UV/LED-Cured Coatings Empower NA Manufacturing Companies

Faster Production Speeds, Reduced Operations Costs, and No VOC Emissions

In today’s manufacturing competitive environment, it is all about the following factors:

- Driving process efficiencies and production speeds.

- Reducing overall manufacturing costs, energy costs, and improving ROI.

- Continued emphasis on employee safety and improving the workplace environment.

- Eliminating VOC and HAP emissions, which contributes to sustainability.

UV coatings encompass and deliver on all four factors, especially improving your sustainability footprint. This article will summarize two customer case studies.

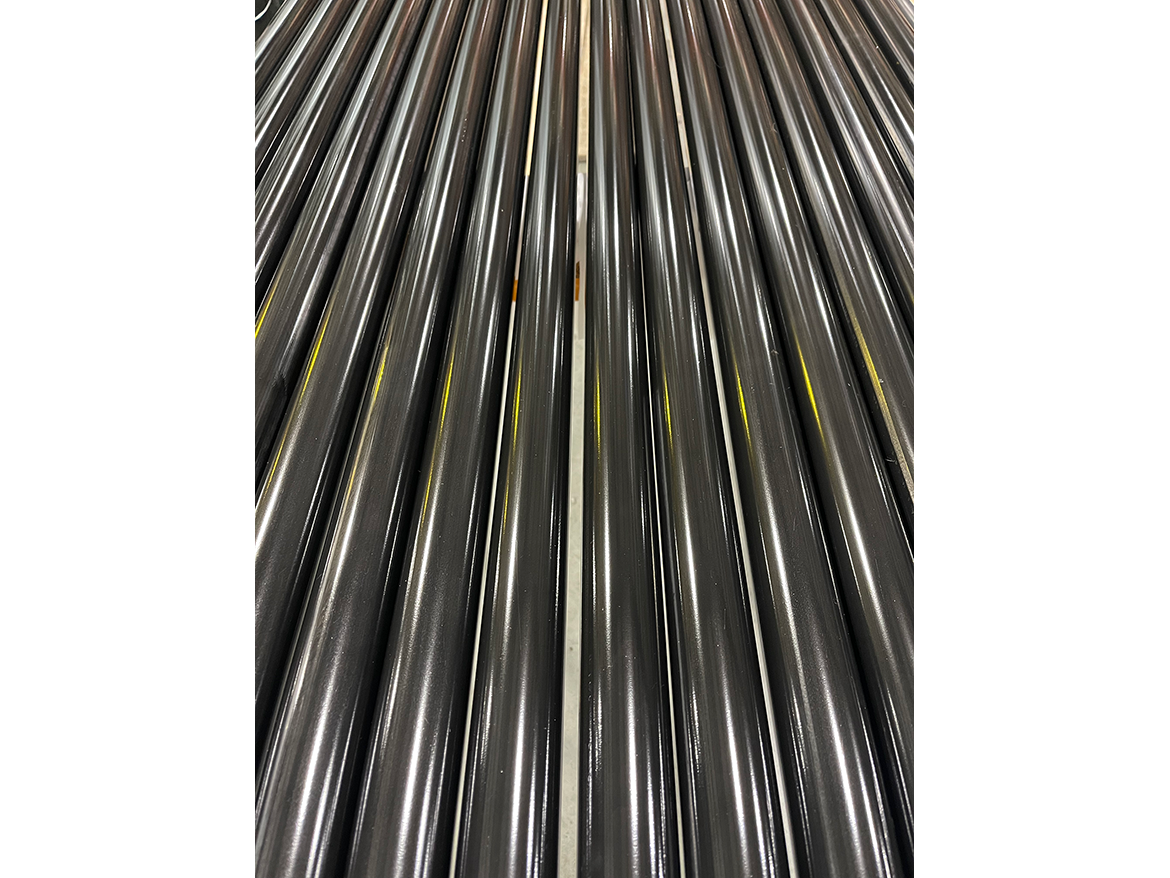

Case Study No. 1: U.S. Sprinkler Pipe Manufacturing Customer

A U.S.-based manufacturer produces the industry’s most complete line of sprinkler pipe—Schedule 10/40/others. For years, the customer had struggled with the mess and flammability of the water-based coating, as illustrated below in Figure 1. In addition, the company’s current water-based coating exceeded two pounds of VOCs per gallon, so not a very sustainable solution.

The disadvantages of water-based coatings can be summarized in the following detail:

- Water-based coatings are typically around 30% solids; the other 70% are fillers that evaporate as waste.

- The fillers that evaporate are normally solvents/by-products that emit VOCs.

- Require costly freeze protection in cold weather (especially in transit).

- Very messy, causing clean-up downtime (Figure 1).

- Slower production speeds because coating requires time to dry.

- Tube blocking: when tube bundles stick together, with no banding to contain the bundle.

- Excessive waste because you need about 3x the amount of product.

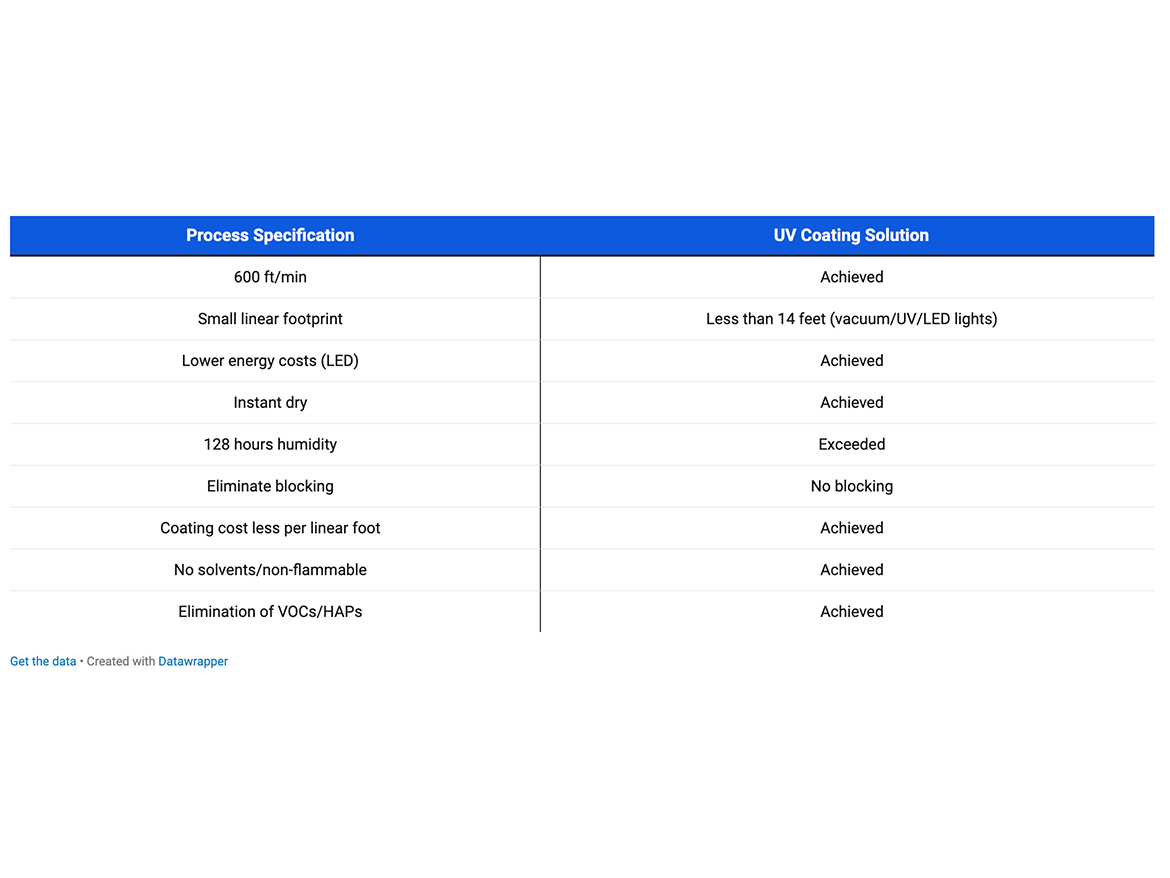

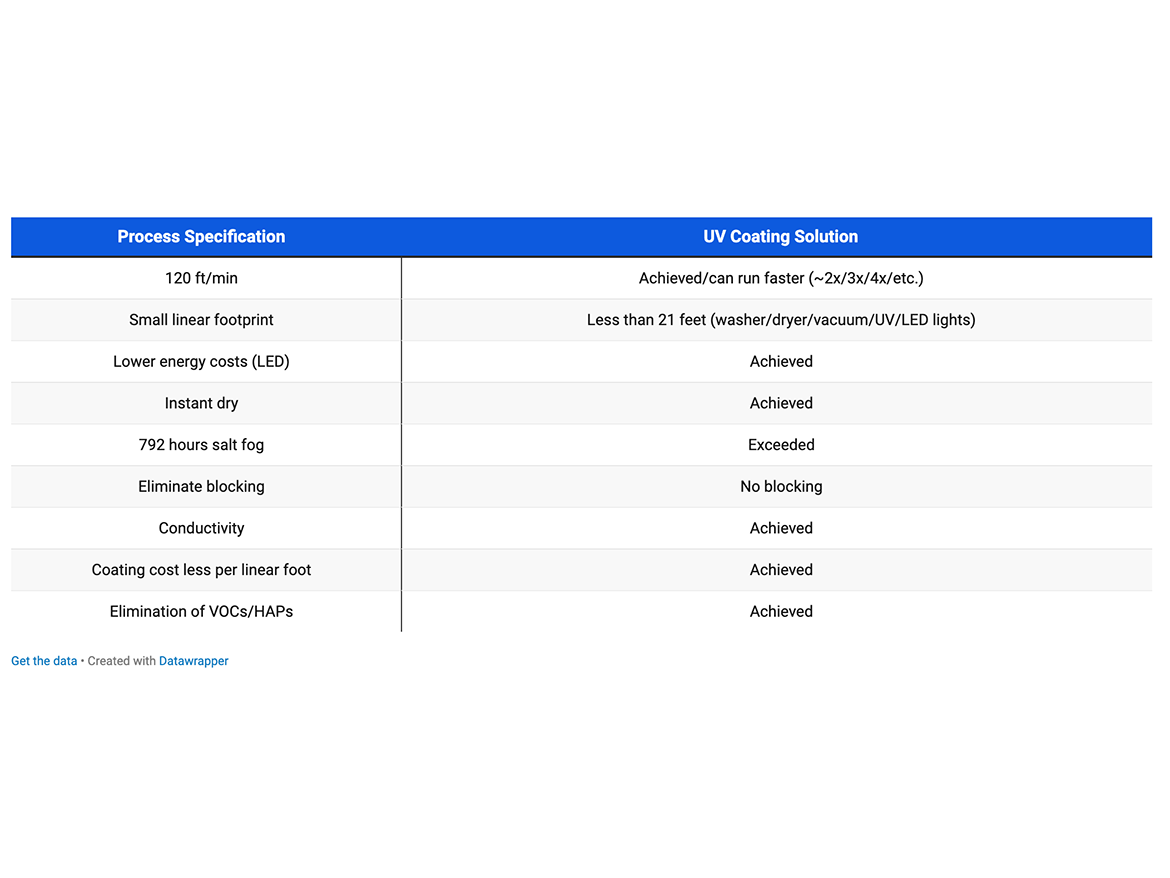

With these disadvantages in mind, the customer outlined the process specifications/product specifications for the UV coatings as defined in Table 1.

Conclusion

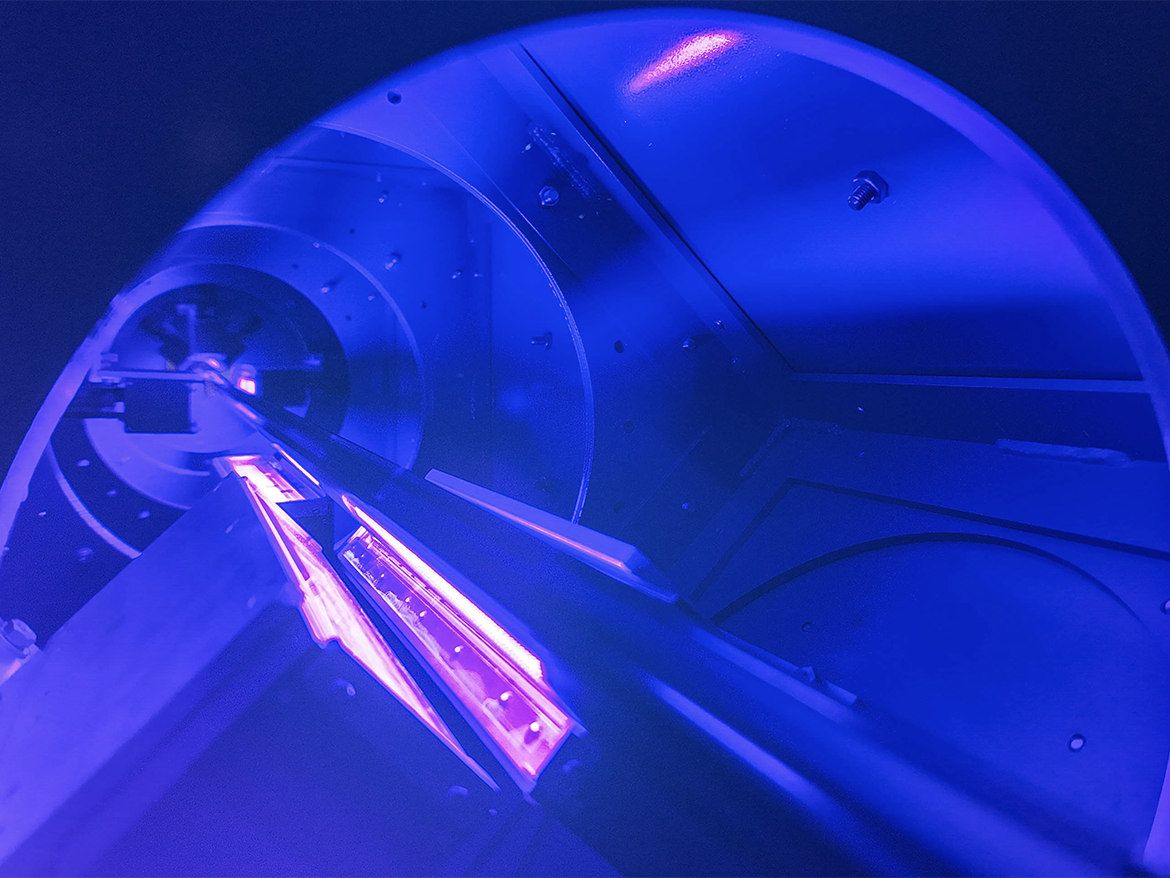

The customer implemented multiple UV/LED coating systems, which reduced energy consumption significantly, eliminated VOCs and HAPs being released into the environment, and created a more consistent, repeatable process. Plus, UV-coating-per-linear-foot costs were less than the water-based coating costs. In addition, the end-product performance and aesthetics far exceeded the water-based coating solution (Figure 5).

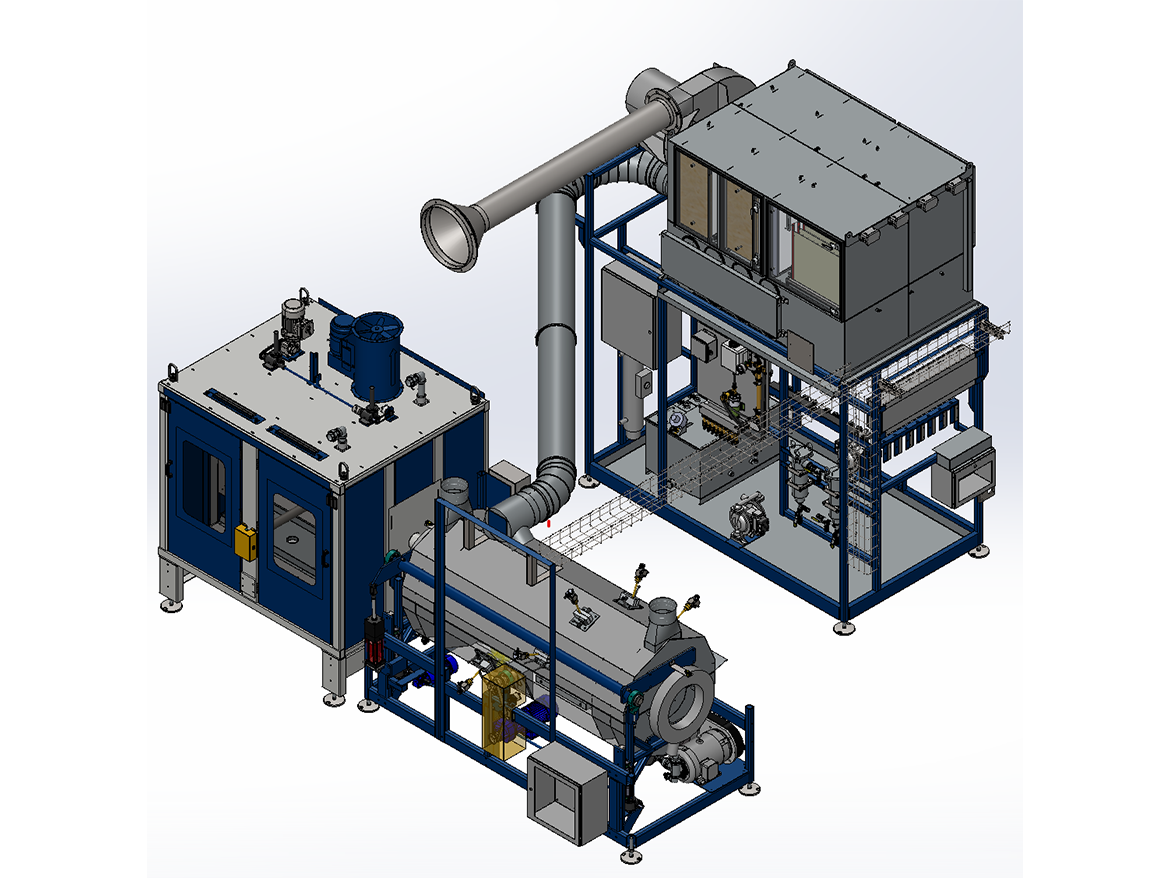

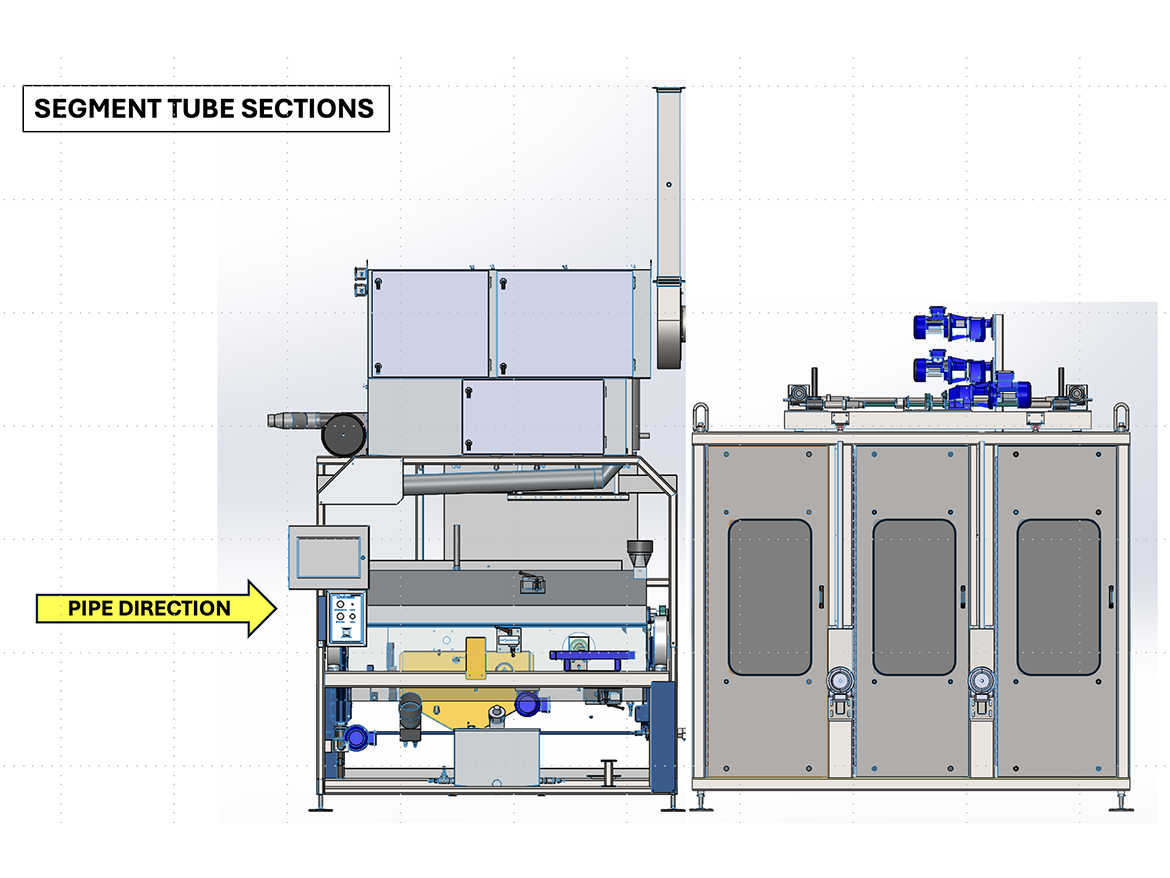

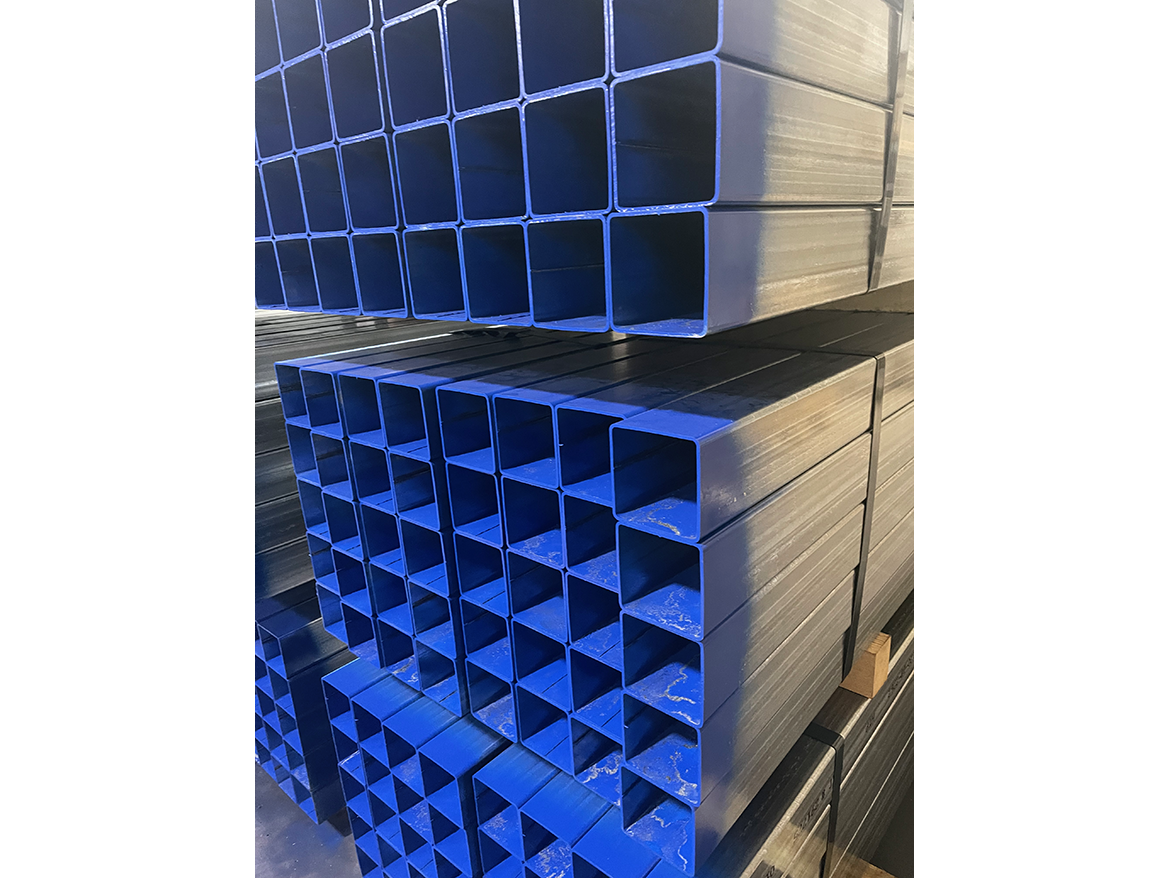

Case Study No. 2: Solar Torque Tube Manufacturing Customer

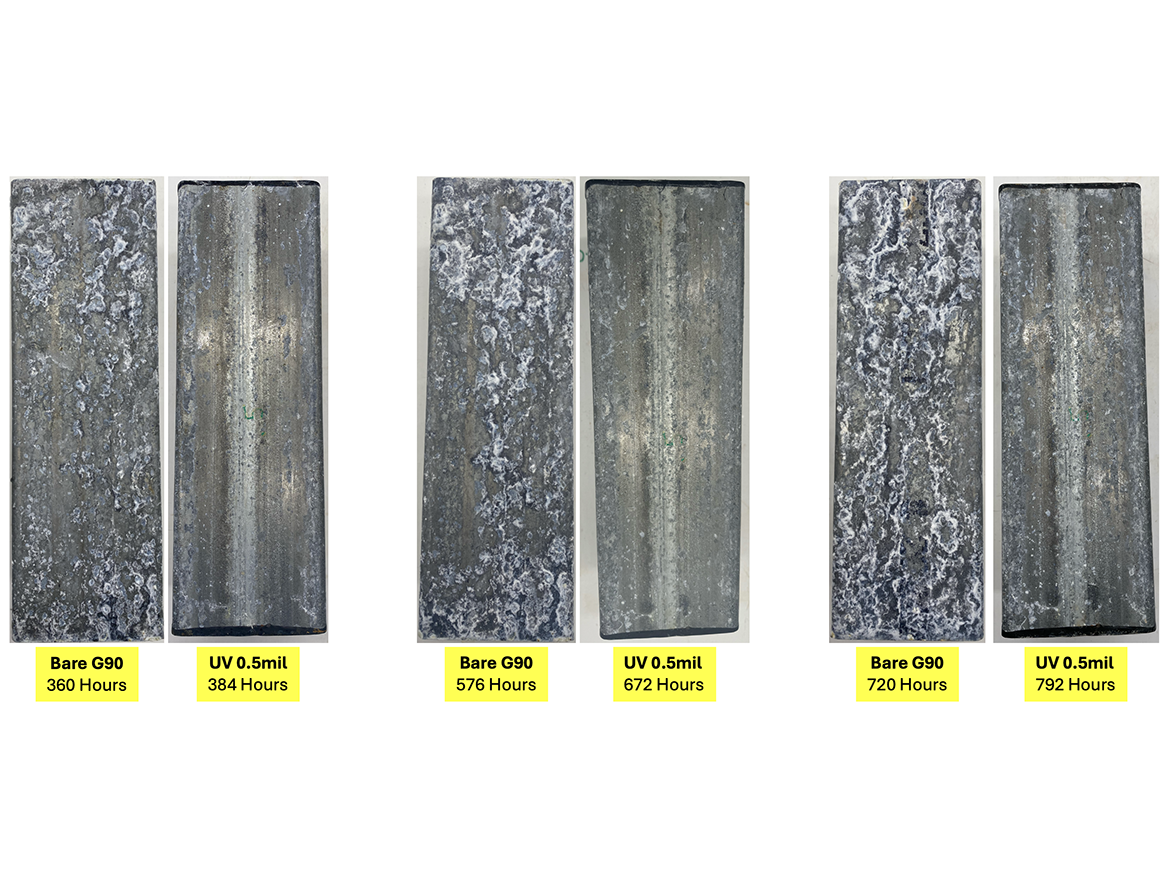

Eliminating white rust on galvanized torque tubes is essential to end-user solar installations. In the case of white and red rust, remediation costs can run into millions of dollars in claims, plus cause significant installation delays.

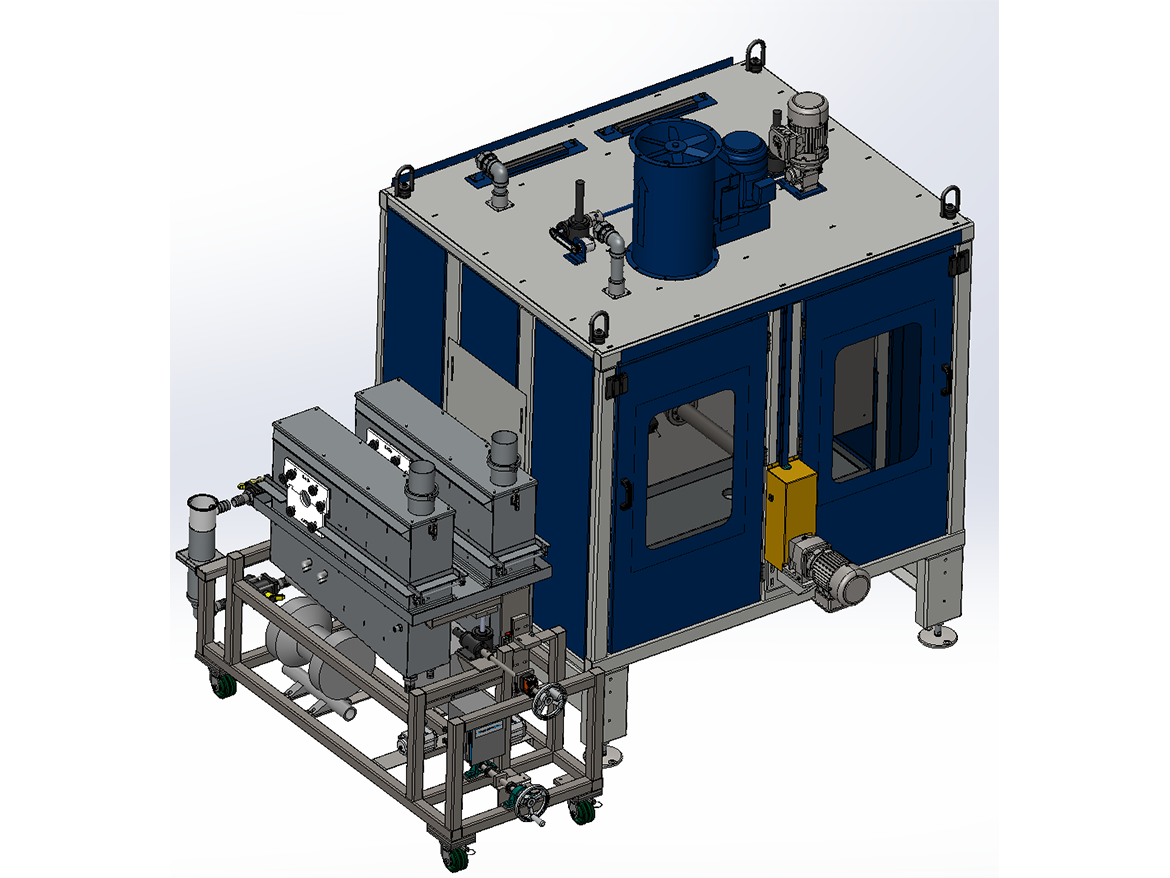

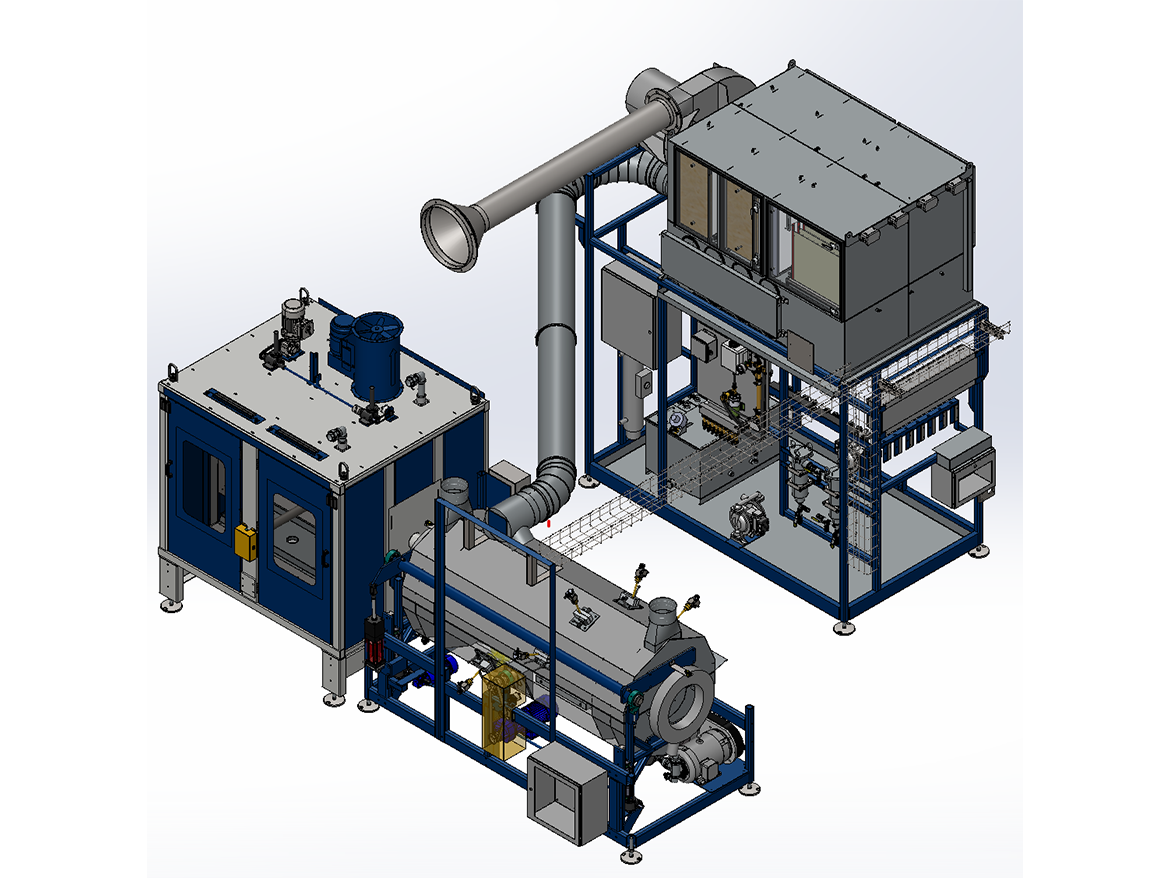

A leading U.S. manufacturer outlined all the critical process and product specification requirements with the goal to produce the world’s best performing and visually appealing product in the marketplace.

UV coatings greatly reduce remediation claims for white and red rust, and is now becoming the standard solution for coating and protecting structural torque tubes in the solar industry.

UV coatings greatly reduce remediation claims for white and red rust, and is now becoming the standard solution for coating and protecting structural torque tubes in the solar industry.

In the case for even more corrosion protection, the coating thickness can be increased to 0.8-1.0 mils. This will provide additional white rust protection for extreme outdoor exposure, without slowing down production speed.

Conclusion

The customer continues to push the industry to implement UV/LED coating systems for torque tube production, which greatly reduce energy consumption, have a much smaller footprint, and offer enhanced overall performance, while also improving workplace safety. In addition to these benefits, UV coatings also eliminate curing and drying issues, eradicate VOCs and HAPs, and mitigates premature white rust and red rust issues, while providing both manufacturer and end user with best-in-class manufacturing solution.

Summary

The overall advantages of UV/LED curing continue to grow as LEDs are more readily implemented into industry applications, as mentioned above in the two customer case studies Outlined below in Table 3 are details on how LED curing technology compares to arc lamps and microwave curing technologies.

The advantages of LED lamp head include the following:

- A typical LED life of 50,000 hours.

- Higher power in order to increase productivity and throughput.

- Minimal degradation of power (UV energy output) over time.

- Instant on/off as LED is only on when producing product.

- 2.5 KW energy usage per hour per lamp at full power.

- Narrow-band UV emission in the high UV-A range.

- No mercury or replacement bulbs.

- Ozone free and safer work environment.

- Much lighter weight.

- Significant reduction in noise.

- Significant energy savings compared to traditional UV-curing systems.

- Low maintenance (no consumables).

- No ducting/elimination of large capital cost and a reduction in dependence on HVAC systems in production areas.

- Extremely small footprint, the typical system is less than 10 ft line space.

As the LED technology continues to be implemented into mainstream UV applications, manufacturing customers will greatly benefit from immediate energy savings, small footprint, and overall workplace safety and sustainability.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!