A Better Synthetic Rutile is Coming Soon

It gives that brilliant white color in so many items used daily – paints, plastics, paper, foods, toothpaste, and other applications – yet hardly anyone talks or thinks about the amazing value of rutile in everyday life.

Natural rutile is a titanium mineral found in the earth’s crust with a high-grade titanium dioxide (TiO2) content ranging from 92%-95%. In contrast, synthetic rutile and titanium slag are man-made, high-grade TiO2 products produced from the upgrading of ilmenite (another titanium mineral, with a typical TiO2 content ranging from 45%-65%). Synthetic rutile and titanium slag have TiO2 contents ranging from 80%-95%.

High-grade titanium feedstocks are often used to produce purified TiO2 for use in paints and pigments, as well as to produce titanium tetrachloride for use as a feedstock for making primary titanium metal via the industry standard Kroll process.

Unfortunately, the global supply of natural rutile is in significant decline, with additional high-grade titanium feedstocks, including synthetic rutile, required to fill a widening supply gap. Given their relative scarcity and significant value in use, high-grade TiO2 feedstocks command a higher price than the more commonly found, lower-grade ilmenite. Long-term price forecasts for ilmenite are currently approximately $200-$300 per ton, whereas synthetic rutile commands a price four to five times that of ilmenite at approximately $1,000-$1,200 per ton.

Current Market Dynamics

Titanium is relatively abundant in the earth’s crust, with the two most significant mineral sources being natural rutile and ilmenite. Global titanium mineral resources are estimated by USGS to be approximately 49 million tons of natural rutile, and approximately 700 million metric tons of ilmenite. Ilmenite is an iron-titanium-oxygen compound and has become the most important source of titanium, now accounting for approximately 90% of worldwide titanium consumption. Ilmenite is also the key ingredient in the production of synthetic rutile. The majority of global synthetic rutile production occurs in Western Australia by the world’s largest titanium mineral companies, Iluka and Tronox, via processes based upon the Becher Process. The Becher Process consists of roasting low-grade ilmenite, using coal, in a rotary kiln at temperatures of more than 1,100 °C in order to convert the iron oxide in the ilmenite to metallic iron. The kiln product is then ‘rusted’ in an aerated salt-solution to remove most of the metallic iron.

Titanium slag is another widely adopted input as a high-grade titanium feedstock, produced in a well-established process occurring via open arc AC- or DC-smelting of ilmenite with electricity, using a carbon reductant in the form of coal, to produce titanium-slag and pig-iron products. Scope 1 & 2 emissions associated with current production of synthetic rutile and titanium slag are significant, estimated at approximately 3.3 tons and 2.0 tons of CO2 equivalent per ton of product (Sovereign Metals, July 7, 2022).

Overall, the current method of manufacturing synthetic rutile is expensive and damaging to the earth. In contrast, IperionX, a metals technology company, is commercializing innovative titanium mineral-enrichment technologies that upgrade ilmenite minerals into a high-grade TiO2 synthetic rutile product, with fewer carbon emissions than current industry processes.

A New Process

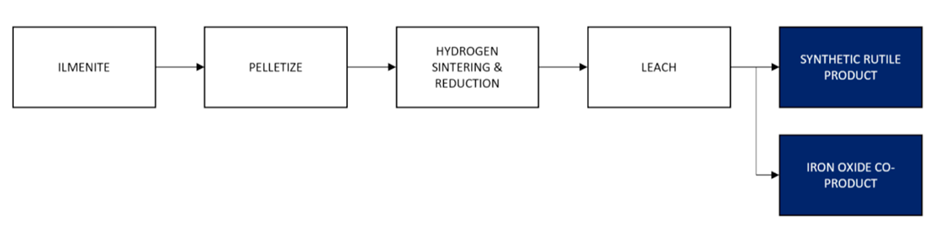

IperionX’s synthetic rutile process starts with the milling of ilmenite, including the potential for ilmenite sourced from the company’s Titan Project, which is one of the largest titanium, zirconium, and rare earth minerals deposits in the United States. The ilmenite is pelletized to the desired particle-size distribution using small quantities of a proprietary solution containing a common organic binder. This process is extremely low-energy and highly efficient.

Following pelletization, the newly generated spheres are charged to an electric furnace, where the spheres are carefully sintered using thermal energy, and the iron oxide in the material is reduced using hydrogen gas, with a clean byproduct of water vapor. The process is done at a relatively low temperature compared to typical metallurgical processes.

Next, the strong and easily handled spheres may be crushed, if necessary, and leached in the presence of hydrochloric acid in order to dissolve away the reduced free iron in the spheres. The leached spheres are then separated from the leaching solution using established liquid-solid-separation equipment. These spheres, now upgraded synthetic rutile, are simply rinsed with clean water and dried in air, leaving a final premium product in the desired size distribution per customer request.

As part of the synthetic rutile production process, IperionX has developed a titanium recovery method with the addition of a primary reagent recovery process, including the generation of the purified iron powder co-product. This recovery process provides the potential for a substantial operating cost reduction over what would normally be realized.

The Future of Synthetic Rutile

IperionX’s groundbreaking low-carbon synthetic rutile process is the result of exhaustive research and development by Dr. Zak Fang and his team at the University of Utah. This, in turn, originated during the development of purification methods for titanium feedstocks for use in Dr. Fang’s proprietary process for titanium metal production, HAMR. Over the last 12 months, Dr. Fang, his team, and IperionX’s R&D division have worked closely together to adapt the titanium purification methods to produce a low-carbon, stand-alone synthetic rutile product.

“It is exciting to see titanium feedstock purification methods developed at the University of Utah for use in HAMR titanium metal production have the potential to be adapted to produce a low-carbon synthetic rutile product,” shared Dr. Zak Fang. “We look forward to the commercialization of this technology as well as continued work on further titanium mineral purification technologies for high-value products containing greater than 99% TiO2.”

Provisional patent applications have been filed for this low-carbon synthetic rutile process technology, adding to IperionX’s robust intellectual property portfolio. Research and development continues on IperionX’s patented low-carbon upgrading and enrichment technologies for very high-grade products with greater than 99% TiO2. The global TiO2 market is estimated to be worth over of $18 billion per annum, with chemical properties that allow for a wide range of applications from paint and pigments, to photocatalysts, pharmaceuticals, and lithium anode materials for batteries.

IperionX’s synthetic rutile product has been evaluated by customers in the paint and pigment industries, and confirmed as a potential high-quality feedstock likely to attract a significant price premium to ilmenite. There is significant potential for this synthetic rutile to be a superior and more sustainable product to other higher carbon, upgraded titanium feedstocks, including titanium slag.

IperionX intends to commercialize this low-carbon synthetic rutile product and has commenced feasibility studies for a synthetic rutile production pilot plant at the Titan Project in Tennessee.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!