Testing for the Real World

Traditionally, coatings companies test coatings to various pre-qualification standards required for use around the globe. Now, asset owners are increasingly seeking reassurance that such products meet the performance requirements for real-life conditions and challenging environments, above and beyond these tried-and-tested standards.

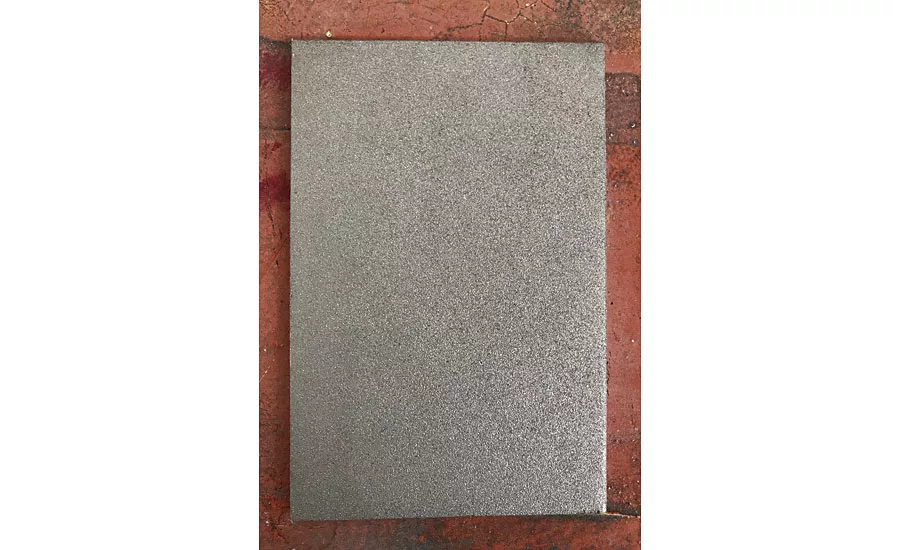

Before they are brought to market, coatings systems are tested for resistance to a range of external influences such as those found in atmospheric and immersion environments. Such testing processes usually take place in the closely controlled conditions of a laboratory, with test panels prepared before the coating is applied and monitored over a period of time to establish how they perform.

In one such test, for instance, steel is subjected to 720 hrs of water condensation and 1,440 hrs of neutral salt spray to simulate a C5H environment the coated steel surface could face once coatings are applied in a real-world situation.

In such circumstances, surface preparation is key. A coating’s performance depends on its ability to adhere to the steel in use, such as the structural steel destined for bridges or buildings. This adhesion depends on how well the surface was prepared prior to application of a coating.

Potential issues that can occur include contamination by residues of oil and grease, so the common method of preparing a surface is abrasive blast cleaning, where grains of abrasive are propelled at high speed. This not only cleans a surface but also increases the surface area by leaving a series of peaks and troughs behind, known as the surface profile.

For some time, there has been concern in the industry about these laboratory-controlled environments not matching the real-world conditions when surfaces are blasted and sprayed in the field. There have even been reports of coatings failing prematurely in the field, so some customers, particularly in the oil and gas sector, have been asking for products to be tested on steel panels that have not been prepared under these clinical laboratory conditions.

Real-World Methods

To meet global corrosion standards, Sherwin-Williams has prepared its products for testing in a real-world setting, and launched a product ‘stamp’ to reflect this testing process, which customers will start to see on branding in future.

Sherwin-Williams has introduced its ‘global core range’ of products, a collection of products available in every market in which the coatings company operates. The decision was made to test the products to global corrosion standards, in particular ISO 12944 and ISO 20340 (ISO 12944-9), allowing the coatings to be used in a range of different regions. The ISO 12944-6 standard describes the types of paint and paint systems commonly used for corrosion protection for steel structures, and ISO 12944-9 specifies the performance requirements for protective paint systems for offshore and related structures.

One of the large oil companies has insisted for some time that the testing for its own pre-qualification is done in a shop, rather than a lab, so there is a significant demand for such testing.

The opportunity had arisen for Sherwin-Williams to test a massive range of coatings systems to these important industry standards. Ultimately, the program of 168 systems has been tested, involving 2,000-3,000 panels and costing an estimated six-figure sum. Testing on this scale is believed to be an industry first.

Testing on such a large scale would be impractical for laboratory conditions, so Sherwin-Williams turned to a paint shop in the North East of England. It was decided all panels would be abrasive blast cleaned to ISO 8501-1 Sa 2.5 grade and sprayed in this ‘real’ environment before testing began.

This exposed the metal panels being used to a range of real-world issues not usually found in a lab, such as surface dust or other contaminants that could affect the adhesion of coatings.

Of course, customers trust and accept the ISO standards as they are, but all standards make reference to certain surface preparations. When carried out in a laboratory, extra care is taken to obtain the cleanest possible surface to eliminate issues with contamination. However, when coatings are applied in real-life conditions, perhaps on stadiums or bridges, the same blasting results simply cannot be obtained. This rationale to carry out large-scale field testing across the board was to give customers new levels of reassurance.

One of the largest variables in the process has always been the surface preparation, but by blasting in a shop, Sherwin-Williams believes it has removed this issue. We expect products prepared in this way to simulate performance in the field.

The steel panels were abrasive blast cleaned to the usual high standard ahead of testing, and coatings applied – the difference being that rather than this process taking place in a laboratory, it took place in a working paint shop. This meant that the panels reflect more accurately the preparation and application situations found in the real world.

The testing itself, with the panels of structural steel, was also supervised by NACE level II coating inspectors who monitored for relative humidity, air temperature and the temperature of the steel.

We are fully expecting to see other coatings manufacturers follow suit, as it becomes the ‘new norm’ for testing to a range of standards across the world. By working closely with customers and reacting to changing requirements, coatings companies can ensure they are providing products that not only operate as expected but will perform and meet real-world conditions.

For more information contact Sherwin-Williams, tel: +44 (0)1204 521 771 or visit http://sherwin-williams.com/protectiveEMEA.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!