A Novel Pigment Production Technology

Kinaltek Pty Ltd. is an innovation company based in Sydney, Australia, and specializing in novel technologies for materials processing. Over the past several years, the company carried out an extensive R&D program and demonstrated full proof of concept for a novel platform process for production of a wide range of inorganic powders based on 27 metals (Si, Ti, Cu, Zn, Ag, Fe, Co, Ni …). The technology is now covered by five international patent and patent applications.1

The technology builds on new scientific breakthroughs by Kinaltek, and is capable of producing a wide range of products including metallic powders, composites, catalysts, superalloys, and coated powders and substrates. Processing starts from low-cost precursors, and reactions are exothermic, requiring minimal energy and producing minimal waste. The technology has been demonstrated for coating glass powders for applications as metallic pigments, and this application is being developed and commercialized under the business name of KinCoat. KinCoat draws on the technology’s coating capability to produce metallic pigments through a low-energy, simplified methodology for applications in automotive, architecture, plastics and antimicrobial powders.

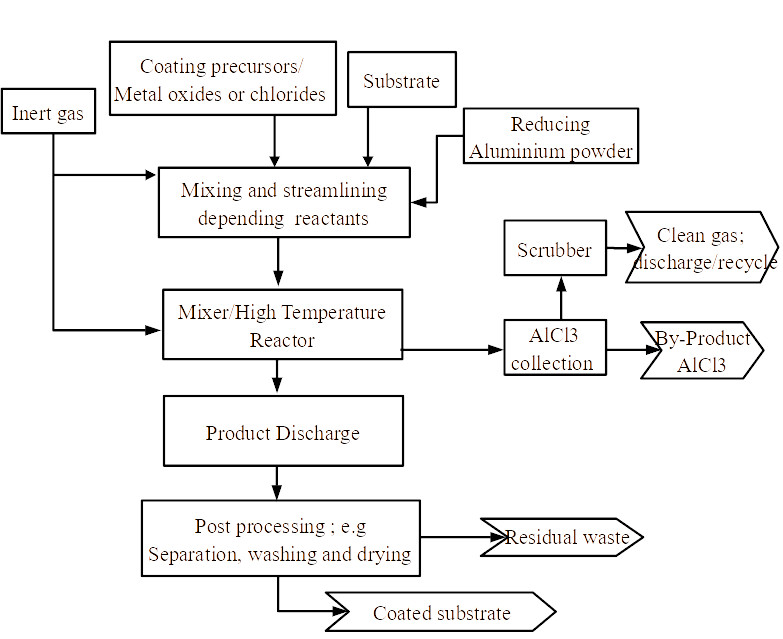

The technology is based on in-situ aluminothermic reduction of metal oxides or metal chlorides in the presence of a powdery substrate. Figure 1 presents a simple illustration of steps for carrying out the process. Precursor powders of metal oxides/chlorides are mixed, together with a reducing Al powder and the substrate to be coated, and then processed at temperatures less 660 ºC, depending on chemical compatibilities of the reactants and the required composition of the coating.

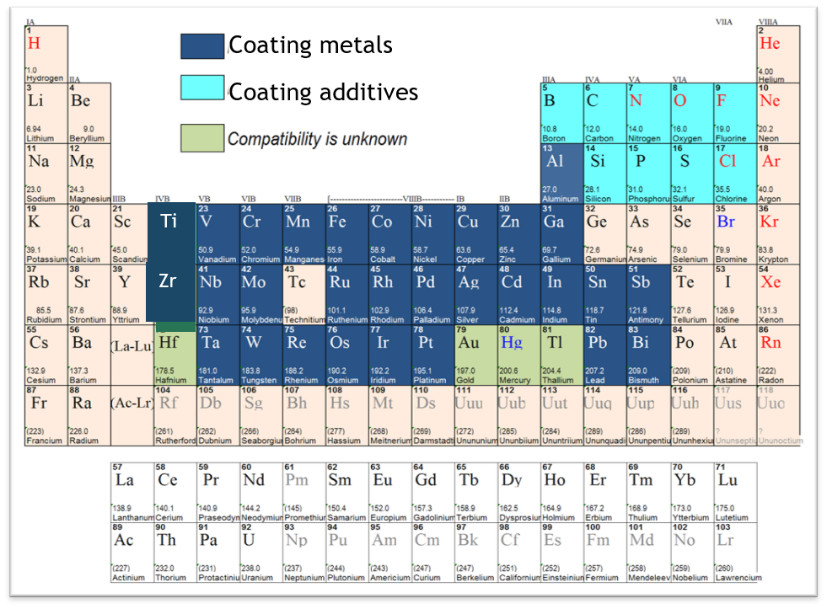

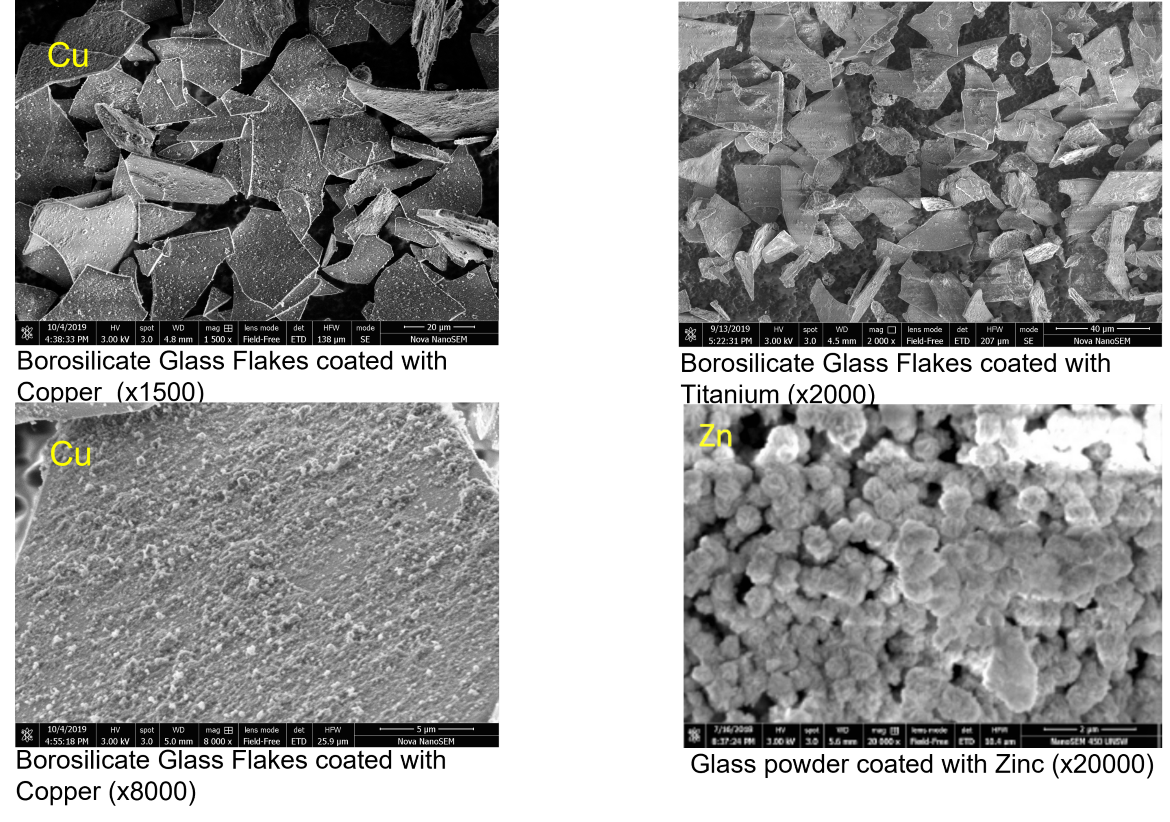

Metal coatings that can be produced using the technology are illustrated in Figure 2 and they comprise more than 27 different elements, including Si, Ti, Cu, Zn, Fe, Ni, Co. Also, the technology has the capabilities of including alloying additives such as C, O2 and nitrogen. Physical mechanisms of the coating process depend on the coating composition. For example, for producing borosilicate flakes coated with Cu, the bollosilicate flakes are mixed with copper oxide or copper chloride and then reacted with Al to produce copper species that coat the substrate surface. For other products such as Si-coated flakes, Si-based flakes (e.g. borosilicate) are reacted with Al to reduce the top surface layer to metallic silicon and then the products is Si-based substrate coated with metallic Si. This is the only technology ever to be able to metallise glass powder through reduction of top surface layer from silicon to silicon metal.

This innovative technology can produce a range of high-quality effect pigments (e.g. autopaint) and functional antimicrobial pigments at reduced cost by up to 90% of current prices. The lower production cost is due to the direct nature of the technology, the lower energy requirements and the lower overall manufacturing cost.

Key pigment products from this innovative technology are Si pigments based on Si, Ti and Cu intended for applications in autopaint, architectural paint and plastics, and Ag-based antimicrobials for applications as additives in paint, plastics and textiles.

Examples of coated substrates are presented in Figure 3. The technology is not limited to planar glass flakes and is capable of depositing metallic coating on all kinds of powder morphologies. For example, it is capable of coating silica nanopowder with silver to produce a hybrid silver-silicon-silica nanoparticles suitable for anti-microbial applications. These anti-microbial powders were tested independently by two universities in Australia and proved effective against common bacteria.

Environmental Impact

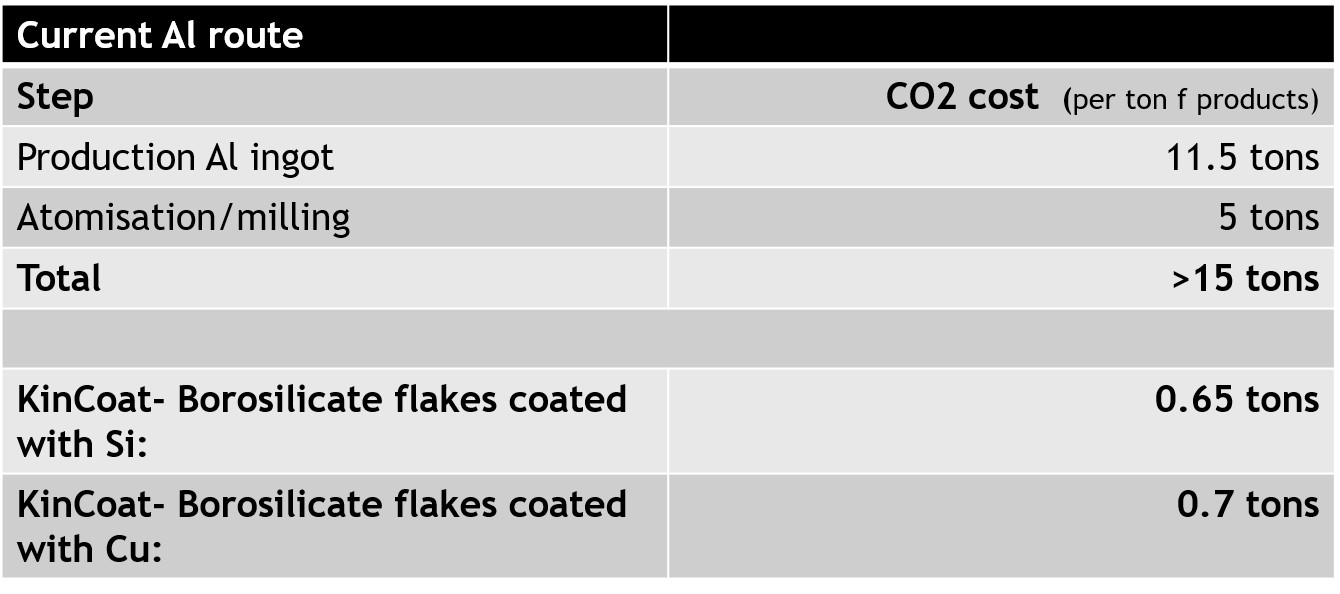

The technology provides significant sustainability benefits over other conventional pigment technologies. A comparison is presented in Table 1 for the CO2 equivalent for production of one ton of KiCoat pigment versus Al flakes. We estimate that our CO2 emissions in producing pigments using this technology are just about 5% of the emissions in producing aluminum pigments.

Market Applications

Effect and functional pigments based on metallic compounds are used in industrial sectors including automobile, paint, chemicals, plastics, cosmetics, energy and infrastructure. The global market is ~US$1-2 Bn. Existing technologies for production of effect pigments are mostly based on two approaches; 1.) vacuum metallization, where mirror-like flakes are produced; and 2.) atomization followed by mechanical milling. For both approaches, further processing is required to protect and modify the flakes, and usually this involves wet processing and calcination.

Also, the advent of COVID-19 resulted in heightened health awareness that caused a surge in demand for all anti-microbial products, however, prices for anti-microbial silver powders are extremely high and range is between US$ 2,000 and $10,000/kg. Because of the high expense, use is limited to high-value and luxury applications. The global market in 2018 was ~US$1 Bn, and there are claims that the market has already reached US$3 Bn.

Other applications include coating powders for general industrial applications. Examples include depositing metallic coating onto inorganic oxide or nitride -based powders.

KinCoat products include a wide range of products suitable for application as metallic effect pigments in automotive paint, architectural paint and plastic additives using flaky substrates, in addition to general industrial use where powders coated with a variety of metals can be produced. Photos of various borosilicate pigments coated with various compounds based on Si, Cu and Ti are presented in Figure 4, together with photos of the corresponding painted panels, prepared using commercial a 2K pack system.

Current Status

The technology has been demonstrated on a small scale for an extensive range of pigment compositions, and the products have already been tested for use in automotive paiint. KinCoat is working towards establishing a commercial production facility and to enable start of work towards full-scale commercial manufacturing of metallic pigments.

Reference Formulation for Automotive Application

Basecoat/Pigment spray

1. Prepare a solution of approx. 45% epoxy and 55% reducer by volume.

2. Add 17% of Perchem 44 paste by pigment weight, including: 10% of Perchem 44 powder (or similar) and 90% of toluene. Perchem 44 powder must be added while toluene is mixing up to 700 rmp and continue mixing until powder was dissolved completely.

3. Add DISPERBYK-2070 0.2% (or similar) of pigment weight.

4. Add 10-15% of pigment depending upon your need for pigment concentration, while mixing up to 200 rpm.

5. Add 0.5% of BYK-1760 (or similar) by total material weight.

6. Mix the ingredients well using a mixer.

7. Load the mixture to the spray gun tank.

8. Spray first coat.

9. Leave for 5-10 minutes to allow it dry.

10. Spray second coat.

11. Leave for 1 hour to dry.

Top/Clear Coat Spray

1. Hardener and top/clear coat are mixed in a 1:2 volumetric ratio with the help of a mixer.

2. Spray on top of the pigment-sprayed panels.

3. Allow to dry.

Figure 5 shows some photographs of shapes painted using automotive formulation using KinCoat pigments.

For more information, visit www.kinaltek.com.

References

-

Patents WO2019095016A1, US10814386B2 and US10814386B.

Copyright and Disclaimer© 2021 Kinaltek To the extent permitted by law, all rights are reserved, and no part of this publication covered by copyright may be reproduced or copied except with the written permission of Kinaltek Pty Ltd. The information contained in this document comprises statements based on scientific research and does not constitute a professional advice or a recommendation. All care is taken in the preparation of this document but Kinaltek Pty Ltd bears no responsibility as to the contents and does not accept any liability with respect to its use or misuse.

All images courtesy of Kinaltek Pty. Ltd.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!