Elevating Anti-Corrosion Coatings with Low Loadings

In the coatings industry, achieving optimal anti-corrosion protection while being resource efficient can be a challenge. Traditional approaches often rely on high loadings of corrosion inhibitors, which can lead to increased costs and environmental impact. However, a paradigm shift is underway. Let's delve deeper into why a new anti-corrosion solution requires lower loadings compared to competitor products.

Understanding Loadings in Anti-Corrosion Coatings

The term “loadings” refers to the amount of a particular ingredient, such as a corrosion inhibitor, added to a coating formulation. In the case of zinc phosphate, loadings of about 3-20% are often necessary to achieve desired levels of corrosion protection. However, this approach comes with drawbacks such as increased material costs, reduced formulation flexibility, and environmental drawbacks due to the presence of heavy metals.

New Technology Makes a Difference

Unlike traditional inhibitors, Intelli-ion® operates on a smart-release mechanism, wherein corrosion inhibitors are released precisely when and where they are needed most.

However, what truly sets this technology apart is its lower specific gravity (1.35) compared to conventional inhibitors. This unique characteristic allows the anti-corrosion solution to occupy more volume within the coating matrix, reducing the overall amount of inhibitor required for optimal performance. For example, the 1% in weight of Intelli-ion will take-up 3% volume in the dry-film thickness. As a result, coatings formulated with Intelli-ion require one third of the loading versus zinc phosphate (ZnP), leading to environmental benefits while maintaining anti-corrosion performance.

If you have previously formulated for 3% of anti-corrosive pigment as part of your pigment volume concentration (PVC) in the dry-film thickness, incorporating 1% of AX1 into your formulation will seamlessly integrate without compromising the critical CPVC (Critical Pigment Volume Concentration) of the system. This allows for the effective enhancement of corrosion protection, while maintaining the integrity and performance of your coating.

Salt Spray Testing: Unveiling the Efficacy of Low Loadings

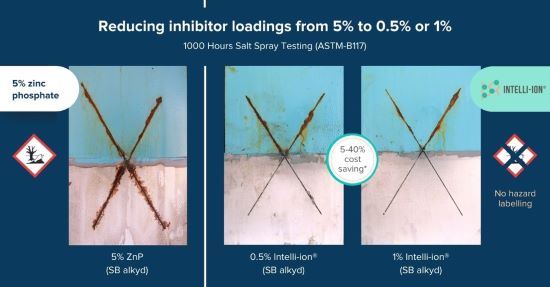

Replacing Current Inhibitors

The testing imagery below showcases panel results following 1,000 hours salt-spray testing (ASTM-B117). A leading primer coating containing 5% zinc phosphate was compared to formulations containing 0.5% and 1% of Intelli-ion’s quick-release ion-exchange inhibitor—yielding excellent results. Significantly reducing the inhibitor loadings can offer coatings manufacturers lower costs*, improved adhesion and differentiation in the coatings market.

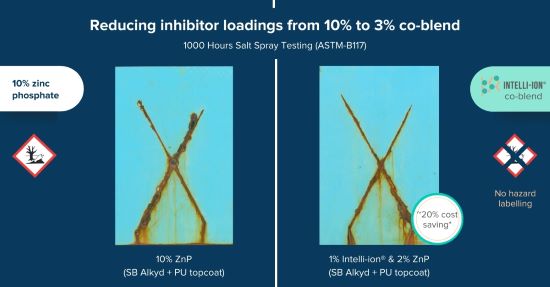

Co-Blending Intelli-ion with Phosphates

Intelli-ion also works alongside zinc phosphate to allow manufacturers to take a ‘step-change’ in their coatings formulation rather than completely replacing their current inhibitor—as demonstrated by the 1,000 salt spray results below (ASTM-B117). Manufacturers are optimizing their formulations to at least half the amount of ZnP to add 0.5-2% of Intelli-ion to take advantage of synergistic protection mechanisms and reduced raw material costs.

In summary, Hexigone's technology offers a compelling solution for achieving the highest anti-corrosion protection while minimizing material usage. By requiring lower loadings than competitor products like zinc phosphate, Intelli-ion can deliver cost savings, enhanced efficiency, and reduced environmental impact. Coatings manufacturers can truly do more for less, ushering in a new era of sustainable corrosion protection.

*Savings depend on current inhibitor loadings and currently inhibitor costs.

Images courtesy of Hexigone.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!