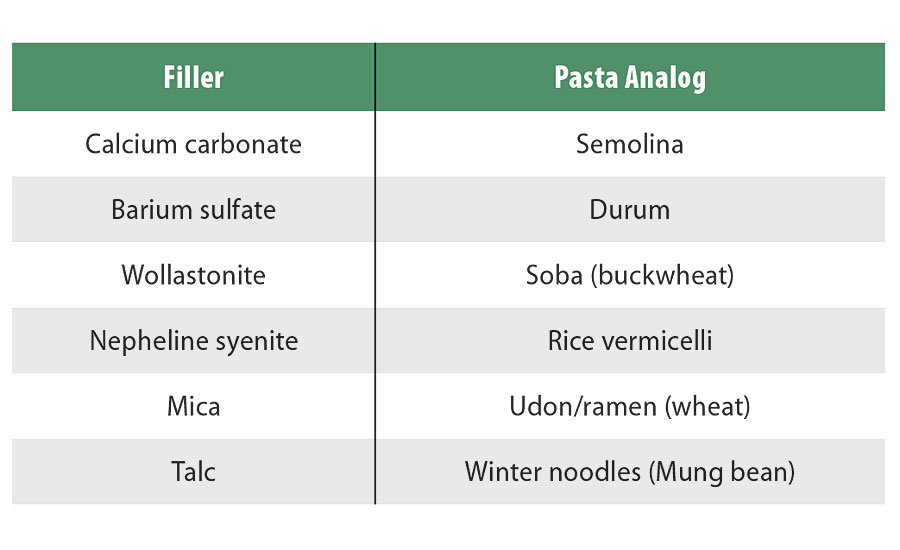

Fillers, just like pasta, are used to extend the formula or dish, establishing that fine balance between the performance of a coating and the overall cost of the formula. Important features such as type, shape and size of the noodles influence your choice of pasta. The same goes for fillers. Powder formulators have a wide range of fillers or extender types to choose from, based on their chemistry (Table 1). In addition, the size and particle shape of a filler greatly affects its performance.

Whereas pastas are based on milled grains combined with water and sometimes eggs, fillers are naturally occurring minerals or synthetic alkaline earth metal compounds. Powder coating formulators tend to gravitate toward soft, low-oil-absorption extenders like calcium carbonate and various grades of barium sulfate. Harder materials tend to erode the critical interior components of powder manufacturing equipment, especially the barrels and kneading blocks of an extruder. Hence, materials such as silicon carbide, silicon quartz and natural aluminum oxide are far less common in powder formulas.

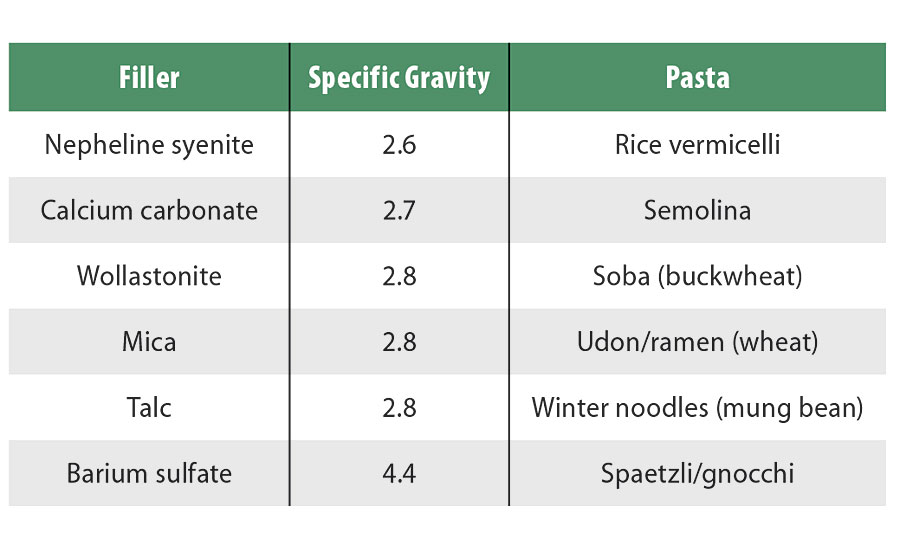

The spectrum of pasta ranges from the light rice noodles common in Asian cuisine to the dense, heavy pastas of Italy (gnocchi), Germany and Switzerland (spaetzli). Fillers also come in a range of densities, or more precisely, specific gravity (SG). SG is a very important property, as it not only affects coating performance but also mileage. Mileage can be described as the amount of a powder coating needed to cover a given surface area. In North America we speak in lbs. per square foot, and in other countries mileage is quoted in kgs. per square meter. Calcium carbonate extenders have a relatively low SG of 2.7, whereas barium sulfate variants possess an SG of about 4.4 (Table 2).

Just as the size of pasta influences the taste of a dish, so does the particle size of a filler. As a chef you may prefer a small size pasta such as couscous or orzo as the basis for your recipe. As a formulator you would choose small particle size fillers such as blanc fixe to maintain high gloss. The median particle size of blanc fixe hovers around 0.7 to 1.0 micron, making it an ideal choice for high-gloss coatings.

Most traditional noodles such as spaghetti, linguine and angel hair are midrange in size and account for the most popular selections for pasta dishes. Most common extenders have particle size ranges between 2.0 and 5.0 microns, and offer a very good balance of cost and performance.

Nano-size materials such as fumed silicas and fumed aluminas, although technically fillers, are typically used as dry-flow additives and are incorporated during the grinding phase of the powder-making process. These are reminiscent of tiny bead-shaped pasta, acini de pepe, found in the most discriminating kitchens.

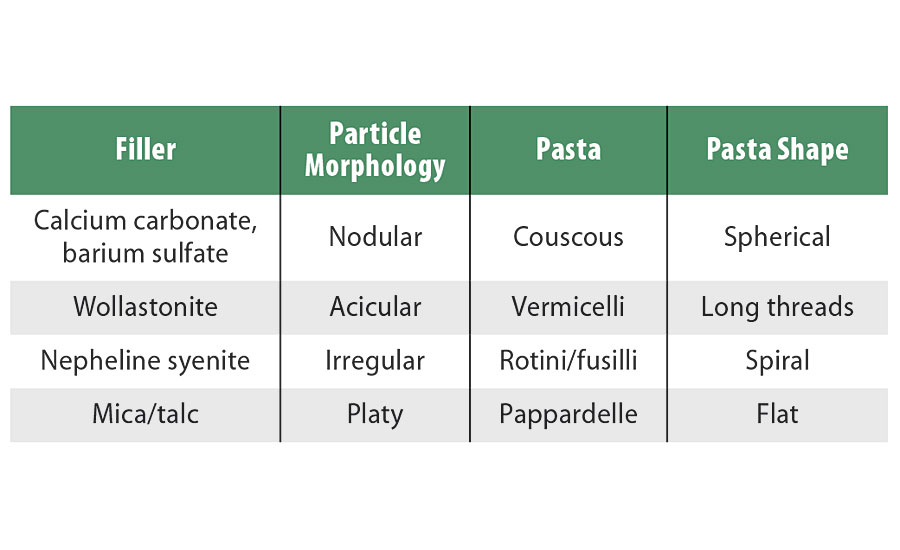

Pastas come in all sorts of shapes, which can affect the taste and texture of your dish. Similarly the particle shape or morphology of a filler affects its functionality and performance. Calcium carbonate and natural grades of barium sulfate are nodular or almost spherical in morphology and work well as general-purpose extenders. The acicular or needle-like particles of Wollastonite form a torturous path for water vapor and ions to traverse through a coating and therefore provide a modicum of corrosion resistance. Platy minerals such as talc and mica also impede the transfer of water and ions through a film, and improve corrosion resistance (Table 3).

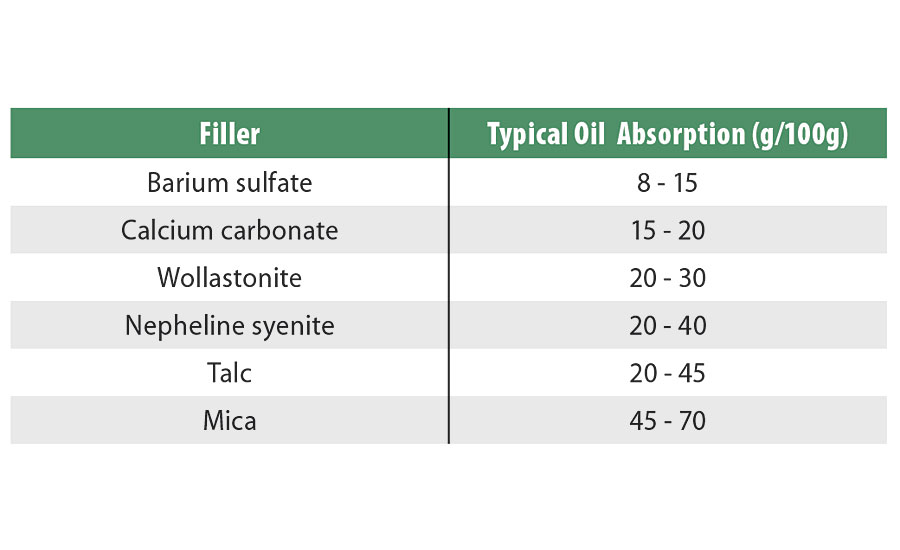

Powder coatings are virtually 100% solids and have no solvent or carrier to assist in flow and leveling, and therefore the oil absorption of a filler is best as low as practical. High-oil-absorption extenders absorb the resinous binder during the flow and leveling phase of a powder coating, increasing the overall melt viscosity and causing increased orange peel or texture. This phenomenon is similar to the manner in which pasta absorbs a lovely marinara sauce. Because of this effect on flow and leveling, higher oil absorptive fillers such as kaolin clay, mica and talc are used sparingly in powder coating formulating (Table 4).

Nevertheless, higher-oil-absorption fillers are sometimes used for functional purposes such as corrosion resistance and also aesthetic reasons such as deliberate texture to meet a cosmetic appearance requirement.

Now that you have learned the fundamentals of using fillers in your powder coating dish, it’s time to prepare a large pot of sumptuous pasta along with a tasty sauce. Buon Appetito!

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!